You must be logged in to rate content!

7 minute(s) of a 891 minute read

4-27-2018

Got the valve last night! Inspected it, all looks good, so slammed it in the head and the heads are now finally ready to go on the short block tomorrow, along with the flywheel and clutch.

For the routing, I'm thinking the same idea of routing everything hugging the block under the motor mount, secured by several P clamps. I'm going to mock up the routing of the oil cooler hot/cold lines (-10AN) along with the driver side drain (-10AN) to see what packaging is like. For simplicity I would love to put a heat protective sheath (at the minimum) over the cold return oil cooler line, then clump all three lines together with a single P clamp to the motor mount adapter plate on the block. If space allows, I would like to have all 3 hoses have individual heat protective sheaths to keep that turbo drain heat away from the other lines.

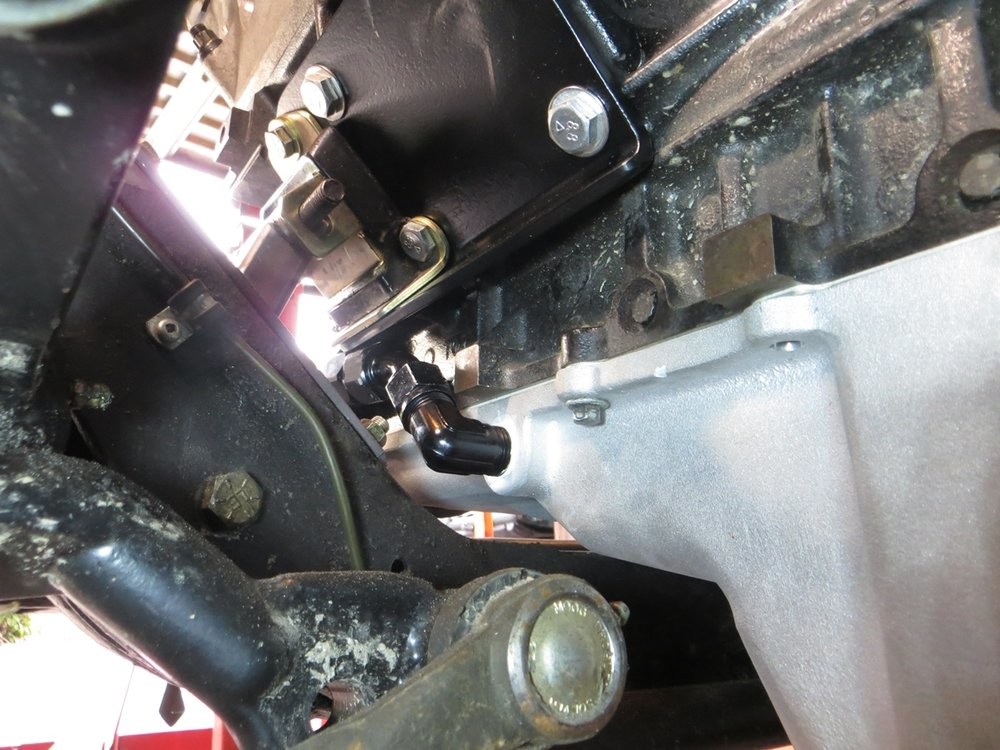

Going forward of the motor mount, I'm going to snake all 3 lines around the P/S pump, then right around the subframe where the turbo drain starts to angle up, I'm going to make a "junction block" for the oil cooler lines. This block will be mounted to the subframe, which is why I'm heavily leaning towards soft lines for all the oil hoses snaking under the motor mount. This block will break up the length of the hoses going from the oil cooler adapter at the pan to oil cooler itself, in case a repair needs to be made. But the main function of this junction block is it will have two -4AN fittings welded to it on the oil cooler cold return side, to pull fresh oil for the turbos as the rest of the oil is en route back to the engine.

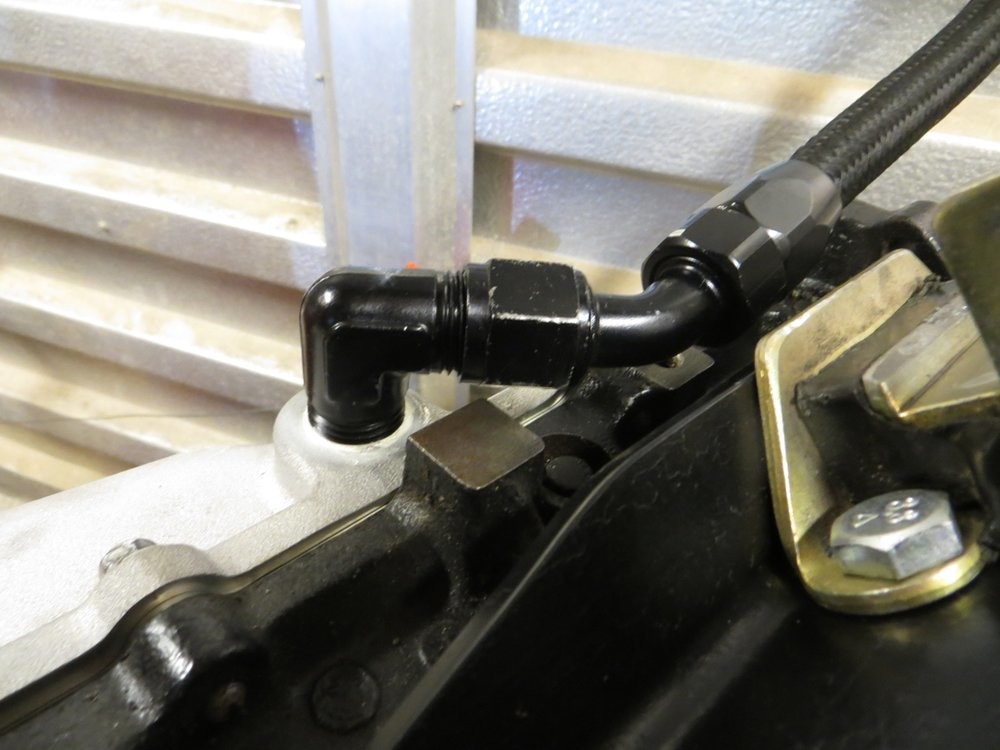

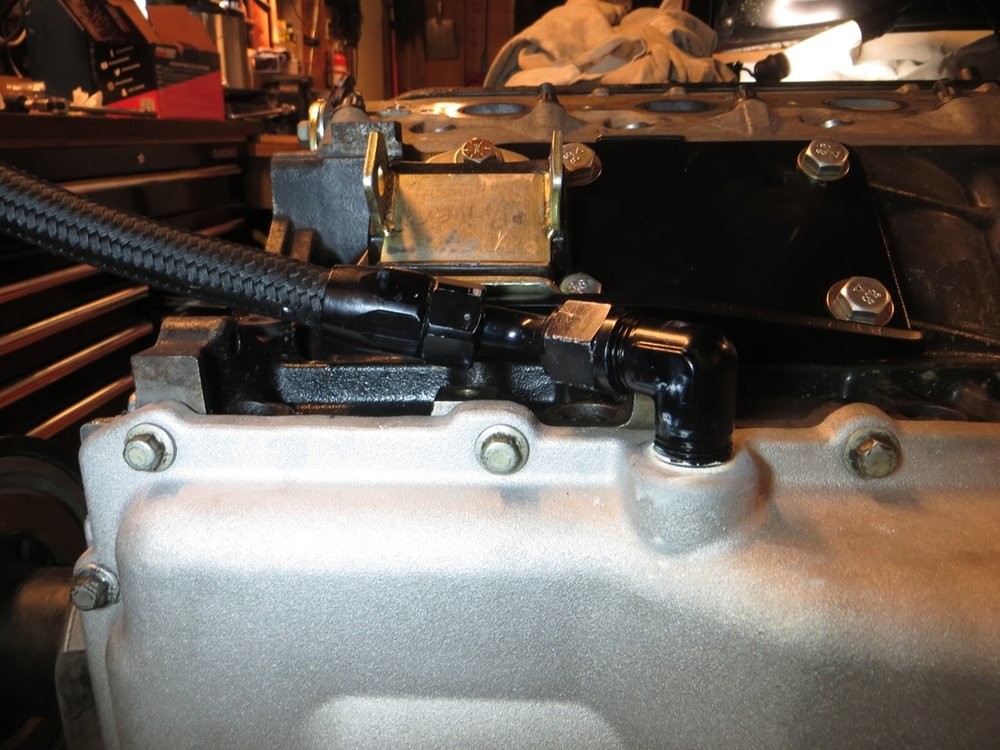

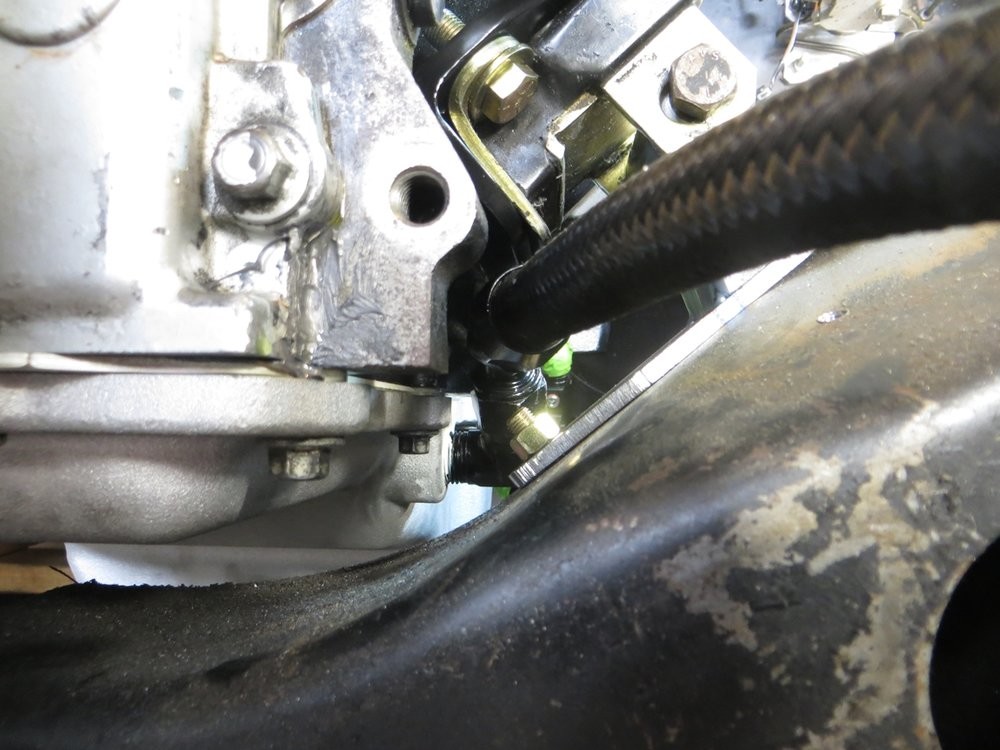

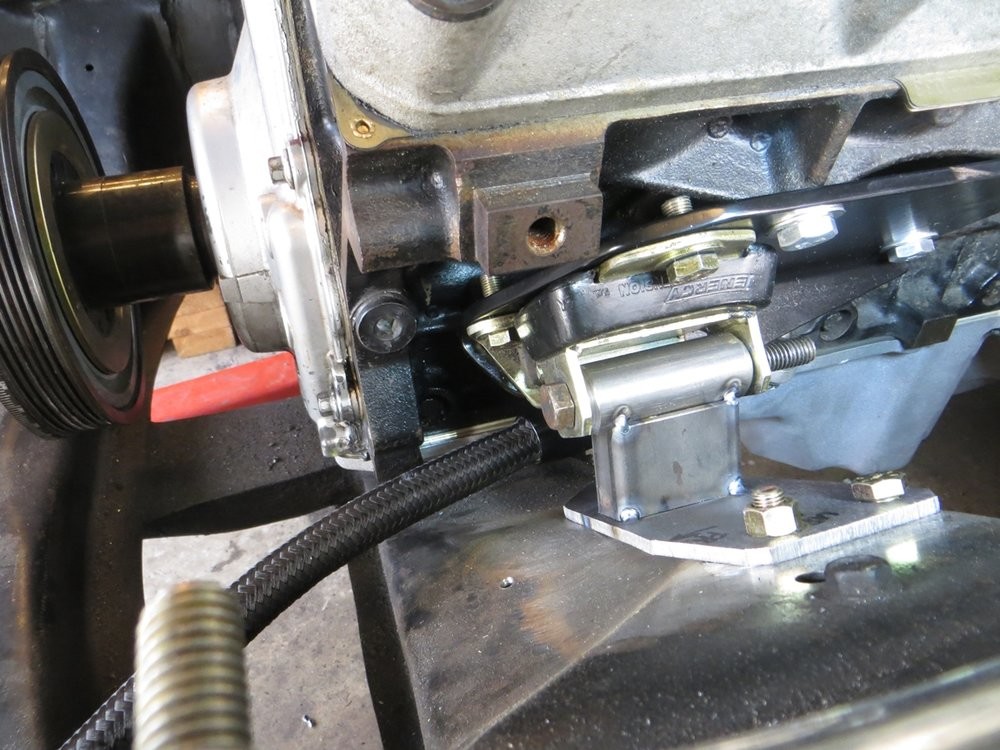

Tried a 45* -10AN adapter fitting on the oil pan, as well as got the motor mount pedestals mocked up..

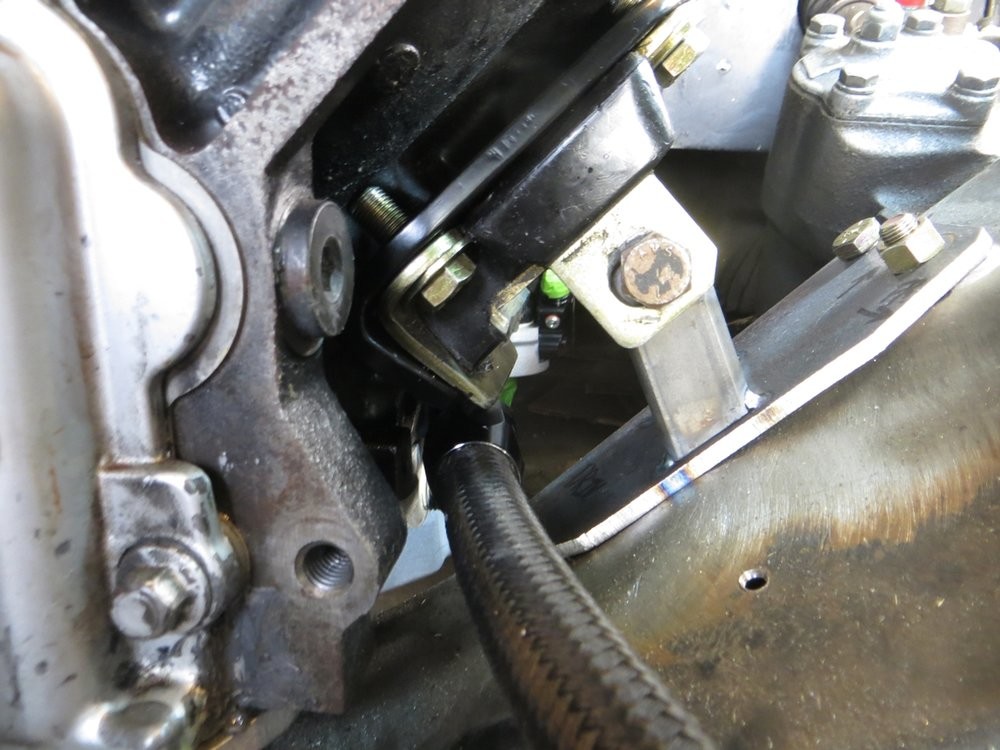

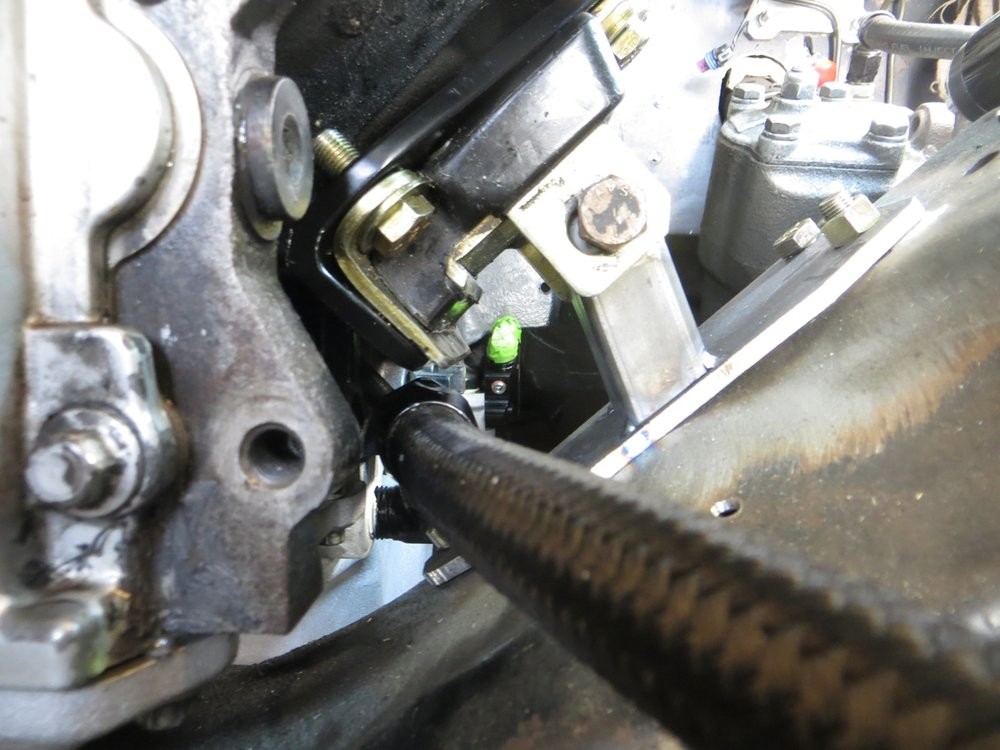

Also cut a clearance notch in the subframe for the alternator plug. It's crazy do go thru all this work just to be able to remove the alternator plug, even though the alternator itself cleared the subframe. Oh well, everything is apart right now so it's easy enough..

This turbo drain routing is super tight to the block, but I'm still unsure what kind of room there will be for the oil cooler lines. I think I'm just going to go with 3x hard lines onboard of the motor mount for the turbo drain and oil cooler lines, just for added clearance...

Proceeding forward, my first turbo (Turbonetics TC76) got low oil pressure back in.... 2012(?) and disintegrated its journal bearing, and let oil leak into the air side. I found trace amounts of oil in nooks and crannies of the truck intake and the intercooler.

Most of the crud on the pistons was some carbon buildup, but other stuff was a bit crustier which I suspect was caked oil from that turbo blowup. Pretty easy to wipe the crap off with a quick spray of carb cleaner and a rag, some of the more caked on stuff needed a thumbnail scratch to be removed... but it's all minty looking now.

Can still see the cross-hatching from the rebuild bore in 2011...

Can see the difference in strengthening webbing on the LS9 head (left) vs the 317 head (right).

Can see how much bigger the exhaust ports are on the LS9 heads, and how much smaller the 317 heads' exhaust ports are relative to the exhaust manifolds.

Comparison of the intake ports between LS9 and 317 truck.

OF COURSE, there is always something. I totally forgot to order the $6 offset-intake LS3 rocker pedestal trays, so that prevented me from installing the rockers, checking for piston/valve interference, double-checking the pushrod length, and if the pushrod length is the same then installing and final torquing the heads. Dammit.. will see if the dealership has these cast aluminum bits tomorrow and maybe, just maybe finally wrap up the motor stuff.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM