You must be logged in to rate content!

6 minute(s) of a 891 minute read

2-14-2018

Haha thanks Clint... that's a funny link.

I'll definitely be covering the power steering lines and oil cooler lines with some high-temp sleeves of some sort, as well as exhaust-wrapping the driver side downpipe in the offending areas. I'll also weld on some bungs to mount comprehensive stainless sheet heat shielding on the motor mount and steering box sides of the downpipe.

I was leaving the UCA bolts long for the time being while I figured out the downpipe routing, then will swap to shorter bolts once I figured out my "worst case" clearances.

Anyone have any good experience with particular heat protection/sleeving? I previously had both name brand and Summit brand aluminum foil heat sleeving and after all the heat cycling the aluminum started flaking off as shown in a previous post.

I'm thinking something along these lines, but getting totally lost in all the different brands/options:

http://www.designengineering.com/cat...ve-lr-technolo

https://www.pegasusautoracing.com/pr...oduct=3299-002

http://www.designengineering.com/cat...ltra-47-sheath

https://www.designengineering.com//c...at-sheath-gold

Haha... Clint, the several times I've mentioned "heat shielding" in the last couple posts, I've been meaning exactly like that. There will be formed (by me) heat shields between the downpipe and the steering box, downpipe and motor mount, and between the downpipe and the oil cooler and PS lines wherever they may end up being.

I plan to do heat sleeving in addition to shielding.. shielding is great for redirecting immediate high heat and creating that thru-flow air gap that you mentioned, but there's no question that the ambient temp under the hood is going to be high, and I'd like to insulate the power steering and cooling lines as much as possible from that high ambient heat.

I plan to do similar design as what I had on my previous setup, but maybe try the formed aluminum sheet that you posted a link to:

2-16-2018

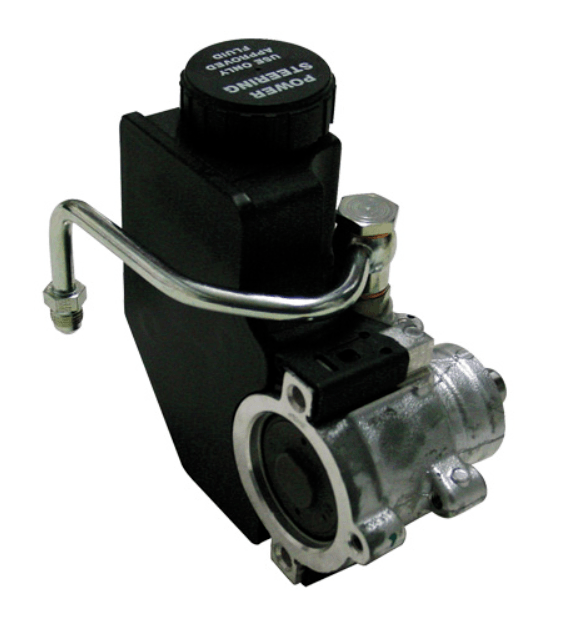

Found something neat today for the GM Type II power steering pump, thought it might be beneficial for others. But first, a little background...

The first time I redid my accessory drive, call it Version2, I went from a trimmed cast aluminum truck bracket for the alternator & old Saginaw pump to custom plate bracketry to hold a newer GM Type II PS pump. When I was researching this I originally wanted to use a straight adapter fitting to go from the pump M16 port threads on the outlet to -6AN male, and then a 90* hose end or adapter, to make sure the pump outlet flow is nice. I ended up not having the room to loop the height of an adapter fitting and 90* end, as well as the minimum hose bend radius under the bracket for the alternator. So instead I used the standard M16 banjo fitting, which I was never really a fan of, thinking that maybe the small banjo bolt holes and sharp geometry could introduce aeration and maybe cavitation and pump whine.

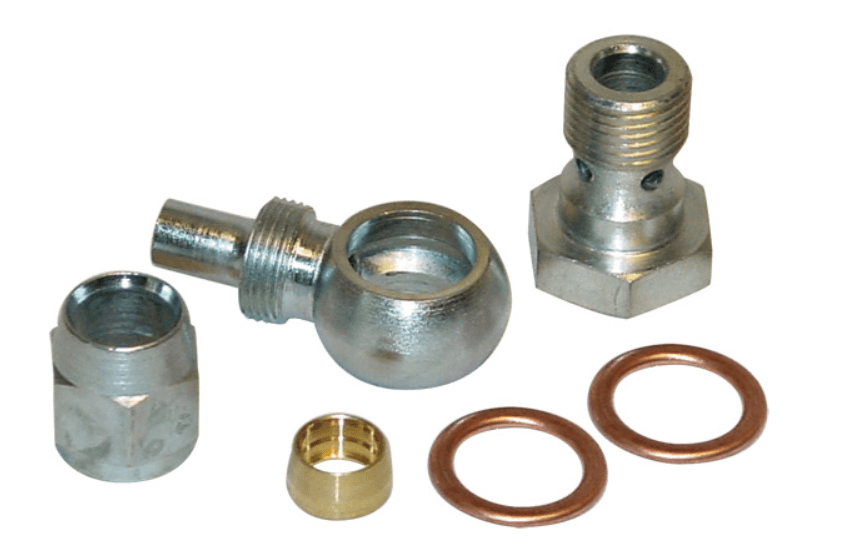

The benefits of a banjo style fitting are: 1) tighter fitting sizing, and 2) companies like DSE etc sell a banjo fitting brazed or welded to nice pump-hugging stainless tubing that wraps around the side of the reservoir for tight fitment. This is great and all for tight areas, but those pieces are expensive at $70-100+, and still have the banjo fitting which may or may not actually affect flow.

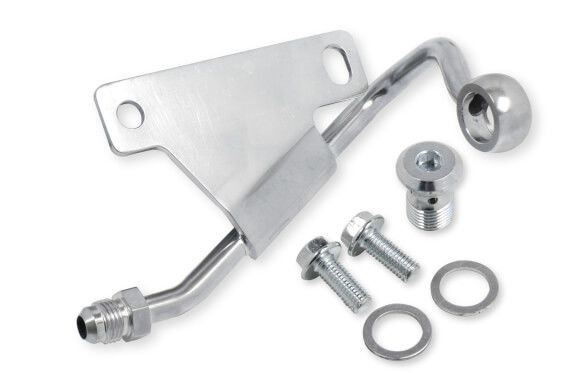

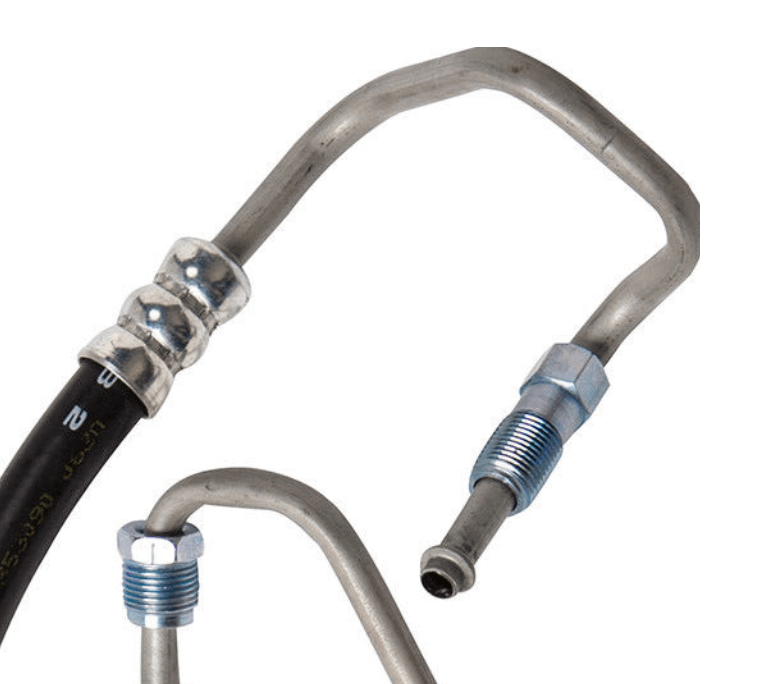

DSE power steering hard line and fitting option...

Danchuk hard line..

Holley hard line...

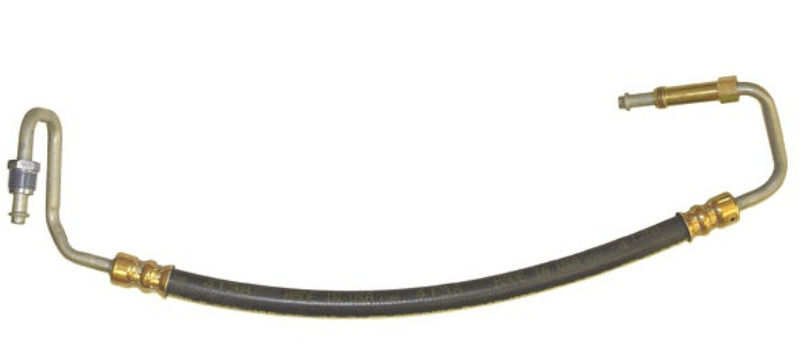

So this morning I was helping troubleshoot a coworker's 1988 Jeep Grand Cherokee, and noticed that its power steering pump has a very similar tight-bend steel tube wrapping above the reservoir, but the part that threads into the pump outlet is an awesome straight fitting! The pump appears to have a straight adapter fitting in it, and every year of power steering pressure hose that I looked up appeared to be the same o-ring fitting, with variations in the tube bend path.

Some research:

Jeep Grand Cherokee, '84-'86, 4.0L engine, little hard to tell which end goes in which direction, also very hard to find any pictures or eBay ads for this model year range...

Jeep Grand Cherokee, '87-'90, 4.0L engine, wraps around the top and back of the reservoir, then straight down (hose end on right side of pic). ACDelco 36358690 or Gates 358690...

Jeep Grand Cherokee, '93-'98, 4.0L 5.2L 5.9L engines, points the hose horizontally to the driver's side...

Jeep Grand Cherokee, '99-'04, 4.0L engine, points the hose down behind the reservoir like the '87-'90 hose. Finding part numbers of Gates 353090 & Gates 365606...

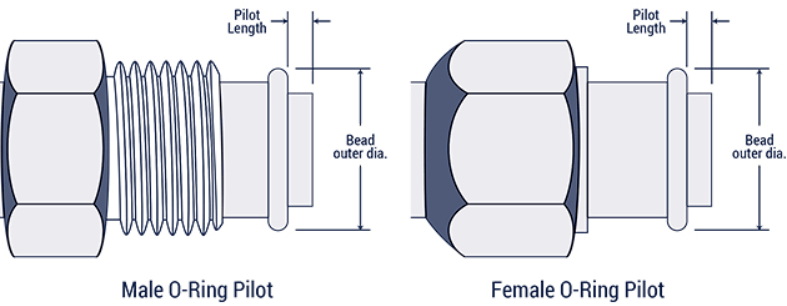

Clint you're totally right, that was a mess up on my end... I've edited the post. They're an o-ring fitting for sure, I was just mis-remembering.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM