You must be logged in to rate content!

5 minute(s) of a 891 minute read

1-2-2018

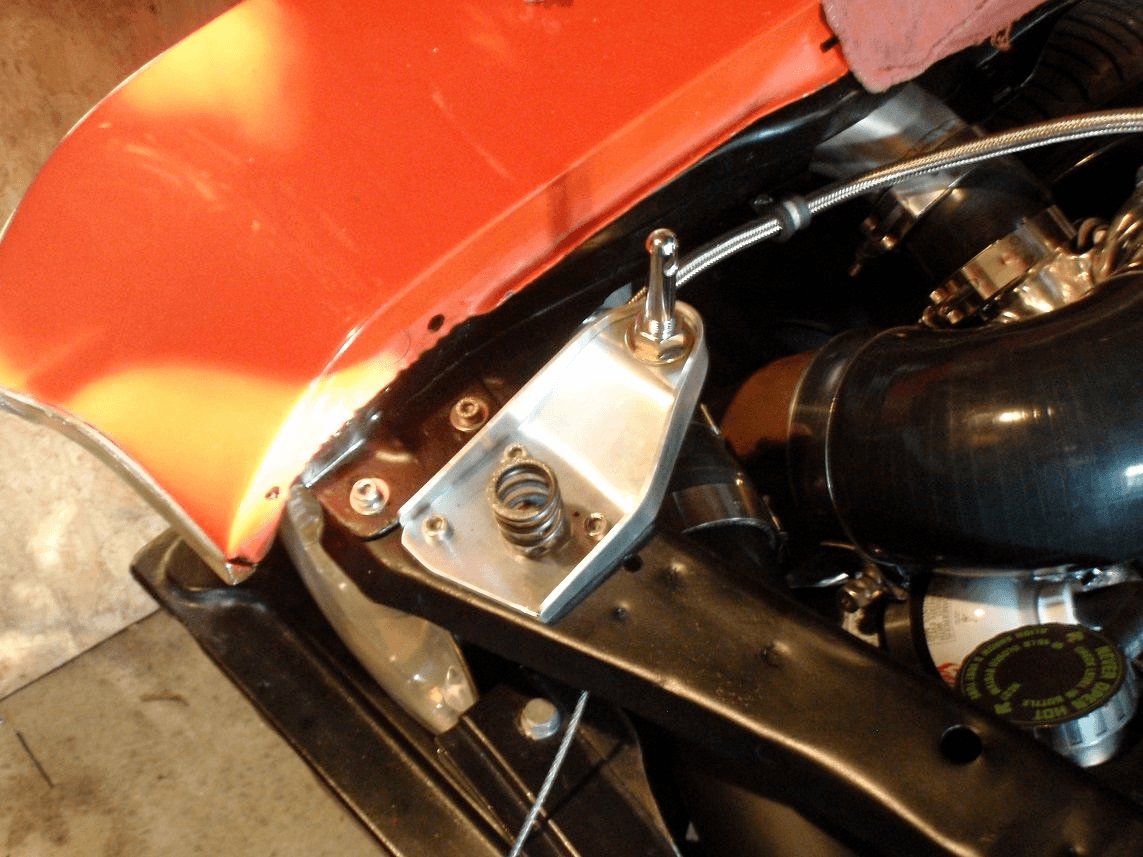

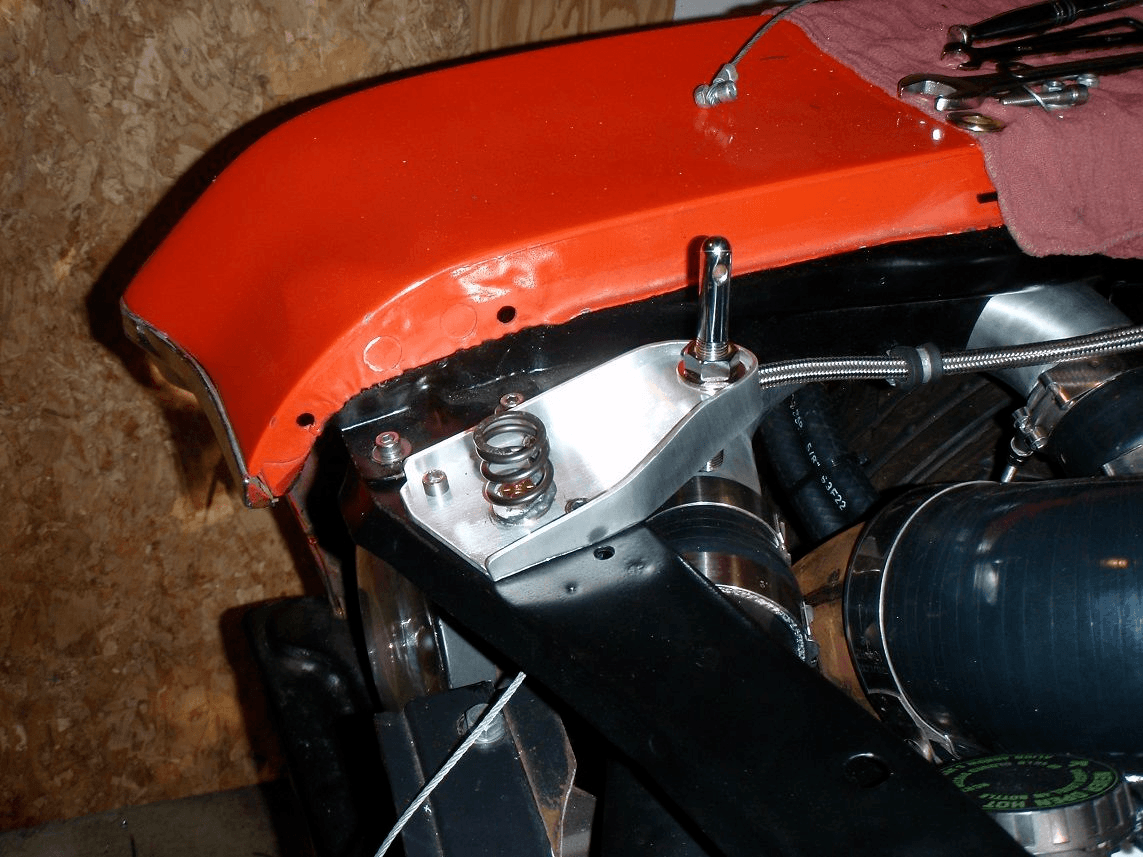

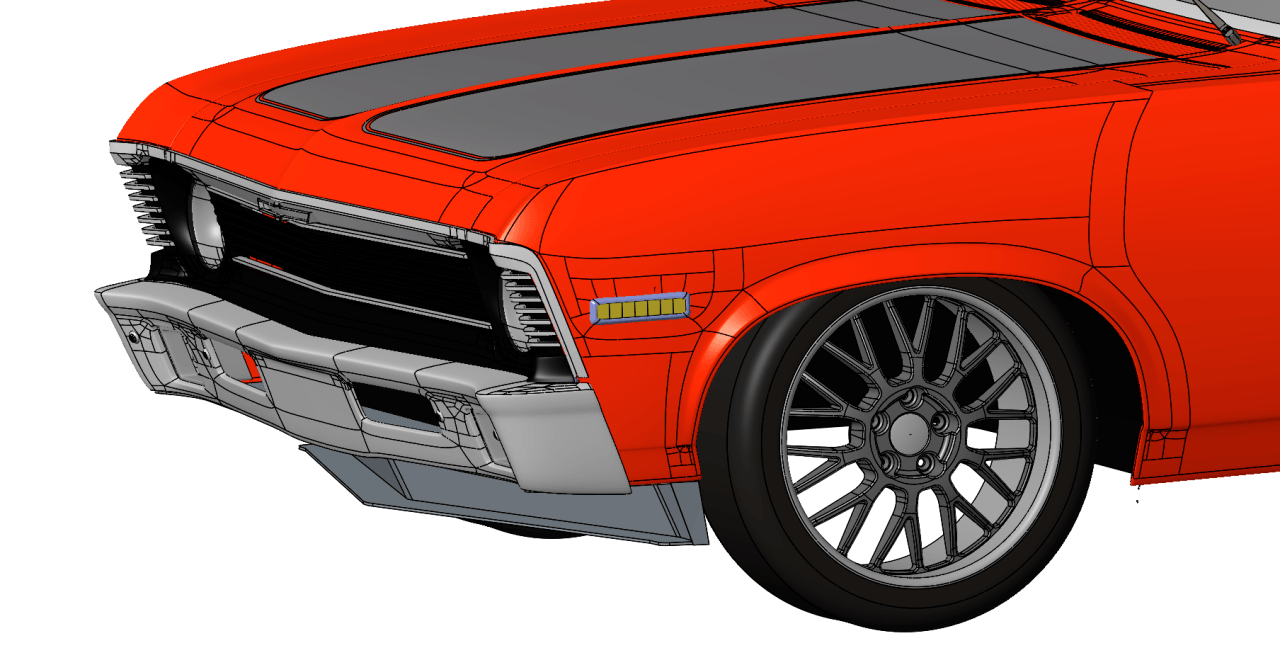

I made the hood pin brackets.. no issues thus far. The springs are somewhat firm but only require 1/8" compression to insert the hood pins, so they're preloading the pin but not by a ton. They have 3 bolts that spread the load onto the rad support well, and the 3/4" high plate around the perimeter makes them super stiff.. so I never really had any concerns with the spring and the pin not being over top of each other. The way I did it way back was to place the pins on the hood in a place that looked visually balanced, then drilled down and made the brackets to fit. A lot of guys just mount the pins to the rad support which angles them forward in a way that doesn't fit the hood well, and puts them really close to the leading edge of the hood which I visually never liked.

While searching my old pics for the hood pin brackets pics, I also found these old ones from when I first got the car when I was 17...

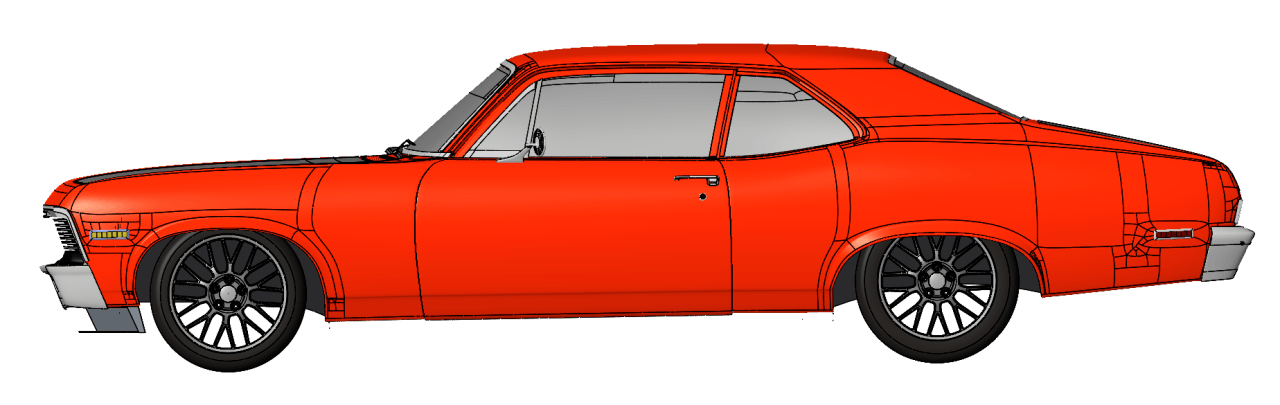

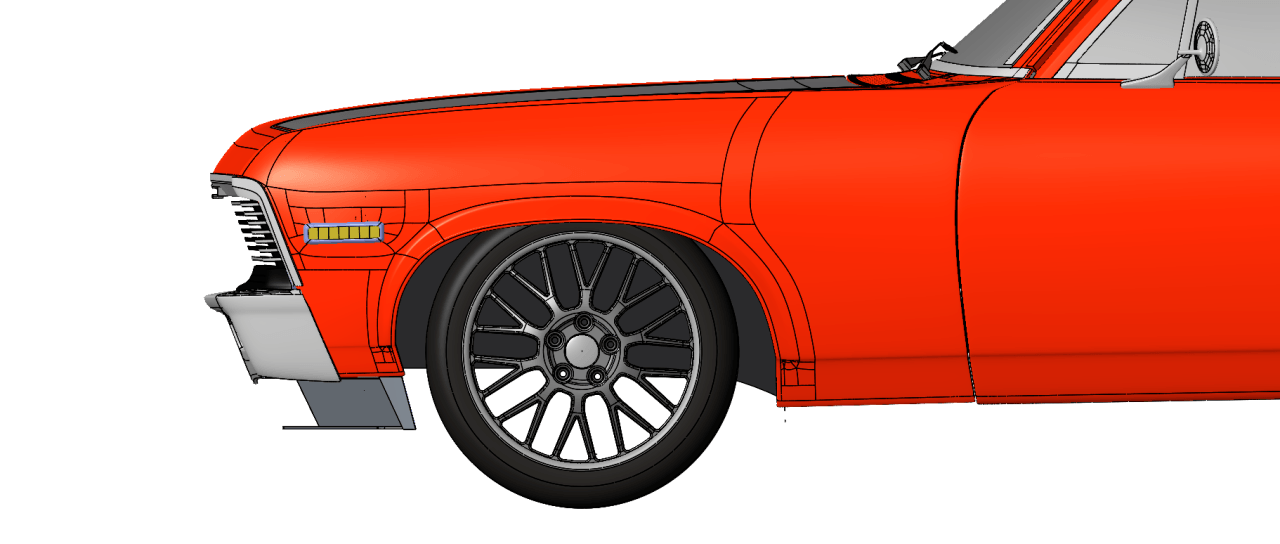

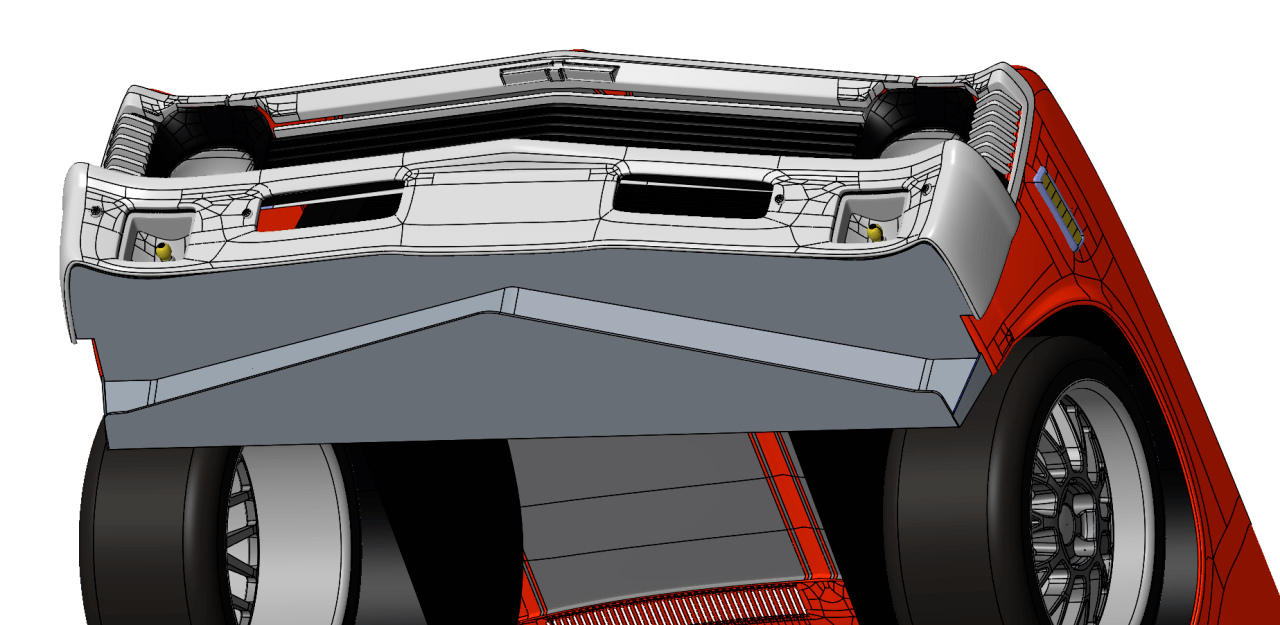

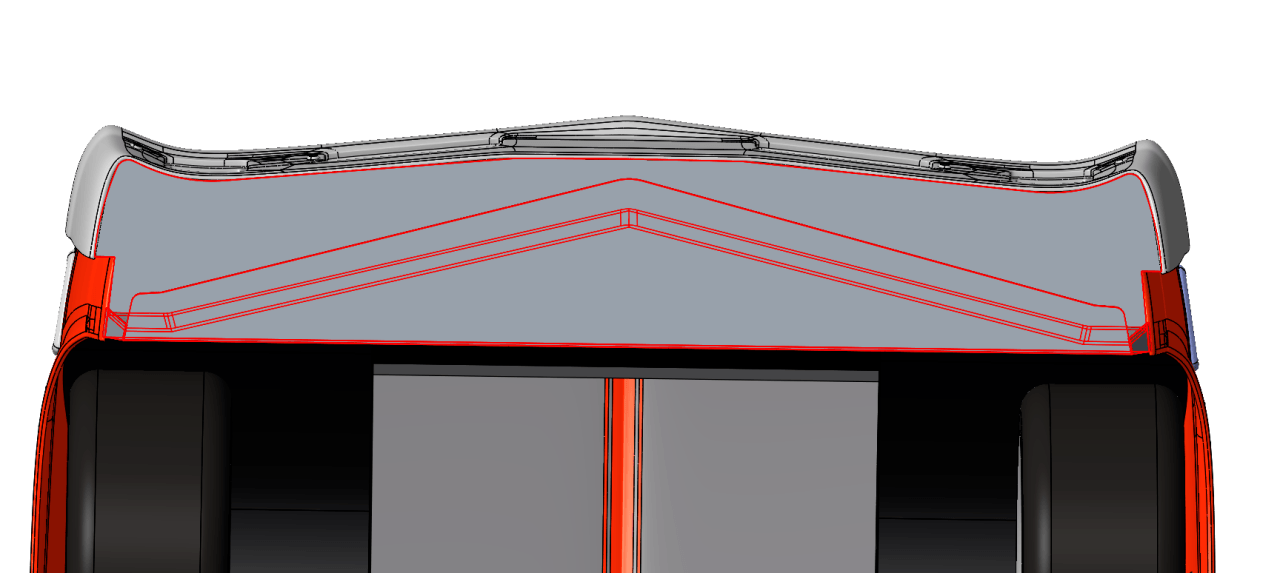

As I wait for some stainless piping and other bits to arrive, I thought I'd finally get around to starting to model an air dam aka mini-splitter idea I've had in my head for a while. I think the proportions are okay-ish enough to not look like a train cattle guard, but also not so minimal that it's pointless looking.

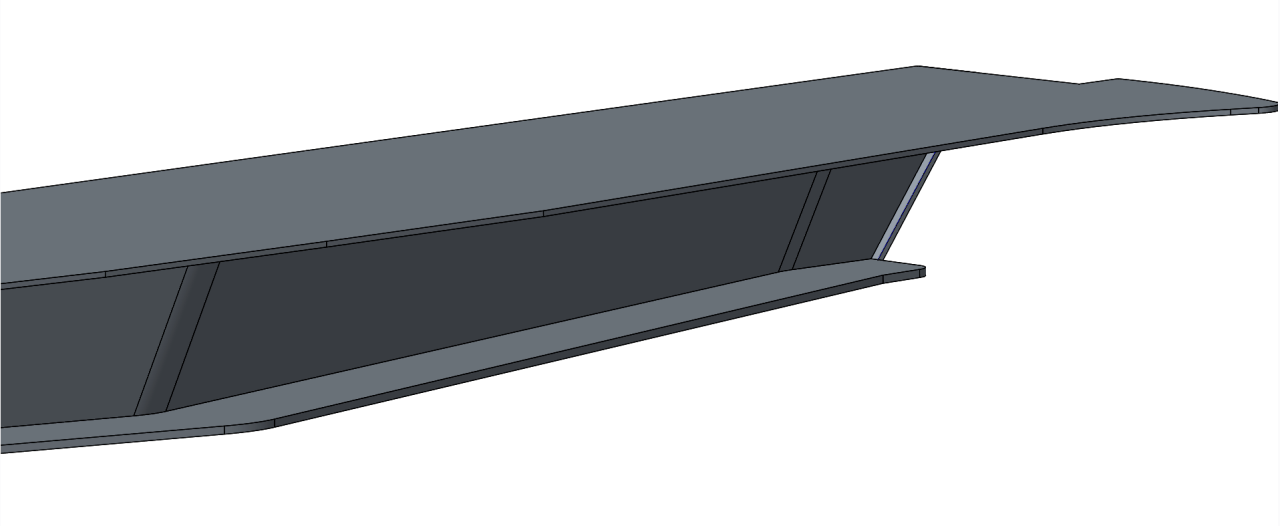

The "vertical" part (air dam) is about the same rake as the bumper, but much more peaked in the middle to help aid airflow getting around the car and not underneath it. On the ends of the air dam are two 1/2"-tall lips that help tumble the air so that there are vortices as the air leaves the air dam, goes around to the side and tumbles past the spinning front wheels (very turbulent air around the wheelwells). And it has a horizontal piece (splitter) that's 3-4" deep across the width, to aid a bit in downforce but also prevent the diverted air from just getting funneled underneath the car.

This design or a piece similar to it would help build up a high pressure zone in front of the car (in front of radiator) as well as reduce the pressure build up in the engine bay by reducing the air that flows under the car. Inner fenders will also go a long way in helping keep airflow (and thus air pressure) from entering the engine bay from the wheel wells. It also helps airflow thru the radiator by closing out underneath the bumper, so air entering the bumper cutouts has nowhere to go except thru the radiator.

I have no idea if this is remotely close to what I'll end up making, but it's the design I've had in my head and wanted to hash out in 3D to see. I'll cardboard it up at some point after the turbo stuff to see what it looks like in real life. I also need to keep ~4" ground clearance since I need it to still go over speedbumps!

I wanted something that is a bit more substantial/sophisticated than just bolting on a 1969 Camaro air dam, but not as extreme as what some are doing out there as shown on these examples..

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM