You must be logged in to rate content!

7 minute(s) of a 891 minute read

12-17-2017

Guess what I picked up today!

Also needed some 0.188" wall 2.0" SS304 for the wastegates to mount to, couldn't find it locally or on AceRaceParts.com, but did find it at OnlineMetals.com, which had a great selection of everything. Since I was already paying shipping for the SS304, I also got some 6" 0.100" wall 6061 aluminum that I'll turn into the surge tank for the trunk... eventually.

12-26-2017

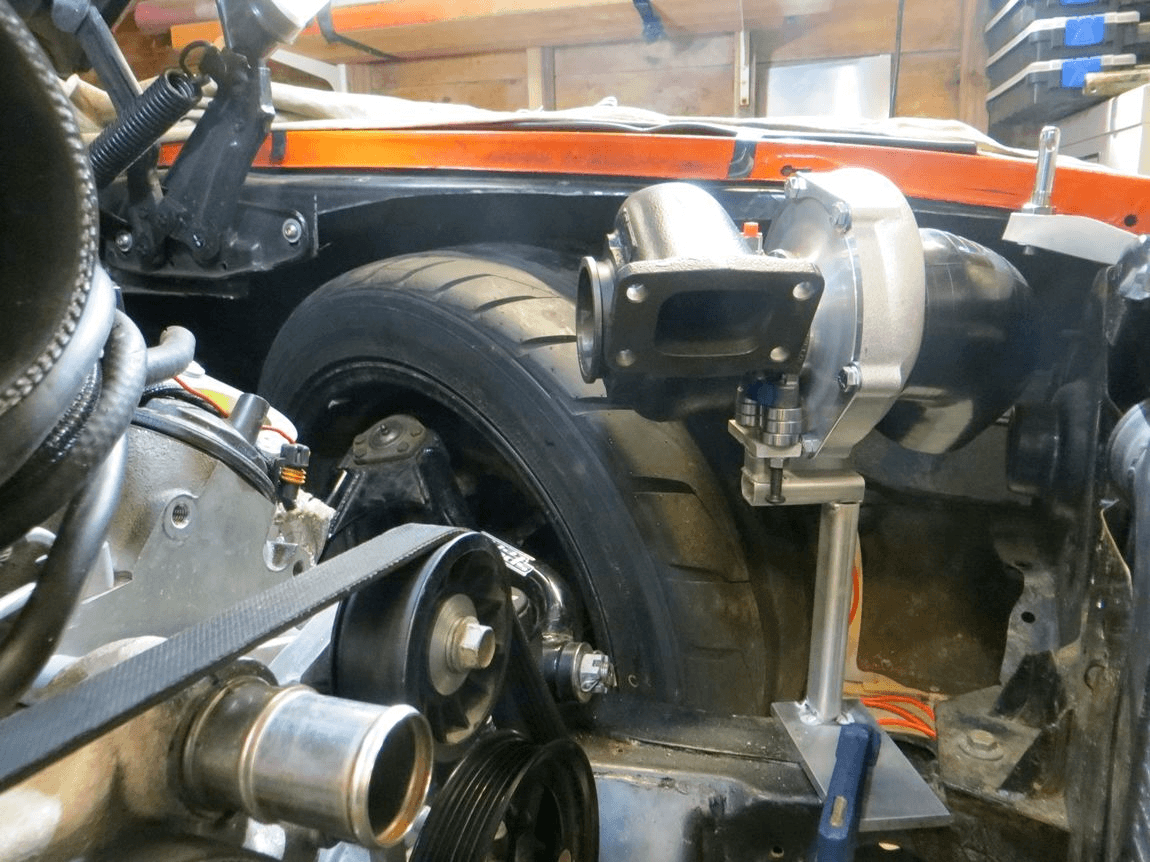

I'm not sure if it was on here or on Instagram, but someone asked me what fender lip trimming I had to do to clear the tire at full lock, so I took some pics and a video.

Because of the camber gain from the Gulstrand mod, at full steering lock the outside tire comes closest to the trimmed fender lip around ride height, and the gap is about 3/8". Any suspension compression past that and the camber gain tucks the rim in and that gap decreases a bit to 1/4" or a little under, but then remains at that until full bump.

Because of the greater steering angle due to Ackerman, the inside tire at full lock just barely starts to rub the fender lip at full lock at ride height, and then continues to rub worse as the tire compresses. So this is okay for parking lot full lock, or hard corners as the car rolls a bit.. but the inside tirewill rub the trimmed fender lip pretty bad with any compression from hard braking while at full lock. I guess I can't Gymkana this car.

The driver side, at full right steering lock...

Here is the driver side cycling thru the suspension, with a pause around half way thru at what ride height would be if there were a spring in and on the ground...

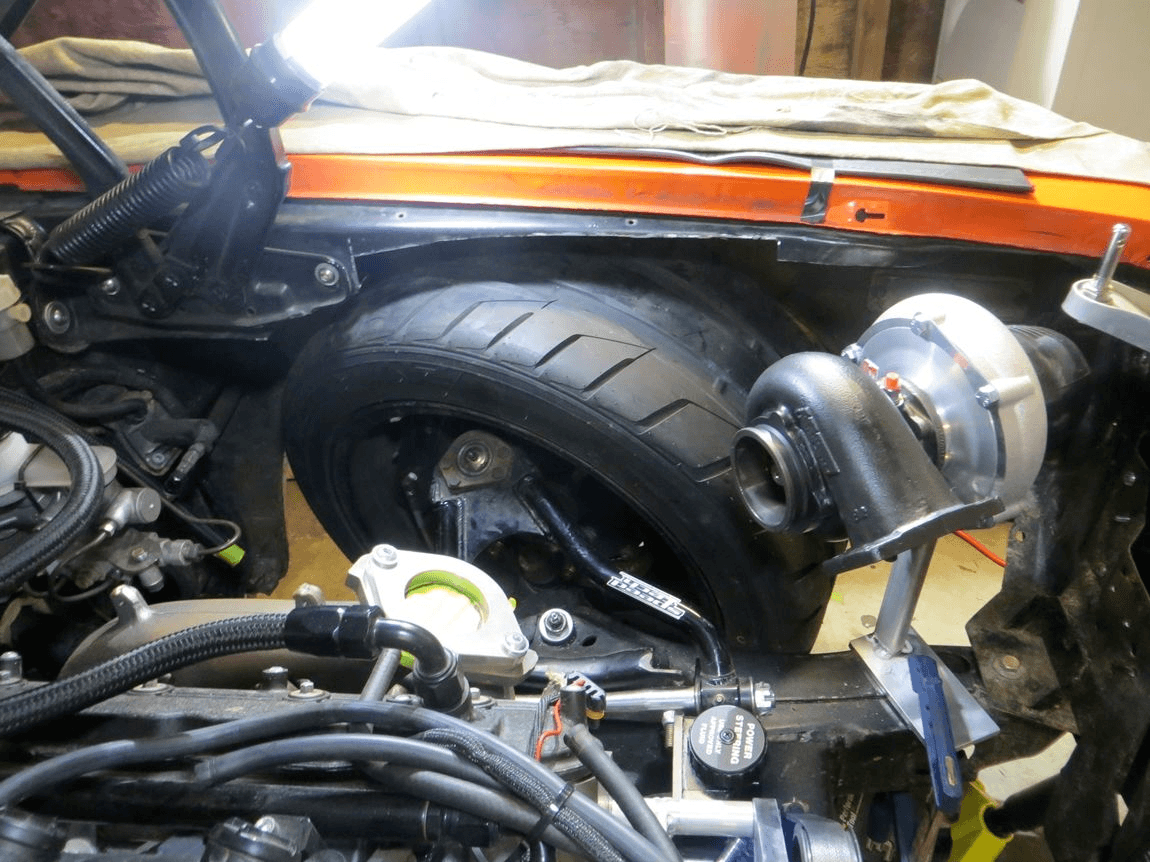

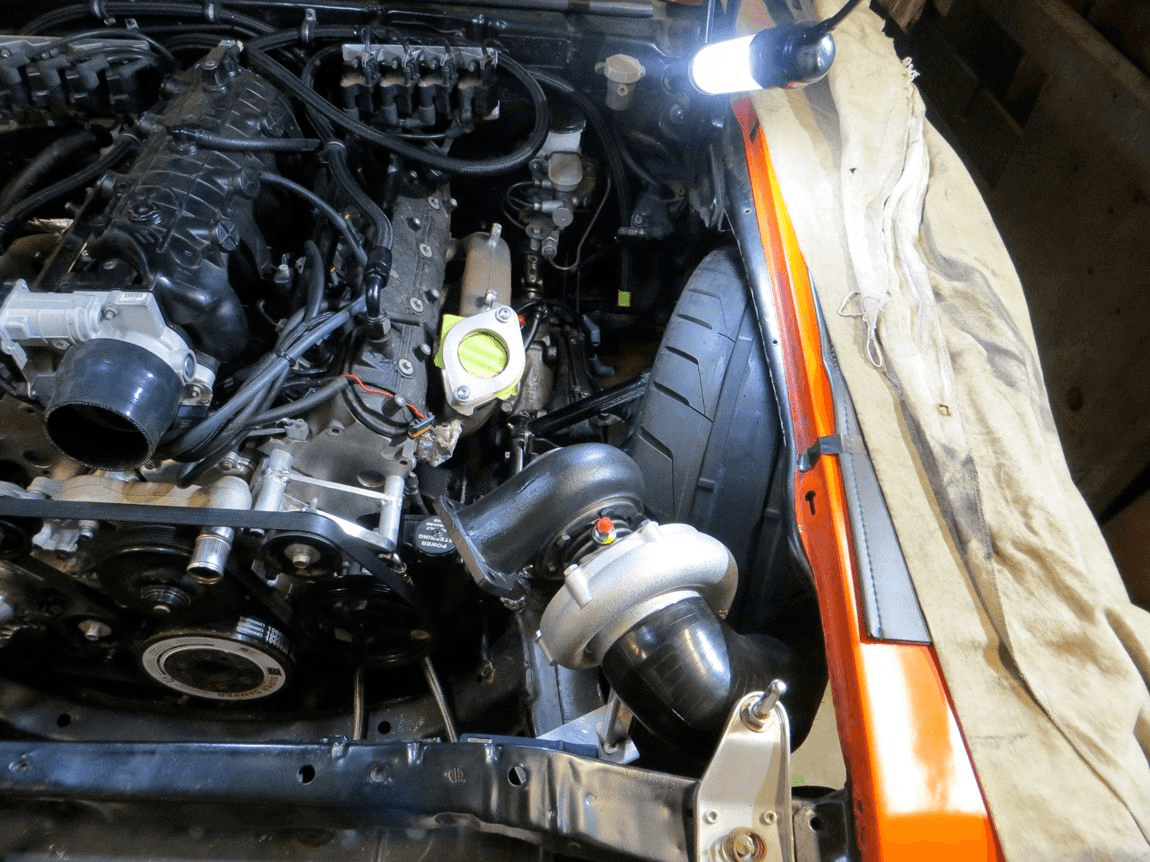

I had a solid afternoon in the garage today. Went from never having mocked up the actual twins to having one side more or less tack welded together in an orientation that looks good for tire (and later inner fender) clearance, taking in mind feasible symmetry between both sides.

But first, some Precision equipment in a not-so-high-precision shed of a garage! Haha

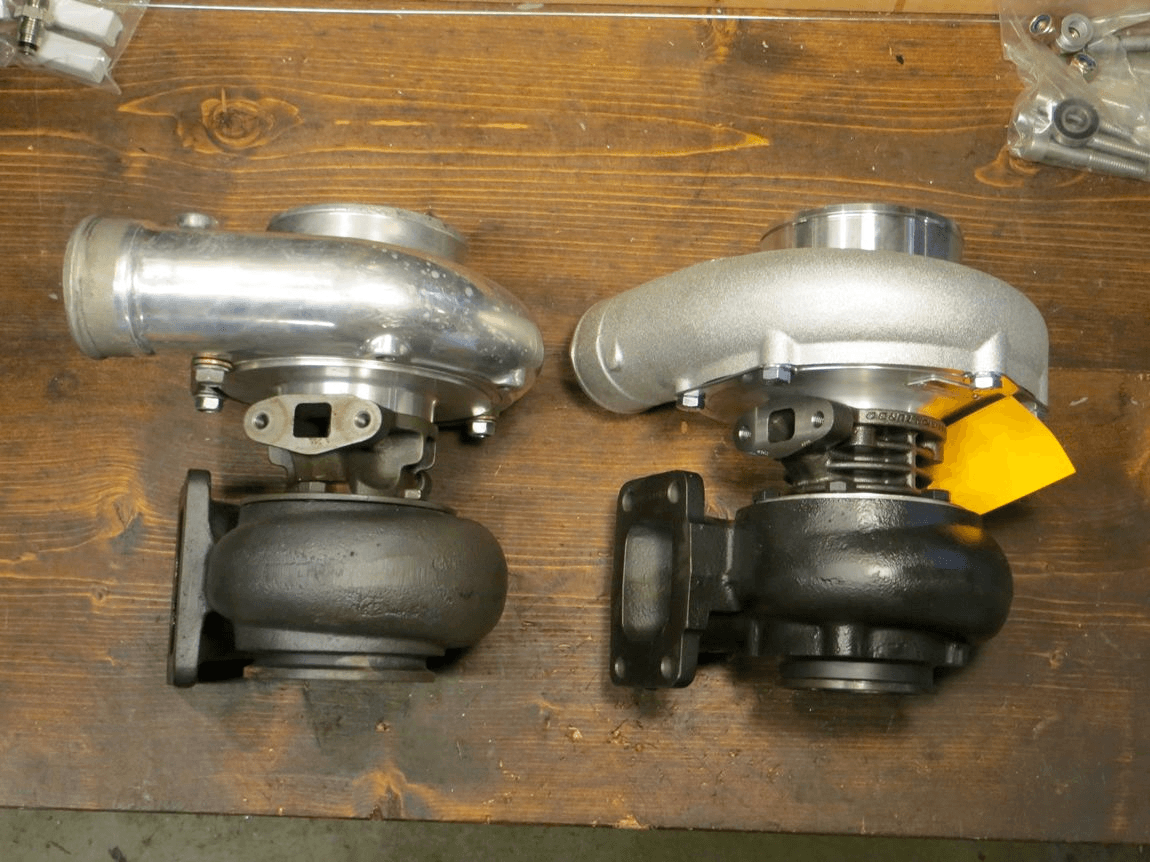

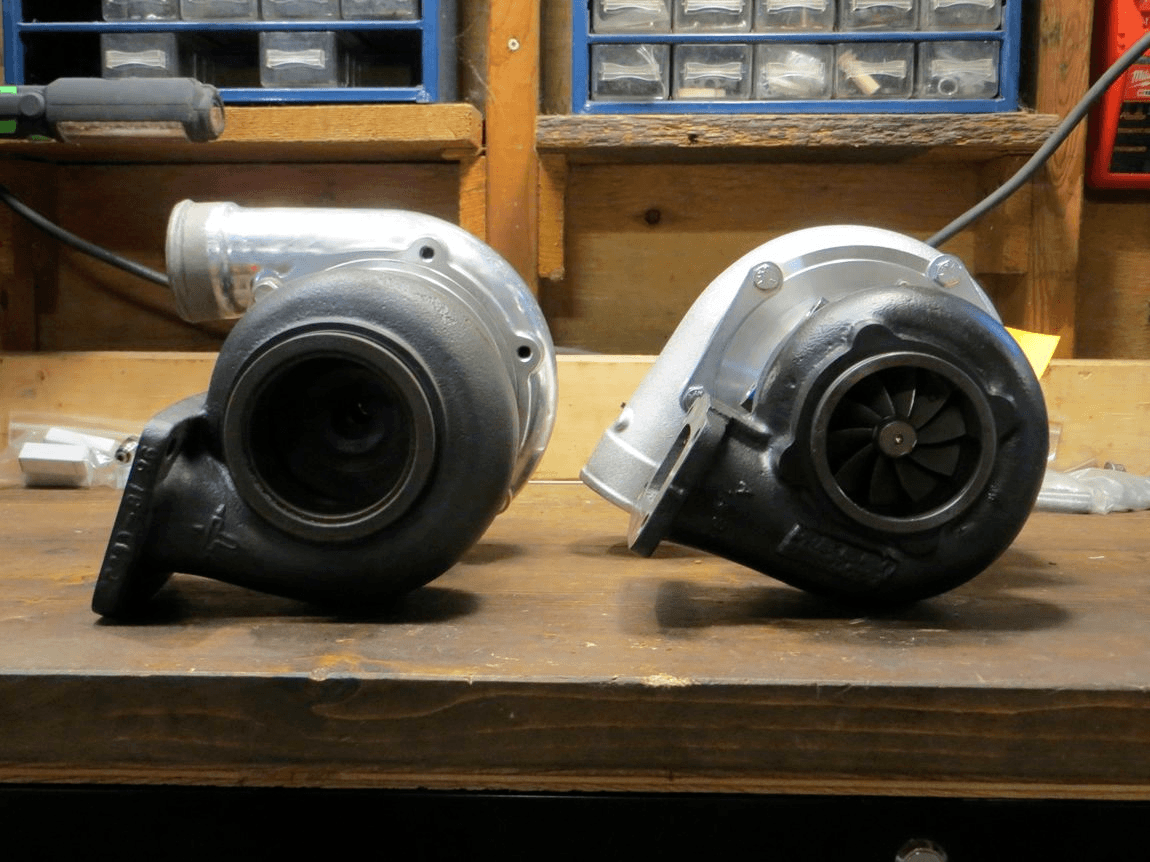

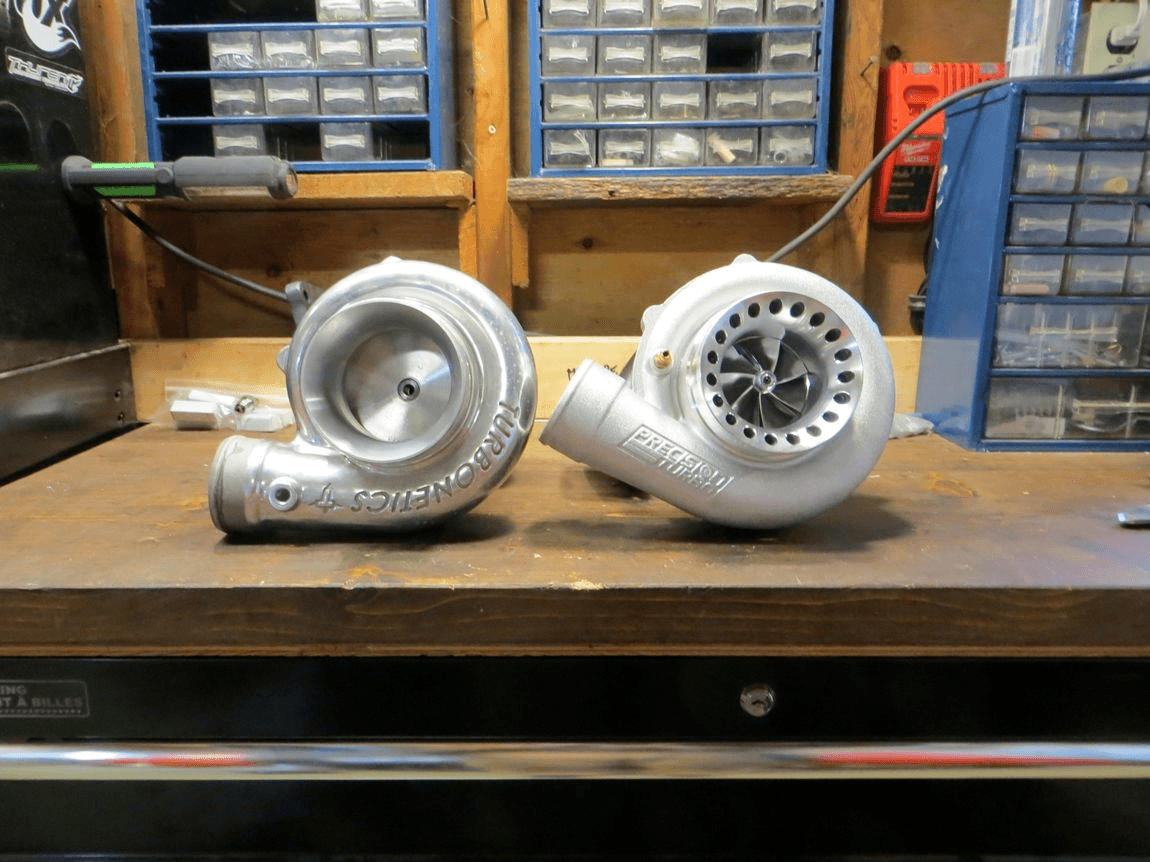

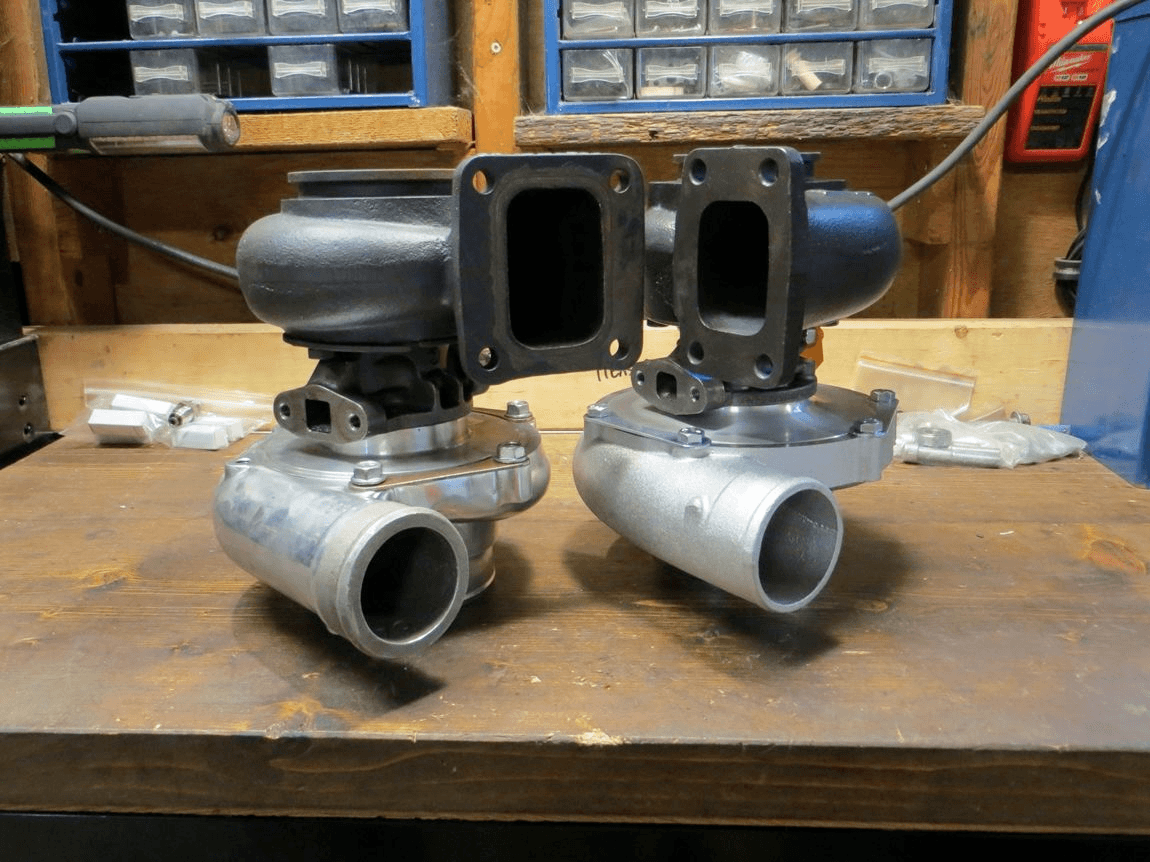

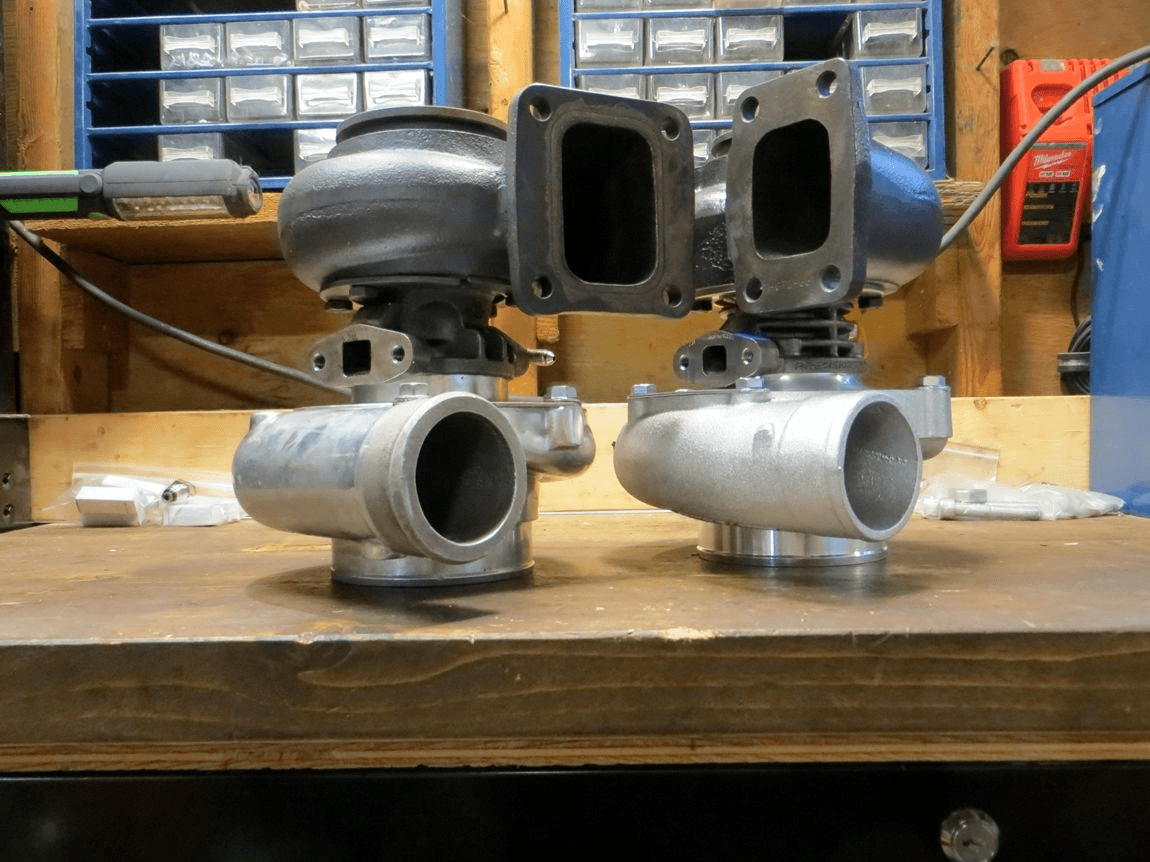

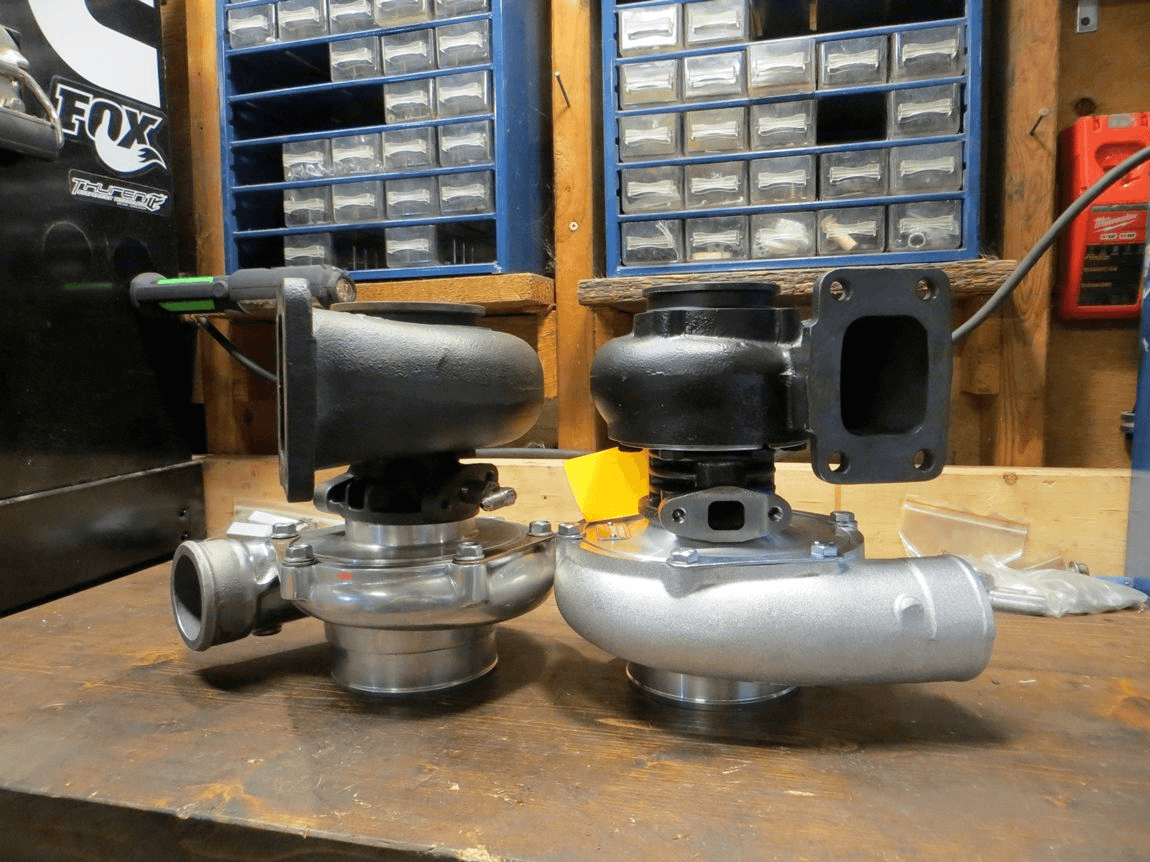

And here are some comparison pictures if this helps anyone else out there. In all my research it was really difficult to get any reliable outside dimensions from any turbo maker, so here is a sizing comparison of the 6466 to a Turbonetics TC-76.. they're practically identical in size. That Turbonetics is one small envelope for a 76mm turbo. No wonder it choked out and wasn't nearly the beast that the old PT7675 was.

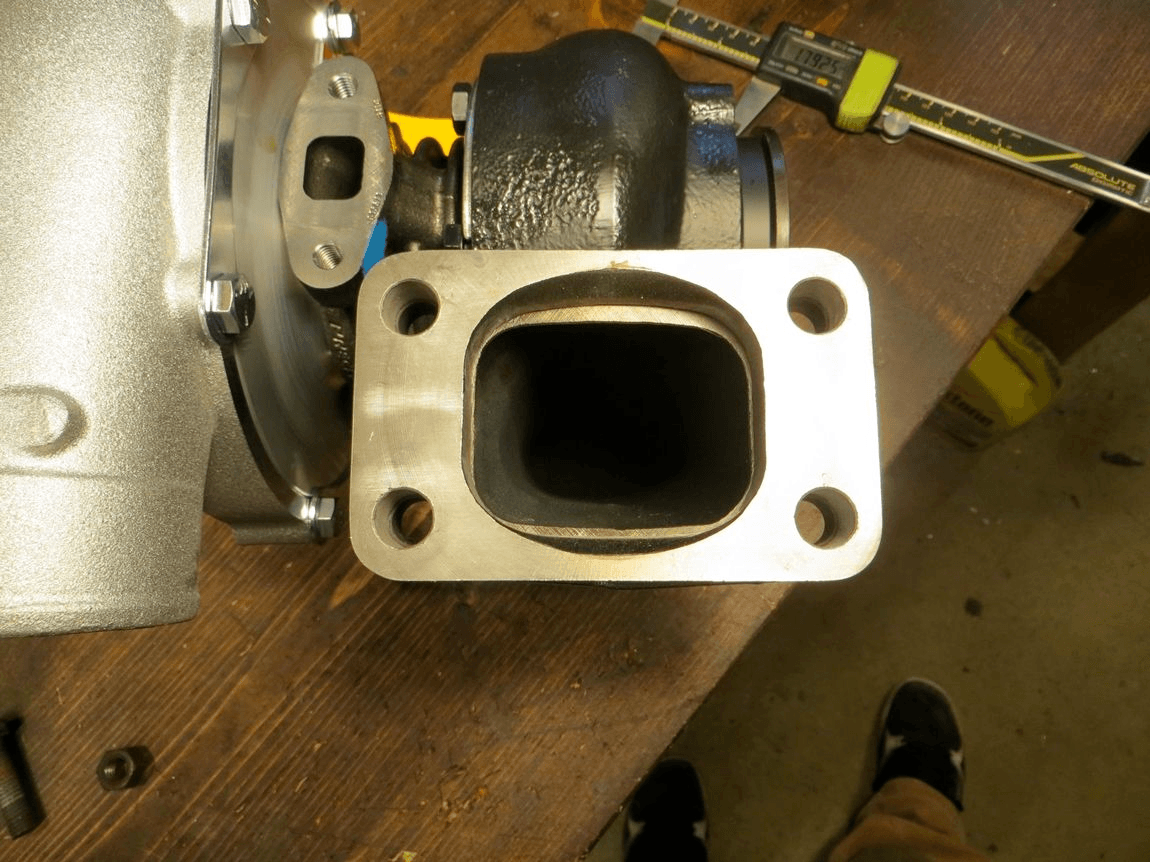

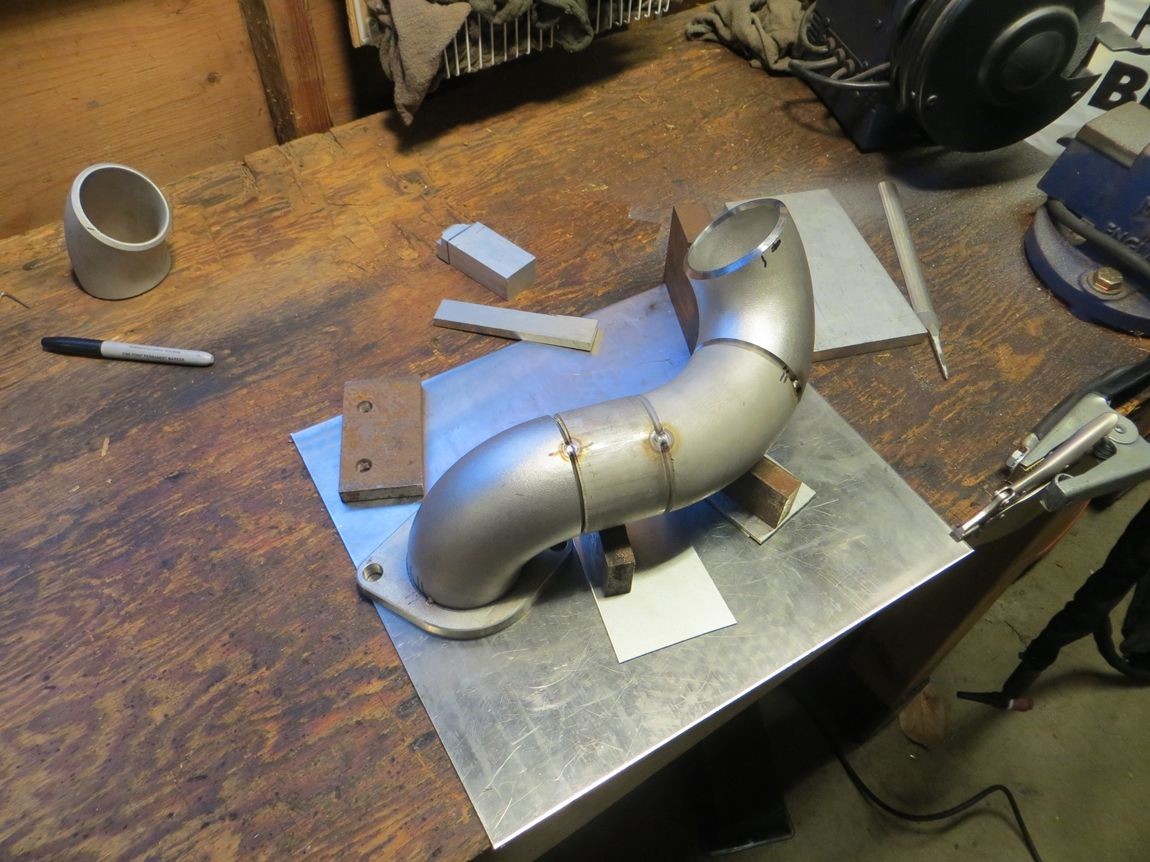

I was surprised to find that the T3 inlet flange I sourced from Ace Race Partswas massively off of the T3 Precision housing inlet. Guess I'll have to order matching inlet flanges from Precision, just bummed because of the wasted porting work I preemptively did. The housing has 10mm holes where the flange has 7/16" holes, and the 6 turbine housing clamp bolts are M8 with a 12mm hex head whereas the compressor housing has 3/8" bolts with 1/2" hex head.. very strange. I spent about 2 hours methodically changing the x & y location of the turboas well as the height, trying keeping it inline with the engine then a variety of angles to try and get the combo of best angling for the pre-turbo hotside (and downpipe) and tire clearance at full lock.

I spent about 2 hours methodically changing the x & y location of the turboas well as the height, trying keeping it inline with the engine then a variety of angles to try and get the combo of best angling for the pre-turbo hotside (and downpipe) and tire clearance at full lock.

I settled on turbo locations that I think will work well.. not finalized, but probably 95% good working location to start fabricating hotside piping as well as roughing out the inner fender.

And started tack welding schedule 40 2.5" SS304. I was a bit hesitant to start just randomly grinding and cutting it in case I screwed it up, as it's expensive and I only got the minimum amount I thought I'd need, but I ended up only having to cut a little bit of straight stuff, and then just massaged a couple elbows with a grinder.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM