You must be logged in to rate content!

6 minute(s) of a 891 minute read

4-15-2019

This weekend I made progress on "inspecting" the fuel pump wiring. I figured if I was going thru the effort of jacking up the car to climb under it, and most likely also dropping the tank to inspect wiring, I might as well just update the whole setup... whoops.

I have always had some fuel starvation below 1/4-full tank, so I kinda want to get rid of that at same time as troubleshooting the fuel pressure drop issue.. Plan is to try the Holley Hydramat setup, and reorient the pumps to allow some more room for an update to the fuel level sender as well, to go from a stock float type to a capacitance type from SpeedHut (same company as gauges, so 100% compatible.

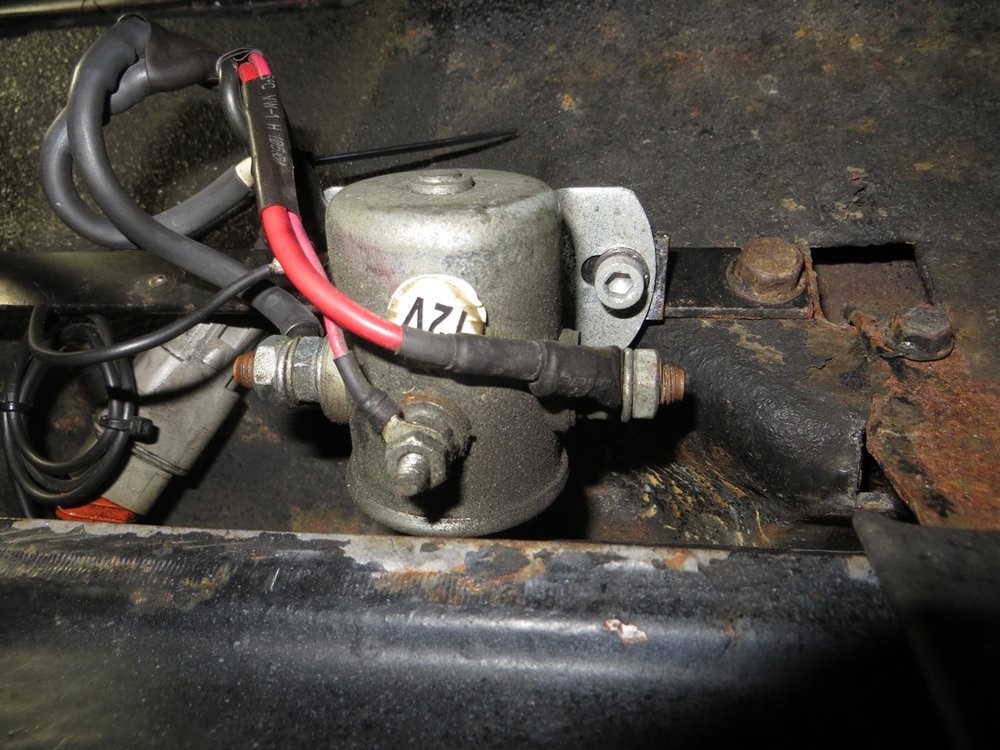

First step was to inspect. I never liked that all the wiring and solenoid is under the car, if there was a failure other than pump-related, so I plan to move the wiring up to next to the battery in the trunk.

Feed from the battery is a single 10ga (by my eye-approximation), which I'll be upsizing.

The ground between the solenoid and the tank was frayed at the mounting point on the solenoid body. This solenoid is supposedly self-grounding, however I originally added this ground to the tank just to be sure. There is a separate/dedicated ground from both pumps directly to chassis, and then another wire from that same location on the chassis to the battery negative (this ground is separate from the 4ga main chassis ground to battery negative). I'll replace with pump+tank ground directly to battery negative.

Out with the old stuff...

Below two pics show the wiring sizing on the battery for fuel pump stuff:

- 2 x 10ga power wires that merge together near the underside pump solenoid to a single 10ga cable on the solenoid

- 1 x 14ga ground wire from chassis near tank to the battery negative

Next up was to redo the fuel pump assembly.

Removal of old design to inspect. The fuel hose that "isn't designed to be submerged" appeared fine inside and outside after spending ~7years submerged in gas. No weird increase in pliability or any degradation to the material itself.

What's interesting and so clearly wrong to me now, is the dual 5/16" pump outlets T-merge into a single 5/16" hose that then fits to a 3/8"-hose-barb-to-8AN fitting on the bulkhead! What the hell! A 5/16" hole is 40% the size of a 1/2" hole (just talking ideally, not considering how the fittings are actually drilled)... this clearly would be a choke point if kept unchanged, if it wasn't already!

There is interesting discoloration on the wires at the Deutsch connector terminal crimps.. looks to me to be heat discoloration, I'm going to have to research high-amperage alternatives to this connector/pin style, if possible.

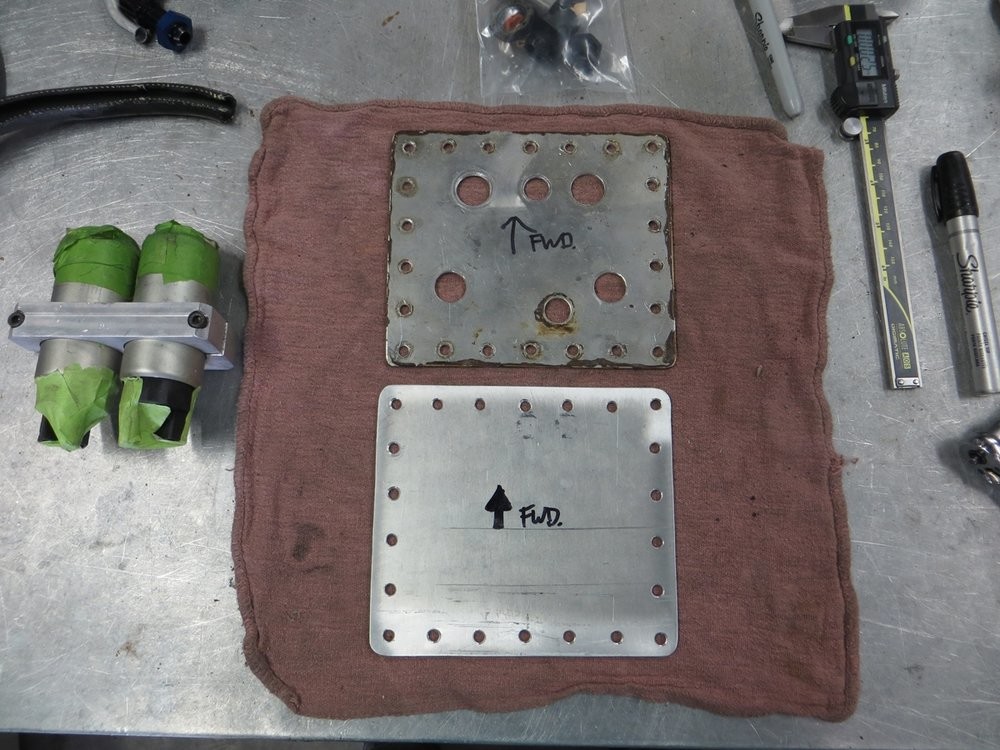

Fabricated bracket all cut apart, to use top plate as a template for a new bulkhead plate.

Do connect the in-tank pumps to remote-located Hydramat filters, I'm using these neat adapters from Z1 Motorsports which convert the hole-and-stud mount of a pump to a 3/8" hose barb.

New top bulkhead plate.. ahhhhhh.. a blank canvas.

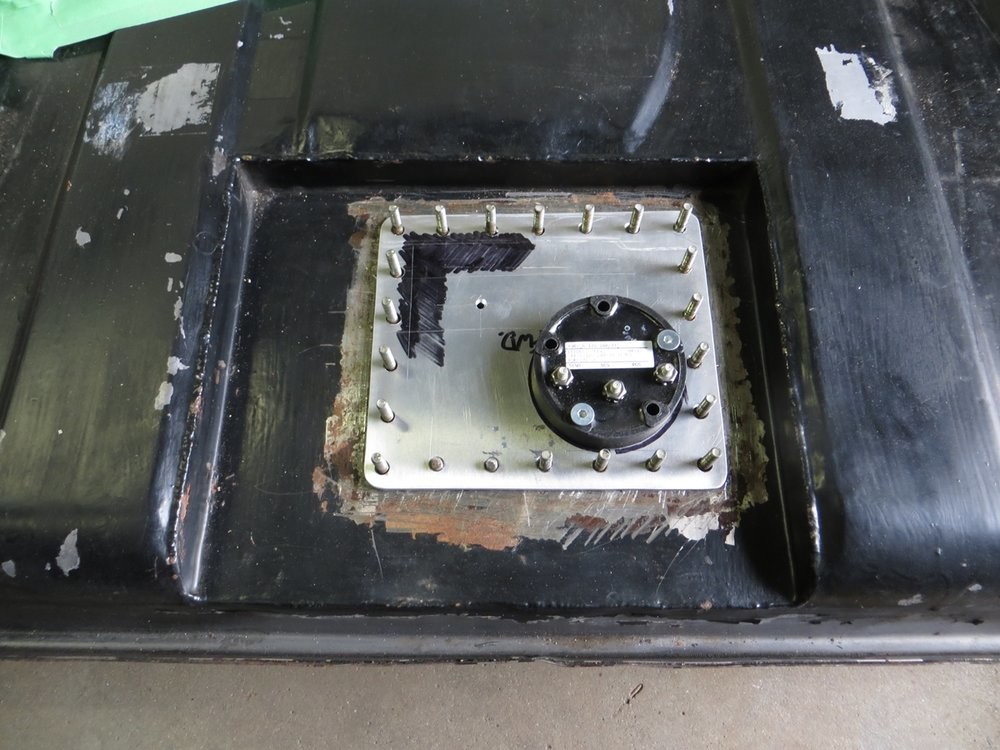

Fits! Here is the top of the new SpeedHut capacitance fuel level sender.

Arranging the various bulkheads and required clearances to cutout shape in tank as well as tool/sockets.

Test assembled.

1) -8AN 90* bulkhead fittings for fuel supply to engine bay

2) -6AN 90* bulkhead fitting for fuel return to tank

3) -6AN 90* bulkhead fitting for fuel tank breather line

4) 2 X electrical pass-thru bulkhead fittings

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM