You must be logged in to rate content!

166 minute(s) of a 341 minute read

12-28-2020

V3.2 build (F2 procharger , 427, etc. )

Compliments of 1dirtyz @ www.ls1tech.com

since its the off-season on this side of the world, i decided to go ahead and start the re buildup of my camaro ( that and the stang and the scout  ) and document it here so i can keep a record of what i done.

) and document it here so i can keep a record of what i done.

my last season racing was horrible for this car, tons of issues that had to be tracked down and broken parts , so i decided to kinda start over.

here is a little background on the car: its a 99 camaro , 427 aluminum block , l-98 heads, th-400 , methanol injection , F1-R blower and front mount . basically a drag car now.

i've decided to upgrade / redo alot of things ( some i already started ), so i'll post pics as i go .

here's how the car started

here's what i'm planing on doing:

-light weight brakes

-travel limiter

-loose some weight

-redo the inside wiring ( basically gut the dash )

-new tranny coolers

-rebuild tranny

-new torque converter

-abs delete

-convert 6 point roll bar to roll cage

-swap out F1-R to F2

-fabricate cog drive

-install ati's blower super pulley

-lower 1-2 gears

-carb intake and elbow

-new intake tube

-tow hook

-fix cooling issue

-install crankcase evac.

-redo tranny cooler

-bigger injectors

thats what i can remember for now

like i said, some stuff ( not much) , i already did , the others i'm just waiting for parts to show up.

6/18/2008

i got a set of aerospace brakes for all four corners , that and with the abs delete dropped about 65 lbs if i remeber correctly off the nose.

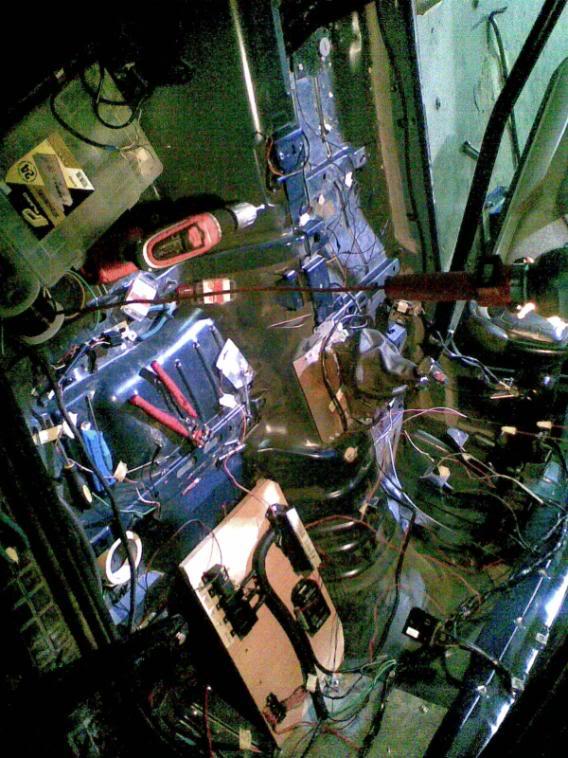

i also ripped and redid the electrical wiring from bumper to bumper , in the bottom of the pic you can see the "nerve center" of the car , all electrical stuff goes there

i also gutted the dash and removed the carpeting for loosing more weight.

also finished up the roll cage conversion , now that was a pain in the ass , definatly have some one do it for you if you can!

i also (finally) changed my 5 year old front runners ( VW bug tires) to M/T skinnies!

here's how the guages came out :

i also finished relocating a few things: i relocated my water injection pump and tank for better access to the location you see here , you can also see the remote battery disconnect solenoid .

i also removed the factory radiator puke tank and relocated my battery to the trunk to make room for the new puke tank and Accusump.

i still need to plumb the accusump , I'm just waiting for a few fittings that should be here soon

i also removed the headlights ( ahhh, the things we do to loose weight  ) and covered up the hole they left with black headlight covers. i had to fab a brace to hold them from caving in at high speed. their bottoms are screwed to the front bumper.

) and covered up the hole they left with black headlight covers. i had to fab a brace to hold them from caving in at high speed. their bottoms are screwed to the front bumper.

i'll snap a pic of that tomorrow , but you can see part of the brace in the last pic.

when i had the heads , the only option was either the truck intake or the l76. i have the carb intake now which should flow pretty well. i totally agree with you , thicker heads are a definite plus , but for now, i'll stick with the l98's till i get a 6 bolt block

as for boost, I'm looking for 20 psi ( the F1-R was maxed at 12 psi on this motor), if the tune is ok , head lifting shouldn't be an issue at that level .

it was washed about two weeks ago ( the car is garage kept) before i went to the track . but on the way there i was driving for 4 hours through a dust storm, and on the way back it was a SAND storm , there was san in every nook and cranny in that car !

this is the crap i had to deal with for 8 hours ! and to make it even more fun :35 mph cross winds !

i live in riyadh, saudi arabia. i am originally from there and live there perminantly. the track you see is actually in the neighboring country of bahrain, hence the 250 mile trip each way to the track. you guys should see that track ! its the same track they hold the F1 races at and to say its a first class facility is an understatement!

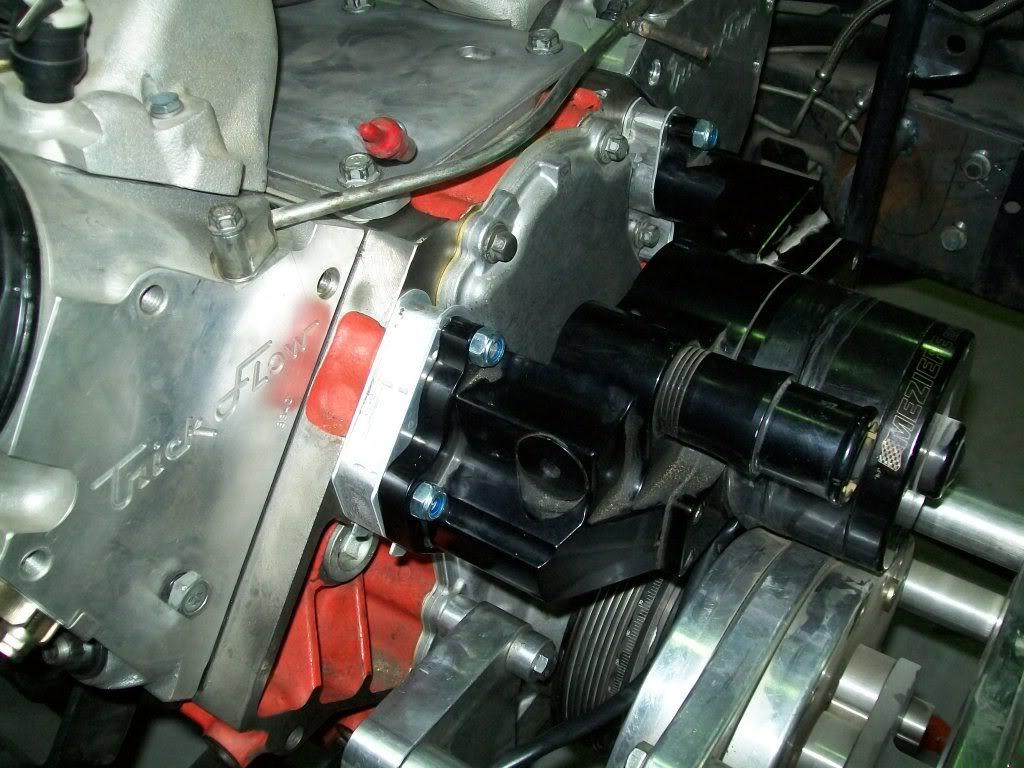

qwiketz, i really don't think I'm getting belt slip ( i also put a cog drive setup on the car to verify - look for the pics soon). the car dynoed about 890 rwhp when i was in the states on pump gas with 408 , i'll dig up the video and post it.

if you are wondering about the boost numbers , you got to figure in the head flow , big headers , and monster cam the car has.

in the states back in houston , if i wash it it rains , in phoenix if i wash it birds think my car is toilet and take dumps on it , here , if i wash it i get a freak'n sand storm!

i also installed the carb intake and the elbow, now i need to fab up a tube from the intercooler to the TB.

you can see how this elbow clears the cowl and the plastic stuff on top of it . an added benifit of this elbow is that it has a wing type of thingy where it bends to help distribute the air better in the intake ( i'll try to get a pic of that soon)

and here is how the headlight cover brackets look like and how the front end looks with them on it

and in a further attempt to clean up the engine compartment (without actually washing it  ) i relocated my methanol injection controller to inside the car. tomorrow i should be getting some stuff in from summit so i can proceed with a bunch of stuff like plumbing in the accusump and other doodads.

) i relocated my methanol injection controller to inside the car. tomorrow i should be getting some stuff in from summit so i can proceed with a bunch of stuff like plumbing in the accusump and other doodads.

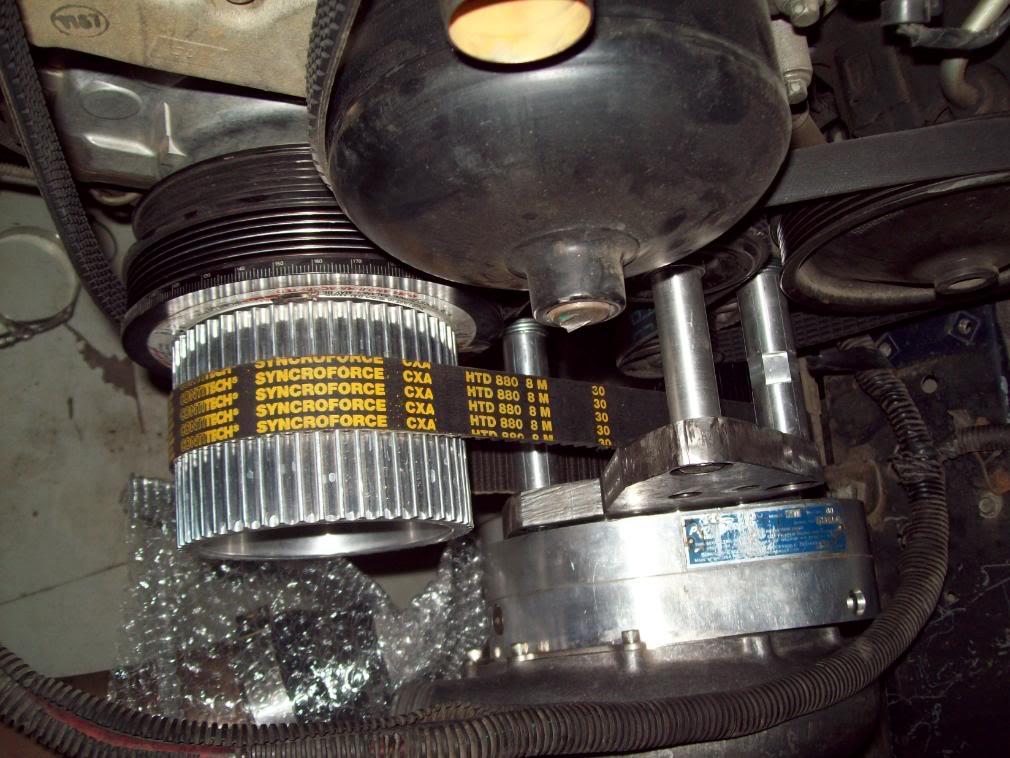

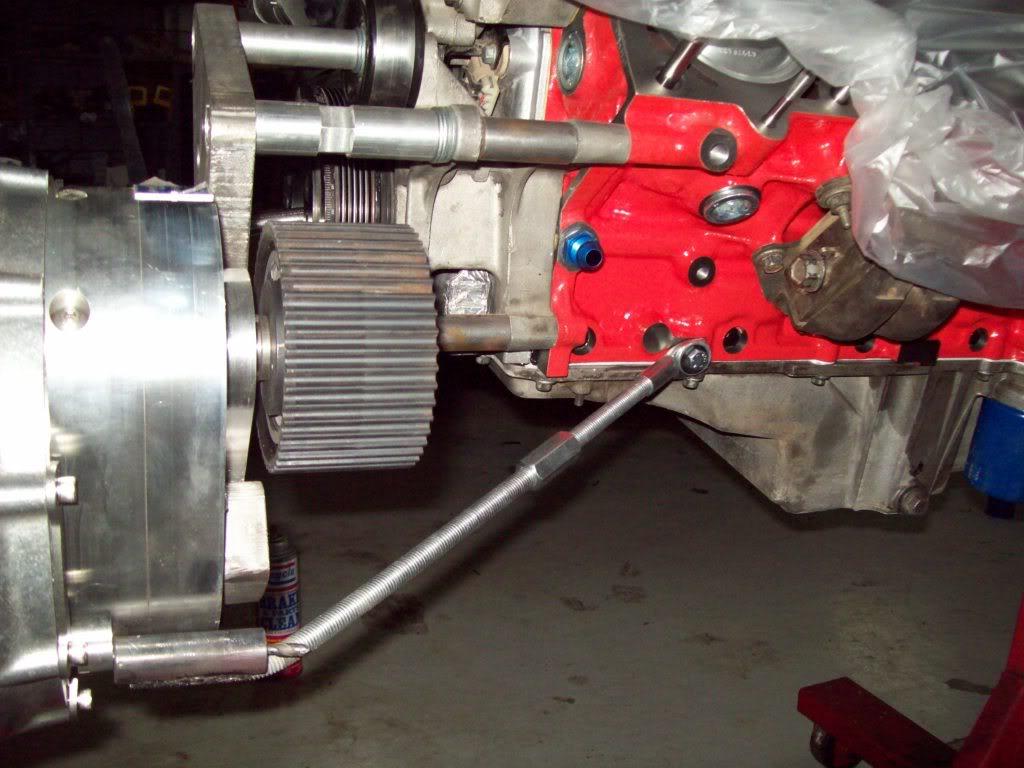

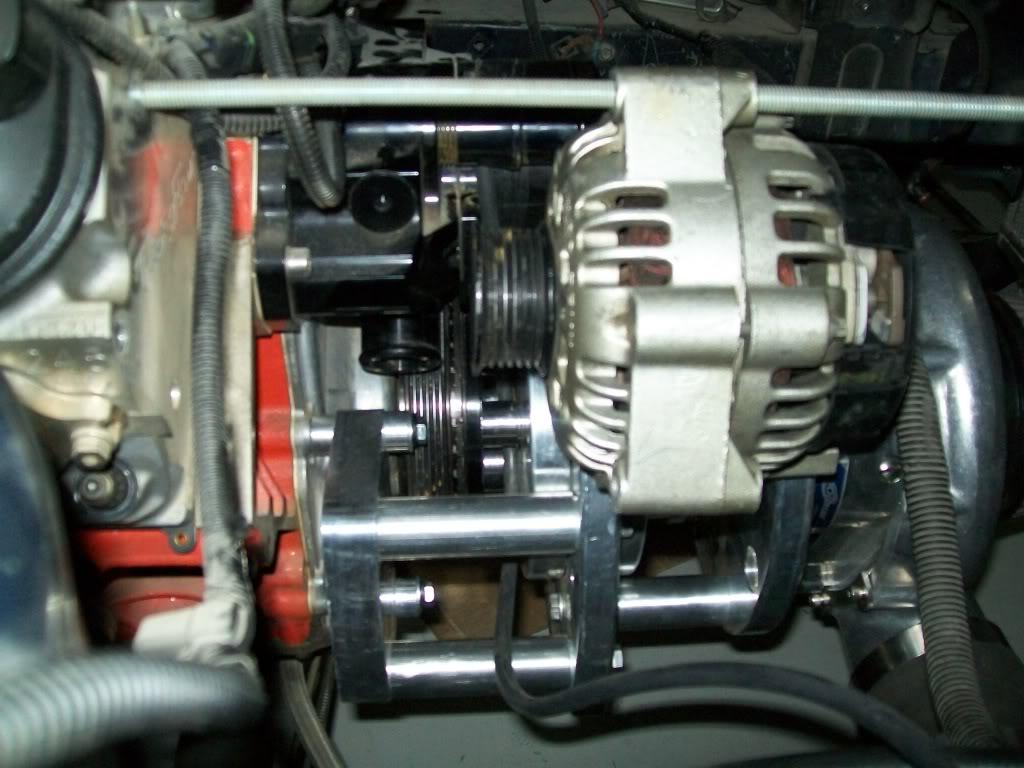

i already installed the cog drive i made ( for the last round ) without the ATI super pulley just to see if all my work was properly lined up and working good ( well it worked great , until i hit the revlimiter a few times and sheared the teeth off the cog belt - as expected  )

)

6/20/2008

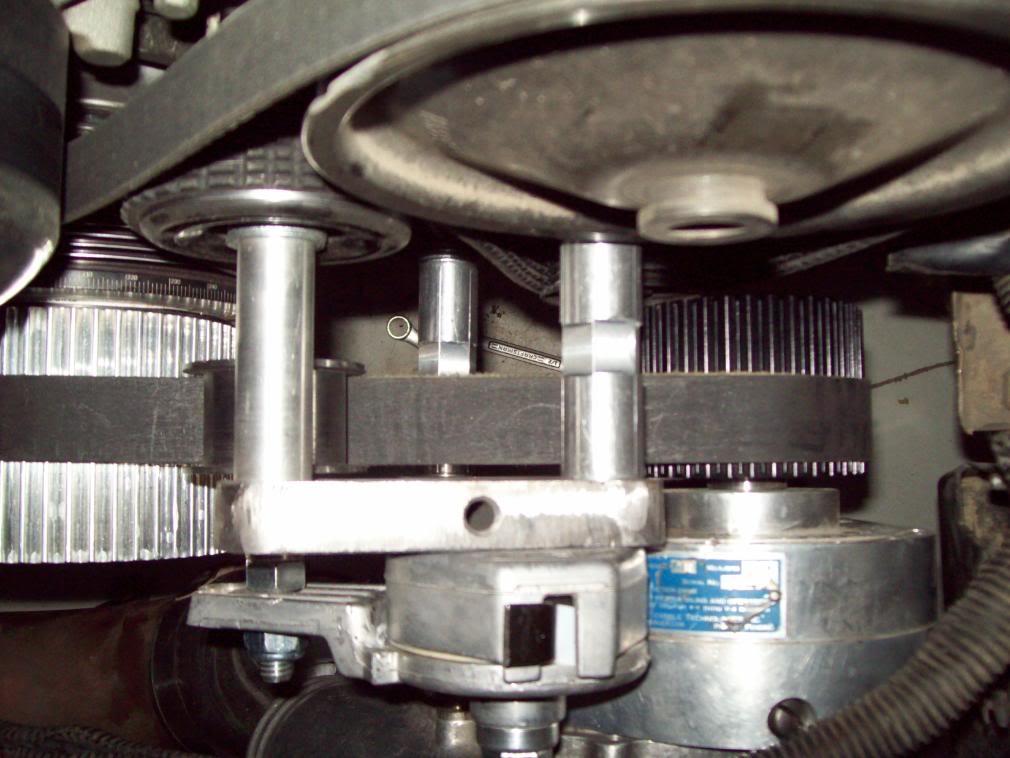

here is what i did to get the cog drive to work :

you start off with a stock ati bracket and notch it to clear the tensioner ( that i fabbed up at a local machine shop - along with the idler pulley and longer stan-offs):

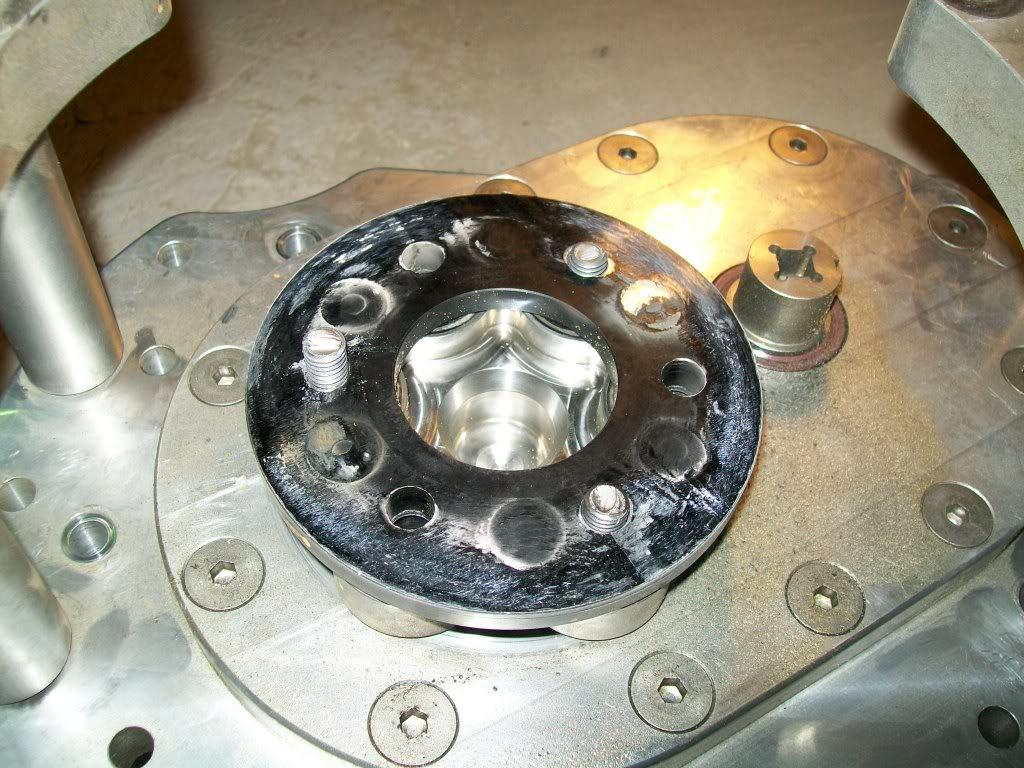

i got a BDS crank cog locally and had the local machineshop redrill it to the ATI balance holes.i used a 55 tooth one here casue i was using a 36 blower cog and didn't want to risk over boosting it on the F1-R - you can also see the standoffs here ( bracket was not mounted properly in this pic)

here's a pic of the standoffs :

and here is the finished poduct

and when you are building a cog drive for 2 cars and a serpentine for a third , all while experimenting , you end up with all these

off couse all this is coming off as soon as i get the ATI super pulley , thats when the F2 goes on , the bigger crank cog goes on , the super pulley , and possibly a wider belt.

next up is relocating the tranny coolers to the where the headlights used to be ( i already did that , but i don't like how they are positioned and will redo them with fans on them).

so just so i remember what i need to do & get tomorrow, i need:

- X2 8" electric fans

- finish up the fuel rail / reg. plumbing

- remove exhaust shield from under tank to see if i can fit a sump on the tank

- mark & remove header extensions for welding evac. hose bung thingy

- get some soda for the fridge

the elbow is from summit (EDL-3847)-- better yet , look up ls1 elbow and check out your choices . one word of advice , if you don't have it , get the edelbrock throttle body with the elbow cause for some reason , the bottom bolt holes on the tb side of the elbow won't line up with the TB ( i had mine mashined to fit.)

the intake is from SDPC -----> and its a GM performance intake for the l-92 heads specifically , no machining required pn : 25534416 . they won't fit the LS1 style heads. ( for that look up edelbrocks manifolds)

6/23/2008

well i got some stuff in from summit today , mostly fittings and what not.

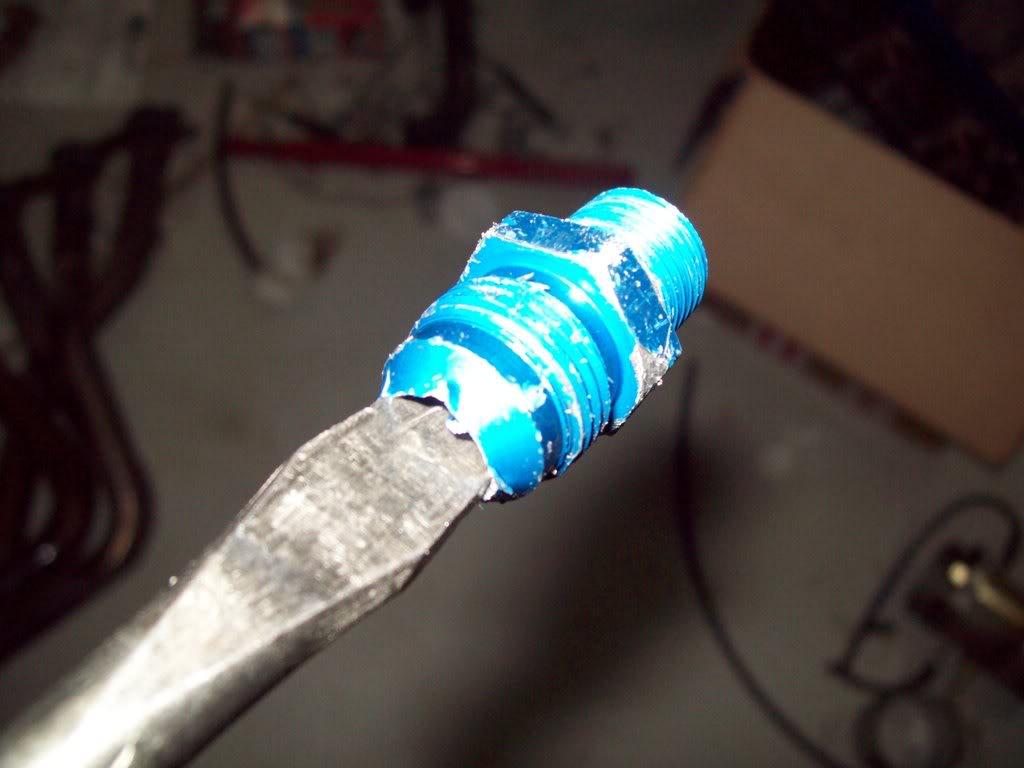

so i decided to plumb the oil accumulator ( A.K.A accusump) using the rear oil galley bolt ( the allen key bolt right above the oil filter) ....... bad idea !!!!!

i removed the driver side header and the block off thingy just above the oil filter so i could try to thread in the fitting ( adapter from the block,s metric thread to -AN male fitting ), because the threaded hole was recessed and how it was angled, i could not thread it in easily and it was a royal pain to tighten , only to find that the 45 deg hose end ( any hose end for that matter ) would not fit in such a tight confine ......

so i proceeded with removing the fitting , and guess what , it won't turn ; i couldn't get a socket on there due to how the whole thing is recessed and i ended up maulling the edges off the fitting . which led me to drive a big screw driver through it so i could turn it

so now its back to plan A ( using the front port behing the alt. and relocating the alternator to the pass side head ).

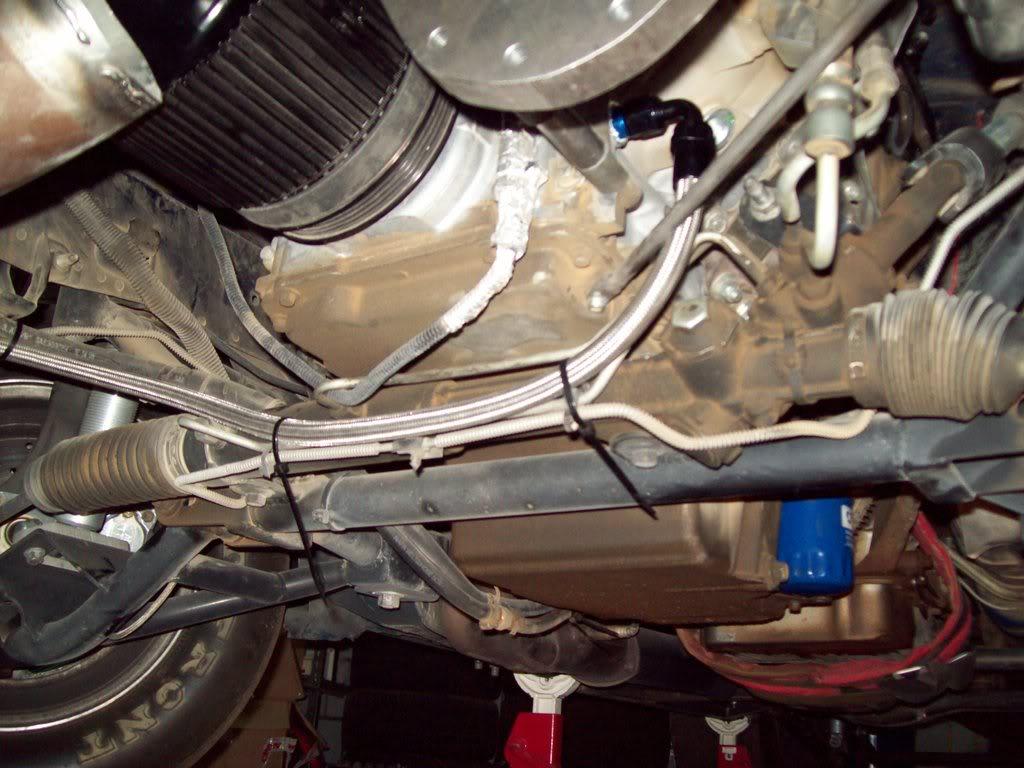

i also managed to redo the tranny coolers ( and add one more  in the process).

in the process).

i now have enough coolers to start a new ice age , and enough oil capacity to jack up crude oil prices by $10

now i hace a fan cooling each side for the coolers too.

here you can see how i stacked 2 coolers on top of each other :

heres the driver side cooler, check out the BOV outlet : the outlet usually peeks through the foglight hole in the bumper , you can see how the part that peeked through got sandblasted !

all i have to do to finish this up is to ground both fans, mount and wire a relay for them in the car . i'm just debating weather to have them tied in to com on with the stock fans , or have them on with ignition with the option of a on/off switch to kill them if i want.

6/25/2008

got my super pulley in today! got to take it to the machine shop to narrow it down a bit ( need to shave 12 mm off it - about .5 inch) i also swapped the crank cog from the 55 tooth one ( the chrome one in the pics) to the 73 tooth one . this got me into some fitment issues with the tensioner hitting the cog. i also found out that the brace i use on the back of the blower that attaches to the oil pan bolt hits the blower cog ( the damn thing is huge (45 tooth ! ) .

so its off tomorrow to the machine shop to :

- machine a new bracket with a bigger / different notch in the side ( i want to use the old one for the stang

- fab up a new brace with a decent bend in it to clear the cog.

- get a new tensioner and machine a slot in the arm so the arm length can be adjusted

i'll post pics tomorrow of the super pulley and the bracket if it is done.

6/30/2008

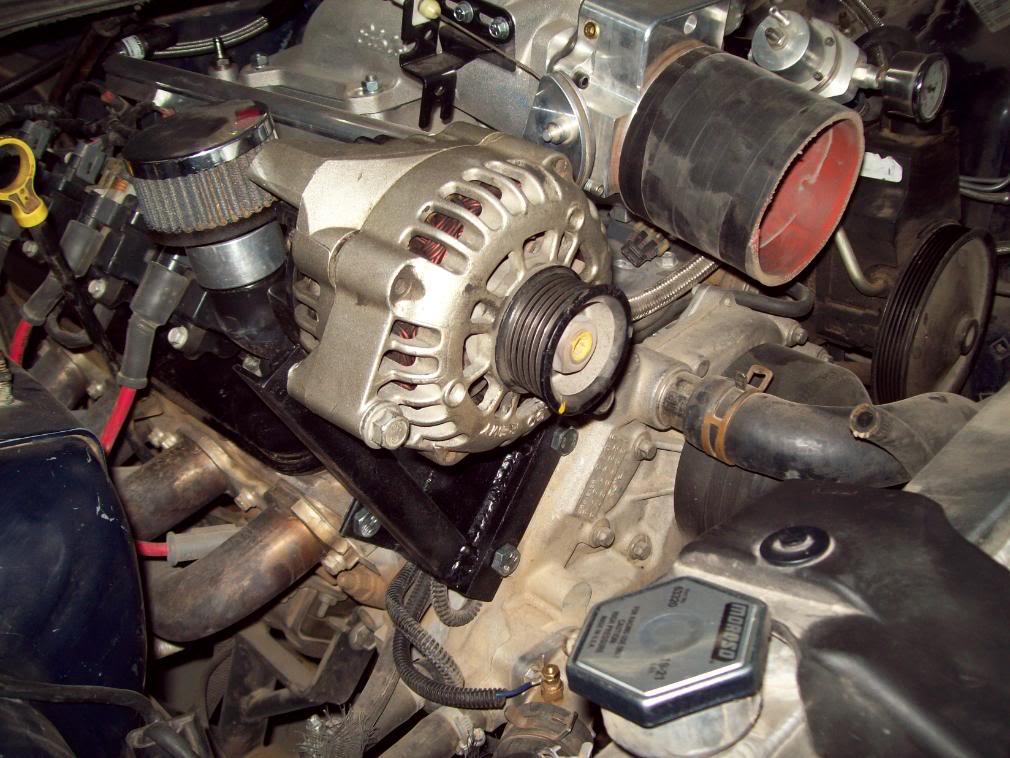

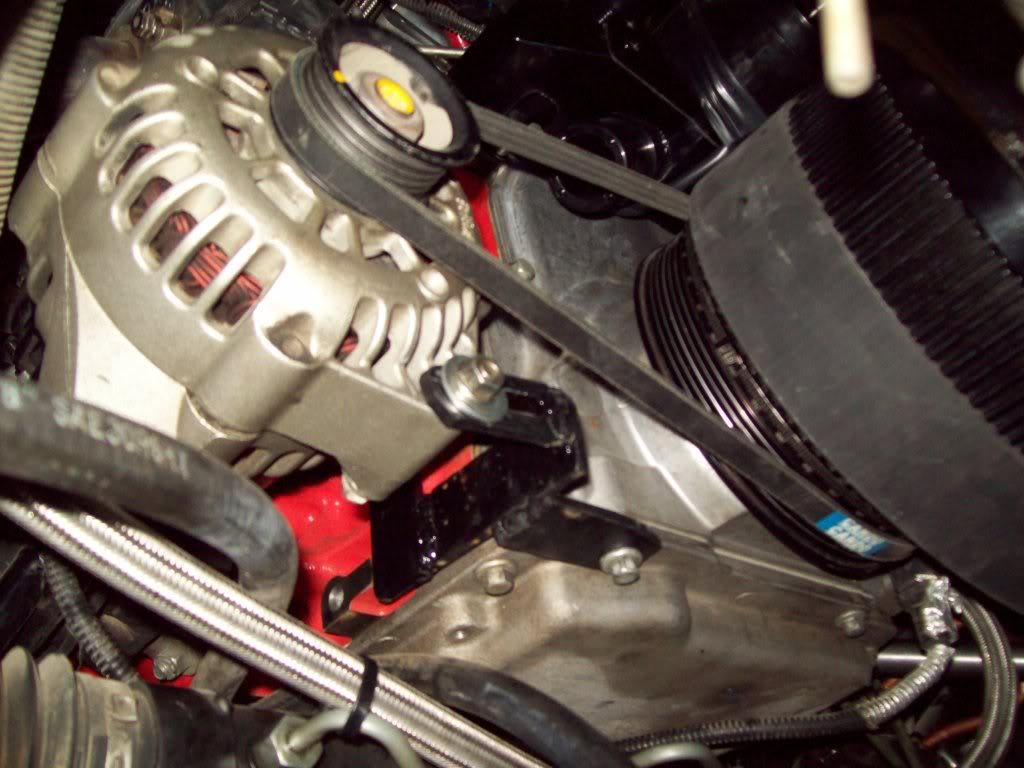

so , i got some stuff in today , mainly the alternator relocation bracket , k&n filter , and other assorted doodads.

i also got the tensioner back from the machine shop, and now its adjustable

the new bracket and brace should be done tomorow. i also had them make new spacers to go inplace of the alternator in its bracket. ( so the bracket won't break)

funny thing happened when i was removing the alternator, i tried to spin it but it was seized! i couldn't figure out why it was like that , but when i tryed to twist it with a bit of force it made some grinding noises and a buttload of sand came pouring out . so i took out the alt. and blew air through it and cleaned it . now it spins freely ! ( stupid sand storm  )

)

i also installed the smokn' hawk alternator relocation bracket loosely to test fit the alternator ( i need to get new bolts and a tensioner - mine is a billet non-sprung one).

happy to report it clears the fuel rail . i used another ls1 alternator to test fit , but i will check final fitment tomorow with the f-body one to make 100% sure.

i also ended up rerouting the alternator wires , which came out quite neat in my opinion

the biggest bummer of the day is that i finally got the super pulley back from the machine shop ( after narrowing it down by 12 mm ), and when i take the F2 out to put the superpulley on it , i find out i was sent the wrong shaft diameter pulley !! the pulley is for the large shaft blower , while mine is the small one - like the F1-r and D1-sc.

the good news is that i will take it to the machine shop tomorow to have them make an adapter if you may call it that . i already talked to the guy there and he said no problem  they do this kind of stuff all the time.

they do this kind of stuff all the time.

another no go was my plan on running a sump in the rear plastic tank. i was hoping it would have a flat enough spot to cut a hole big enough for the sump and epoxy it in place. i checked and it seems like it wouldnot work. guess i will just stick with what i have now: a bulk head fitting in the bottom of the tank with a -10 hose connected to it . i'm also planning on drilling another hole somewhere in the corner of the tank and install another bulkhead connector and cap to work as a drain for when ever i need to drain my tank.

what i have planned for tomorow :

- drop off the pulley and have the machine shop make an adapter.

- pick up the new blower bracket and alternator spacers

- install vacuum block and route vacuum hoses

- install the alternator and its bracket

- install the blower bracket and tensioner

- most likely buy a battery for putting in the rear.

on a side note, i just ordered an intercooler for the stang ,, which should be here in a couple of weeks ,which means all my parts will be accounted for and then , the stang build thread commences

7/5/2008

time for some updates:

the super pulley is a no go  - just ordered a new one , but i will try another machine shop !)

- just ordered a new one , but i will try another machine shop !)

got a battery ( yay!  )

)

finished wiring the fans , they now come on with the ignition on , and i have a swith to kill them if i need to .

i also finally finished all the vaccum lines , i used a vacuum block i took off my stang a while back ( who said fords are useless  ) and routed the main line from the manifolt to it , then from the block to various other thingys :

) and routed the main line from the manifolt to it , then from the block to various other thingys :

got the alternator and tensioner mounted for the last time :

also got the alternator bracket spacers done and installed :the brace (the bar sticking diagonally ) is the old one , i didn't like how the new one turned out , so i'm building a totally "redesigned" brace . the tensioner now clears the crank cog and has sufficient travel::

here is a side by side shot showing how i notched the new bracket :

also almost finished the tube going from the intercooler to the TB, i welded a bung on it to thread in the IAT sensor, and will be welding two nuts to hold the methanol nozzles on there too.

so , up next is the following:

-label the switches on the dash ( just two labels  )

)

-plumb the oil accumulator from the block to the canister.

-remove the passenger side header extension to weld the crankcase evac. thingy

-travel limiter

-put driver side header back on

-remove tranny for rebuild and maybe , just maybe , swap out the oil pan gasket .

-wire the alternator light and the AFR warning light from the dynojet commander

7/9/2008

i got some stuff done in the last few days. i also managed to get a new fiberglass hood for my stang and this lightweight seat ( also fiberglass), all i need to it is upholster it and fabricate a mounting bracket/ base for it.:

also managed to finish up plubming the oil accumilator:

i finally got around to installing a drain on the gas tank, it basically a bulkhead fitting with a cap.

( what do you do when you need some one to hold a wrench on one side of the car while you are on the other side, but no one is around??? )

according to my all knowing excell sheet, i finished 40% of the items on my list

so hopefully tomorrow i will finish cleaning the inside of the tank and button it up.

i should have the methanol injection nozzle bungs welded in on my intake tube , i already welded the AIT sensor bung on there. i might even paint the tube black.

and from the list i posted in the post above, i will be putting the header back in so i can fire the car up to see if there are any leaks and what not.

after that , the tranny comes out and we see what kind of damage we have

7/13/2008

finally got to work on the car again ( now that we crossd the " getting the engine started" milestone with the stang) .

i managed to finally finish the intake tube from the intercooler to the tb, i welded a bung for the IAT and two bungs for the methanol injection.

i also finished the crank case evac thing. i welded the bung on the header extension and routed the big'ol hose . off course there had to be some action , after welding the bung on the extension - and laying down some of the finest tig weld beads i have done - i come to find out i welded the bung so that it faced upstream of the exhaust ( it needed to be like the pic below so the siphon effect takes place). so out came the grinder and bye bye welds  ... pure genius

... pure genius

i also started on the new seat , i mounted the floor brackets ( thanks rufretic for the idea)

and mounted the old seat brakets i had to the seat ( they're adjustable)

i just have to finalize the position of the where both brackets meet and then its off to the upholsterer for some padding on the seat. might i also add that using a file to grind away on a fiberglass part is always fun, especially when you are not wearing a mask or long sleeves and gloves

i also managed to kill two spiders and one huge Mf'n ant

I'mhoping to go to the garage tomorrow to finishup the seat, wire the alternator warning light and the AFR warning light, and then start her up and put her on the lift so i can get the tranny out. if i'm lucky ( or feel like it ) that should all be done tomorrow

7/15/2008

well the seat is done, all i have to do now is make an adjustable brace for the back.

i also ( finally) wired the AFR warning light as well as the alternator charging light ( i put that one in the dash cluster).

minor setback though, i primed the fuel system to see if i had any leaks, and sure enough , i had guisers couming out from the injectors and fuel rail

i guess i have to redo the bracket that holds the rail inplace and maybe even get bigger orings for the injectors.

also pushed the car on the lift and started unbolting the tranny. i also managed to sell my mild steel sphon torque arm , so i can now order ( already did ) a chrommolly one

i'm also debating weather i should get a CSI trans shield to replace the flexplate shield and tranny blanket i have now. but i guess my wallet side of the brain is currently winning this debate

so for tomorrow , i 'm hoping to :

- pull tranny out

- pull torque arm out

- see if i can pull the oil pan gasket out without yanking the engine out ( i just said see, not try  )

)

7/19/2008

ruf, the blow off valve if a godzilla one , i used to have a vortech mondo one on there but took it off back when i was having boost issues ( turned out to be a broken supercharger  ) this one has a bit more spring pressure. with the vortech , at idle it would open , but withthe low vacuum of this engine the godzilla stays shut at idle untill you give it gas and let off ( basically as soon as it sees a bit more vacuum ).

) this one has a bit more spring pressure. with the vortech , at idle it would open , but withthe low vacuum of this engine the godzilla stays shut at idle untill you give it gas and let off ( basically as soon as it sees a bit more vacuum ).

the hose you are talking about is the feed line to and from the oil accumilator ( acusump) on the side. helps keep things oily

like i said before , i took the tranny out inorder to see what was going on with it . it was not shifting from 2nd into 3rd fast enough ( would take about 1 to 2 seconds) , even though i had a manual valve body on it. plus the trans temps were reaching the sky

( i wonder where all that sand came from  )

)

the transmission was built be tristar over here (big tranny company here ), i specifically told them to use borg warner clutches in the tranny and that it would be used strictly for racing and the what kind of abuse it would see. they said no problem , we know what we are doing .

well after taking the tranny appart , i find out they only used borgwarner clutches in 1st gear ! the second and 3rd gears had cheap raybestos junk in them! , they also used a cheap plastic washer instead of the brass ones that are supposed to be used on the input shaft . apparently they used the cheapest rebuild kit out there and charged me for premium everything .

here's how the clutches looked like after 8 dyno pulls and 3 track runs:

freak'n a$$holes

7/19/2008

got the intake back on the car after fixing the leaking injector situation

snug and dry now

i just need the tranny to be here so i could put it back in the car and then i could start it and see if the accumilator works . so far its been holding the air charge that i put in there before 4 days .

super pulley should be here by next week , and then its F2 time

7/29/2008

so , back in town and i got parts

the torque arm arrived ! so that's hopefully going in tonight.

some other stuff arrived as well , but no sign of the super pulley

tranny should be done too.

hopefully i'll get the tranny tomorrow and have it in as soon as the CSI shield shows up.

another to do item is the new dipstick, i'm tired of the fixed metal tube one , so i ordered a lokar blingy one  it even has a disconnect and plug on the tranny side so you don't need to remove the whole dipstick off the car every time.

it even has a disconnect and plug on the tranny side so you don't need to remove the whole dipstick off the car every time.

i'm also considering using quick connect fittings on the tranny cooler lines. i had them on there before , but they seemed to restrict flow . what do you guys think? should i use them or keep the setup as is?

7/30/2008

i got something done today

i finished installing the torque arm on the car , took me about 20 min start to finish, which made me feel good cause the first time i did it - 5 years ago - it took me a whole afternoon , guess a lift makes all the difference

all i have to do now is set the pinion angle

didn't get a chance to check on the tranny , but it should be done by now, all it needed was to have the pump installed. no word on the CSI shield though

i called summit up today and was informed that the super pulley has arrived there and is due to be shipped out today

( off course i totally forgot to ask about my tranny shield  )

)

8/10/2008

wohooo! got the super pulley in yesterday, and its off to the machine shop today to have it narrowed, it should be done this afternoon.

i guess i should go back to working on the camaro now  , i just have to tidy up the mess i made in the garage while working on the stang.

, i just have to tidy up the mess i made in the garage while working on the stang.

the transmission shield should be here in a couple of days i hope , and then i could bolt the trany back in !

8/13/2008

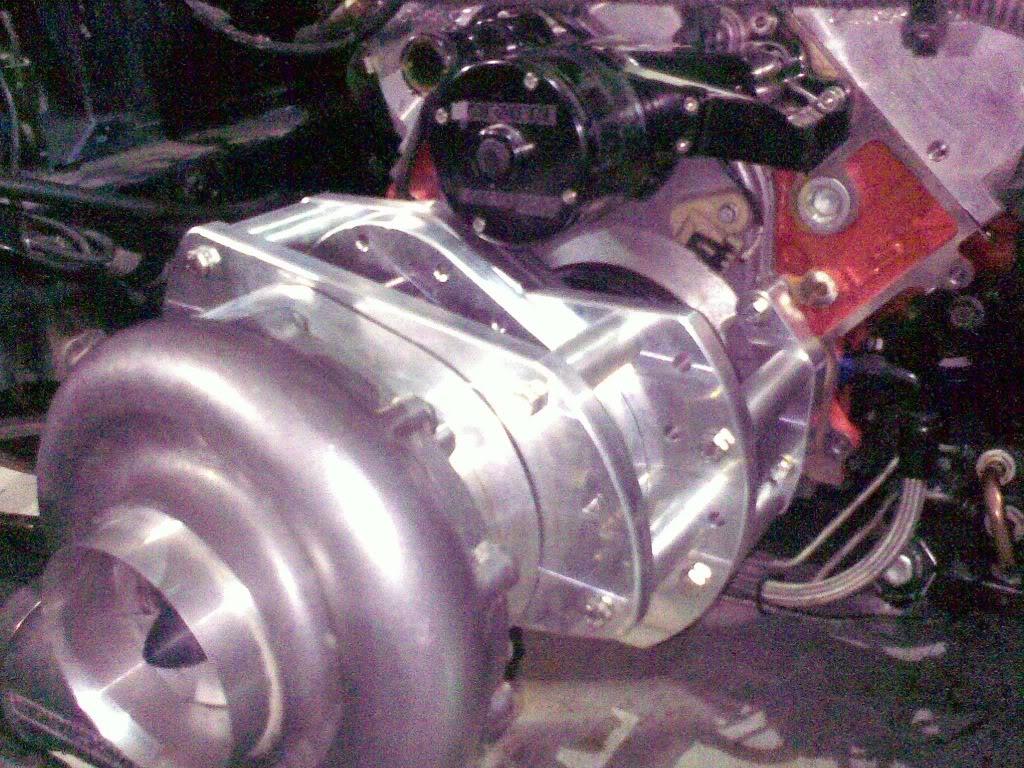

Its F2 time!

Heres the mandatory blower glamour shot:

and here is the pulley installed ( note to all who are thinking of installing this pulley on the f-body bracket: you need to use the small spacer ring that pushes the pulley/ cog out from the blower , or else the cog will touch the bracket and cause a big mess!! ) :

I thought I had room for the dinky little filter I got , but apparently not  , guess I have to find me a cover for the intake hole. ( sorry but i couldn't find a better pic to show )

, guess I have to find me a cover for the intake hole. ( sorry but i couldn't find a better pic to show )

Another little snag I ran into was the blower brace; I was planning on running it from the oil pan to the top most mounting hole that is not used by the bracket. That worked fine with smaller serpentine pullies, but with the cog pulley being so big there would be no way to use that hole with the brace I had (I was planning on making the same brace you see here , but with a longer tube part on the end to clear the cog) :

But luckily the blower has several other mounting tabs on the body of the unit that are further out:

(the big ones by the drain bolt and the snail retainers)

'll be using one of those along with a longer tube section on the brace to make the brace assembly. I think its going to work out fine.

I also got my sexy looking CSR trans shield in yesterday

i also managed to stuff the tranny back in , just need to get new converter bolts since the old ones were getting mushed from all the times i took them on and off

and here is how a sexy CSR shield looks installed on a car

More misc. stuff done too; I relocated the trans temp sensor to the pan , installed the drive shaft, and finally managed to clean ( read : shuffle ) the mess I had laying on the floor of the garage. Sure feels good to walk around without the fear of slipping on oil

another thing i noticed while under the car is that the oil pan leak might not be from the oil pan gasket, it may be from the main cap external bolts . so i'll be taking one off to see if there was thread sealer or silicone used on them , if not then i'll be doing that.

i guess all i have to do now is bolt the converter, hook up cooler lines ,fill the tranny up with oil , check the side bolts and then i can fire her up !

next on the list :

- get cog belt

- set pinion angle

- fab blower brace

- upholster new seat and fab bracket for it

8/23/2008

so i finally get to start the thing

it fired right up with no issues thankfully .

i got a belt for it that was a bit longer than i would have liked ( it worked , but the tensioner was almost bottomed out) , so went and got a shorter belt, which didn't work. with my rotten luck  the belt size i need falls between two sizes (1000 and 1040 ) and i need 1020 to be perfect . the solution : get a bigger cog pulley

the belt size i need falls between two sizes (1000 and 1040 ) and i need 1020 to be perfect . the solution : get a bigger cog pulley

another thing i noticed, there was a small leak from one of the transmission coolers , it has a cracked tube , so i have to replace that .

i also took the tranny out again last night, cause i have to take the engine out now . why you might ask???? well i think i just sold my long block! and you know what that means?? : its LSX time !!

i'm gathering quotes from a couple of places right now, and should be ordering one as soon as early next week hopefully!

wish me luck !

10/12/2008

i got to take the seat to the upholsterer , and i just got it back ( should have the pic uploaded tomorrow ). looks pretty cool if you ask me

the short block should be ready soon , i'm thinking in about 10 days it should be ready to ship. i also decided to go with a set of TFS 6 bolt heads done by TEA . should be placing the order anytime now, and they should be done in about 2 weeks

12/15/2008

man its been a while since i poisted in this thread , but here goes :

i finally got the short block in ( thanks trevor @ tsp ! ) as well as the tfs heads from TEA and the super victor intake manifold .

i was so pumped up about getting the stuff that i forgot to get the camera so no pics today

i couldn't do much to the block other than set it up on the engine stand since i still didn't get the head gaskets ( should be here in a week ). i also ordered some misc. stuff as well as a new oil pump which should be here in a week or so .

i also got my magna fuel big a$$ pump and fittings , fuel rails, -10 hose and fittings , low oil pressure warning sensor and light , and spool.

so for tomorrow , i'll start assembling the engine - well as much as i can without the oil pump and head gaskets  , then maybe clean the engine compartment in preparation for the arrival of the engine

, then maybe clean the engine compartment in preparation for the arrival of the engine

i'm just wondering if the intake elbow will clear the hood with the super victor intake , last i remembered i had some space left before it touched the hood with the gmmp intake , although i think i might need to trim the plastic cowl thingy .

other than that , i got the flu so i can't think right now

12/17/2008

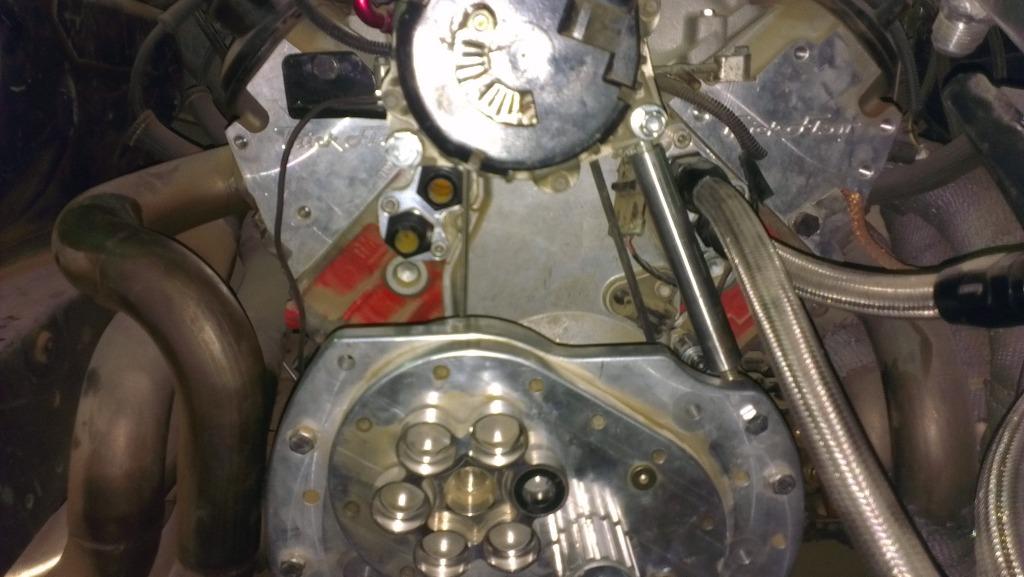

so i got some stuff done already; i finished the bottom side of the motor ( windage tray, pickup tube , pan , pump) as well as installing the cam, lifters & retainers, timing chain and cover, engine mounts ,knock sensors , and water pump . ( can you tell i was excited  )

)

and here is a bling shot of the heads :p

i also shoved the harmonic balancer on there and tightened it down , then i installed the blower bracket to check for alignment ( wich needed a bit of tweaking ).

right now i have to pin the crank ( since the balancer is already pinned ) and fab a blower brace that goes to the side of the block.

i did have a small issue with one of the plugs in the rear of the block , right now its sticking out a bit to the extent of hitting the rear crank seal housing/ cover .

the problem i'm facing right now is that the plug has a square hole in it to tighten it ( like what you have on the side of a diff housing ), but its neither a 1/4 inch nor 3/8 , its something in between . now i'm assuming the plug is pretty tight in there - since i coudn't move it - so i'm planning on taking the cover to a machine shop to take about 2 mm out of the indent facing the plug in the cover so it clears it.

so next up is :

- pin the crank

- fab the brace

- fix the cover

- clean the engine bay

- drop the short block in the car and start bolting stuff like tranny and what not

- start on the fuel system

that should have me pretty occupied till i get the gaskets and bolt the heads on

12/21/2008

got some things done

i pinned the crank , fixed the rear cover , and kinda cleaned the engine compartment ( ddidn't have a shovel big enough  ), i also finished fabbing the blower brace:

), i also finished fabbing the blower brace:

i also figured out where i'll be running the -10 fuel line and how i'm going to route it . also found out that the magnafuel pump is bigger than i thought  so i'll most likely be mounting it up in the area where the rear bumper once was. i'm just trying to figure if i can mount it in a way that it would not interfere with the chute mount i'm planning on getting later on. speaking of -10 hose

so i'll most likely be mounting it up in the area where the rear bumper once was. i'm just trying to figure if i can mount it in a way that it would not interfere with the chute mount i'm planning on getting later on. speaking of -10 hose  i opened the box of 20 ft -10 hose i ordered a while back and somehow it got mislabled and had -8 hose in there)

i opened the box of 20 ft -10 hose i ordered a while back and somehow it got mislabled and had -8 hose in there)

now all i have to do is get the head gaskets and button this puppy up and i'm in bussiness

next on the list :

-get my intake from houston999 who is "testing" it on his camaro

-mount the pump

-route the lines from pump to front of car.

-remove old pumps and some of their lines .

-i "should" start finishing up the wiring inside the car ( ses light , alt light , and low oil pressure light - will do it as a shift light deal thingy)

-if i'm not lazy i might even weld up the travel limiters up front

12/31/2008

small update,

got the intake back and got the 160 lbs/hr injectors on there as well as the rails. i'm holding on plumbing the rails till i get an idea how everything will look after i nstall the alternator ( to see if it clears the inlet to the rails.)

i already routed the fuel line from rear to front, just need to put hose ends on it and fix it in place.

i removed the old pumps and fittings associated with them.

and off course no progress on the wiring  or eht e welding of the limiters

or eht e welding of the limiters

the head gaskets should be here in a few days after that its only a matter of hours and the engine is in the car. they got delayed at ups due to the holidays.

1/20/2009

just my rotten luck ! i got the gasket in and i started to put the motor together, then i find out all the nuts for the smaller head studs are the wrong size !

so i call up texas speed and they get in contact with arp and get everything squared away  , arp will send replacements, but due tot he fact that i'm in a hurry , texas speed sent me nuts from a package they have and will replace them with the ones arp is sending ,,, now thats service !

, arp will send replacements, but due tot he fact that i'm in a hurry , texas speed sent me nuts from a package they have and will replace them with the ones arp is sending ,,, now thats service !

other than that , i routed the impedance converter harness , and the fuel system is all plumbed and finished up , i also mocked a junk engine in there to see how the intake and elbow will fit , and then proceeded to slice away at the cowl  ( i got pics and will upload them soon ), now the edelbrock low profile elbow fits

( i got pics and will upload them soon ), now the edelbrock low profile elbow fits  ( note : low , not ultra low

( note : low , not ultra low  )

)

i really don't know if i would be able to make it to round 3 or not , but i'll be trying ! i also would like to attend qatar's round 1 happening 1 week after bahrain.

next up on the list i guess is finishe up wiring stuff, travel limiter , and hopefully slap the engine in there and get her all buttoned up and broken in

1/26/2009

so the nuts are on the way , and i had a bit of progress

don't think i'll make it to round 3 , but 4 looks like a definate yes

here are some of the pics i promised :

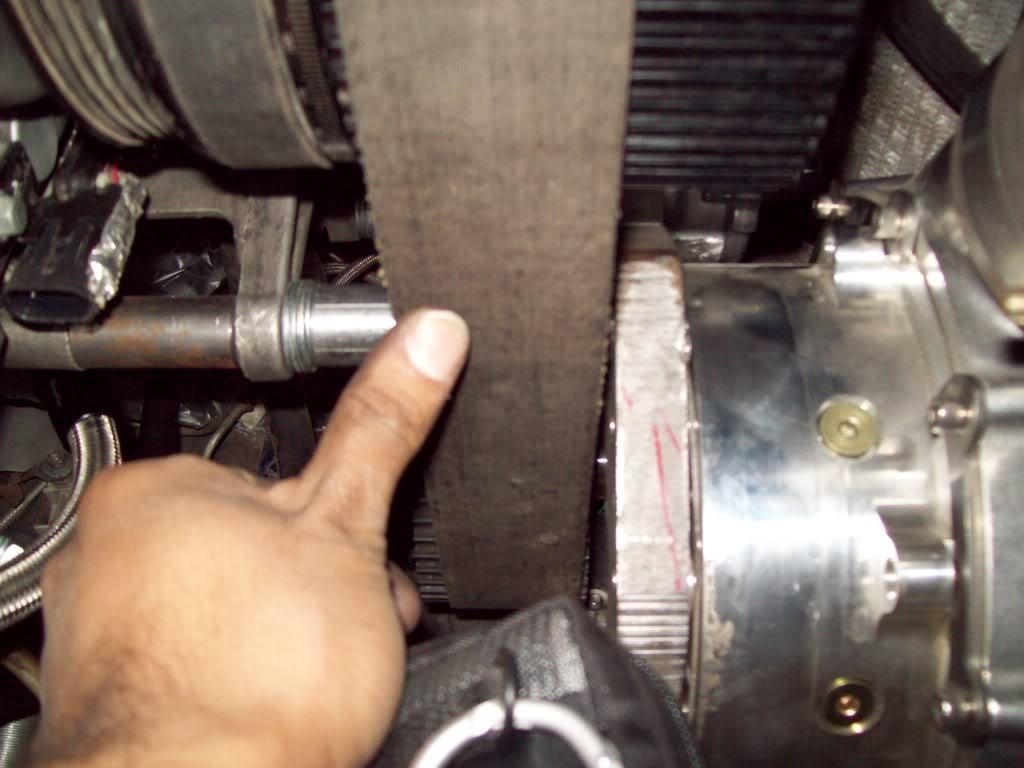

50mm cog belt and tensioner on the car

you can see how much wider i can go  ( i see a 70 mm belt in my future

( i see a 70 mm belt in my future  )

)

edelbrock elbow ( not the ultra low on , but the low one ):

how much it sticks out :

i also have the impedance converter all mounted up and wired, started on the pump wiring and it should be done today , as well as wiring the low oil warning light and the alternator light .

as soon as i get the nuts , i'll bolt the heads on ( and do the whole torque /loosen / retourque deal ), slap the headers on , and plug in all the sensors and hopefully fire her up !

then i have to weld those damn travel limiters ( this was supposed to be one of the first things i did on the car  )

)

hoping to have her fired up some time in the next couple of days

1/31/2009

finally finished the heads  , i retorqued the headstuds a few times. also bolted the valley cover finally , the low oil warning light sensor ,the intake manifold, and finished the driver side rockers.

, i retorqued the headstuds a few times. also bolted the valley cover finally , the low oil warning light sensor ,the intake manifold, and finished the driver side rockers.

i'm debating weather to run the ultra low elbow ( i think it will clear the stock hood with this manifold ) or go with the one you see in the pic

2/1/2009

well a minor setback but i think i goit it fixed  : i installed the alternator , which is relocated to the front of the passenger head , and found out that the fuel feed line doesn't like where the alternator is

: i installed the alternator , which is relocated to the front of the passenger head , and found out that the fuel feed line doesn't like where the alternator is

so to fix this i need a 180 -10 hose end , but untill i get it , i used a 90 deg hose end and a 90 deg fitting on the rail . good enough engineering at its best :p

i also finally buttoned up the rockers, covers, harness and impedance converter. but found out i have to enlarge a hole and tap it for the knock sensors. the old location had an issue with the headers

should have the thing running by Wednesday i hope

i'm also playing around with the idea of ditching the alternator and powersteering pump , and installing an electric water pump to clean up the engine compartment and free up some horsepower . i will need to add another battery in the rear to make this work .

2/8/2009

WOHOO! i fired her up last night ,,,, got 50 psi of oil pressure right away , which is good

had a few issues to tackle though, the car would not start with the injector driver connected , it had spark but no fuel ( could this be cause the battery was weak ). i had to connect the injectors directly to the stock harness and only then would it fire right up ( ran rich for the 3 seconds it did , but it ran  )

)

i'll go back tonight and recheck the grounds for the converter box and finish wiring the low oil pressure light .

then its off to a buddies shop for reprogramming and tuning ( basically pillage azooz's red mustang tune  ) .

) .

i will be getting a new cowl hood , as i really feel bad cutting the vfn one i have now, and a local guy here makes cowl hoods to order relatively cheap.

i was thinking of something like this to clear the elbow and the charge pipe from the intercooler:

what do you guys think ??

well not all is well today  ,,, i took the car to a friends shop for the tuning part, but we couldn't get the car to fire . it would start if we had the injector driver bypassed and the injectors connected directly to the harness, but when i connected the impedance converter box it would not , only an occasional pop from cylinder 5 .

,,, i took the car to a friends shop for the tuning part, but we couldn't get the car to fire . it would start if we had the injector driver bypassed and the injectors connected directly to the harness, but when i connected the impedance converter box it would not , only an occasional pop from cylinder 5 .

i tried re grounding the harness and that didn't help , i tried a new relay and that didn't help either. i also went and used another AEM converter and nothing happened then, so i now have the box being faulty ruled out .

we also went as far as to pull the whole harness out and do a continuity test on all the wires, and they were all ok.

i don't know whats going on here ,,,, why is it not working ??

tomorow we'll get the harness from the red stang and give it a try , at least if that doesn't work we can rule out a bad harness.

2/14/2009

inally figured out what was wrong with the harness ; turnes out i reversed the polarity on the injector pigtails some time ago , which meant no signal to the injector driver .

any how , the car runs great now, i had to fix a leak at one of the tranny coolers , and the travel limiter is on the car now. we also set the pinion angle and weighed the car ,,,, which came as surprise to me cause it weighed in at 3200 lbs without me in it !!! ( still have stuff to replace in the car like chromoly cage and sfc, as well as ditching the p/s and water pump and alt.)

i also found out that the serpentine belt i have is a bit too long causing the tensioner to fully extend .

all that is left now is a few heat cycles, then change the oil , then maybe hit the dyno !

2/15/2009

anyhow, i did an oil and filter change for the car today and and let her idle again ( trying to get in a few heat cycles in the motor before beating on it.

well found out that we didn't fix the trans cooler leak  , so the one on there is going off and a new one put in tomorow. another curious thing i noticed is that the headers started glowing red after 5 minutes of idle.... initially timing was set to 10 deg. , so we changed it to 30 and the problem still remained ( afr was at a steady 14.7:1 to 15:1) . so we tried changing the timing in other tables ( the car idles at 1100 rpm and has almost zero vaccume at idle ) and that seemed to help it a bit , we couldn't let it idle longer cause the puddle of trans fluid was getting to be a lake

, so the one on there is going off and a new one put in tomorow. another curious thing i noticed is that the headers started glowing red after 5 minutes of idle.... initially timing was set to 10 deg. , so we changed it to 30 and the problem still remained ( afr was at a steady 14.7:1 to 15:1) . so we tried changing the timing in other tables ( the car idles at 1100 rpm and has almost zero vaccume at idle ) and that seemed to help it a bit , we couldn't let it idle longer cause the puddle of trans fluid was getting to be a lake

what is a good number for idle timing do you think i should shoot for ? and do you think this is timing related?

another strange thing is that the car keeps seeing knock at idle ( regardless of the timing we had in it) , some where in the 2 to 4 deg. range.

it i most likely false knock , but is there a way to desensetize the knock sensors at idle or low rpm's and have them operate normaly at higher rpms?

so tomorow i'll slap in a new cooler, put on the intake tube , and if all goes well with the header glow take her out for a spin around the block

2/18/2009

Fixed the header glow issue  , turns out i had a faulty tps sensor and needed a crank relearn.

, turns out i had a faulty tps sensor and needed a crank relearn.

fixed the cooler too , and should have it off the lift and messing with the tune today.

all that is left i guess is making sure the alt. is charging, new serpentine belt and getting the new cowl hood

2/24/2009

well i just got my day old cowl hood from the paint shop and decided to see hoy it looks on the car , well it look goooood  , so i decide to take the car out for a spin to make sure everything is working good,,,,,,, and the hood flew off !!!

, so i decide to take the car out for a spin to make sure everything is working good,,,,,,, and the hood flew off !!!

in mu rush i forgot to put the pins on  but luckly the damage was minimal , the driver side rear corner has about 2 inches of it cracked , and one of the pin holes is damaged, but other than that , its all fixable

but luckly the damage was minimal , the driver side rear corner has about 2 inches of it cracked , and one of the pin holes is damaged, but other than that , its all fixable

on a positive note , the car pulls good ( even though i did it from a 10 mph roll in third )

3/15/2009

here are some update pics

my sexy cowl hood

i ditched the stock tank in favor of a 5 gal. cell in its place , frees up some space down there since i will be relocating the trans cooler to the rear and also remounting the fuel pump so it hangs vertically

i'm also scaling the car and setting corner weights soon , as well as finally strapping it on the dyno and making a few pulls .

i also just ordered a set of lower rear control arms and a new converter , since the old one won't work propperly with the new combo . those should be here within a week .

3/25/2009

got bad news ,,,,,

it snapped the belt twice now on the dyno on the first pull around 6k rpm

could not get a single full pass.

it seems that there is still flex in the bracket causing the belt to rip and break.

i also swapped the tensioner to a solid one and i still broke the belt ( second belt).

i'm bummed out right now , and seriously thinking of contacting one of the vendors here to purchase one of his brackets/crank support deals

3/31/2009

quick update :

i decided to remove everything and start over again ; i took the whole front end off the car in an attempt to rebuild it better.

upon tear down i found proof that the bracket was flexing : the all thread used to hold the alternator bracket to the block and the blower bracket was all bent ( both rods) .

i also made a new alternator bracket that mounts the alternator on the pass. side :

i also relocated the transmission coolers to the rear by the fuel cell to free up the front end. and i also removed the power steering pump and water pump ( planning on using a race electric pump). and i finally installed my rear adjustable lower control arms

as for now i have the following planned :

- electric race water pump

- build a different brace for the blower bracket ( kinda like EPP's unit ) cause i'm running out of time and will be ordering a different blower mounting setup)

- remount the intercooler ( read "properly" mount the intercooler  )

)

- cut top core support and weld ends

- install new smaller radiator which frees up front of blower for breathing

- might cut lower core support and fab tubelar one in its place depending on the radiator i find

- later down the road order a remote mount water pump and install it in preperation for the new bracket.

i guess thats it for now

will post progress pics tomorow i hope

4/4/2009

its so slow it only needs this radiator to make it run  :

:

i'm thinking of running it later on down the road , should free up some space and weight

i also cut the upper core support and now i can stand up the radiator  and the blower bracket mount braces are done , just need to finalize where the tabs will go and weld them on , then maybe weld the bar that will hold the radiator in place .

and the blower bracket mount braces are done , just need to finalize where the tabs will go and weld them on , then maybe weld the bar that will hold the radiator in place .

and the race water pump should be here today and i should have it on the car by tomorow , then its time to wire the trans cooler fan and the water pump.

the shorter hub is already on the car now and i should have the pics of how close it pulls the balancer to the cover by tomorow .

so i guess it time for reassembly soon ,,,, i should have the brackets done by today then its :

- mount the blower and brackets and check alignment

- place the radiator in place and finalize mounting

- mount the intercooler

then it should be ready i hope

4/11/2009

more updates :

finished up the supercharger bracket brace  and it looks cool i might add

and it looks cool i might add  ( still need to get some jam nuts)

( still need to get some jam nuts)

i also got the electric water pump installed as well as the rear control arms .

here you can see the remounted alternator and how it lines up with the new hub and balancer combo i used:

and here is a pic of where i installed the trans cooler in the rear of the car where the stock tank used to reside  : ( need to get a smaller diameter fan )

: ( need to get a smaller diameter fan )

and ever wondered how much an F2 would hang on an fbody bracket? here's your answer

is just a bit higher than the oil pan line ! ,,,, guess i got to give madman a call and get some save your ass ( and blower ) bars:

i also got the neil chance converter in there, and i got a new spring for the bov ( softer ) and a bunch of radiator hoses to cut and splice my way from the pump to the radiator

so i should be ready to boogey tomorow i hope .

wish me luck!

4/27/2009

well we put the thing on the dyno ( finally  ) and made two pulls before the belt lost its teeth

) and made two pulls before the belt lost its teeth

first time the car only made 10 psi , and remained flat at 10 psi from 3500 to 6500 rpm. after scratching our heads we found out that i forgot to remove the little cone filter i had on the blower and that the spring we put in the BOV might be too soft.

another thing we noticed is the idler would get pushed up after the run.

on the second run the belt shred its teeth  which tells me the braces are working fine sice the belt did not rip . i'm thinking the idler moved up too much ( it actually did ) and caused to much slack on the belt . the cure for that would be to use the "jack " bolt to lock the tensioner in place (think of the original ATI setup ) that way when the the belt tries to "expand" it can't push the tensioner alog the slot.

which tells me the braces are working fine sice the belt did not rip . i'm thinking the idler moved up too much ( it actually did ) and caused to much slack on the belt . the cure for that would be to use the "jack " bolt to lock the tensioner in place (think of the original ATI setup ) that way when the the belt tries to "expand" it can't push the tensioner alog the slot.

other than that it made 730 @ 10 psi on a mustang dyno

5/18/2009

finally got around to fix and dyno the car

i put a holdown or jack screw ( or bolt ) on the tensioner to help keep it in place, and it seems to have done its job

did two dyno runs but the dyno was not reading rpm so we just did pulls under load to see if every thing is kosher ; and boy did it perform

we soon foundout another problem  , the boost guage only went up to 20 psi

, the boost guage only went up to 20 psi

hp uners log showed about 27 psi at around 6500 rpm

so , now i have to fix a few odds and ends, like fixing the carpet and making a new tensioner idler with better walls ( slanted ) to help prevent the belt from fraying.

i also have to put the front of the car back together so it looks like a car again  , and try to get some more dyno pulls in with Q16 before our race in two weeks .

, and try to get some more dyno pulls in with Q16 before our race in two weeks .

6/1/2009

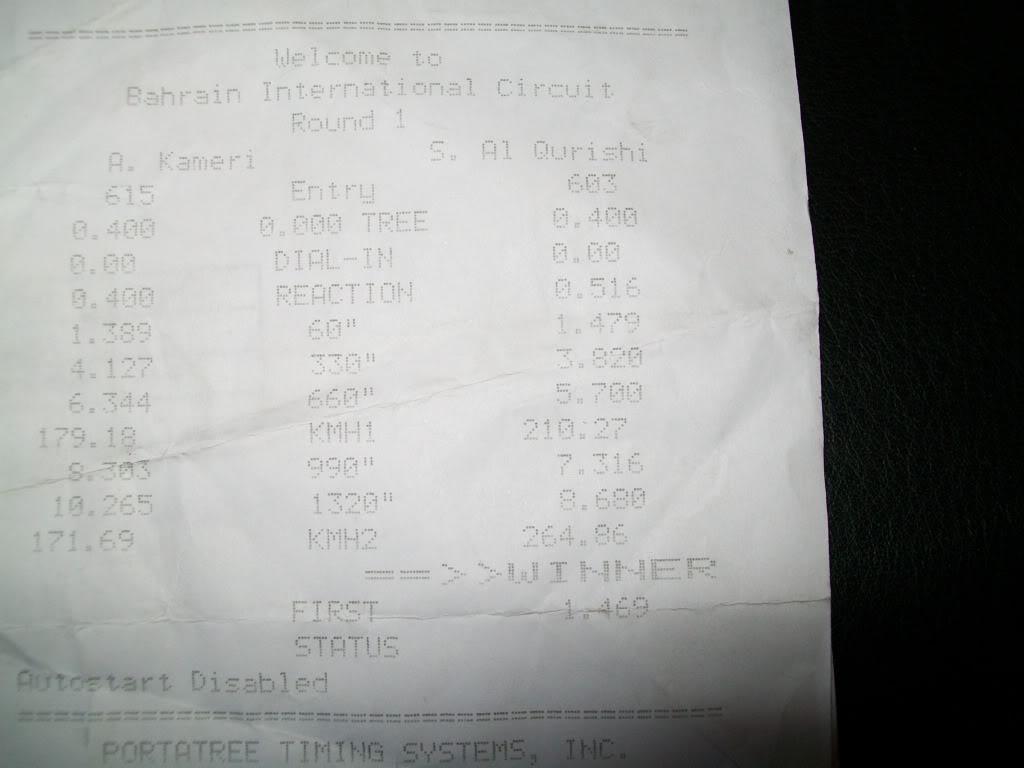

we had a race coming up last weekend ( weekends over here are thursday and friday), the car was ready to be put on the trailer tuesday morning so we can be at tech inspection on tuesday evening , but wouldn't you know it , the devil (known as azooooz on this board ) talked me into swapping his regular rotation F2, gear drive and dual 16v batteries to my car from his mustang that was not ready for this round.

so the mad rush tuesday evening started and by wed. morning the car was done !

i couldn't beleive it either , the gear drive fits with the radiator i had ( bee cool ) which was only moved forward a bit .

( the shitty part is that i got a ton of pics but it seems my camera got stolen at the track  )

)

anyhow , we head to the track and make a few passes ( not one of them was a clean pass ) , i had no idea what it would do cause i never tried out the new converter or blower , tires were old, suspension setup was a bit different and the track was so so

i never managed to stall it up on the foot brake , but flashing it netted something like 5500 rpm  - but soon lost traction around the 60 ft mark. we were having issues with data logging so no data in the begining , but the inboard camera showed 27 psi on the guage

- but soon lost traction around the 60 ft mark. we were having issues with data logging so no data in the begining , but the inboard camera showed 27 psi on the guage

one of the passes i turned on the meth injection and the car bogged bad under wot, so i decided to ditch that idea  , and finally on the last pass on friday the car launched ok , pulled HARD in 1st ,,,,, and then fell on its face after shifting into second ...... intercooler hose blew off

, and finally on the last pass on friday the car launched ok , pulled HARD in 1st ,,,,, and then fell on its face after shifting into second ...... intercooler hose blew off  ,,,, but i got third place over all

,,,, but i got third place over all

here are some pics i snapped with my phone (excuse the crappy quality ):

any how , the gear drive and other stuff will be returned back to the owner

and i'll be waiting for my new bracket to show up

i also have to add this :

GEAR DRIVES ROCK!!!!!

10/14/2009

well since i really liked how well the whole gear drive setup worked, i bit the bullet and ordered one.

i managed to find a straight trade for my reverse rotation F2 with a regular rotation F2 , so it just made sense to go that route

gear drive should be shipping anytime now.

as for the car , didn't do much the last 7 months  but i did manage to take apart the tranny , only to find that i burned 3rd gear ( trans oil pressure issue ).

but i did manage to take apart the tranny , only to find that i burned 3rd gear ( trans oil pressure issue ).

and i just finished wacking the lower core support :

only to replace it with this sexy peice of fabricated awsomeness

all i have to do now is weld a couple of tabs on to it so i can mount the stock radiator or a smaller on if i decide to go that route.

up on the list is draining the gas tank ( i know i should of done it ages ago), installt he gear drive , fab up some sort of alternator bracket , weld bigger beads on the ends of my tubing, and weld the two new ATI Race BOV's

10/22/2009

well i was wrong,,,, the gear drive showed up wednesday!

i'm going to get my but into gear and work on installing this thing today as well as other assorted odds and ends

and now on to the pics :

10/31/2009

more progress

i got the assembly all mounted up

and now i'm toying around with how to mount the alternator , i'd like to run it off the balancer of possible , but that would man running it low in the passenger side and real close to the frame.

an alternative is to run it off the output of the gear drive , but i'm worried it might not get enough rpms ( since i'm limited to 18 teeth max on the output side; wich means i have to run something much smaller than that on the alt. ) ,

any how , here are more pics

i just ordered a new radiator ( much smaller than stock) that i'll be running to the side of the gear drive, should be here soon .

i also finished up the charge pipe from the blower to the intercooler. all that is left is welding the BOV's on the inlet tube to the blower ( i have one , still waiting for the second one ) and i should be done with the piping.

11/5/2009

guess what the UPS santa dropped off

this was supposed to go on the camaro back before i got the gear drive , sooooo, this will find it's way to the mustang after i finish the block adapter and crank support

think its beefy enough

11/15/2009

radiator finally showed up yesterday, and i've been working hard trying to get the car done . it has to be on the trailer and ready to go by tuesday night

decided to postpone the alternator deal for now and just run dual batteries in the rear and charge them between rounds.

i also finished the charge pipe with the dual BOVs :

here is the radiator ( with foot as refrence  )

)

and here is where i've been trying to mount it :

given the time crunch i might just not use that radiator now , and just go back to the old one for this race and take my time fabbing a mount for this one later .

i also got the MSD 2step in , but i doubt i'll be running it now since i want to install it cleanly

i learend some thing though , i should always have some sort of tubing and metal instock for "emergency" fabrication

11/25/2009

well i manged to get the damn thing in there , and it worked out pretty good . i have to redo the hoses , i'm just waiting for some fittings to arrive and i might be able to route the hose from the other side of the pump instrad of it looping like that.

i did manage to take it to an 1/8 mile track , and i'm glad to say that all my last minute stuff held up

well,,, except for this stuff, which wasn't last minute cause i had it in the car for about a year now:

think its fixable ??

everyone told me that these lower gears are junk and it was a matter of time before i destroy them ,,,,, well their time was up !

other than that , i'm happy with how the car did ,,, i managed to get a personal best 60 foot time of 1.32 with my 2.5 year old slicks!

and the msd 2 step worked great too ( install was too easy ! ).

so next on the list :

-fix tranny untill i can get a new built trans from the states

-install spool and 3.08 gears

-redo cooling lines and radiator bracket

-change the gear drive ratio from 1.3 ( 17-18 psi) to 1.6

-if i have time take it to a local fab shop to have a new chromolly cage put in.

-probably send the converter in to get restalled , i need it to stall about 1000 rpm lower (and to tighten it up on the big end)

-get a vacuume pump on the thing!

12/27/2009

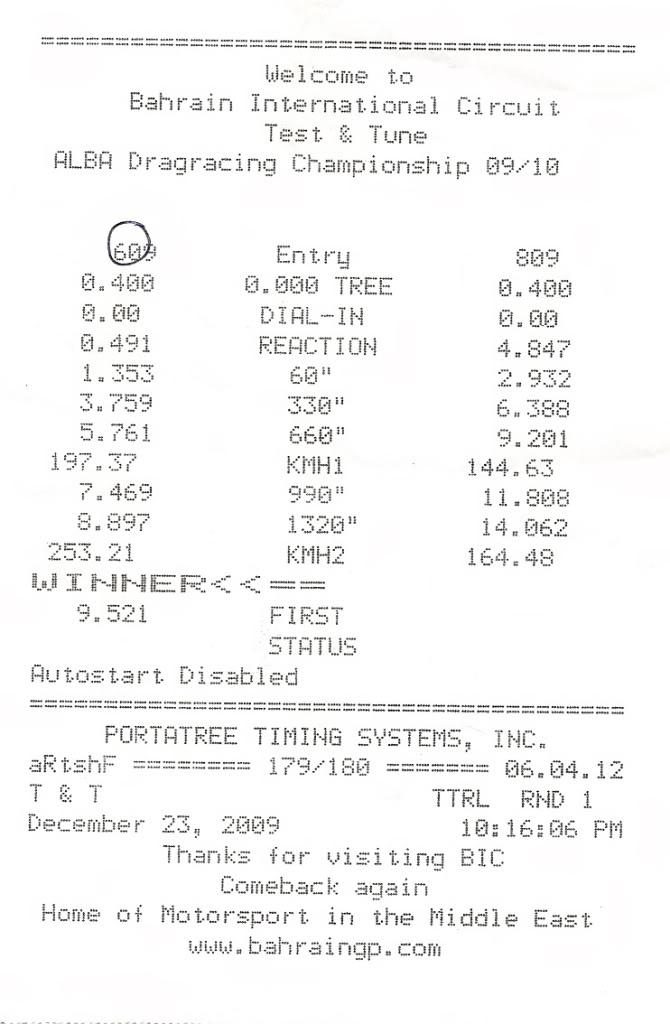

well i finally got into the 8's!!!!

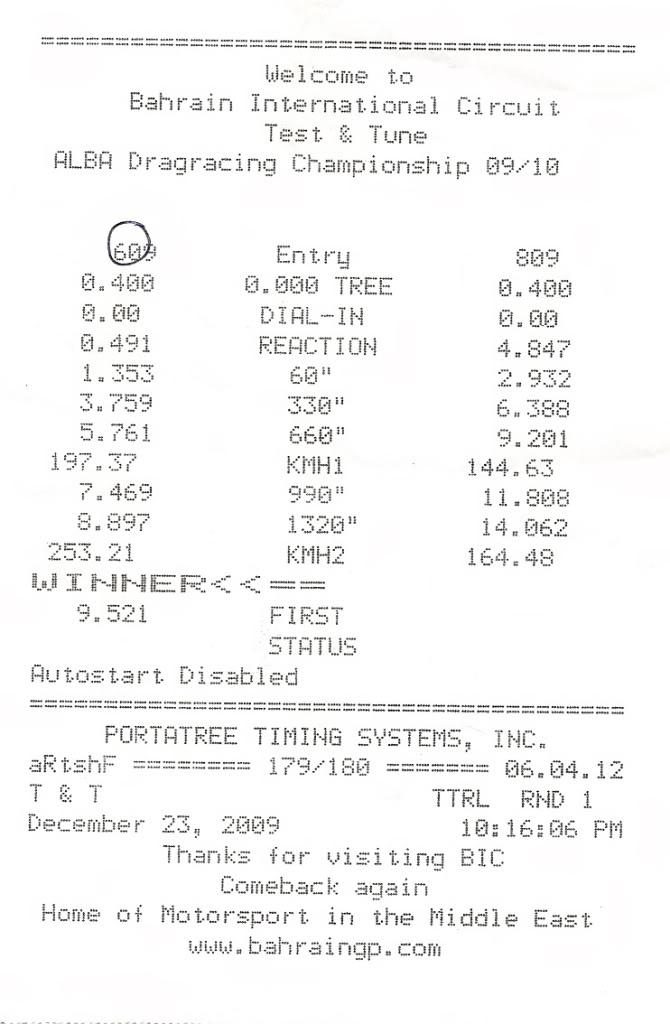

took it to the track this weekend and got this

funny thing is that i got a 1.35 with a bunch of wheelspin and pedaling ?!!?

oh well , its good and bad news for me ; good news is i'm sure i can squeeze a better 60' with new slicks ( ones on there are 3.5 years old!), and drop the time with higher boost and a more aggresive tune.

bad news is on the fifth pass the car just shut off mid pass,,,, found out today that of all things the back half of the reluctor wheel seperated from the front half and was spining on the crank!

you can see how the two holes don't line up anymore ( sorry for the crappy phone pic):

from what i can see now it seems that the two sides of the reluctor wheel are riveted or sort of stamped together and that is what failed .

guess the its time for a bearing inspection

it still has alot left in it ;

tires are real old and worn , it spun on that launch , it was on low boost ( 17 to 19 psi ) , and the tune was just a base conservative tune.

1/1/2010

sorry, fixed the reluctor wheel pic .

here's more:

so , repairs are in order; ordered a new reluctor wheel and the tool to install it . should be here in couple of days

3/1/2010

man its been a whils since i updated this !

long story short :

changed the geardirve ratio to 1.6 , got 31 psi  , ran a 8.8@ 169 mph! ( took it real easy launching it - 1.6x 60' and short shifted second ) but it ran a bit lean and hurt the gasket.

, ran a 8.8@ 169 mph! ( took it real easy launching it - 1.6x 60' and short shifted second ) but it ran a bit lean and hurt the gasket.

took the motor appart , freshening things up now . should be done soon .

the parachute and mount came in , mount got powder coated and is on the car , got to install the chute and cable soon :

the chromolly cage and SFC showed up too , so it was time to gut the car ( again) and start chopping and welding :

hoping to have it done within the next two weeks , since we have a big race coming up in Abu-Dabi on the 18th . i'm hoping for mid to low 8's ( shouldn't be a problem with a decent launch and propper shifting  )

)

i might even try the transbrake there .

the never ending to-do for this time are :

- weld up SFC and cage

- install chute and window net

- wire two step to the brake pedal and install switch

- wire in a seperate button for the transbrake ( don't want it on the shifter - kinda hard wired my brain that the shifter button is the N2O button  ) will make it a button on a the end of a coiled wire .

) will make it a button on a the end of a coiled wire .

- screw the tires to the wheels

- figure out a way to run an alternator or find a 16V battery somewhere.

4/12/2010

nothing much to report , we never ended up going to abudabi ,,,,, long story

the cage and through floor sfc's are done, so is the chute and window net. i still need to screw the tires tot he rims and wire the two-step and the t-brake .

i found a 16V batt and now i have it running the pump by itself and the 12v. one running everything else (never went though with the alt. project  )

)

i am trying to make it to the next race , but we'll see how that goes.

i did get in a few parts for the car , but since we just have a race on the 15th and one more 3 weeks later and the the season ends , i deciced to start that round of repairs and improvements then .

this includes engine freshen up , kirky seat , new radiator bracket , alternator (?) , new engine wiring harness, redo interior harness ( clean it up a bit ), and a few odds and ends here and there.

10/12/2010

man it been ages since i updated ,,,

lets see ,,, well i tore the engine appart again to replace the rods , kinda felt it was time to get better ones so i got a set of brand spank'n new howard's rods:

i also wasn't very happy with the engine wiring harness: it was the original one with all the unneeded wires taken out , plus it was integrated with the body harness. i also had an issue with it where the crank signall was intermittent due to a bad connector. so i decided to order a harness from ls1wiring.com where it would be a stand alone harness that can be swapped out without ripping appart the entire car's harness:

so since i was starting from scratch i decided to rip the interior and wiring all out :

and how the new harness looks like on the car :

the plan was to redo the interior harness to minimize any chance of mishaps , i also needed a new relay and fuse board . so after being inspired by SMKN TA 95's panels i decided to build my own ,,,, and let me tell you after starting this project that no matter what he's selling his boards for its a steal !!! man building them is pretty involved!

the plan is to have a complete underdash harness that ties in the instrument cluster, rpm guage and lights , center cluster , outer sensors and devices , and the control panel.

right now i finished the under dash harness, as well as most of the panel , i have to start building a bracing system for the panel so i can mount it in the passenger side footwell , then build another brace thingy to use as a laptop mount ( more on that later  ), here is how the panel base looks like ( still needs to be powdercoated):

), here is how the panel base looks like ( still needs to be powdercoated):

and this is how the panel itself is coming along , its made from a sheet of lexan and i'm planning to cover it with some carbon fiber sticker sheet  that way you know i'm serious

that way you know i'm serious

and how it looks under the dash next to the relocated PCM :

and here is the underdash harness :

so i started a list of other odds and ends to to finish on the car , of which is finally drilling some rim screws in the the wheels:

and i got a new kirky lightweight seat and some brackets from racecraft :

the brackets will enable me to mount the seat on the stock mounting studs:

another thing i wanted to do is clean up the front end. i didn't like how the radiator was posotioned and how the hoses went all over the place. so to fix that i decided to chop off the funky green brace i had before and redo stuff

first off was to build a radiator cradle or bracket , so out came the bent metal tubes and the welder and i slapped a few peices together and got this

and how it looks with the radiator in place:

and to help with the water pump hose routing issue i made a set of water pump spacers that spaced out the pump about 3/4"si i can use the port on the driver side of the pump and not have the hose hit the cam sensor :

so that sums it uo pretty much

i still have to run the positive power cable from the battery to the panel , and build me an ignition panel (starter button and ignition switch) and run the ground cables. i also have to mount the charging posts in the back and connect the power windows .

another thing i have to finish is welding some panels to cover the holes left behind after cutting the upper core support. and maybe figure out how to incorporate a cross brace somehow.

i also plan on redoing the cables running from the batt to the starter to the alternator ( or where it used to be) and grounds, right now its a frankenstined mix of stock and other stuff  so that needs to be taken care of .

so that needs to be taken care of .

also on the list is redoing the nose support for the front end. i was thinking of getting rid of the plastic/fiberglass peice up front and building a tubelar one that bolts to roughly the same location and also to the front of the frame rails ( where the crash bumper bolts up) this will also serve as a mount for the intercooler and from that i can weld some braces/outriggers to brace the bottom and sides of the bumper.

i'm also thinking of running a mechanical belt driven pump up front but the jury's still out ( till i do some research on the subject  )

)

also on the list (i have to order it first ) is a lightweight steering coloumn and wheel , should drop about 15 lbs off the car

so to sum it up :

- postitve wire to panel

- ground stuff

- install dash

- connect wires

- mount radiator and hoses

- weld core support plates

- starter cable and ground

- charging posts

- bolt up seat and brackets and rear seat support

10/18/2010

got some more done ,,,, and did i mention how much i hate electrical work !

but at least i'm almost done,, i managed to finish the fuse panel , i had it covered in carbon fiber adhesive wrap to give it that " i'm cool cause i use carbon fiber stickers" look  :

:

and how it looks in the car:

also had the instrument cluster guages all wired up a while ago as well as the center dash panel . the center panel now has trans temp guage , boost, and AFR guages, as well as a methanol pump light , trans brake plug port ( stereo jack used to plug in the trans brake switch if i'm running it ) and switches for the methanol injection, trans cooler fan , and 2 step activation.

all i have to do now is connect a few wires here and there and electrical stuff inside the car should be done. which leaves me with connecting the trans temp guage and t-brake wires to inish , as well as running the main + cable to the starter and running the signal wire. also have to install the front radiator brace (took it off to take it to poweder coating but realized later i didn't have time to get it done)

so up next :

- ground stuff

- install dash

- connect wires

- mount radiator and hoses

- starter cable and signal

- install header on driver side

- bolt up seat and brackets and rear seat support

- connect a battery and see if it works

11/6/2010

ok time for some updates :

been working alot on this thing lately, trying to make the race this wednesday .

i finally got most of the wiring done in the car. i just had a small issue with ignition switch but it should not be an issue. also got the dash in place and bolted up , i just need to bolt up the center console now. ( no comments on how clean the car is  )

)

its amazing how much wiring can come out of a car that has been already worked on

also got the kirkey seat bolted in and bolted in to the stock location using racecraft brackets, all i have to do to finish it is install ( and slightly modify) the seat back brace , but i probably will do that when i come back:

furthermore , i got the radiator bracket back from powder coating and i bolted it up along with the hoses, radiator and fan:

and in preperation for the new bumper brace bracket that i will be making later , i installed the frame horn plates ( these plates will be the base that the nose of the car will be bolted to ) and welded some nuts and a spacer so i can bolt the intercooler on to :

and finally got all the intercooler piping and header installed as well as the coils and what not.

so all that is left is bolt up the nose , drop in the batteries, oil change and coolant, check the shifter and fire it up to make sure all is fine and dandy

later down the road there will be some major weight reduction thats going to take place but more on that later  evil:

evil:

11/14/2010

well its been an interesting weekend

got the car all done and ready , put it on the trailer and headed east

i managed to get a couple of test and tune runs on wednesday after tech inspection ( the race was thursday and friday) and quickly noticed there was a problem :

the car would not hook ! it would jump off the line and unload around the 60ft. mark .

it almost seemed to not want to weight transfer at all!

so i started to mess around with the suspension setup ( it was setup exactly like last time out and it worked pretty well then); i loosened the rear shocks as well as the travel limiter, wich seemed to help a bit. i don't need mention that on the second run the two step i installed kinda worked , the switch got stuck open and i had to stop using it ( i had it connected to the brake light switch - which was cracked  ) and mid run the car just shut off ,,,,,,,, forgot to tighten the + battery terminal

) and mid run the car just shut off ,,,,,,,, forgot to tighten the + battery terminal

well , come qualifying day and after two test runs the last day i decided to drop tire pressure down to 9 psi from 10 to see it it helps, the first run it hooked better ( looking at the log i only gave it 30% throttle in 1st and around 50% in second ! ) but it just broke traction mid second gear wich netted me with a horrible 10 second pass IIRC , which by the way does not get me in the field . i have to add that the weather was humid and there was condensation everywhere , so that could have been a factor.

so in the second ( last ) qualifying attempt i decided to pull some power off the line by cutting some timing and giving it more suspension travel up front ( about 1.5 to 2 " i think). the car still spun in first and second and got a 1.47 60foot ( even thogh it was half throttle through first gaer and second) but i got a 8.8x@161 mph pass !

off to eliminations , first run i decided to pull more timing and remove the travel limiter all together ; it launched ok-ish (1.4x 60 ft) then unloaded and only spun in first gear , second was full throttle ,,,, wich netted a personal best of 8.6@164mph !!

i was seeing somewhere around 26 psi and the AFR was a RICH 10.2 !

i don't know if it's the hoosier slicks i got on there right now or something else that's causing my traction issues ( slicks have less than 10 passes on them but are about a year old), i always used M/T's and like how they hook , i just went with TNTaddict's advise and tried the hoosiers to see if the work .

in any case , there are some chages on the way along with some major weight loss in the process , i'm thinking 8.0's are really close in my future

11/15/2010

Here are some pics i got off another fourm (thanks again shaker  :

:

you can see how the car twists to one side , even though it has a beefy antiroll bar, i'll have to look into that too

11/27/2010

uggggh, totally forgot about the season opener race in qatar this weekend

sure its only an 1/8 mile track but i really can use the track time to dial in the car .

so in my infinate wisdom i decided to remove the whole rear end and torque arm off the car in anticipation for some goodies  , so now i have to put those back on , as well as the transbrake solinoid and blower and blower drive. then i have to scale and adjust the swaybar and pinion angle . i also have to fab up some sort of panel under the engine to act like a containment system to prevent oil leaking on the track in case of a "catastrophic engine failure" , and if i have time fix the 2 step switch

, so now i have to put those back on , as well as the transbrake solinoid and blower and blower drive. then i have to scale and adjust the swaybar and pinion angle . i also have to fab up some sort of panel under the engine to act like a containment system to prevent oil leaking on the track in case of a "catastrophic engine failure" , and if i have time fix the 2 step switch

forgot to mention that i had to take all the stuff infront of the engine off ( blower , drive, balancer and waterpump) so i can get to and replace the front main seal wich decided to leak .

i wonder what it would do launching off the trans brake at 4k rpm

12/5/2010

time for a quick update ,

didn't make it to the first round in qatar last week , but i think i'm ready for the second round this weekend ( thursday and friday ) . they have their races on a pretty tight schedule ; they have a race every weekend for three weekends then they pause for a weekend and contiue with one more race the weekend after xmas . then the venue changes to the Abudabi track at Yas marina where they will have the same deal where they race every weekend for four weeks !

any how , on to the pics

so i did get the rear end back in as well as the blower drive, blower, and transbrake . and i finally wired the VSS (speed sensor ) so i can log it

also managed to set pinion angle (wich was set at +1 for some reason ! )and adjusted the sway bar .

another thing i had to do was get the engine tray fabbed up and mounted , and here is how it came out :

it tucks in nicely and sits higher than the headers , so it shouldn't scrape that bad

and since i'm uploading and posting pics , here is the 8.6 from the last race in bahrain :

the speed is in KPH which comes out to 164.04 MPH

this is with spinnig all through 1st

12/20/2010

time for an update :

went to Qatar for the second round , trying out the transbrake and the 2 step as well as working on the suspension . i also hooked up the VSS sensor so i can log speed

did a few test and tune runs before qualifying and in the first one launching off the footbrake the car got a 1.38 60' (not really pushing it ) which is good because that meant the traction issue i got was solved .

the next runs ( including the qualifying runs got progressively worse , i didn't know it at the time , but the plug wires i had ( 4 year old MSD) were shot , it got so bad that the car would not stall high enough to engage the 5000rpm 2step and would just bog as soon as the brake was released and the car would not pull properly ( almost felt like it had a missfire)

anyhow , after i came back i decided to take a look at it and two of the wires simply came off without any effort at all, which means i was racing on 6 cylinders  and would explain the overly rich readings i was getting .

and would explain the overly rich readings i was getting .

on a positive note , the geardrive was working great ! i maxed out the 3bar sensor i had pushing 30 psi, but the missfires took their toll on the bushings :

also started to work on the tubelar front end to hold the face and headlight covers on, it will be a one peice design. some pics of the progress i made :

still need some trimming and a few tabs welded on to hold everything in place.

then its off to the powder coaters to have it and some other peices done.

also got the AFCO shocks in today , i ordered a set of fronts and rears as well as adjustable spring perches for the rears. and will dig in to those pretty soon .

also got some remote water pump fittings coming in soon , i already have the remote pump (had it for over a year and a half) and was thinking of installing it to clean up the front of the engine some more.

the pump will mount right next to the radiator and will have two lines connecting it to the block . i'll snap some pics as soon as i get the stuff in .

i've also been toying around with the idea of a belt driven fuel pump , its dependable , greater capacity for feul delivery, and lighter ( i loose the 16V if i go belt driven). i'm still in the "thinking about it " phase.

so next on the to do list is :

- finish front end brace

- install shocks and springs

- new gear drive bushings

- remote water pump and weld mount

- figure out how to get an alternator on there ( so i can run a smaller battery in the rear )

12/27/2010

Got more stuff done :

i'm almost done with the face brace

just need to drill a few more holes in the tabs and have it powdercoated

and i just got the new geardrive bushings from the supercharger store, these are the new improved ones ( black) and should hold up to the abuse. a lspped them on and installed the blower/geardrive assembly.

also started working on the remote water pump , i decided to go that route to free some space for the alternator as well as better looks

the water pump will be placed just next to the radiator outlet and connected via a 3 inch hose like so :

to do so i had to weld a pad for the pump to sit on , so out came the tig welder and :

and here is how the block adapters look like with -12 hose ends sticking out of them:

all i have to do now is make the -12 hoses and send the brace off to be powdercoated .

i also got a nice xmas gift for myself

a set of front and rear AFCO double adjustable coilovers and adjustable spring perch :

those will go on next

1/14/2010

some updates i guess ,

i still didn't put on the suspension parts , but i did talk to kurt urban regarding the exhaust i have on the car and we came to the conclusion ( well he did , i just basked in his glory  ) that the current 1 7/8 headers i have now are choking the car and i need headers with primaries with at least 2-1/4" or ideally 2-3/8" primaries with a 4.5" merge collector (necking down to 4") .

) that the current 1 7/8 headers i have now are choking the car and i need headers with primaries with at least 2-1/4" or ideally 2-3/8" primaries with a 4.5" merge collector (necking down to 4") .