You must be logged in to rate content!

7 minute(s) of a 341 minute read

6-20-2008

here is what i did to get the cog drive to work :

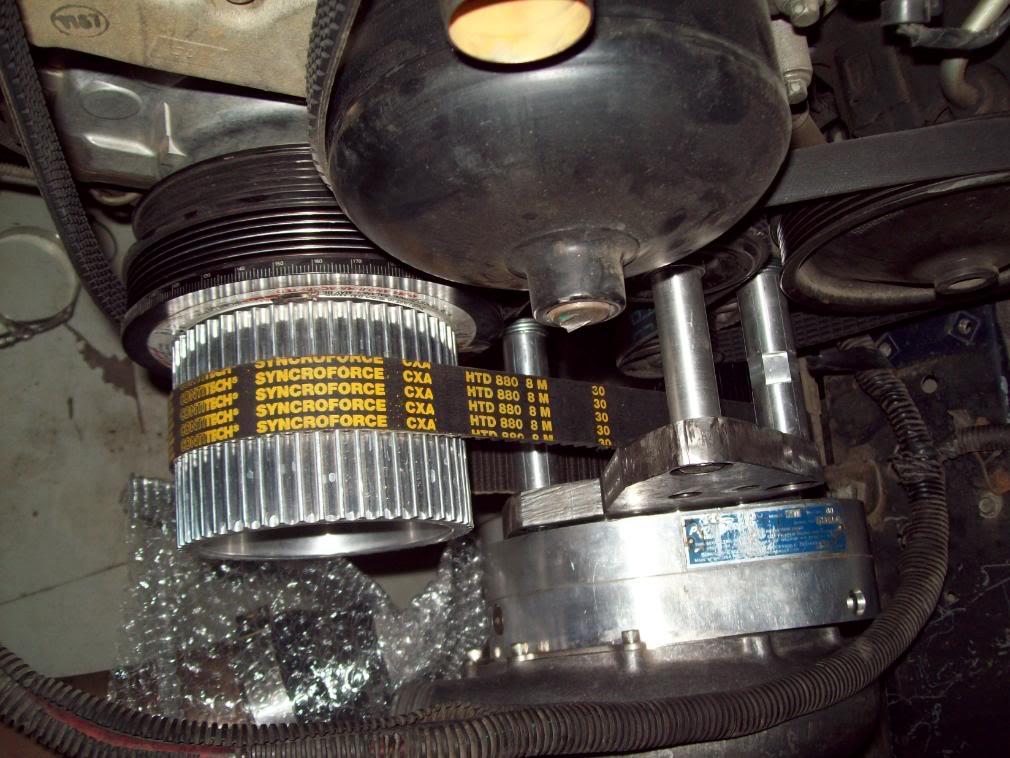

you start off with a stock ati bracket and notch it to clear the tensioner ( that i fabbed up at a local machine shop - along with the idler pulley and longer stan-offs):

i got a BDS crank cog locally and had the local machineshop redrill it to the ATI balance holes.i used a 55 tooth one here casue i was using a 36 blower cog and didn't want to risk over boosting it on the F1-R - you can also see the standoffs here ( bracket was not mounted properly in this pic)

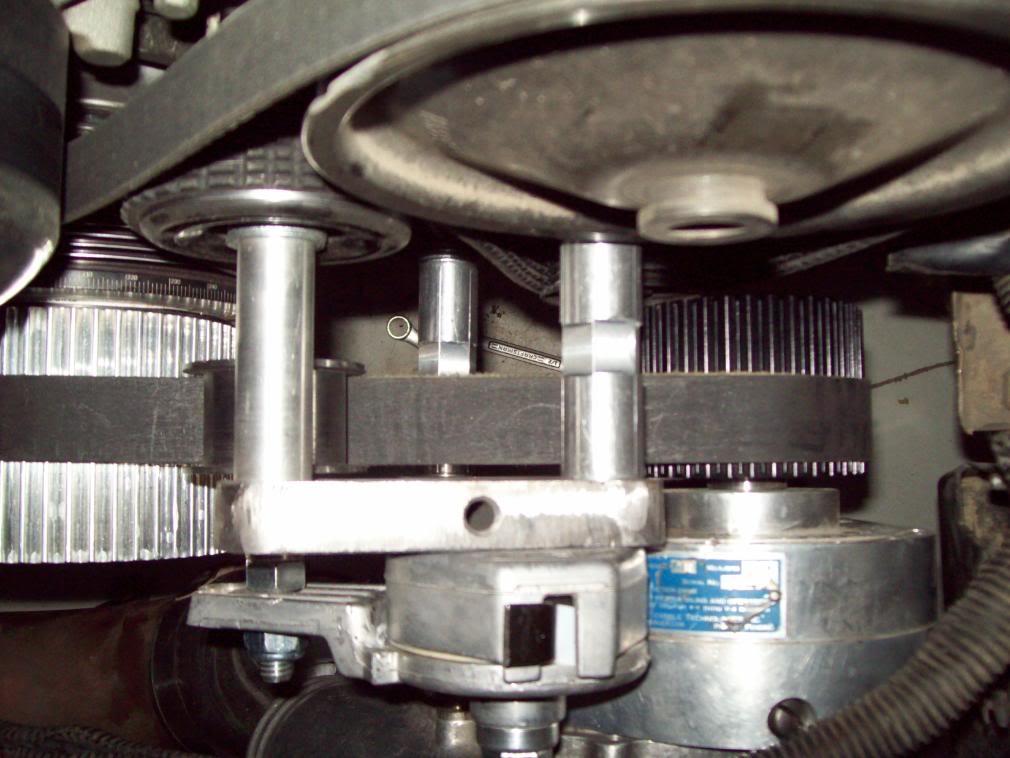

here's a pic of the standoffs :

and here is the finished poduct

and when you are building a cog drive for 2 cars and a serpentine for a third , all while experimenting , you end up with all these

off couse all this is coming off as soon as i get the ATI super pulley , thats when the F2 goes on , the bigger crank cog goes on , the super pulley , and possibly a wider belt.

next up is relocating the tranny coolers to the where the headlights used to be ( i already did that , but i don't like how they are positioned and will redo them with fans on them).

so just so i remember what i need to do & get tomorrow, i need:

- X2 8" electric fans

- finish up the fuel rail / reg. plumbing

- remove exhaust shield from under tank to see if i can fit a sump on the tank

- mark & remove header extensions for welding evac. hose bung thingy

- get some soda for the fridge

the elbow is from summit (EDL-3847)-- better yet , look up ls1 elbow and check out your choices . one word of advice , if you don't have it , get the edelbrock throttle body with the elbow cause for some reason , the bottom bolt holes on the tb side of the elbow won't line up with the TB ( i had mine mashined to fit.)

the intake is from SDPC -----> and its a GM performance intake for the l-92 heads specifically , no machining required pn : 25534416 . they won't fit the LS1 style heads. ( for that look up edelbrocks manifolds)

6/23/2008

well i got some stuff in from summit today , mostly fittings and what not.

so i decided to plumb the oil accumulator ( A.K.A accusump) using the rear oil galley bolt ( the allen key bolt right above the oil filter) ....... bad idea !!!!!

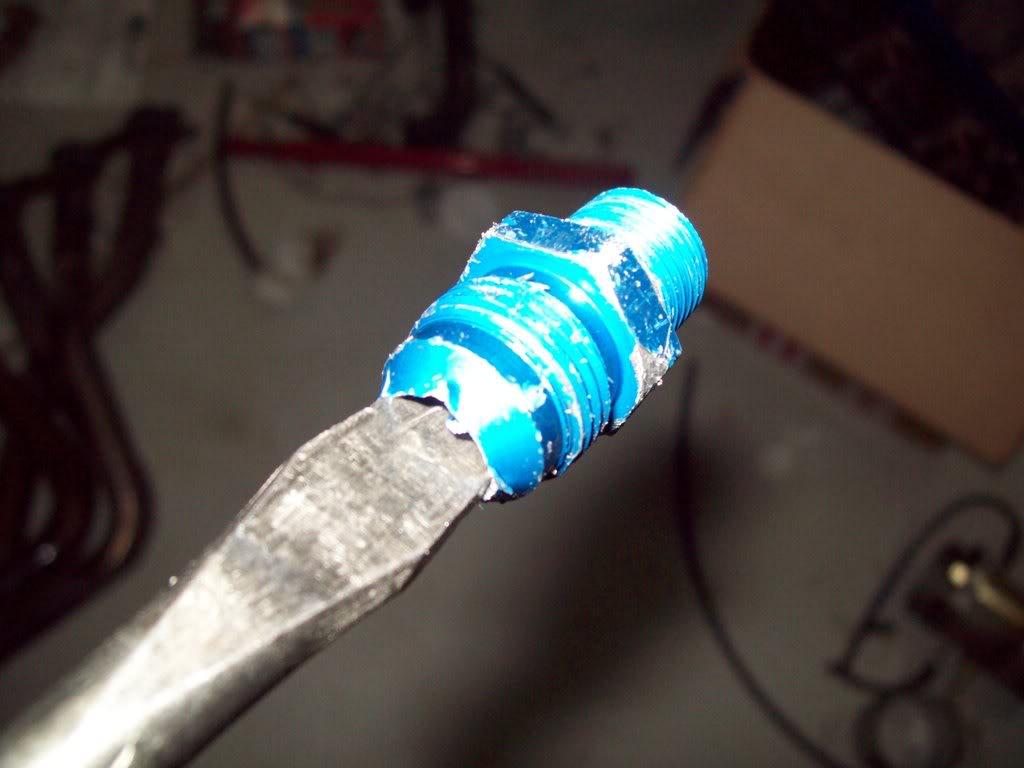

i removed the driver side header and the block off thingy just above the oil filter so i could try to thread in the fitting ( adapter from the block,s metric thread to -AN male fitting ), because the threaded hole was recessed and how it was angled, i could not thread it in easily and it was a royal pain to tighten , only to find that the 45 deg hose end ( any hose end for that matter ) would not fit in such a tight confine ......

so i proceeded with removing the fitting , and guess what , it won't turn ; i couldn't get a socket on there due to how the whole thing is recessed and i ended up maulling the edges off the fitting . which led me to drive a big screw driver through it so i could turn it

so now its back to plan A ( using the front port behing the alt. and relocating the alternator to the pass side head ).

i also managed to redo the tranny coolers ( and add one more  in the process).

in the process).

i now have enough coolers to start a new ice age , and enough oil capacity to jack up crude oil prices by $10

now i hace a fan cooling each side for the coolers too.

here you can see how i stacked 2 coolers on top of each other :

heres the driver side cooler, check out the BOV outlet : the outlet usually peeks through the foglight hole in the bumper , you can see how the part that peeked through got sandblasted !

all i have to do to finish this up is to ground both fans, mount and wire a relay for them in the car . i'm just debating weather to have them tied in to com on with the stock fans , or have them on with ignition with the option of a on/off switch to kill them if i want.

6/25/2008

got my super pulley in today! got to take it to the machine shop to narrow it down a bit ( need to shave 12 mm off it - about .5 inch) i also swapped the crank cog from the 55 tooth one ( the chrome one in the pics) to the 73 tooth one . this got me into some fitment issues with the tensioner hitting the cog. i also found out that the brace i use on the back of the blower that attaches to the oil pan bolt hits the blower cog ( the damn thing is huge (45 tooth ! ) .

so its off tomorrow to the machine shop to :

- machine a new bracket with a bigger / different notch in the side ( i want to use the old one for the stang

- fab up a new brace with a decent bend in it to clear the cog.

- get a new tensioner and machine a slot in the arm so the arm length can be adjusted

i'll post pics tomorrow of the super pulley and the bracket if it is done.