You must be logged in to rate content!

12 minute(s) of a 341 minute read

12-27-2009

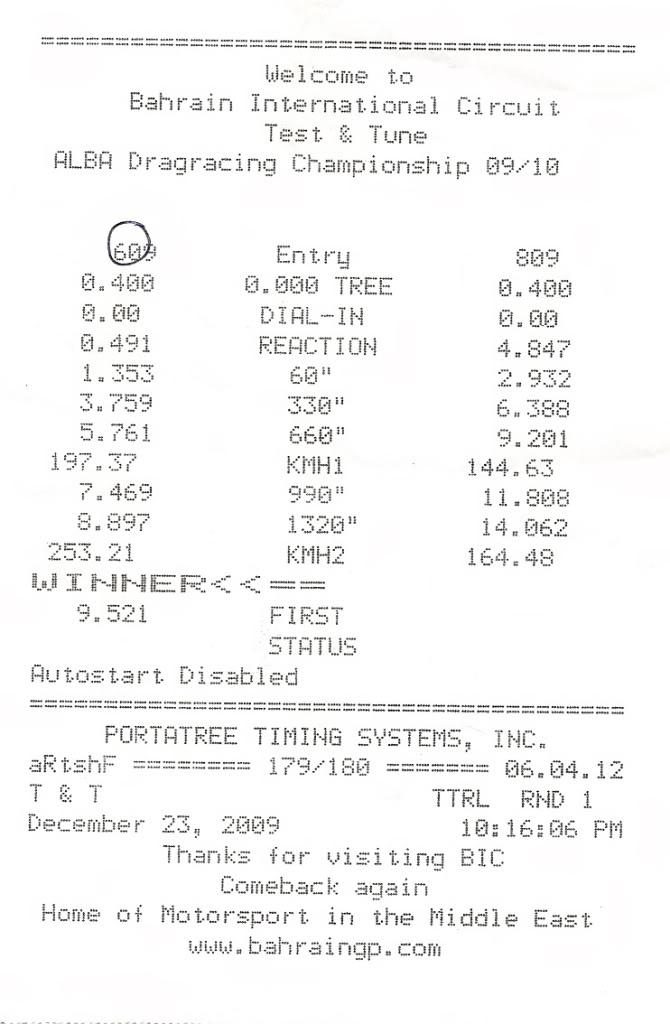

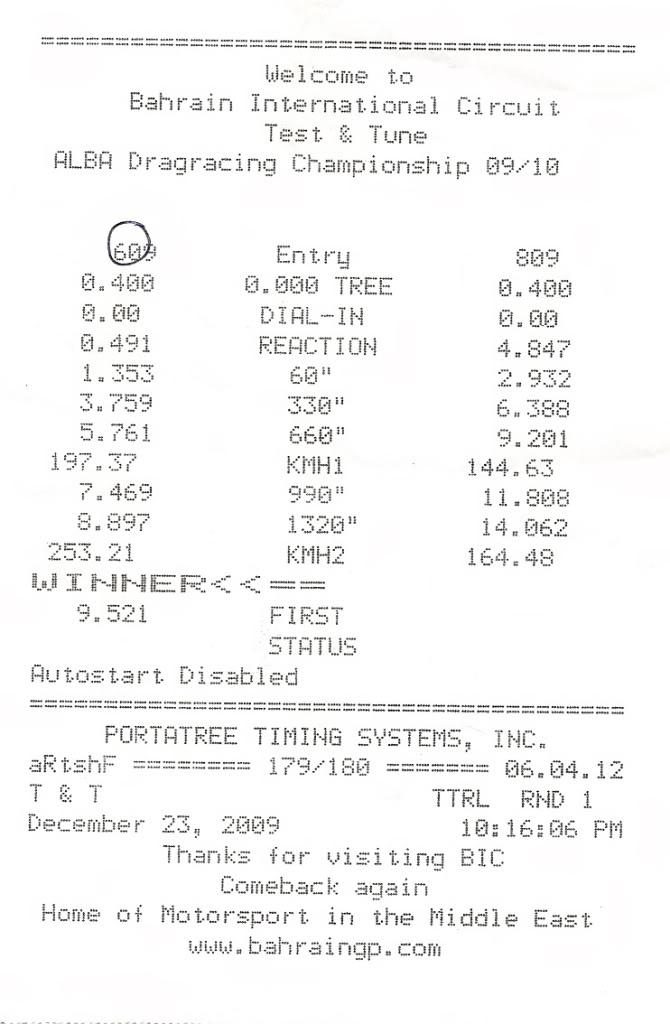

well i finally got into the 8's!!!!

took it to the track this weekend and got this

funny thing is that i got a 1.35 with a bunch of wheelspin and pedaling ?!!?

oh well , its good and bad news for me ; good news is i'm sure i can squeeze a better 60' with new slicks ( ones on there are 3.5 years old!), and drop the time with higher boost and a more aggresive tune.

bad news is on the fifth pass the car just shut off mid pass,,,, found out today that of all things the back half of the reluctor wheel seperated from the front half and was spining on the crank!

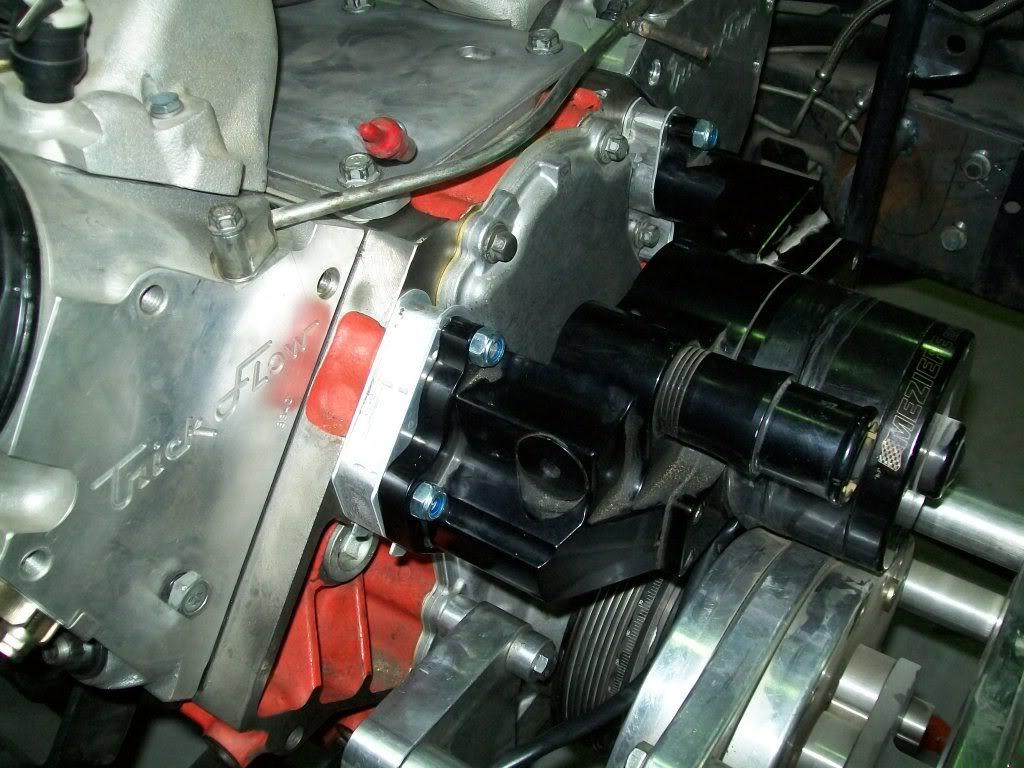

you can see how the two holes don't line up anymore ( sorry for the crappy phone pic):

from what i can see now it seems that the two sides of the reluctor wheel are riveted or sort of stamped together and that is what failed .

guess the its time for a bearing inspection

it still has alot left in it ;

tires are real old and worn , it spun on that launch , it was on low boost ( 17 to 19 psi ) , and the tune was just a base conservative tune.

1/1/2010

sorry, fixed the reluctor wheel pic .

here's more:

so , repairs are in order; ordered a new reluctor wheel and the tool to install it . should be here in couple of days

3/1/2010

man its been a whils since i updated this !

long story short :

changed the geardirve ratio to 1.6 , got 31 psi  , ran a 8.8@ 169 mph! ( took it real easy launching it - 1.6x 60' and short shifted second ) but it ran a bit lean and hurt the gasket.

, ran a 8.8@ 169 mph! ( took it real easy launching it - 1.6x 60' and short shifted second ) but it ran a bit lean and hurt the gasket.

took the motor appart , freshening things up now . should be done soon .

the parachute and mount came in , mount got powder coated and is on the car , got to install the chute and cable soon :

the chromolly cage and SFC showed up too , so it was time to gut the car ( again) and start chopping and welding :

hoping to have it done within the next two weeks , since we have a big race coming up in Abu-Dabi on the 18th . i'm hoping for mid to low 8's ( shouldn't be a problem with a decent launch and propper shifting  )

)

i might even try the transbrake there .

the never ending to-do for this time are :

- weld up SFC and cage

- install chute and window net

- wire two step to the brake pedal and install switch

- wire in a seperate button for the transbrake ( don't want it on the shifter - kinda hard wired my brain that the shifter button is the N2O button  ) will make it a button on a the end of a coiled wire .

) will make it a button on a the end of a coiled wire .

- screw the tires to the wheels

- figure out a way to run an alternator or find a 16V battery somewhere.

4/12/2010

nothing much to report , we never ended up going to abudabi ,,,,, long story

the cage and through floor sfc's are done, so is the chute and window net. i still need to screw the tires tot he rims and wire the two-step and the t-brake .

i found a 16V batt and now i have it running the pump by itself and the 12v. one running everything else (never went though with the alt. project  )

)

i am trying to make it to the next race , but we'll see how that goes.

i did get in a few parts for the car , but since we just have a race on the 15th and one more 3 weeks later and the the season ends , i deciced to start that round of repairs and improvements then .

this includes engine freshen up , kirky seat , new radiator bracket , alternator (?) , new engine wiring harness, redo interior harness ( clean it up a bit ), and a few odds and ends here and there.

10/12/2010

man it been ages since i updated ,,,

lets see ,,, well i tore the engine appart again to replace the rods , kinda felt it was time to get better ones so i got a set of brand spank'n new howard's rods:

i also wasn't very happy with the engine wiring harness: it was the original one with all the unneeded wires taken out , plus it was integrated with the body harness. i also had an issue with it where the crank signall was intermittent due to a bad connector. so i decided to order a harness from ls1wiring.com where it would be a stand alone harness that can be swapped out without ripping appart the entire car's harness:

so since i was starting from scratch i decided to rip the interior and wiring all out :

and how the new harness looks like on the car :

the plan was to redo the interior harness to minimize any chance of mishaps , i also needed a new relay and fuse board . so after being inspired by SMKN TA 95's panels i decided to build my own ,,,, and let me tell you after starting this project that no matter what he's selling his boards for its a steal !!! man building them is pretty involved!

the plan is to have a complete underdash harness that ties in the instrument cluster, rpm guage and lights , center cluster , outer sensors and devices , and the control panel.

right now i finished the under dash harness, as well as most of the panel , i have to start building a bracing system for the panel so i can mount it in the passenger side footwell , then build another brace thingy to use as a laptop mount ( more on that later  ), here is how the panel base looks like ( still needs to be powdercoated):

), here is how the panel base looks like ( still needs to be powdercoated):

and this is how the panel itself is coming along , its made from a sheet of lexan and i'm planning to cover it with some carbon fiber sticker sheet  that way you know i'm serious

that way you know i'm serious

and how it looks under the dash next to the relocated PCM :

and here is the underdash harness :

so i started a list of other odds and ends to to finish on the car , of which is finally drilling some rim screws in the the wheels:

and i got a new kirky lightweight seat and some brackets from racecraft :

the brackets will enable me to mount the seat on the stock mounting studs:

another thing i wanted to do is clean up the front end. i didn't like how the radiator was posotioned and how the hoses went all over the place. so to fix that i decided to chop off the funky green brace i had before and redo stuff

first off was to build a radiator cradle or bracket , so out came the bent metal tubes and the welder and i slapped a few peices together and got this

and how it looks with the radiator in place:

and to help with the water pump hose routing issue i made a set of water pump spacers that spaced out the pump about 3/4"si i can use the port on the driver side of the pump and not have the hose hit the cam sensor :

so that sums it uo pretty much

i still have to run the positive power cable from the battery to the panel , and build me an ignition panel (starter button and ignition switch) and run the ground cables. i also have to mount the charging posts in the back and connect the power windows .

another thing i have to finish is welding some panels to cover the holes left behind after cutting the upper core support. and maybe figure out how to incorporate a cross brace somehow.

i also plan on redoing the cables running from the batt to the starter to the alternator ( or where it used to be) and grounds, right now its a frankenstined mix of stock and other stuff  so that needs to be taken care of .

so that needs to be taken care of .

also on the list is redoing the nose support for the front end. i was thinking of getting rid of the plastic/fiberglass peice up front and building a tubelar one that bolts to roughly the same location and also to the front of the frame rails ( where the crash bumper bolts up) this will also serve as a mount for the intercooler and from that i can weld some braces/outriggers to brace the bottom and sides of the bumper.

i'm also thinking of running a mechanical belt driven pump up front but the jury's still out ( till i do some research on the subject  )

)

also on the list (i have to order it first ) is a lightweight steering coloumn and wheel , should drop about 15 lbs off the car

so to sum it up :

- postitve wire to panel

- ground stuff

- install dash

- connect wires

- mount radiator and hoses

- weld core support plates

- starter cable and ground

- charging posts

- bolt up seat and brackets and rear seat support