You must be logged in to rate content!

7 minute(s) of a 251 minute read

11-6-2014

11-6-2014

thanks guys!

so I work 12hr days 4 on 4 off 4 nights 4 off. But the past month and for the next 2 months I have been working 2-3-even 4 of my days off trying to save up so we can build our dream house, and dad gets the shop he's always wanted. Needless to say I haven't been working on the car, but I have finally uploaded most of the pics I have, sadly I lost alot of good pics somewhere, I need to have this car finished by spring, correction, I HAVE to finish this car by spring or it'll never get done if were building a house. Im close but still oh so far...

Didn't like the look of a huge aluminum square in the front of my car so I painted it black, I've read alot of circle track guys do this anyways so I don't see the harm:

installed!

So AutoX cuda inspired me to do a similar setup for my breathers, like the old trams am racers, I bought aluminum 1 1/4" tubing (sorry not sure were the photos went) and 1 1/4" aluminum 90 degree bends, two 1 1/4" K&N breathers, and 2 goodyear 1 1/4" rad hoses Part #60083, had my buddy weld it up the lips on the valve covers to mount them, and weld up the pipes. Got it powder coated black, I think it looks really good! It also clears the airgrabber setup on my hood:

got tired of waiting for my MP viscous fan setup so I went to the yard and bought this fan from a 90 dodge truck with a 318

got it powdercoated, new clutch and fan shroud and installed

bought a new heatercore (it was bugging me that it was the only thing that hasn't been replaced) to my surprise (not really) it was no where near where I needed it mounted so I had to resolder the mounting plate

I didn't like the fact that the only option for a torque strap out there was a $100 option, So I made this for les than $10, grade 8 fine thread rod, 3/8" heim link and the washers/bushings from my prothane kit that were suppose to be for a stock sway bar, but seeing how I'm running the bigger Hellwig's, they were perfect!

my almost 2 year old son decided that he wanted to install it!

I installed the TTI exhaust with the dougs cuttouts, fit pretty good, the only thing I had to modify was the pipe from on the passenger side from header to cutout:

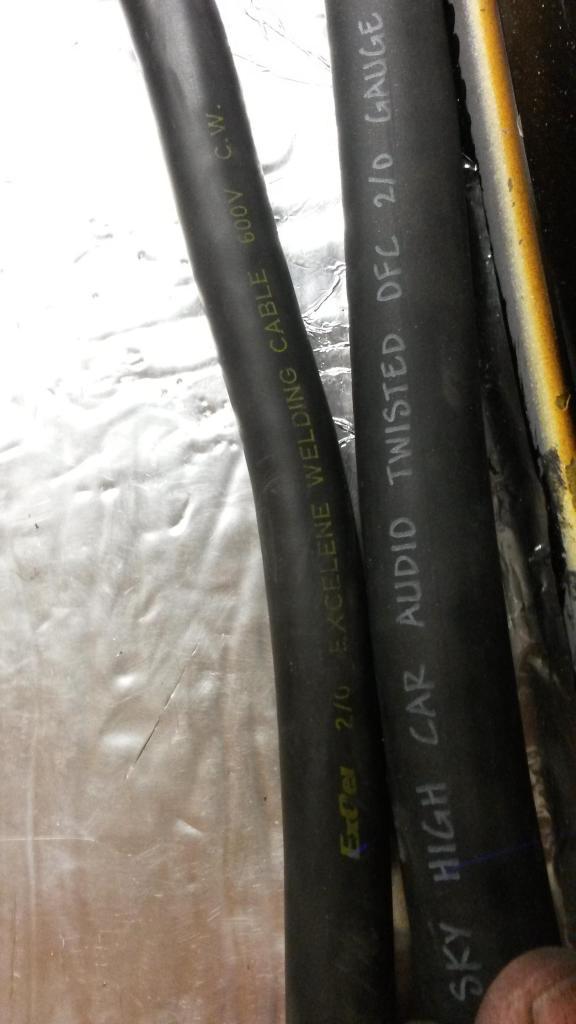

I bought some premium 2/0 cable for my battery relocation, I wanted 1/0 but this is what my buddy had, he's in the custom stereo business and even at his price it was $7.50 a foot, but as big as this stuff is, you can bend it around your wrist, its that flexible! And the amp draw you can pull on this stuff makes welding cable look like yesterdays knob and tube. This pic is the comparison of the two.

I bought 3/4" wheel spacer adapters for all for corners, premium quality all made with grade 10 bolts, the reason behind this was

1) To clear the long hub on the front of the car for my wheels

2) widen the track as much as possible

Since I'll be running the Enkei RPF1 18X9.5" +15mm on all 4 corners these will push those wheels out as far as I'd like to go. Now that I have the wheels I could have went with the 18X10.5" +15mm but I would have to extend the wheel studs and use a 10mm spacer. So for now I'm gonna use these rims and do the bigger rims down the road.

I am a little bit too close for comfort in the rear so I have shaved the inner lip as much as I possibly could to get more clearance, as you can see it was never a straight line to begin with, I gained as much as 3/8" in some areas and as little as 1/8." overall I have about 1/2" clearance from the tire to the inner lip, I'll get more pics on that later:

Last but not least I finally got my hands on a radio delete bezel!!!!! and a tach option dash as well!!!! (paid way to much for them) This is so cool I just wanna mount it on my wall! I restored the guages like I did with my other bezel, used my 150 mph speedo, cleaned it all up nice, I may do a layer of clearcoat on the bezel, haven't decided yet...

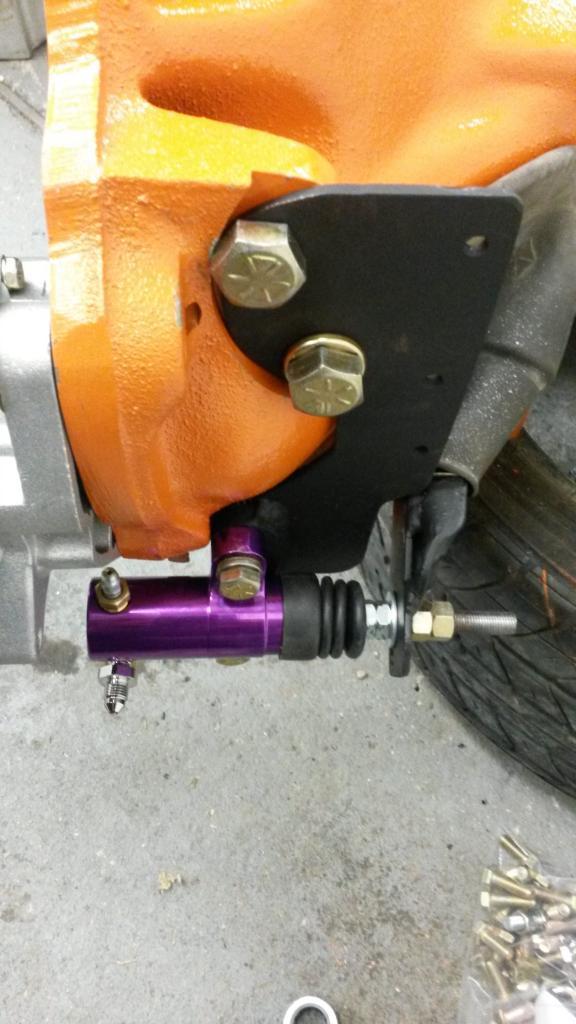

finished my custom slave cylinder, Had to put two clearance dents on the header but other than that I think this should work awsome! I could not for the life of me drill any holes in the clutch fork(must be made up of adamantium) So I had to weld on the extend plate for the clutch (i wanted to have it bolt on originally), tapped the push rod all the way, heres what I got so far:

So that's kinda where I'm at at the moment ![]()