You must be logged in to rate content!

2 minute(s) of a 95 minute read

11-21-2016

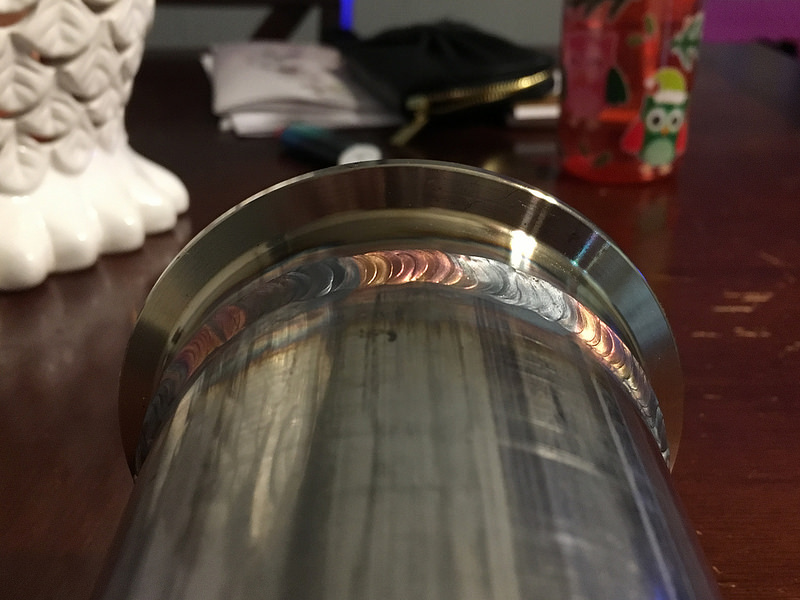

Realizing I have to build a stainless section of exhaust that goes from the turbo to my existing aluminum downpipe, I needed to get my stainless welding under control. I have only done aluminum and that's what I learned on.

The past few attempts I tried earlier this year, I had nothing but terrible results with over heating the weld. Turns out it was a gas coverage issue with a leak I found at the torch (wrong size insulator).

I fixed the leak and did some practicing yesterday using a Fupa 12 cup. This is with no backpurge, 3/32" blue tungsten, 1/16 308l filler. No backburging as I still need to order the dual regulator.

I'm hoping to get the car fired up by next week with the new turbo setup.

11-24-2016

Got the turbo outlet finished. Waiting for my dual regulator to arrive so i can backpurge it before fully welding.

Oil lines, wastegates then radiator next.

Does anyone have a trick for lining up vband flanges that do not have the male lip/female slot like the vibrant pieces?