You must be logged in to rate content!

5 minute(s) of a 88 minute read

9-27-2013

Thanks Tuna.

It sounds great. Am really happy with it and spoke to Mike T about it yesterday. He was impressed with the tq figures to date.

The difference it made from the first run @5500rpm to the second run @5700rpm with more fuel, 40hp shows us there is a bit more left in this.

Mike T suggested I put a sight glass style tube on the side of the pan to see if it actually runs out or we have a problem with pickup.

Here is a clip showing it first running an setting the timing

Cheers

9-29-2013

Ok, I think I'm on top of it now

Found I had too much oil and that my pickup needs to be lowered by 1"

Also put some more drain holes in my baffle

Hopefully once I drop my pickup deeper into the pan it will be ok

Cheers

10-17-2013

Ok, I decided to take a different tack with the oil pan. I was going to get Steve Reynolds to make an alloy pan for me, which he was happy to do, but not till the new year.

I want to get the motor back on the dyno, so my research started with help from buickstage1.

I had some 16g folded up to my dimensions, bought another pan gasket and 5/8" pickup tube from TA.

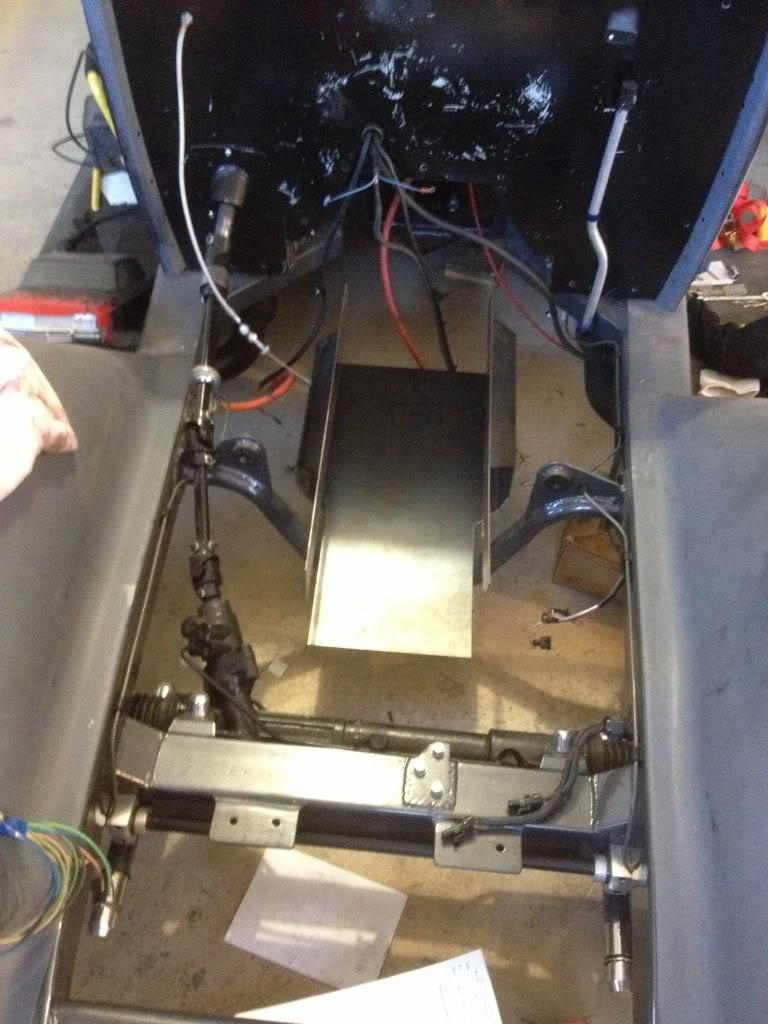

Here is the start of the new oil pan with cut outs for the front

Plenty of room

One side is bigger than the other to allow for the starter. Here are the fillet plates tacked in

I also bought a Canton Race Products windage screen kit, which was pretty easy to install

I made this baffle to put in the middle from left to right

Then I put these bevels on the holes to promote oil flow in one direction, to the back

Then I made an enclosure for the pickup I made. The idea was to trap oil in the back where the pickup is.

Then I beveled the top of each opening to promote oil in

Here it is mocked up. You can see where the pickup is located. It actually sits on the floor with a 3/8" high foot holding the screen off the floor. I made the pickup out of some 2"x 2" box and cut a 3/8" bottom piece out of it but leaving the end to create a foot. I then drilled 95 holes (count them if you like ![]() ) in a plate to act as a screen.

) in a plate to act as a screen.

Steve Reynolds look away now!!

Here is what is left of my old oil pan

I had to make these as straight as I could so it would be easier to weld together

Sorting out the front

Here it is tacked together.

This project gave me the excuse to by a TIG and give it a go. Here was one of my last welds.

Found that the 2 surfaces have to be so clean. Had to dig out a few contamination bubbles ;)

Cheers

Nice pics!

Posted by Diggymart on 5/12/20 @ 2:53:28 PM