You must be logged in to rate content!

21 minute(s) of a 519 minute read

2-1-2017

Thanks for the feedback. I appreciate it. I need to get the car down on the wheels and outside so I can get some longer distance pictures but paint the lower valance so it doesn't stick out as much. We have also started to reshape the lower valance so that it is the inverse shape as the upper grill. The corners will be rounded more and some of the harshness removed when that happens. I will see what that looks like before it goes much further. My gut feeling is the lower side scoops are not quite the right shape either and they need to be removed, smaller or softened as well. I guess I need to take this in baby steps to see where it goes.

I will have to leave the larger center opening there since I will allow cooling for oil and tranny coolers. I had also planned on using the side scoops as brake ducts but we'll see about that one.

2-6-2017

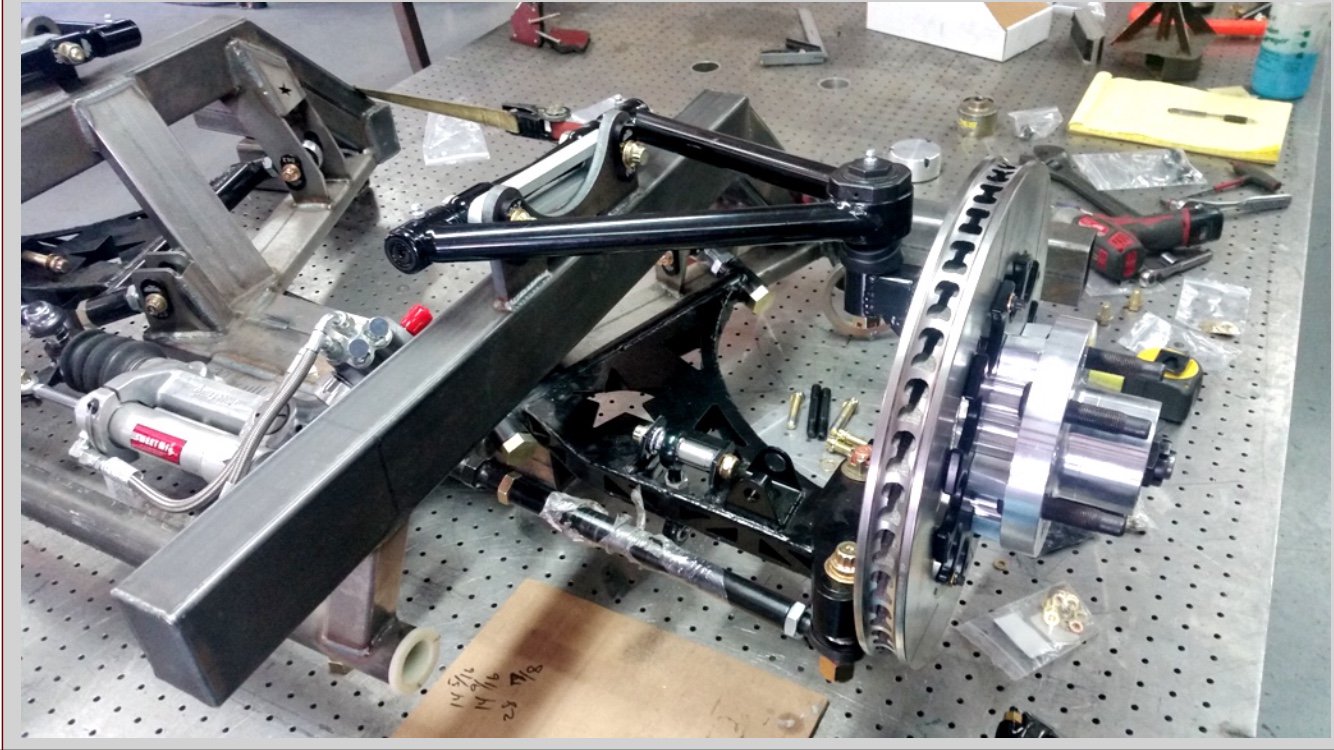

There is a little delay but n the fabrication of the upper control arms but the front crossmember is welded. I am told it will be 1-2 weeks before it will be ready to ship. It is starting to get exciting! Thanks Ron Sutton Race Technologies!

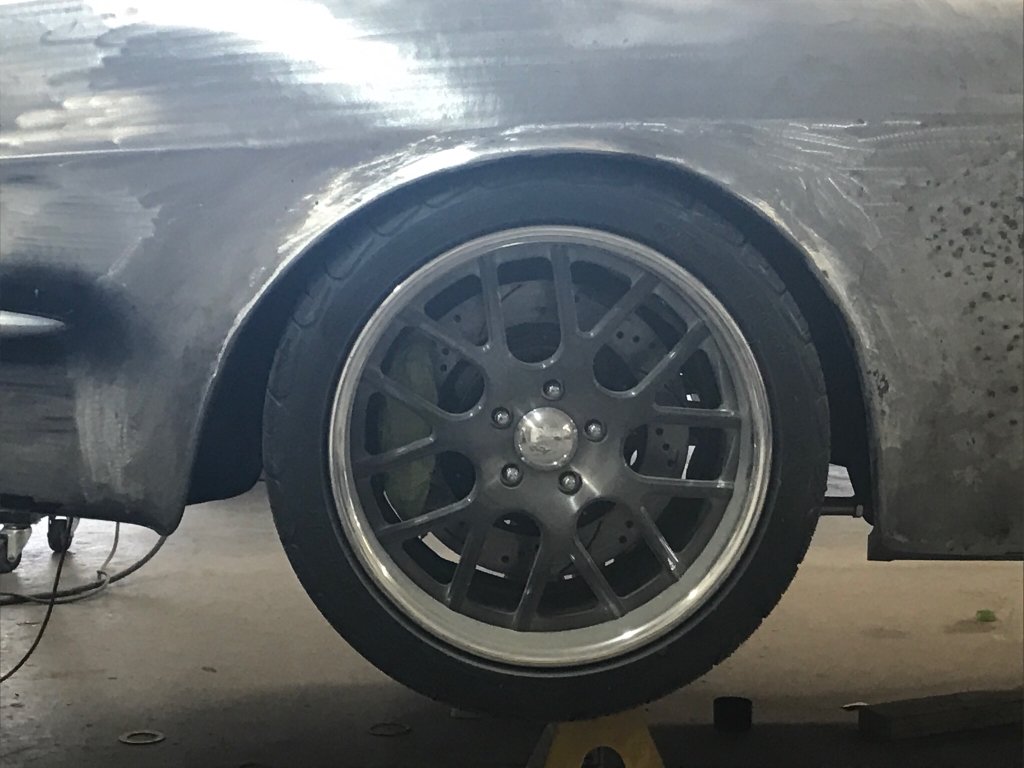

Here are a couple pictures of the car on the ground. It will be slightly lower in the front and higher in the rear when it is at ride height. The hood isn't on in the picture since they were installing the new hinges. The original hinges got lost at the shop at some point. The splitter will be about 4.5" off the ground when done.

Anyone have a measurement on an original car from the front nose sheetmetal where it ends below the bumper to the ground?

2-14-2017

A little bit of progress this week. The heater controls came in. It is a pretty cool unit from Restomod Air. It has one button you push to change from fan to temp to zone and then you twist the knob to adjust the settings. It should make for a pretty clean install.

The metal work this week was focused on two areas. The hood was fit to the body which required quite a bit of cutting and welding. The original hood opening had quite a lot of bondo to make it look right. Not any longer!

The body man also started working on the rear front fender arch. Since we eliminated the pinch weld by blending it into the rocker it left a small triangle shape void the length of the rocker.

The new opening is about 3/4" flared more than stock and extends down below the rocker slightly. This will match the modified body line on the rear quarter. Here is the modified front fender.

Here is the other side which hasn't beeen changed yet.

Here is a picture of the rear wheel opening to show how it matches the front.

2-23-2017

The hood has a done. That required a lot of cutting and welding to get those right. The car had some pretty significant body damage in its life that wasn't repaired very well. There was a terrible graft in the middle of the front fender and the nose was pushed over almost 1/2". That is all fixed now.

The passenger side wheel arch is now done and reworking the shape of the lower grill opening should be done now. I will take some pictures tomorrow. They are also painting the valance grey and the splitter black epoxy so I can get a better visual of what it will look like.

My suspension is almost done with assembly. There was a delay with the upper control arms but they should be done soon. With a little luck it will ship out to me next week.

The glass guy will hopefully come over to try out an idea he has for 1 piece door glass. I would like to eliminate the wing windows. He also need to come up with a plan for the rear quarter glass. The plan for now is to cut out a section from a windshield that has the right shape. If that doesn't work I will have some plexiglass made.

Beyond that there really isn't much metal work to do. Mainly touching up some areas and getting ready for the filler portion of the job.

The glass guy thinks the door glass out of a Ford Flex will be able to cut down. He owns one and told me the side glass is safety glass (like a windshield) which can be cut where tempered cannot. If not I will live with vent windows. If they can be cut to fit then my doors will require more metal work to create a place for the window scrapers to mount since the original trim will no longer fit.

My hope is to have the car assembled by July but that looks much more unlikely. To be on pace for that I needed to have the car painted by now. I still have to have the suspension reworked and then some inner fender modifications to do. I think I will be lucky to have the car back to me for assembly and wiring by June. That creates a delay with the upholstery. Since the car will be shipped to Nebraska to have the interior done it will be somewhat out of my control then. Tracy Weaver at The Recovery Room will be doing the work for me and I think they are one of the best shops in the country. They should have it for about 3 months but if I can't get it to them early enough it will take a back seat to cars they do for the Riddler Award.

It would be great to have it done by November but that may not happen. There is a chance I could have it displayed at this years SEMA show if it is done soon enough. That show starts on 10/30/17 if I recall correctly.

To answer the question, I have no idea when it will be done. I am kinda done even trying to guess. I would have thought it would have been done a year ago.

3-2-2017

The front valance has been shaped to better flow with the original grill. We painted the valance with gray epoxy and the splitter black so it would better blend with the car. I think it looks better with the softer edges. It will be nice when it is back on the ground.

The gaps have been set in the deck lid and they started working on the latch for it now.

I have not been able to get a profile view of the car for a long time so it was nice to get a glimpse today. When I stood back I did not like the lack of a point on the front bumper so they will be reworking it to better match the rear.

The license plate trim was made and I think it will look killer when it gets chromed!

The gas cap has also been shaped to fit the quarter panel. It is a little high now but will be made flush after final body work is done. If you press on the top and twist slightly it will pop up then it can be twisted to remove.

The biggest thing I am waiting on now is all the glass and then the front suspension to arrive. Once it is in we will have to gap the doors and make some modifications to the engine bay panels. It is starting to come together!

One cool thing is it looks like I may get a sponsorship from BASF. It looks like they may pay for all the materials! They have expressed some interest in having it at SEMA but that may be a long shot. Guys like Chip Foose tend to be in the paint manufacturer booths. It is pretty hard to compete with them.

3-3-2017

t will be fun to show the car but I am more interested in getter my it out on the road. Doing some spirited driving on the street, auto crossing it and some road racing via open track events.

I was hopeful to have it done this year for a potential chance at going to SEMA but work is progressing slower than I have planned. We'll see what happens but I am not holding my breath.

3-7-2017

The shop is still finishing up on the small items. They are about done with the trunk latch and as usual they are exceeding my expectations. They fabricated a nice metal cover that will be screwed to the latch bracket. It will hide the mechanism and will provide a mounting point for interior panels. There is still some finishing touches to do but that is mostly on the trunk lid itself.

3-10-2017

The minor touches continue. They were able to put a flange around the spoiler mechanism to Jane interior panels. The struts were also minted to the deck lid. Due to the additional weight I will need to increase the pressure on the struts. It should work great when I have the right pressure struts.

The to-do list (for body work) is getting pretty short now.

1. Rework the ends of the front bumpers

2. Fit door and side glass

3. Modify the frame not of the rear wheel opening by flaring it just a little.

4. Adjust the doors once the suspension is installed.

5. Fabricate new engine compartment panels due to the new front suspension.

I guess the list isn't as short as I thought it was.

3-13-2017

I just found out that my front suspension should be shipped out on Wednesday. I received all the specs and it looks great! The Ackerman, Roll Center and all the other specs look right where they should be. This thing will be an absolute beast on the track! I also have the specs to tame it down for a more comfortable street ride. Alignment will be a breeze since the setup uses slugs to set it up and will not slide out of spec.

I am really starting to get excited to finish this car and get it on the road.

3-20-2017

The bumpers are now done and the slight flare to the front edge of the rear fenders is done. I added another item to the to-do list and they have almost finished it. It was to add a turn signal to the outer valance opening. My original plan was to have the turn signals installed around the projector bulbs in the headlight. My concern now is that they would not be visible if the lights were on. The new turn signals function as daytime running lights as well as turn signals. The theme of the grill was continued to the lights. Parallel grill bars on the top and bottom but these will likely be painted black to match the splitter. This one is almost done. It needs a curved piece on the inside edge of the lense like it has on the outside.

3-20-2017

Glad to help. To finish off the subject and to help others out I ended up using 75 lb struts. I added quite a bit of weight to the trunk lid with the spoiler and additional bracing. I think a 40lb strut would likely work for a stock trunk lid. As it is I can lift it up and it will stop at any position I leave it at. When the lock is released the deck lid will open about 1" so you can put your fingers under it to lift. Since I no longer have a handle I needed something to help open it the first little bit.

3-21-2017

Metal work has been the biggest underestimate of costs in this project. I did the rough metal work (firewall, mini-tub, transmission and driveshaft tunnel) and left the visible bodywork to the professionals. I have over 1,750 hours of work from the body shop so far. From here I may have another 50 hours of metal work then the bodywork begins. That shouldn't be too bad since the metalwork is pretty darn straight now.

I will have to get back to you on how many hours of body work.

3-23-2017

I started to do the modifications to my headlights to retrofit projector headlights in them. I need to do some filing and trimming on the edges but I like the way it is going.

4-3-2017

Two steps forward and one step back. I received some good news that it looks like we can eliminate the front wing window and have a plan of action on the quarter window glass. The plan is to use side safety glass from a Ford Flex for the door glass and a section from a Mazda Miata windshield to make the quarter glass. Both will take some trimming but since the door glass on the Flex is safety glass we will be able to trim it unlike if it was tempered glass.

The step back is with the lights. I fitted the projectors to the headlight buckets and when I did I wrapped everything in blue tape to protect the finish. When I had everything lined up and ready to glue I pulled off the tape and when I did it peeled the chrome off the projector shroud. Since it is all glued together I will have to start all over again. I had a few choice words when that happened. The good side is I was able to upgrade my projectors to a newer version that will provide a better beam of light. I hope to have the new parts in by this weekend and be able to start on that project again.

4-7-2017

It is ready for the suspension work. It should be shipped fro Ron Sutton Race Technologies early next week. The control arm mfg accidentally shipped two of the same side upper control arms. That delayed shipment by about 3 weeks. Now I just have to wait for my chassis guy to have the time for install.

4-13-2017

After a couple months of waiting my new suspension is on a pallet and on the way to me! Here is a sneak peak Ron Sutton sent me. http://www.ronsuttonracetechnology.com/

4-17-2017

I too k a little video of the car today. I tried to incorporate as many details as I could. I also took some pictures of the door next to the window. We had to build it out since the wing windows will be deleted for a one piece door glass. That should really clean up the look.

Now I need to figure out how to load the video.........

I usually use tapatalk to do the uploads but they must have stopped me from doing video uploads. I had to use You Tube for the video link. Here is the link.

5-11-2017

The Chassis shop finally has some time to work on the car. It will head over there on Monday to have the front clip and rear torque arm installed. After that the front wheel wells will need some work and then off to mud and paint work. Progress has been really slow in the past month as I was waiting for the chassis shop. The only real item that was done last month was mounting the trunk release solenoid. Pretty boring stuff but nicely executed.

I have decided to make some changes to the e-brake setup. When the new suspension is installed it will cause interference issues with the factory e-brake so I have decided to go with an electric emergency brake. I will mount it on the panel separating the trunk from the cabin. I should work pretty well and I will post pictures of the setup as I get all the parts in.

6-19-2017

They had the frame jig already. They use it for racecars all the time. They did have to build a ramp system for my car since most race cars they load on the jig by lifting from the cage with a fork lift.

I have given up on timelines with my car. LOL! I hope it will be painted by fall and then I have to reassemble the car and ship off to have the interior done. Driving this time next year is a likely goal.

8-4-2017

Not much progress has been made on the car the past 2 months. The chassis shop is swamped with race cars and have not started on mine. They should have some time in the next couple weeks to work on the car. I hope that they can finish it in that time period.

In the meantime I have been making some improvements to the engine that is going in the car. I upgraded the springs, added titanium retainers, installed bronze bushings in the rocker arms and added a Fast intake manifold. I did it so I could eliminate the weak point of the engine, the roller bearings in the rockers, add stability to the valvetrain and add a few more HP. I considered porting the heads but did not want to go through the hassle. If I end up blowing up this engine I will port the heads and add a stroker kit. Doing that should get me up to about 650-700 hp. The sensible side of me won out this time. How much power does one really need? I think I have enough for now but the little voice in my head is always telling me "you need a little more". LOL!

9-11-2017

Unfortunately I don't have much progress to report. The shop still hasn't started working on the suspension install. I do have a couple other updates on items I am starting to acquire. I ordered a new set of front wheels and tires for track days. I will have new Boze Performance wheels 18" x 11" fitted with 315/30 BFG Rival S rubber. I will keep my existing 18" x 9" wheels and 275 tires for street use.

I have also decided on moving over to a different engine management system. I have narrowed it down to a Haltech 2500 setup or a Holley Dominator. The reason I will be using one of these is for DBW capabilities and I will also be using the traction control software they use. This car is pretty short and narrow. I am looking for a little piece of mind that traction control has to offer. Easier setup and tuning is a plus. I will wait to buy that for when the car is closer to paint.

9-13-2017

The new front tires are in.

9-23-2017

Installation of the front clip has started. So far the fit has been terrific. It actually looks better in there than I imagined thanks to the guys at Rhom Innovations and Ron Sutton Race Technologies. This thing is going to be incredible on the track and street!

11-7-2017

Not much to update right now. The fabricator working on my car caught his had in an engine fan and tore it up pretty bad. They have finished mocking up the front suspension and are ready to weld it into place.

On a side not I have decided to go with a Haltech engine management system. I will be utilizing their traction control setup as a plus.

Ron Sutton has also talked me into a fire suppression system as well as a data logger. I am looking into those now and should have a sense of direction on those by the end of the week. I am currently leaning toward an Aim data logging setup. I like the software a little more than Racepak and it is also the cost is a bit lower.

My new wider Boze Wheels should be here this week. Thanks Zak you guys are fantastic!

Great photos!

Posted by Diggymart on 12/4/23 @ 3:59:23 PM