You must be logged in to rate content!

9 minute(s) of a 519 minute read

2-1-2017

Thanks for the feedback. I appreciate it. I need to get the car down on the wheels and outside so I can get some longer distance pictures but paint the lower valance so it doesn't stick out as much. We have also started to reshape the lower valance so that it is the inverse shape as the upper grill. The corners will be rounded more and some of the harshness removed when that happens. I will see what that looks like before it goes much further. My gut feeling is the lower side scoops are not quite the right shape either and they need to be removed, smaller or softened as well. I guess I need to take this in baby steps to see where it goes.

I will have to leave the larger center opening there since I will allow cooling for oil and tranny coolers. I had also planned on using the side scoops as brake ducts but we'll see about that one.

2-6-2017

There is a little delay but n the fabrication of the upper control arms but the front crossmember is welded. I am told it will be 1-2 weeks before it will be ready to ship. It is starting to get exciting! Thanks Ron Sutton Race Technologies!

Here are a couple pictures of the car on the ground. It will be slightly lower in the front and higher in the rear when it is at ride height. The hood isn't on in the picture since they were installing the new hinges. The original hinges got lost at the shop at some point. The splitter will be about 4.5" off the ground when done.

Anyone have a measurement on an original car from the front nose sheetmetal where it ends below the bumper to the ground?

2-14-2017

A little bit of progress this week. The heater controls came in. It is a pretty cool unit from Restomod Air. It has one button you push to change from fan to temp to zone and then you twist the knob to adjust the settings. It should make for a pretty clean install.

The metal work this week was focused on two areas. The hood was fit to the body which required quite a bit of cutting and welding. The original hood opening had quite a lot of bondo to make it look right. Not any longer!

The body man also started working on the rear front fender arch. Since we eliminated the pinch weld by blending it into the rocker it left a small triangle shape void the length of the rocker.

The new opening is about 3/4" flared more than stock and extends down below the rocker slightly. This will match the modified body line on the rear quarter. Here is the modified front fender.

Here is the other side which hasn't beeen changed yet.

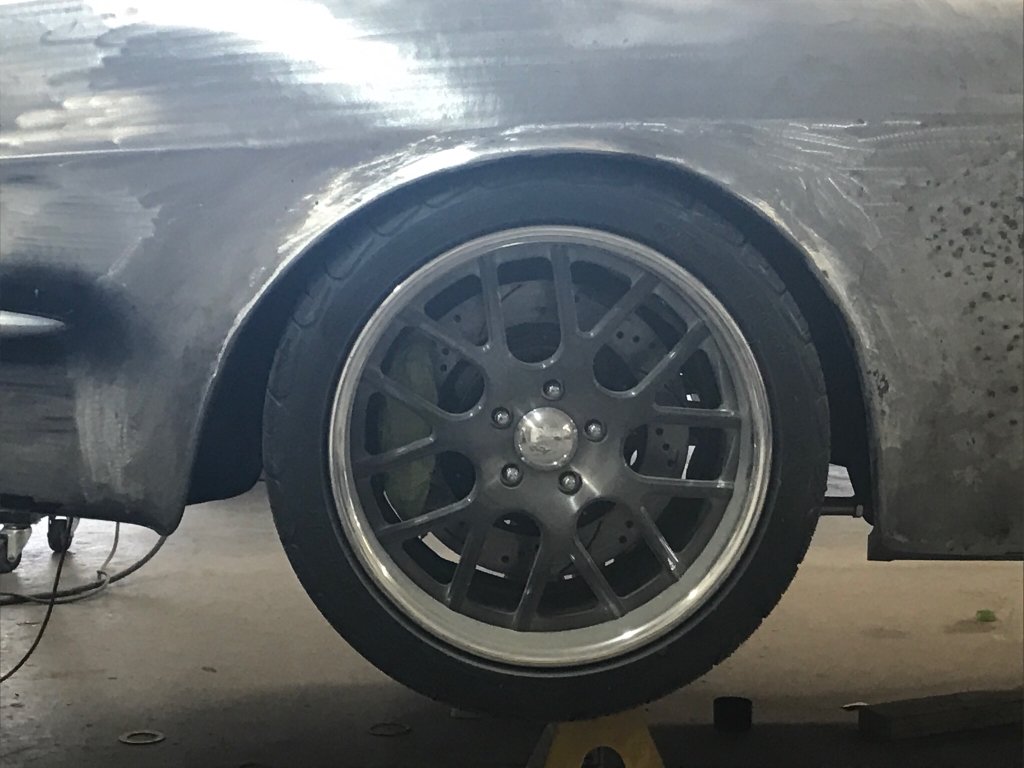

Here is a picture of the rear wheel opening to show how it matches the front.

2-23-2017

The hood has a done. That required a lot of cutting and welding to get those right. The car had some pretty significant body damage in its life that wasn't repaired very well. There was a terrible graft in the middle of the front fender and the nose was pushed over almost 1/2". That is all fixed now.

The passenger side wheel arch is now done and reworking the shape of the lower grill opening should be done now. I will take some pictures tomorrow. They are also painting the valance grey and the splitter black epoxy so I can get a better visual of what it will look like.

My suspension is almost done with assembly. There was a delay with the upper control arms but they should be done soon. With a little luck it will ship out to me next week.

The glass guy will hopefully come over to try out an idea he has for 1 piece door glass. I would like to eliminate the wing windows. He also need to come up with a plan for the rear quarter glass. The plan for now is to cut out a section from a windshield that has the right shape. If that doesn't work I will have some plexiglass made.

Beyond that there really isn't much metal work to do. Mainly touching up some areas and getting ready for the filler portion of the job.

The glass guy thinks the door glass out of a Ford Flex will be able to cut down. He owns one and told me the side glass is safety glass (like a windshield) which can be cut where tempered cannot. If not I will live with vent windows. If they can be cut to fit then my doors will require more metal work to create a place for the window scrapers to mount since the original trim will no longer fit.

My hope is to have the car assembled by July but that looks much more unlikely. To be on pace for that I needed to have the car painted by now. I still have to have the suspension reworked and then some inner fender modifications to do. I think I will be lucky to have the car back to me for assembly and wiring by June. That creates a delay with the upholstery. Since the car will be shipped to Nebraska to have the interior done it will be somewhat out of my control then. Tracy Weaver at The Recovery Room will be doing the work for me and I think they are one of the best shops in the country. They should have it for about 3 months but if I can't get it to them early enough it will take a back seat to cars they do for the Riddler Award.

It would be great to have it done by November but that may not happen. There is a chance I could have it displayed at this years SEMA show if it is done soon enough. That show starts on 10/30/17 if I recall correctly.

To answer the question, I have no idea when it will be done. I am kinda done even trying to guess. I would have thought it would have been done a year ago.

3-2-2017

The front valance has been shaped to better flow with the original grill. We painted the valance with gray epoxy and the splitter black so it would better blend with the car. I think it looks better with the softer edges. It will be nice when it is back on the ground.

The gaps have been set in the deck lid and they started working on the latch for it now.

I have not been able to get a profile view of the car for a long time so it was nice to get a glimpse today. When I stood back I did not like the lack of a point on the front bumper so they will be reworking it to better match the rear.

The license plate trim was made and I think it will look killer when it gets chromed!

The gas cap has also been shaped to fit the quarter panel. It is a little high now but will be made flush after final body work is done. If you press on the top and twist slightly it will pop up then it can be twisted to remove.

The biggest thing I am waiting on now is all the glass and then the front suspension to arrive. Once it is in we will have to gap the doors and make some modifications to the engine bay panels. It is starting to come together!

One cool thing is it looks like I may get a sponsorship from BASF. It looks like they may pay for all the materials! They have expressed some interest in having it at SEMA but that may be a long shot. Guys like Chip Foose tend to be in the paint manufacturer booths. It is pretty hard to compete with them.

Great photos!

Posted by Diggymart on 12/4/23 @ 3:59:23 PM