You must be logged in to rate content!

348 minute(s) of a 720 minute read

1-12-2021

1991 244 Build Thread

Compliments of Smokeyfan1000 @ www.turbobricks.com

4/19/10

This is a 1991 N/A B230F with LH 3.1 244 car. It will remain N/A , much to the dismay of many here on TB. I apologize. But it's too good a car to +Turbo IMO. I want it to run for many, many years to come.

OK, here's the plan.

This build includes: Replace Clutch & PP,CPSensor, flexdisc,universal joints in D Shaft,new header pipe, with 2.50" collector mod to it. And 2.50 MagnaFlow cat and 2.50" pipe to the 2.50" MagnaFlow straight thru, or DynoMax Super Turbo muffler, and a 2.50" L pipe tailpipe with a nice SS tip.

Also..Painting the engine block, & peripherals, while it's still in the car.And refurbishing all/anything I can for appearances sake. I plan a cam change for a little added performance at a later date All show & kinda slow. It's N/A after all.

All four new Brembo brake rotors and EBC Green Stuff pads, IPD SS brake lines, all of them. And possibly a Mstr. Cyl. plus I will bleed brakes with ATE Super Blue Racing Fluid.

Also inspect & repack F wheel bearings. New Bosch Fuel Filter. Also installing all new VDO Vision 52mm gauges. OT,OP, VM, WT , Vacuum gauge..

All Super-Pro poly bushings F & R, Four (F & R) Bilstein HDs strut & shocks, IPD S to S brace,the new style IPD lowering springs, IPD Lower Chassis Brace,YoshiFab Firewall to Strut Braces(very nice pieces I might add!) IPD Adj. Upper Torque rods, IPD adj. panhard rod, brace the front lower control arms, and brace the rear trailing arms, then repaint my older IPD 25/23mm Sways to match the rest of the IPD blue susp. parts.

Also Upper Strut Mts.,Lower ball joints,outer tie rod ends, inner tie rods & boots,

Also, install new Hepu WP, a new Scantech Harmonic Balancer, new cam/timing belt & all the other belts, all the accesories bushings with IPD poly bushes, new Bosch Voltage Reg., & Turbo MM heat/oil shield.

New OEM Volvo Diesel MMs, new trans mount(MTC), and hopefully the new IPD blue silicone hose kit for 240s, as soon as they are available.

Also, drill & tap 2 drain plugs for Oil Temp senders(one for a spare)

Also,finally, install leather shifter boot, and a new leather steering wheel cover, and new replacement HL lenses.

And whatever other mods cross my mind during the build. I'm sure there will be plenty of these.

YEP! Let the wrenches fly...

Tranny's out now.

The DS and Ex. System.Check out what was "left" on the exhaust system.

I pulled the Clutch & PP. This is what I found after inspecting it. I suppose the results of overheating the clutch & PP when I was stuck in snow this winter. Believe it or not, IT NEVER MADE A SOUND!! The clutch was slipping bad though.

Ever see a PP do this? In 3 places no less!! Maybe I need a scattershield.

Had the flywheel resurfaced today.I also cleaned , with a stiff brass brush,the outer circumference of the FW, where the CPS "reads".

Cleaned ALL bolts removed thus far too, as well as all the holes where bolts go.

Cleaned up the driveshaft(notice the OEM Volvo alignment marks STILL on it.

Cleaned (with GUNK & CRC Brakleen & a plain & a vibrating toothbrush!)the back of the engine & cylinder head, pass. side of eng. block,oil pan,bottom of frt. engine cover,frt. crossmember,& CAM rack & pinion steering assembly,and bottom parts of subframe too.

All from UNDERNEATH the car. Oh, what fun it was! Pics below:

I took the starter motor to the starter & alt. rebuild shop today for a refurbishing, so did this tonite.

OK, I have a "Volvo clean & shiny fetish", I admit it.

I cleaned the driver's side of engine block, cylinder head on exhaust side & intake side, with Gunk & CRC Brakleen. Then.....

I removed the Cat. con. heat shield, cleaned it on both sides ,THEN I cleaned the driveshaft tunnel (underneath the car) perfectly clean.

Then reinstalled the Cat Heat shield. I'm beginning to think I have OCD .

With the cat shield back on.

I took some old spark plugs,hammered away the porcelain,& cut the metal post off, and used them to keep dirt & cleaners out of the cylinders while cleaning the area around the S plugs on cyl. head. Cleaned it spotless.Also sprayed down & cleaned the intake/F.injectors & rail . Now that I have everything cleaned on engine, time to continue with the build.

Pics:

Had the original starter motor rebuilt today. It's nice & clean to go along with the rest of engine & engine compartment.

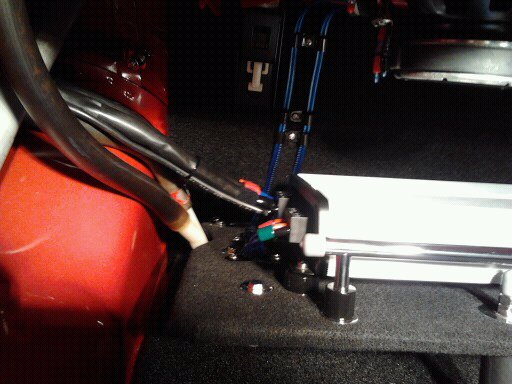

Redid the wire from OP guage to OP sender. Covered with sheathing,to where it gos under Oil pan, covered with shrink wrap, then used shathing again to the sender.

Hoping to make OP sender wires last longer/look neater.

Pressed in poly bushings in alt lower mount & adjuster mount. They are a pretty snug fit. Used C clamp & vise with wood & large sockets to seat them properly. Should make for firm mounting of alt.A few pics of them:

Gonna replace the P/S and A/C compressor BUSHINGS today. Looks like it's gonna be a bit of work.

Wasn't too bad. Cleaned all the brackets & bolts up while I was at it.

Figured might as well replace the frt. cover gasket too. Will paint engine after getting FC gasket off, and masking all non painted items.

Had to pull dizzy, so I cleaned it and installed new oring on her. Scotchbrite pad did wonders for looks.

OK, After removing everything but intake & exhaust Manis and after wallowing on carport cement floor in Gunk , CRC Brakleen and grease for a week & half, I finally got the block cleaned up nicely and decided to paint the engine block.

OK, got this far, Box,WP and front cover & seals.

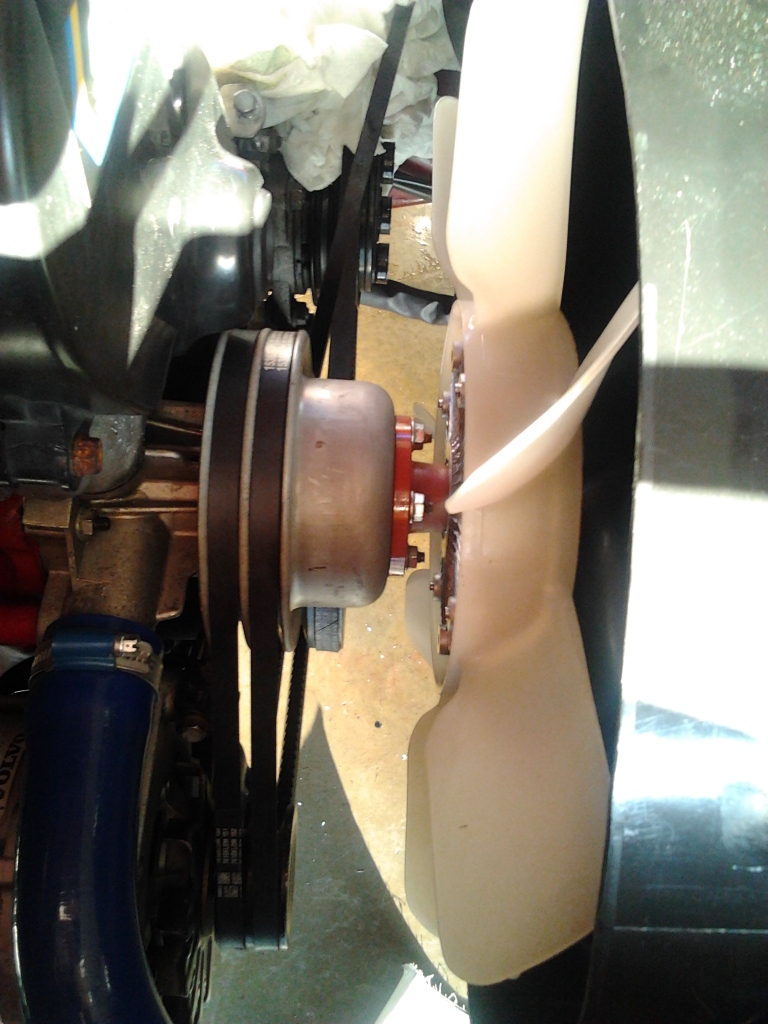

Got the frt. cover,Tbelt,& covers,new Scantech HB & dizzy back on.

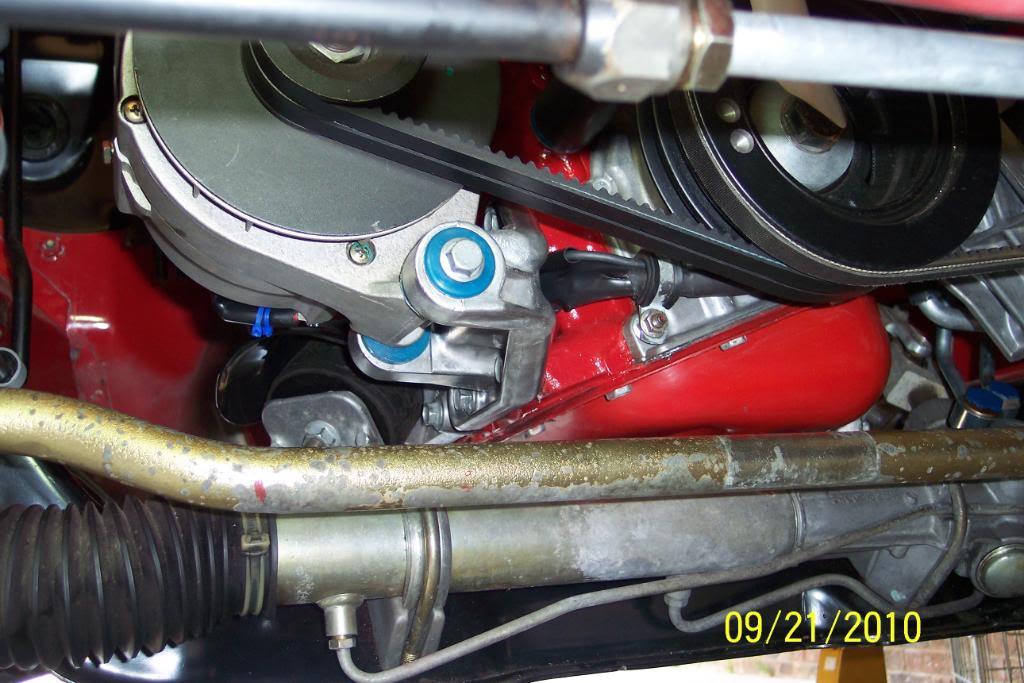

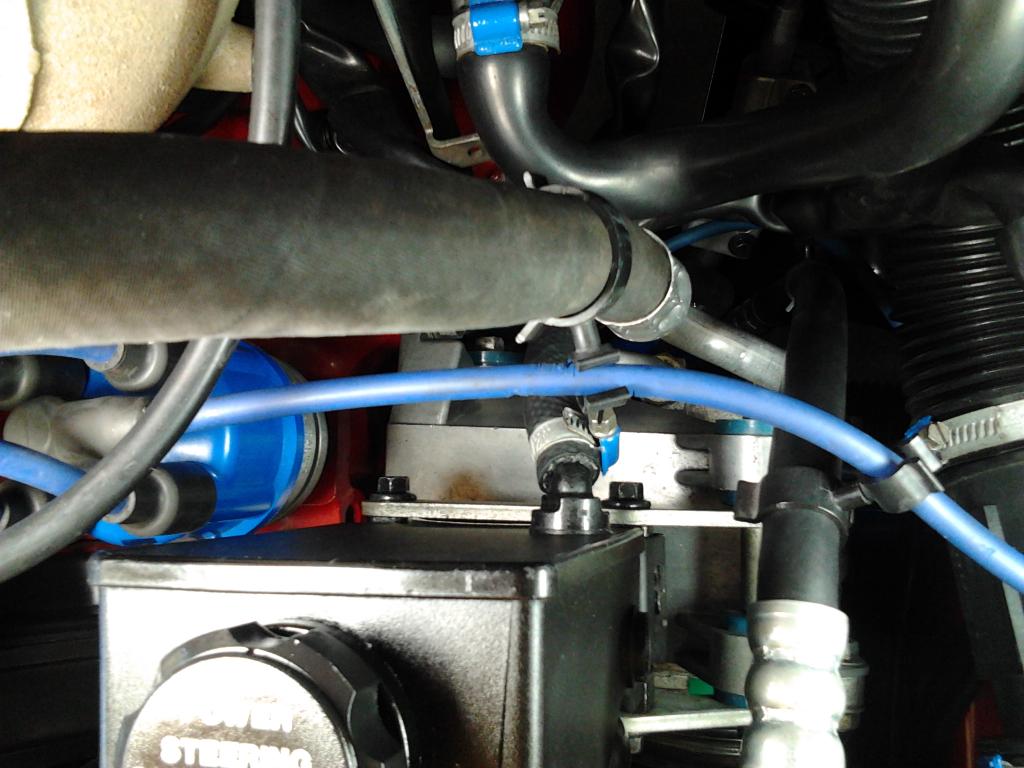

Also installed new Gates P/S hoses, cleaned P/S pump's pulley, repainted P/S pump & rad. overflow reservoir's bracket, and cleaned inside of reservoir, and painted P/S hose's banjo bolt heads blue(they were a little tarnished).

Also cleaned the WW bottle 's bracket & WW bottle. Trying to be thorough.

Also got the VDO Vision's WT sender (p/n 323-095), installed, sheathed & wired. BTW the block drain hole, in the block, is 3/8-18 NPT, in case anyone wanted to do the same mod.

This allows ya to keep the OEM "no numbers" gauge in the IC, still working, & it's sender in cylinder head,but still have a VDO Vision WT gauge to read actual temp.

Ok, been wanting to reinstall the lower heat shield. But due to fact I used preheat hose for an additional cold air intake to airbox, said lower shield had the metal pipe still on it, looked bad.

So, I took it off. Used a donor upper heat shield to cut a cover fro the hole left. Used SS bolts to bolt in place.

And installed on ex. mani. with SS bolts for good looks for a long time.

I found this lurking at the bottom of the 1986 strt hsg. tube. The removable spacer on the early tubes. This being out,should give me a lot more gland nut thread engagement. For sure & FTW.

Well I got the Billy in the pass side 1986 stut hsg. Thinks look a lot safer/better to me. Hopefully I did this correctly.

No threads showing at all.

1986 srut hsg's spacer removed and showing the Billy fully seated in the strut hsg tube.

Now tomorrow I'll buff the small amount of rust in certain areas on the 1986 strut hsg, and paint it with Rustoleum Black. Pics soon.

Ok ,I dug all the dirt & gravel stuck between/in the "spring plate" and tube,then I cleaned the hella out of them with gas & CRC Brakleen, dried them down, masked off the bolt holes & tube & painted the strut hsgs, Rustoleum Gloss Black.

And painted the new tie rod ends, lower ball joints, GT plates, braced lower control arm and some bolts.

So I found the pass. side outer wheel brg blued a bit, so bought new Timken frt wheel brg kit, tapped old racess out, new ones in, greased the brgs .

Then cleaned off the hub on a wire buffer motor,masked it off & painted the backside of hub with Rustoleum 500*F Engine Paint(dark blue), it's drying now. This is passenger side hub,& I'll do the driver's side the same way.

I got the painted hub on, and...

OK, except for the brake pad backing shims, which I realized I had not yet ordered, I have the rest of the pass. side done, minus putting on the tie rod end. Wheel brg is now adjusted also.

Now, I'll do the driver's side the same way.

OK, here lately the weather has been bad, and not much progress.

I did manage to score a 240 diesel engine's Oil dipstick, and it has a blue handle on it, instead of a red handle like a normal B230F gasoline engine has.

Only problem is it's about 4 3/4" too short. Since I wanted to use the blue handled dipstick, I modded it.

I took a spare dipstick from a B230F, and cut it off about 3" from the top. Didi same to blue one.

Figured out just where to cut both so they'd overlap about 2". Ground the 2" area on both flat, so they'd mate together and have a smaller overall OD.

And then I brazed them together. Pics below.

9/12/10

First open hood and make sure your 240 has the big hole on passenger side radiator support wall .

First off, you remove airbox, open it up, and remove all of the temp operated preheat pipe "flapper valve"l inside the airbox.Bracketry, flapper & ALL. It pops out of little holes in airbox housing it mounts in.

Now clean the hella out of the airbox.

Now seal ALL the holes left in airbox from removal of the flapper. ANd the the deep " funnel shaped" hole in airbox side facing the front of car. Use Black PermaTex RTV Sealant.

Now find donor car, and pull the the plastic hoses/piping off on ithe OEM Volvo airbox off a 86-93 240, AND BE SURE to get the BIG rubber grommet and big C clip

that goes around the hole where accordian comes thru DS radiator support wall, from the airbox.

Now...On the driver's side I used the OEM Volvo parts(IE the 90* elbow, and the upright "snorkle" that has a 90* bend at bottom. I cut theupright snorkle toward midway in the upright, a littleat the time, until it fit in the 2 inch diameter(it's bigger on the bellmouthed ends) ABS plastic 90* "home type"water pipe. Have to "cut & try" by removing a little at the time. Use big, long straight cut tin snips made for heavy gauge duct metal.

I then used a little ABS plastic pipe cleaner to clean the parts where they meet, and then used a little ABS plastic glue, slid the two parts together. Make sure you have it all turned the right way here.

Then, I used PermaTex RTV Gasket Maker, to fill in the "bell" part of the 90* ABS elbow to the upright snorkle. Being careful to fill in the void completely, but making it look neat & professional.

On the Passenger side, I used a new IPD aluminum foily "Preheat pipe". Make sure you use one that is clean on the inside BTW, if using a used OEM one.

BTW,The OEM Volvo preheat pipe is made a lot better, but it's $100.00. Both are make to thread on the nipple on the bottom of the airbox. On the other end of it,instead of running it to the ex mani heat shield's nipple, I ran it to/towards an existing hole in the radiator support wall, that it on the passenger side. I think it's the hole made there for Rt hand drive car's airbox.

To connect it and make it look neat, I just used the OEM Volvo 90* elbow, the same one that attaches to the short accordian "tubing" that comes to the inside/thru the radiator support wall from the OEM Volvo airbox. This is all in the behind the grille area. It all fits in the passneger side hole on a 86-923 IINM. Mine is a 1991. Percussionist's 82 240 has the hole also.FWIW. 77,78,79 use a different set up and is even more easily modded & can use just one 4" ABS 90* elbow, I did this to my 79 245, helped a lot!

Now to connect the preheat pipe, to the other/big end of the OEM Volvo 90* , inside the engine compartment area, I used a 1969(IIRCC) 140 dual carbed B20, accordian "pipe".

On the 140 it ran from the plastic fliter/airbox, to the radiator support wall . I just so happens that is is the correct size on one end,to connect to the preheat piping , and the correct size on the other end to fit the big OEM 90* that sticks in thru the hole, into the engine compartment. I used a SS worm drive clampo to hold it there. And used silicone to hold it to preheat pipe..

I used some small malleble aluminum strappping I bought a Lowes, and cut, and bent/formed them to meet the ABS 90* elbows tops and tye wrapped them in place ,to the brakets, where they don't move & hit the A/C condender coil .

The aluminum reheat hose run under the radiator, and is fastened on both ends, and just sorta holdds itself in place due to it's stiffness. Same as Volvo did it.

The beauty of this mod is is uses mostly all OEM Volvo parts. All are easily found in the JY.

Pics below.

The existing pass. side hole.

Braket holding ABS 90*.

69 140 airbox accordian intake pipe.

Where preheat hose fastens to bottom of airbox.

Sealed holes in airbox.

9/13/10

The S to S brace is just laying on there for idea of how it'll look when installed, as it header pipe.

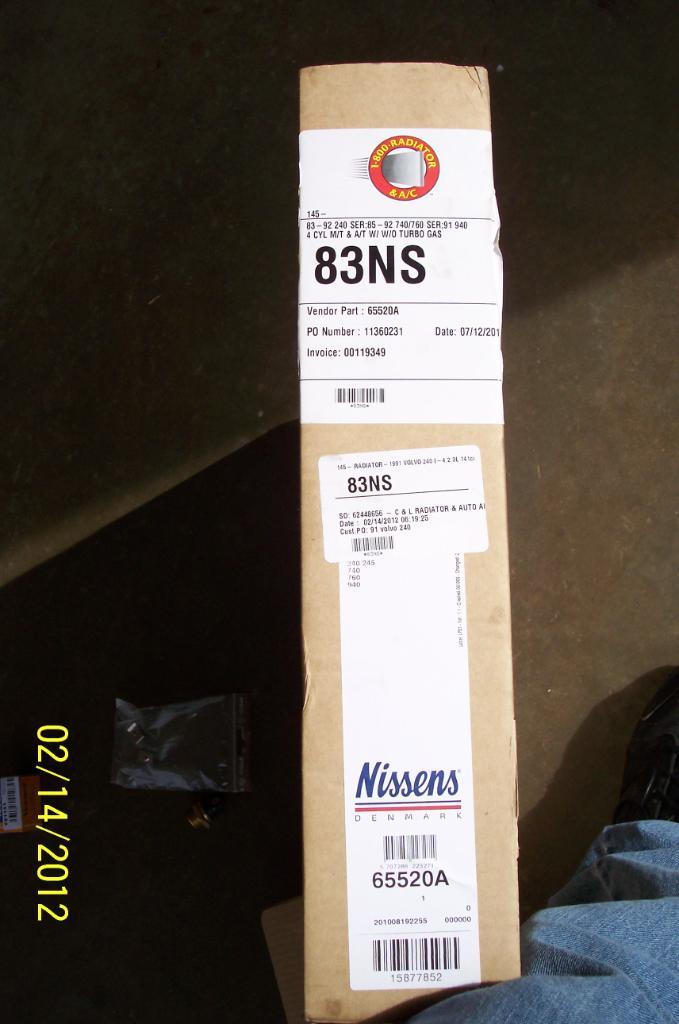

One hose clamp short of being able to fill Rad with 50/50 AF/H2O. It's on the way though. Now it'll be on to suspension/brakes.

Tonite's pics below:

Pics of modded lower n/a heat shield:

I removed the OEM 52mm OT,OP, VM,Vacuum gauges I had , & replaced them with VDO Vision 52mm gauges. Bought blue light bulbs and installed them in all the gauges too

I now have VDO VIsion 52mm OT,WT,OP, VM, and vacuum gauges, fully numbered.

I'd like to find a place to mount the OEM 52mm clock And a aftermarket tach. Still working on that.

Also , remember the "dual air intake" mod, using the preheat hose as an additional intact for the airbox?

I modded the "snorkles" today. Gained some ID to them. And now they'll face to the front of the car.

Where I joined the 90* elbow to the snorkles.

Masked off the 90, painted snorkles with Vinyl Paint, to make look better.

And on the car, still gotta make small bracket for each.

Made some soft aluminum brackets today. Material available from Lowes & lends itself well.

I used the OEM Volvo pre-existing holes that were in the top radiator/fender cross brace/support , and used some Volvo bolts that I already had. They are the black ones in far sides of pic, in last pic.

Used black wire ties to fasten bracket to 90* elbows. Elbows are pretty ridgid & should stay in place . Gonna remove, paint them black, & reinstall them.

Well, got the FW, C & PP on tonite/early this morning. Got the Clutch release arm boot & T/O brg on CR arm which is now on the frt. of trans.

Which BTW, is holding 2.7 qts. of Royal Purple SychroMax Synthetic trans oil and has a new trans mount bolted on.

Percussionist is coming by in a few hours this morning(A BIG THANKS to percussionist too!!), to give a helping hand sliding the trans in place, so as not to break the fragile CPS bracket.

I bought two long bolts, cut the heads off, ground them to a point, to screw into block, to guide the trans up & in, to make it easier/less a hassle.

Trans is in, thank heaven. Percussionist was instrumental in helping with the install. Another pair of hands is very helpful when installing a trans.

Still need to install CCable(can't see the end of pedal under dash...yet. Pretty well hidden on a 91 244 it seems. I'll find it though. Starter wires too.

Got the P/S & A/C comp all done up last nite. And the new CPS is in place. On to MMs & more odds & ends.

OK, tonite I got the new clutch cable on, along with the little rubber block & the big heavy "counterweight"on the release arm & the new throttle cable installed.

Should be all set in this dept. for a long time.

And good thing too, it's tight fit under the dash, plus with my eyesight not good as it used to be, it was hard putting in those clevis pins & retaining clips.

And also installed new brake & clutch pedal rubber pads for good measure.

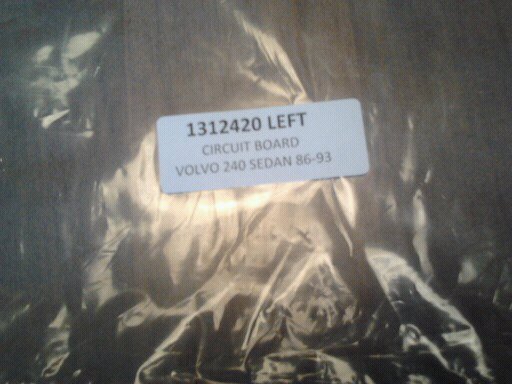

And BTW, the reverse light wire harness was irrepairable(to get it right)

So I ordered a new one. It is $105.00 dollars for 2 wires 2 feet long.. After the Parts guy brought me back to conscienceness, I paid for it.

Makes me think copper must be very hella rare in Sweden. So waiting on that before finishing up trans install & installing Drive Shaft and gear lever.

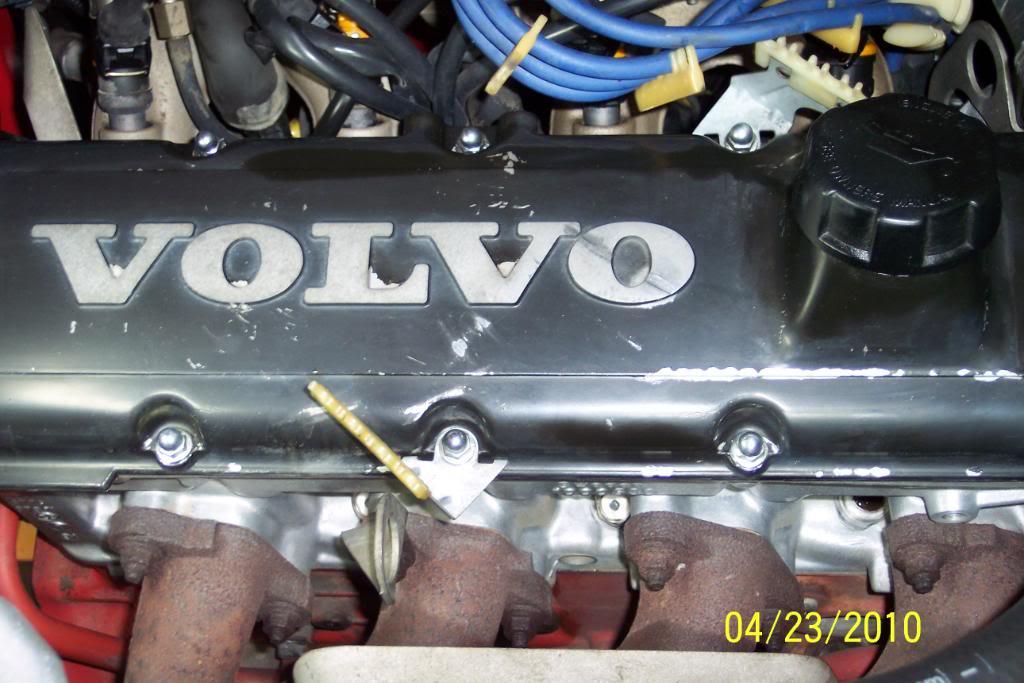

I decided to go for a little "bling". Now I have a shiny cam cover that is debadged. I'm playing around with different color OIL caps.

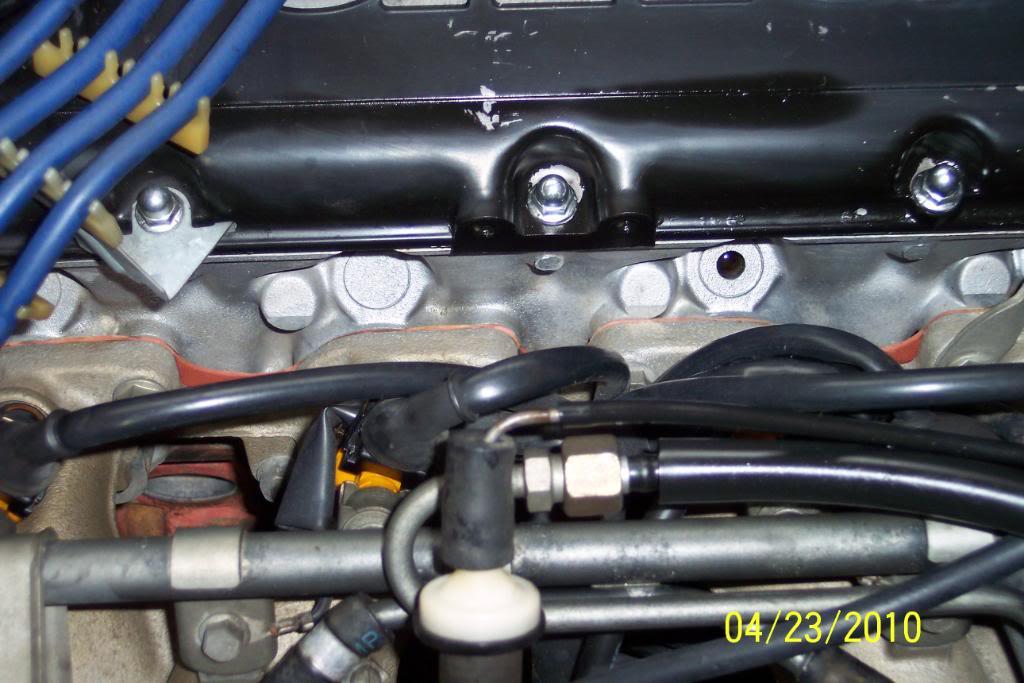

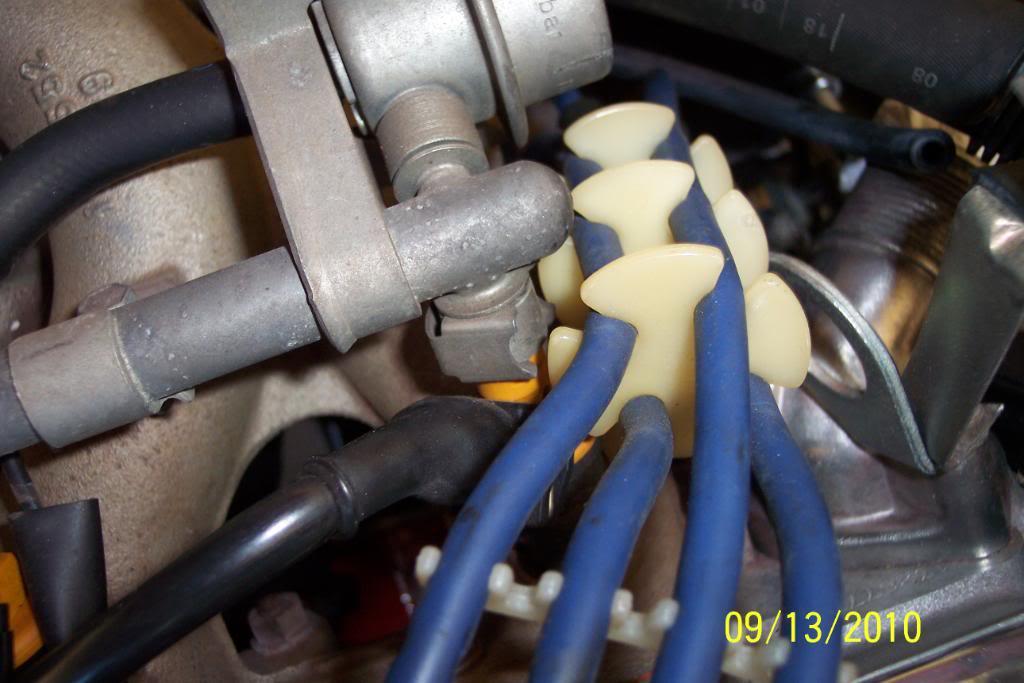

Got the cam cover on today. Modded the spark plug wire looms also,to keep wires & looms off the cam cover.I didn't want cam cover to get scratched by wires & looms.

Used all OEM Volvo parts here, just modded them a little. Came out right neat IMO.

And use the OEM Volvo spark plug wire holder, to hold the coil wire to inner fender, so it won't bounce around.

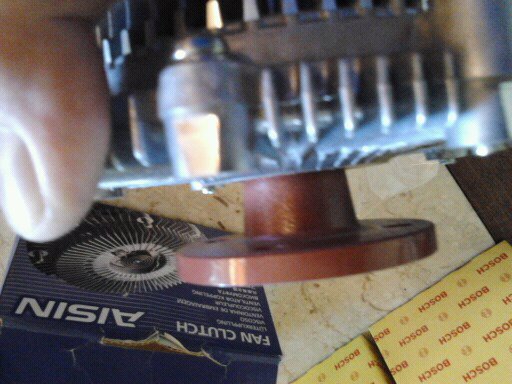

Well, got the new OEM Volvo Diesel MMs ,along with the turbo heat/oil shield for the pass. side MM. on tonite. Hopefully will make pass. side MM last longer on an N/A too. Also new oil filter with IPD magnet on it. Got 4 qtss of Castrol Edge oil too. And cleaned the cooling fan spotless last nite.

Hopefully the new early model fan/alt belts arrive next week. Having Alt /OP sender and top belt adjuster clearance issues. Going with the earlier 7mm longer belt. Hope it works.

And maybe the new OEM reverse light wiring harness will come in, and I can finish all under the hood & start suspension rebuild. We'll see.

Since I had bought those blue humped IPD radiator hose & heater hose clamps, I thought it would look better detailed if I painted the rest of the clamps on other things blue to match.

So.... I used a "model car" paint brush and some Rustoluem Spray paint & had at it.

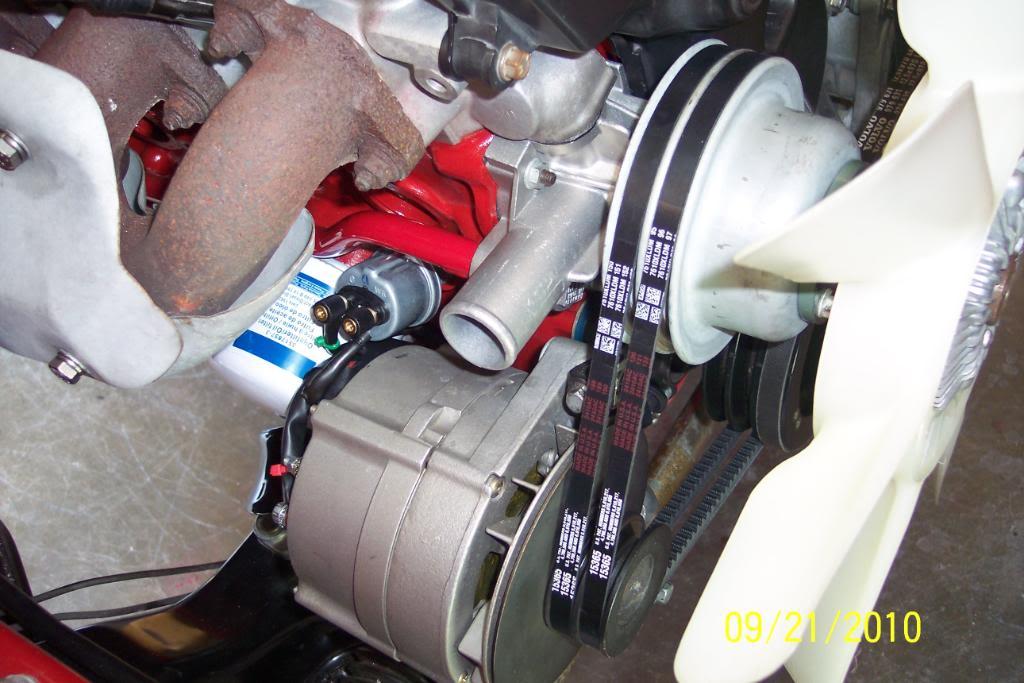

For some strange reason,I had a problem with the Alternator clearing the OP sender, with the OEM Volvo 9.5mmx 818mm alt/WP belts. Not sure why,but maybe Scantech HB pulley's grooves being deeper or shallower, or the IPD Poly alt. brkt bushings, or Hepu WP or a combo of one or more, sure which.

All I know is before I took it all apart, the OP sender cleared the backside of Alt, OEM 9.5 X918mm long belt was long enough & top Alt bolt cleared WP Pulley.

I even tried the early B21 9.5mm x 925mm belts, still too short.

So, after much refitting,hair pulling, and cussing , I found both sets of the OEM belts too short to let alt clear OP sender, and also the top Alt holding bolt was hitting the backside of WP Pulley. WTF? If that don't beat all! Maybe visited by Swedish Trolls?

So I decided that a longer belt would keep me from having to relocate th OP sender. Although I had purchased some Harley SS braided oil lines, just in case I did not find said longer belt.

So....after 4 hours of "belt hunting" today, I think I have found some that will allow OP sender to clear back of alt, and top alt bolt not hit the backside of WP pulley.

And which will still leave a little adjustment left in the Alt/WP belt adjuster. Have trial fitted it, and I think it'll cure the problems.

BTW the belts I found ,that I think will work OK, are O'Reilly's "Master Pro" V Belt, p/n 7365(& under that number is: 15365), belt width/length is: 10mm X 942mm OC (3/8 X 37 1/8). OC = outside circumference??

Funny thing is A/Z's 11 x 940mm belt was a bit too long. Go figure.

I am still unsure of what actually caused the OEM belts to no longer be long enough. Has to be HB or IPD Poly, or both. IMO. What a "long strange trip it's been".

Pics of alt/wp belts that appear like they are gonna work OK. For other's reference if/when they have same problem. FWIW.

Well looks like the belts worked out just fine. And I still have about 1 inch left in Alt's adjuster slot. OP sender clears Alt, as does top alt bolt clears WP Pulley. Clearance problem must have been the Scantech HB + the IPD Poly bushings. Tolerances "stacking up".

Percussionist came by to help me get the stuff ready for the Parts sale, but we worked on the belts/alt/A/C Comp/P/S reinstall/belt set instead. THANKS percussionist!!

BTW, does anyone know if those little screw on "barrell nuts" on the VDO Oil Pressure sender( holding the wires on) will stand the heat from the exhaust manifold WITHOUT melting? I need to know soon. If so, I need to get regular metal nuts.

Pics below:

Belt part numbers for other's convience FWIW.

5/10/11

Well it was too cold over the winter,and got sidetracked this Spring on landscaping in the yard.

But now I'm back on the car. Did this little mod. Remember how the plastic plate under the sun roof crank & the one that covers the mirror mounting place & the sunvisor's mounts turn a ugly off white/yellow look when they age on a n/a 240 sedan?

Also painted the white side of sunvisor too. I was not trying for the "ricer" look I just wanted something better than the yellowed plastic look and something that would look acceptable, so now it's "two tone" black on white.

And I painted those hideous gold chromated mounting screws too. Now they are also black & nearly now invisible An improvement IMO. [/B]And it's now different from the norm.

5/12/11

Maybe ya'll remember I had Avalanche Performance make my OEM Volvo shift lever into a "short throw shifter"?

This is the next small mod I'm working on...and when finished it'll look like this.

And I'm making them for sale,and I currently have a group buy going to have custom shift knobs with the M47's shift pattern engraved on it. We need a minimum of 20 buyers to get the custom made knobs at a decent price.

In this pic, that's a Hurst 5 spd shifter knob with incorrect 5 spd shift pattern on it.

But I needed a knob to go by to get started. I believe this idea was caused by a flashback to my Chevelle days. Actually ,I just don't like it when the OEM knob comes off in my hand.

So I've made a weld-on/JB Weld on adapter(your choice) , that will let the lever accept a shift knob that threads on, like a Hurst shifter or such. And a polished aluminum sleeve to cover the lever's serrations and a polished SS shouldered jam nut for the knob. Came out pretty well, IMO.

5/19/11

Well, pics probably look about the same, but I did finish installing my thread on shift knob adapter into the lever, & lever reinstalled in the car, and greased the pivot with that IPD green grease. Very stringy grease, so should stay in there longer IMO.

Shifter is done till I get a custom M47 shift pattern knob made.In the meantime it's a incorrect 5spd pattern Hurst knob. I want a custom M47 white knob.

5/28/11

I've had this done for some time. Old School Grille Mods.

6/11/11

Well, I rethought my additional air intake. I didn't like the way it was so close to ex. mani, and heatsoaking from bottom of radiator, plus it was long as hell.

I have been trying different set ups. Might go with this idea. Just a trial fit here. Still would like to use a 90* ABS plastic pipe elbow to catch a little more air. Have to see if that is doable as this is the same snorkle, but turned upside down. Need to source another snorkle and 90+ elbow to see.

This routing keeps the piping away from heat better, is shorter(only 3 feet long total, as opposed to 7 feet the other way) for hopefully more real "ram air" effect, plus it's lots lighter too.

Of course, again this is using all OEM Volvo 240 parts. I routed the hose through a rectagular hole ,that was already present in the center of the air dam/radiator "scoop" panel. I enlaged one side 1/4" or so.

Also...I'll have to notch/cut a U cutout in the bellypan to run this set-up. And make a seal for it. I also plan to slide a piece of 3.50-19 motorcycle inner tube over the preheat pipe to further insulate it, and protect it from punctures where it goes through the scoop panel..

We're talking about the snorkle on the left here...... Right one goes to airbox as it normally does...............................

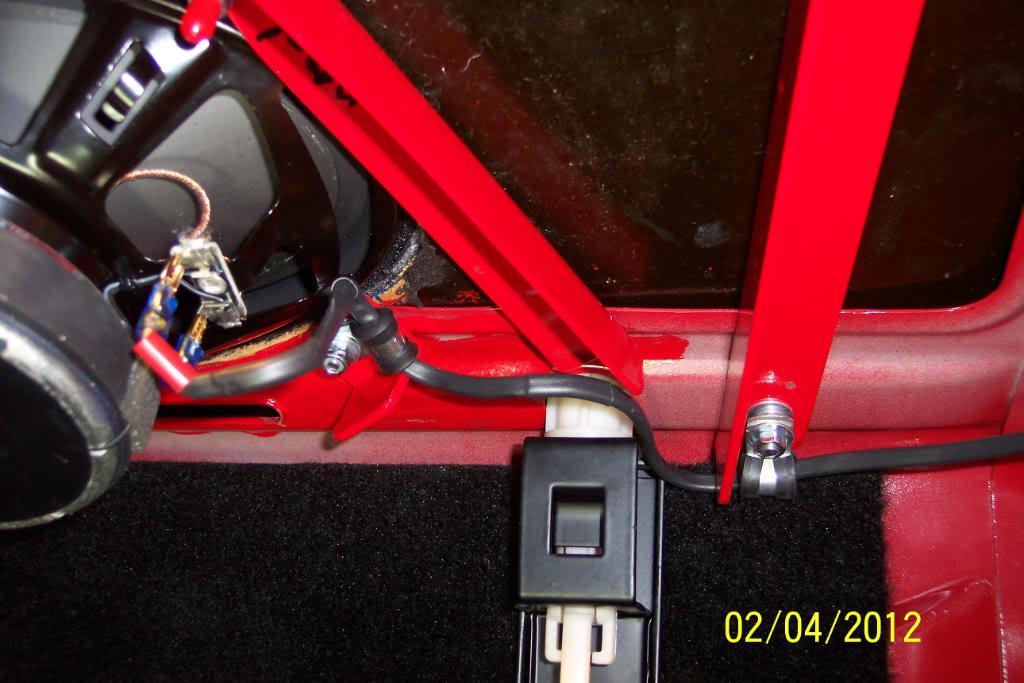

And the other day, I decided I wanted some interior floorboard courtesy lighting. I used the "Fasten Seat Belts" bulb socket & bulb as it never gets hot.. Wired two per driver's side, two passengr side and hid them behind the flared heat duct that protrudes down through the underdash felt pads. And wired them to the door jamb's light and key buzzer button. So they work with the dome light on the delay timer.

Then I thought I'd also like to have the same lighting but on a manual on/off switch. So I found a rocker switch with rounded "body" and a yep, you guessed it, blue LED.

Mountd it on the bottom forward left side of the bottom of the steering column's cover/box.

So, now I have delay timer entry/exit courtesy lighting in the floorboard area. And courtesy lighting in the floorborad area while driving if I so wish.

Mine's a 1991 244 so it hs the "knee bolster, therefore I let the lights hang down further on driver's side, as the kneebolster still keeps them from view. On passenger side I tied them up a little higher to keep them out of sight. And your feet do not hit them either. Just tie wrapped them to the flared heat duct above the felt pad. Looks & works great. Volvo shoud have done this IMO. Hopefully this will save a doopocket when new passenger gets in up front too.

And passenger side, delay timer lights on.

Proof ya can't see them when ya look down.......blue wires are showing because this was before I buttoned it all up

And how I made each of the four harnesses up. Easy peasy.

6/15/11

OK, I've been sorting out the lasest mod to the additional air intake to the bottom of air box's preheat hole.

I opened up the hole in the air dam/rad air scoop a little more, and used an old Harley 19" inner tube to insulate & protect the preheat hose. I now need to make some type of bracket to help hold it. Maybe just tie wrap it in place. Not sure yet.

I modded another snorkle I had in my vast collection of them,and ABS glued and RTV sealed another 90* ABS elbow onto it. I'll be using a 1982 242 Turbo silicone hose to join the preheat pipe to the new snorkle.

I'll also tie wrap both ends of the inner tube to keep water/dirt from finding it's way between the inner tube & the preheat pipe.

This is a mock up, but pretty close to what it'll look like after I adjust the snorkle /90* elbow positioning, paint it's mounting bracket black, RTV the turbo hose to the preheat hose & clamp it, and the snorkle..

I think this is going to work just fine after I cut a U shaped hole in the belly pan to allow it.

What I used..........

And how it fits........

The Harley 3.50/19 inner tube insulation. Well whattaya know, it has a blue stripe on it. Matches the other blue items well IMO

A look from a few feet back....

OK, finished the driveshaft rebuild. Rebuild consists of: 1) New Corteco guide bushing, 2) New FEBI/Bilstein guibo/flex disc, 3) Euro center support rubber (I know gonna go with it), 4)New SKS center support brg, 5 & 6) 2 new Precision/Federal Mogul U joints greased with 7)GreenGrease Brand green grease(naturally) 8) Painting the completed driveshaft .

I wiped off any & all excess grease on outside of the new U Joints after greasing them

Then washed,cleaned, degreased the driveshaft with Brakleen.

Then sanded & cleaned with Brakleen again.

Masked off the grease fittings with tape, masked off the Guide Bushing with tape, and masked the Center Support rubber & bearing with tin foil & tape

Then painted the drive shaft & also painted the U Joints & yokes rather lightly for rust prevention.

The paint I used is Rustoleum Professional High Performance Enamel in Semi Gloss Black.

Should look nice & somewhat OEM like when it dries.

Pics below;

6/21/11

OK. Are ya'll ready for the DOUBLE BARREL? I finished the second cold air intake ducting. I think I like this set up much better than the 1st set up I had on it.

I'm going to "pan in" around the hole in the belly pan to cover up most all of the hole that is cut a bit too big.

I plan to buy a new belly pan before too long. When I do, I'll use the panned in old belly pan, to cut a neater, better fitting hole around the piping in the new belly pan.

I'm considering moving the two horns somewhere out of the way of the A/C Condenser and radiator.

Seems other have done this. Anyone got any tips of where else to mount the horns outta sight?

I had to add another OEM plastic piece to the aluminum pipe to make it long enough and to use the Silicone Turbo Hose to join the 90* elbow piece to the aluminum hose. Here's a pic of how I did that. Not beautiful but it works. Used blue RTV as I happened to have a new tube of it.

With the belly pan on.....

6/22/11

No, I used to have a lot of ducting for the air to travel through. the right hand side on only has less than 1.5 feet. The left one is only 3 feet long, now.

The idea here is the one OEM snorkle's ID is 1 7/8" diameter in smallest place(see pic below). IME this is not large enough to flow enough air at Hi RPM . Especially with a hi perf cam later I have planned for later on, and the 2.5" exhaust I'm going to install.

Hell a Harley carb throat is that big. And it's only 74-88 ci

This set up will allow 2/3-twice the airflow. And does away with any chance of preheat by ex. mani air, and with 90* elbows should provide more, cooler air to engine. And possibly a bit of ram air effect at higher speeds.

And yes it works. Already did this some time ago to my 245. Coupled with a free flow exaust it does make a very noticeable increase in acceleration. And with a better cam later on, it'll really help.

Don't believe me? try it for yourself........and remeber most 86-93 240s are breathing through this restriction, and were never built with hi perf in mind in 1991.

Ok now that we have that cleared up..........

I wanted to move my horns to a different location to allow better airflow to the A/C Condenser coil & rad, seeing s how it was cramped with 2 intake hoses & two horns in front of the coils. I fabbed a stright bracket & mount it to the outboard end subframe rail where the bumper mounts to the bumper shock.

Then bolted on the 2 horns to the straight bracket.. I had to ue a longer(1.25) 8mm bolt. The OEM wiring harness for the horns was slight re routed & was long enough as it was. Cool.

And also cleaned & painted the verticle support behind the grille semi gloss black.

So... from this.......

to this............

6/23/11

I made a bracket that fits & fixes the problem perfectly. Here's pics of the making of it. The rubber pad is off a 240 frt license plate bracket. I cut & ground off flat the tit off the back off it.

I refitted the grille. It clears AOK with the 90*ers pulled out as far as possible now. So no problems here now. And looks more pleasant without the ugly horns showing through the grille.

7/3/11

Well, I finally got my a$$ started on removing the LTAs(Lower trailing arms for Matt) and I now have one of those big PITA OEM bushings out of the diff's bracket for them. I used my homemade tool for this.

I made it when doing same susp work on my 79 245 about 12 years ago. Luckily I kept up with where the tool was. And it works pretty well too.

I used several of the small jackstands. One under pinion on diff, one under DS rotor hat, one under axle hsg on PS. And Floor Jack under diff's carrier end. Pass Side Axle JS is soon to be swapped/replaced to to rotor hat. I am leaving the torque rods on, to keep diff located/fromtilting/moving while I do other bushing .Hopefully this set up will work OK. First time I've done it this way though, Usually do one at the time.

Here's a pic of DS LCA bushing I removed (the big one in diff brackets). I'd say it was past time for new rer susp. bushings . Wouldn't you?

These are not the worst condition ones I've removed for rear of 240s. These aren't toooo bad, but still should be replaced.

I don't have a new OEM Volvo bushing. The pass side bushing appears to be in much better condition though. (see pics below) now have

I can post pics of how I have the diff/rear axle "suspended" for LCA & it's bushings, removal and the homemade tool I used to press them out if that would help any.

I'm using SuperPro poly to replace them. The later 240 OEM bushings appear to be made weak /er for a smooth ride to me.

But I could be wrong........ I imagine the Volvo engineers had their reasons. Seems I remember someone said, that they should articulate some.

FWIW, the IPD adj panhard rod & adj torque rods come with poly bushes already installed. So I actually only need to install the 4 LCA bushes. Yay! LOL.

And FWIW, these were OEM Volvo bushes I removed. Says VOLVO on both of them , & then I notice the lettering telling they are made in England .

I was expecting them to be made in Sweden, or Germany. I presume the "DOWN V NED" marking is actually telling installer "downed" with arrow pointing to the downward position bushing is to be installed in the diff brackets/LTA.

I expect this is due to the fact position of bushing is important . Due to the fact the solid rubber portion should carry the downward load, and the hollows should face fore & aft.

Next step is to wash the undercoating off the lower control arms (LCA), and cut the plates I'm going to brace/box them with. Then get it welded. Still deciding how much bracing/boxing I really want to do on them.

Left = dvrs side, and right = pass. side in pics

Necessity truly is the Mother of Invention...........

This is for the big LTA bushings mounted in those ears on the rear axle hsgs.

And these two items, along with my homemade 20 ton press with a 40 ton sized frame, presses out the small bushings in the LTA, on the LTA's small end.

I save any type of round steel or aluminum, brass part, as it's nice to have things to make specialty tools from and it usually comes in handy, & saves a lot of time hunting things that'll lend themselves, when it's time to make a tool.

Pic of how I used the jackstands to support diif & help keep in alignment , enable me to remove both at once, & to help ensure re -installing the LTA will be relatively easy.

Probably overkill, but I'd rahter do too much than not enough & wish I had,

7/6/11

Well guess what! Spray Can Undercoating is hard to get off your hands & out of your hair.

Did this.............colorful huh? LOL

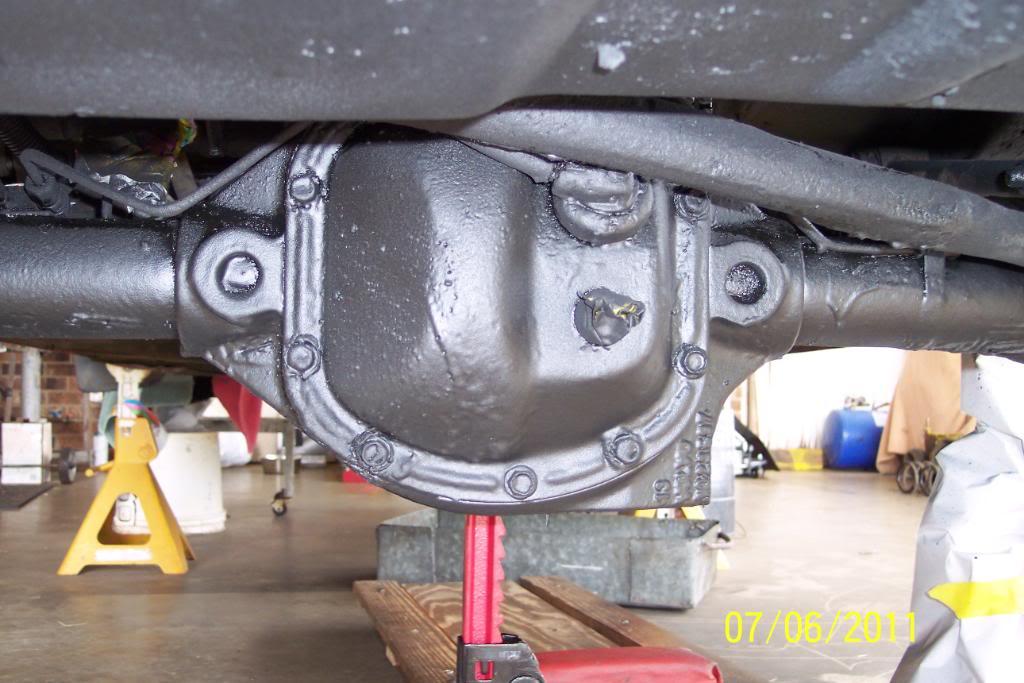

rear

Gasoline tank & rear axle is now undercoated. Next the floorpan..........

And by the way, I discovered, then uncovered, then recovered the OEM Volvo proof on the diff ratio.........

I wouldn't build a hi perf turbo engine unless it was from the ground up with the right/good stuff.

I was gonna build one for the 242, but sold the car. It'd only make me get myself in trouble anyway

Plus I decided I'd rather spend it on something else. I just want a clean, good handling n/a daily driver with maybe 25 hp more than stock. I am planning to be driving this 244 for quite sometime. So I want to do "rust prevention" steps so it'll stay solid.

Turbo is cool, but I'm better off without one most likely.

7/7/11

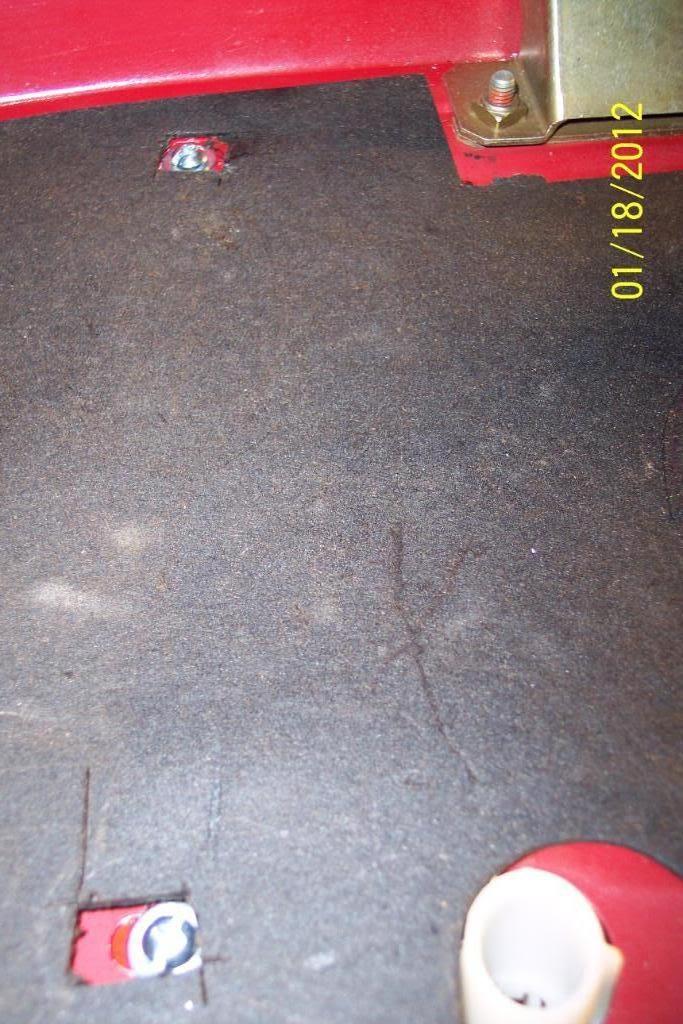

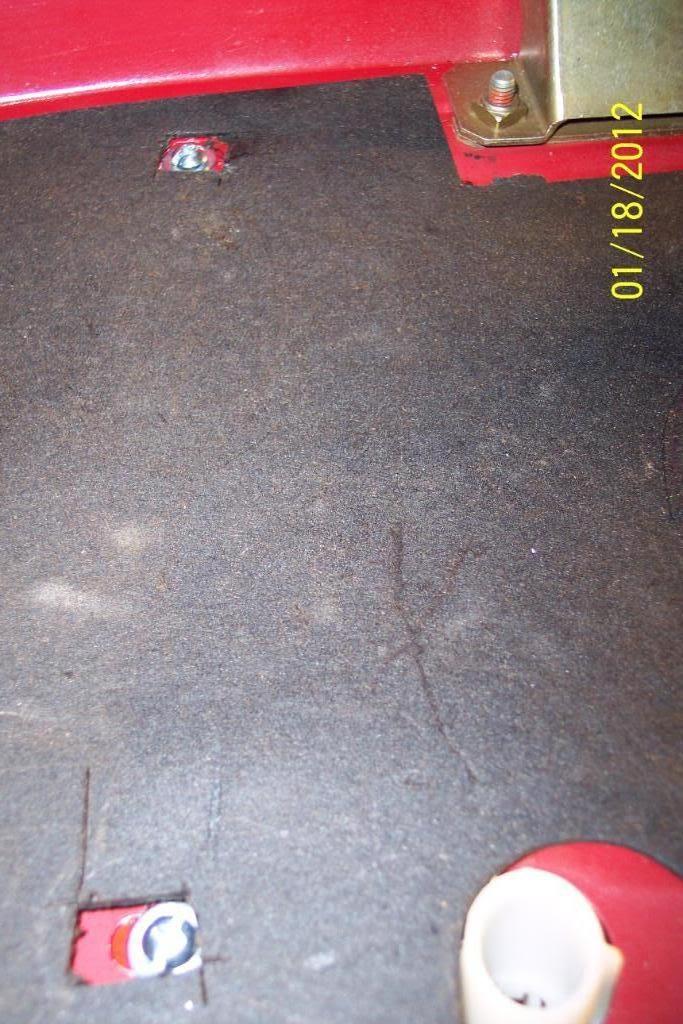

OK, got the floorpan undercoated. Took a lot of masking paper & tape. And a bit of clean up afterwards. But it is finished for the most part.

it was still pretty well undercoated as it was to start with, but I think the added undercoating will help protect the original undercoating and add a measure of rust protection, plus it does look much cleaner now, which is always a good thing.

So now the car is as clean & neat on the bottom as it is everywhere else. YES!

Pics below:

7/8/11

And I finally got around to doing what I call detail freak's details...or as Homer puts it, "Gawdy Blue" accents on the diff's drain & fill plugs.

I just didn't want them to rust further, and I hate to get the undercoating in my sockets and/or wrenches, so I painted them blue.

I like the fact that they are easily visible now too. I told ya'll I'm a detail freak. Ya'll believe me now??

7/15/11

Got the LTA bracing plates cut. Both LTAs are at the welders as I type. hopefully get 'em back tomorrow. Painting & undercoating them is next.

I decided to brace them as shown in pics below:

The top will be braced like this......

Close up of "small end" bracing......

On the bottom of the small end I'm going with this.

And the bottom will be 'full length" braced. I'll drill a weep hole in the lowest spot to drain any water than gets inside the LTAs, when I get them back from the welder.

OK, I re thought my bracing due to recommendation from John V. I went & pick the LTAs back from the welder. luckily he had not welded any braces on yet. Shoulda seen the 51 Chevy that was there. HOT ROD mag car for sure...

NOW...back to the build.........I remade the 1st top side & bottom side brace on small end. Pics tell the story.....

I received the Custom thread on knobs with the custom,OEM Volvo/M47 shift pattern today!

Naturally I had to immediately install my white custom knob onto the adapter I installed into the lever a while back.

After I installed it, I do believe I had a "flashback" all the way back to 1975 during my 1969 Chevelle SS 396 with Muncie M21 4 spd. and Hurst shifter days ,while sitting in my 240. ..............

I received the Custom thread on knobs with the custom,OEM Volvo/M47 shift pattern today! Incidentily, they were made by Bruce Roosa of www.koolknobs.com.

Bruce Roosa is the man that made all of the custom made dash knobs & gearshift knob for the old & highly customized Cadillac Show Car "Cadzilla" .

It is owned by Billy Gibbons of ZZTop fame. He also makes them for a lot of Hot Rods and other show cars as well as custom knobs for many NHRA Drag racer's personal cars.

The quality & craftmanship of these shifter knobs is unsurpassed, and totally 1st Class! They all look Simply Impeccable!

Here is a pic of the other "Smokeyfan1000's Custom M47 Shift Pattern Shifter Knob Group Buy" shift knobs that some other Tbers ordered.

I highly recommend Bruce Roosa's work and anyone desiring a special, made to customer's specification, custom shifter knob should contact him at his website www.koolknobs.com

He will make you ANY KIND of shifter knob you want.

7/17/11

Well, after a rethink, I have changed the bottom, front small end bracing. Instead of being welded on the inside of the small end LTA slot, I made another to be welded on the outside of the bottom small end. I like this way better as it fits the slot in LTA better. And offers more strength IMO.Where it wraps around the eyelet, it'll be welded on both sides to the eyelt & LTA.

Then there will be a short piece welded over the butt joint of where the top & bottom braces meet, and it'll be welded on both ends & sides, & to the other two pieces. That ought to hold the eyelet it there, By Golly!

I'll take all this stuff back to the welder tomorrow morning. Hopefully it'll get welded by Thursday or so... Pics....

7/19/11

While all the License dael was back in '97, it's still cheaper to do the speed limit. I'd only consider acting up, in the country, in sparely populated area. Not many left either.

Got lucky & LTA are weldd & back in my possession. Here's pics of the fully welded/braced LTA. I think they'll take anything I can dish out...and then some.

The final braces weighed about 2.75 lb. The OEM LTAs weighed about 9 lbs.

They now weigh 12.5 pounds each. Both weigh figures acheived on Bathroom scales though. So just the welds weigh about 1.25-1.5 lb..

That for those that were curious as to what everything weighed, and now weighs.

Pics below:

Small end's bottom brace.

Small end's top side brace

Bottom brace

After I debur & paint them, I muight be able t weigh them on more accurate scales ,at the shipper I use .

7/20/11

I cut & chamfered the access/weep hole in the bottom brace in shock mounting area of bottom. I used a hole saw. Looks good to me.....

Cleaned them with Brakleen & will primer them with Rustoleulm white primer, then paint & undercoat ,em

Pics of weep hole.

It's also for access to bottom of shock during shock installation. It's no larger than the hole in the YoshiFab bottom braces.

Got them cleaned & primed with Rustoleum White Bare Metal Primer.............. Might paint them light grey as John V Outside Agitator suggested. Dunno yet...

OK, I dropped back the other day, and removed & painted the 2nd CAI I made. And cleaned off the modded OEM Intake pipe. Also found a looonger black tie wrap for each one, for a neater appearance.

Anyone know if paint wil stick to the Turbo Silicone Hose? I'd like to paint it flat black also, but unsure if the paint would disssolve/damage the Silicone Hose.

But.. for now..looks like a little neater/cleaner install now. And when grille is installed is almost invisible. I'm thinking about removing the VCOA plaque, or moving it to another place on grille.Pics..

7/21/11

I painted the LTAs....... Black...at... High Noon, ...for a Western Effect.

I like to paint all my parts except the engine and brake calipers ,with Rustoluem Spray Paint.

I used Rustoleum Semi-Gloss Black over the Rustoleum Bare Metal Primer on the LTAs .

Since all the extra bracing makes it very difficult to get spray the paint on the backside of the top braces and down into the small end, I used the World Famous "S.T.I.R. Method of Spray Painting" . I'm sure you're all very familiar of the S.T.I.R method right?

Luckily the small hole in the taper end, and my round weep hole did give me enough of a place to shoot paint through them & it helped a bit.

I expecting that the coat of primer plus the S.T.I.R. Method coat may make it a little difficult to weasel the shock, it's spacer & the diff bushing in. I'll have to wait till they dry, to see.

Yep, the LTAs are now, as black as a Jug full of Midnight....Pics...

7/25/11

Well, why I've been letting the LTAs bake in the hot NC Sun to dry fully, I installed the IPD Lower Chassis Brace. It was quite an easy install & only required two 3/8" holes to be drilled. Luckily I have a right angle drill and a new bit which made it go all the easier.

And there is plenty of room to install and remove the n/a header pipe without removing the IPD Lower Chassis Brace. A big plus I think.

However, I am seriously considering sawing off the 1/4" of threaded bolt that protrudes through the brackets & the nuts, to gain an extra 1/4" of ground clearance.

I'm not very fond of the bolts sticking down 1/4" more than needed. recipe for possible problems if they hit something someday, IMO. I plan to loosen them, and put some blue LocTite on each bolt/nut also, then retighten them to 20 ft/lb as IPD suggests..

Pics below:

7/26/11

Well, I flipped all the bolts over except the crossbrace bolts. I sawed them off,.. I reinstalled the bolts with blue LocTite on them & torqued tham all to 35lb.

Then I painted the bolt heads & nuts with Rustoleum Semi-Gloss Black. Looks mich better & I have 1/4" more ground clearance this way.

I also added a silver IPD decal for a little extra coolness. Pics below:

I installed the LTAs small end Super Pro Poly bushing in early this morning (read 3:00AM), after installing the IPD Lower Chassis Brace up front.

Masked off the small end polys, and undercoated both LTAs with 3M professional Grade Rubberized Undercoating. Again using the STIR method on the small end of LTAs, but a nice even, run free coat everywhere else.

I'll have to let the LTAs set up/dry /cure for a day or two now. In the meantime, I'll install the LTA's large bushings in diff brackets. Then take care of mowing the damn yard again.

7/27/11

Volvo Porn....My Tool In Action....... otherwise known as LTA/Diff bushing Installation

7/29/11

Since I'm waiting on FCPG to ship my big LTA bushes, After I installed another steering wheel( I have a few), as the one that's been in it was actually out of my 79 245.

Cleaned/washed new wheel. Then I thought I'd go ahead with the lacing/install of the

new Wheelskins Black Leather Steering Wheel Cover I got from IPD .

Instructions say 1 hour install time...Big Lie. Took me around 4 hours with ciggie breaks.But I took my time so I could do it right. FWIW, it's not hard to do just an aggravating, time consuming, repititious job requiring patience, or as in my case, a lot of ciggie breaks.

It fits very well & looks waaaay better than the 13 year old one that was well worn & was originally on my 79 245's steering wheel that's been in this car. Then Armor All-ed the Interior a bit.

I do love the way the Wheelskins Black Leather cover makes the steering wheel's rim diameter larger, as it fits my hands much better & I find it much more comfortable.Pics.

I wanted something different from the run of the mill/everybody's got one plain jane 82-89 OEM 240 horn pad . Yet I haven't made enough money yet,to buy a MOMO or similar, 3 spoke race type steering wheel

While I like the '78 242 GT horn pad's "simulated spoke pattern" , I still disliked the orange/red GT emblem in the center a great deal ,because it doesn't go well with my 240's interior.

I just spent the better part of today modding my 1978 242GT steering wheel pad. It's something I've been thinking about for over a year. I have been looking high & low, for an appropriate way to do away with the old, faded, and unbecoming to my 240, red "GT" emblem in center of the 1978 242GT steering wheel center pad I have.

I wanted to mod it in such a way, so as to make it appear as if it was possibly an OEM Volvo option. Yet,I wanted something inexpensive I could use to mod the GT horn pad.

Also.. I wanted it to be a more modern,a more unique, but still understated, yet still classy & exquistly tasteful appearance, than what the '78 242 GT horn pad already had. And it would have to be something no one else has ever done/ had.

So....... I already had some stereo shop grained black ABS sheet plastic left over, that I thought would lend itself perfectly for replacing the original red GT background in the GT horn pad. But I still need something to use for an emblem. So, I only had to look as far as all the Volvo hat pins & lapel pins I have, (quite a few) and decided on the one in the pics because..........

Since my last name begins with "R".....

Since I like the Volvo 240 R Sport look/ tried to mimick the R Sport Rally car look by mounting my Hella 500FFs on top of the front bumper......

Since my suspension is modded to somewhat of an R Sport spec equivilent..

Since I bought this attractive little R Sport emblem from IPD about 1 year ago, that is a simply beautiful chromed "R" in a perfect size....

And lastly because I'm a "Detail Freak from Hell".......

I chose to do this........ And I think it came out simply fantastic too...... I can't seem to quite catch it's true appearance. It's under the car port, and can't roll it in sunlight. But here's daytime pics....

7/30/11

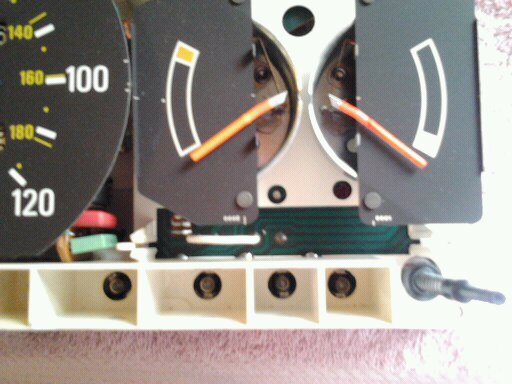

Don't know how many have ever noticed that on a 1991 240 sedan(and wagons I presume..), that the blue colored "Hi Beam lights are on" indicator, doesn't tone down the white light behind it very much. Or maybe mine was faded badly.

Anyway..It has always blinded me a little & bothered the hell out of me. On older 240s with M46 , the OD light is same way.

I took a spare IC I had, pulled the backside off of it, removed the colored warning lights strip and cut the blue hi beam indicator off the colored strip. I left the hole where it fits on the peg that locates it on IC.

I placed it behind the one already on there. Muuuuch better. I can tell hi beams are on, yet it's not too bright & no longer blinds me. A big plus for nighttime driving IMO. I've done the same deal , in the past, on my 1979 245's OD indicator light.

Sure.. it's a silly small detail. But it's agravated & blinded me for over 4 years now...ah ah.. no more!

Here's a good pic of it.........

8/3/11

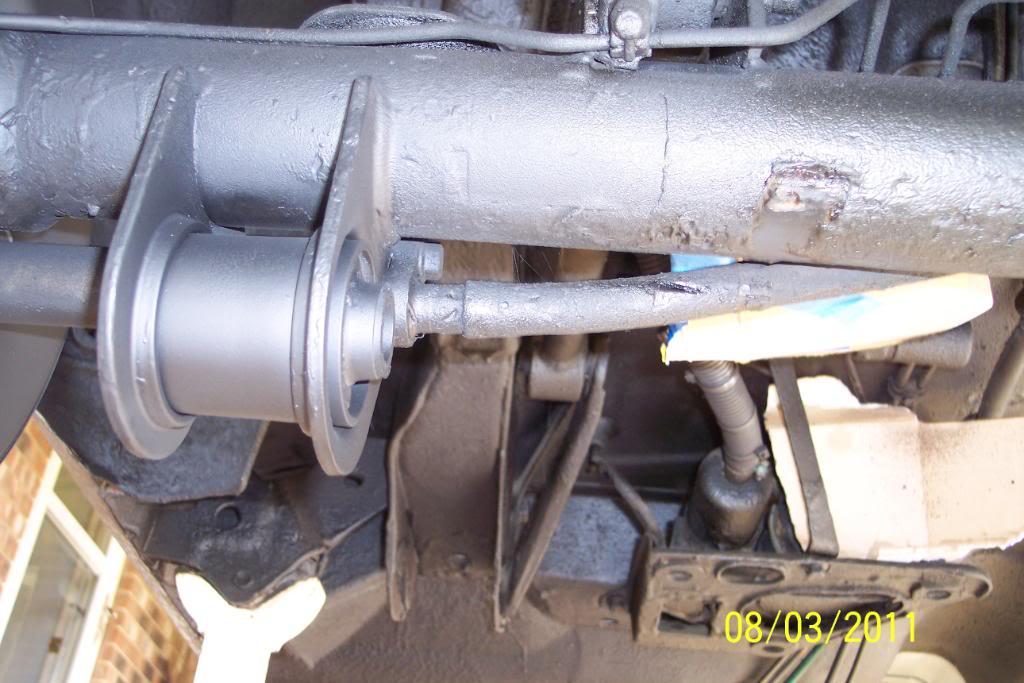

So I have the FEBI/BILSTEIN LTA bushings in, now. The poly just did not suit me for this big end applicaton.

I painted the exposed parts of the LTA bushings to keep them from rusting, as well as the brackets.

Now....I'm looking under the car,& everything is just so damn clean.......wait.....except the little part of floorpan between the muffler heat shield & rear bumper. which I undercoated promptly.

Then I happen to gaze at & see the end of the diff's rear axle housings & the flange on the end, as well as the disc brake backing plate/shields, were sorta unsightly looking . So I masked off the brake calipers, and commenced to painting those said parts.

Now... anything & everything, on the bottom of the car is spotlessly/ you can eat off of it clean. Literally! WORD.

I'm beginning to wonder how I'll ever get the courage to drive it in the rain & snow now.

Pics below.............

8/5/11

Hot diggity dog! I now have the rear suspension parts installed. I still need to check & torque all the bolts to Volvo's specs, but it's all there & bolted on or in , as the case my be.

And I need to touch up a few spots of the undercoating, and "spot spray" undercoating on a few bolt & nut heads, and possibly paint a few bolt heads & a few nuts with a modeler's brush and paint . I'm going to have to mask carefully for this touch up.

For the Record.....

This includes the following:

Braced,Primed ,Painted,& Undercoated OEM Volvo Lower Trailing Arms

IPD Adj Torque Rods/w/ blue poly bushes

IPD Adj Panhard Rod/w/ yellow poly bushes

IPD Rear Lowering /Sport Springs

IPD 23mm Rear Sway Bar

Bilstein HD Rear Shock Absorbers

Next thing to do, is , possibly give the rear ATE Brake calipers an uplifting additional quick coat of red Dupli-Color Caliper Paint, then, install the new rear Brembo Brake Rotors & install the EBC Green Stuff Brake Pads with shiny, new anchor pins & clips.

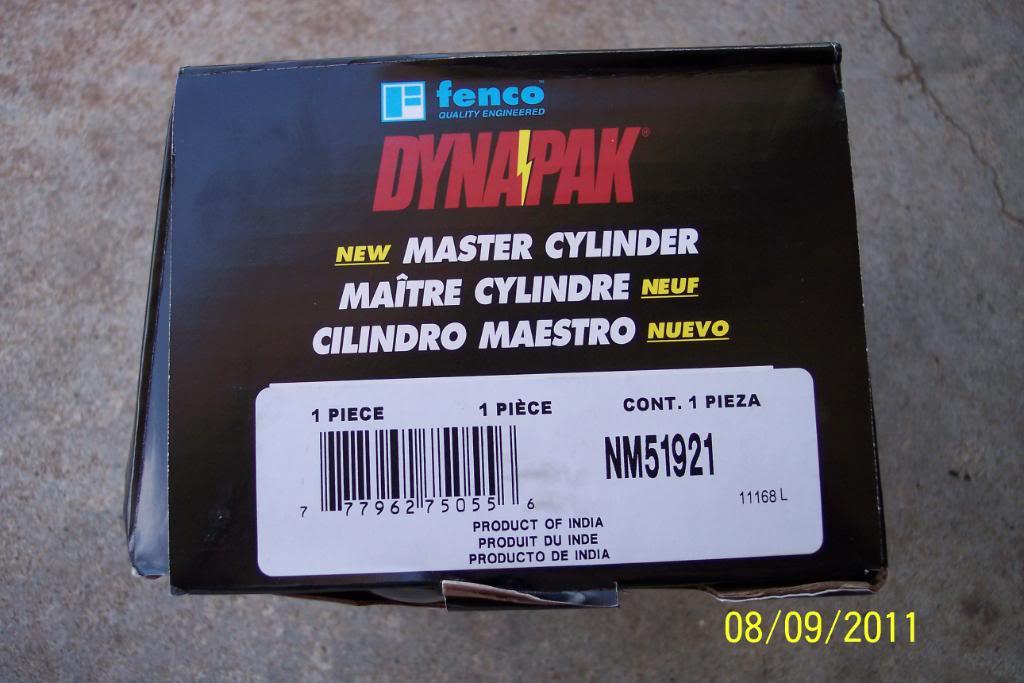

Then I will install a new Fenco Brand Brake Master Cylinder, and then, purge the entire brake system of it's old brake fluid, by bleeding the entire system with ATE Super Blue Racing Brake Fluid.

I have a plan in order, to keep all the bled brake fluid off of all my pretty, newly installed painted parts.

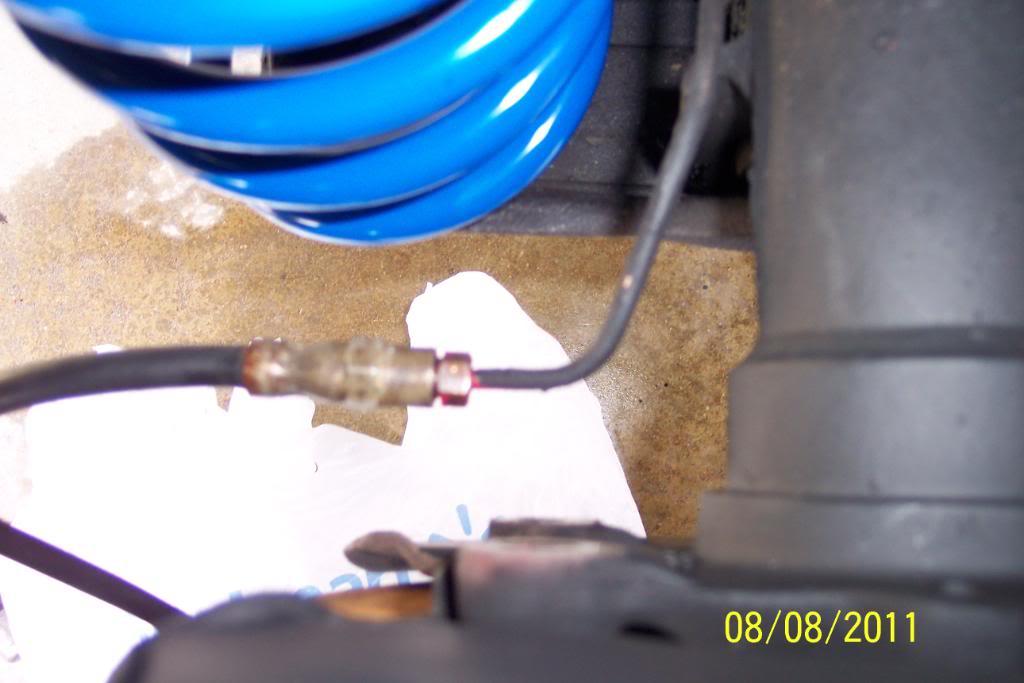

It involves clear hose, a few rags and plenty of tin foil.....and I'll cover that scenario with pics, when I begin it. It worked well with installing the IPD SS Brake Lines on the front of the car.

Pics...

8/9/11

I removed the rear calipers, cleaned all the caked on brake dust, on the inside of the housing where the pads reside, masked off the pistons & seals . Then I painted them with red Dupli-Color Caliper Paint. I'm allowing a couple days for them to dry fully, in the Sun.

I also bought a new brake master cylinder. It's a FENCO Brand, a new unit not a reman/rebuilt one. Box says a product of India, but when I opened the box, the Master Cylinder is in a plastic bag, with a sticker on it that reads..Made In Italy.

I used one of these on my 79 245 back in late 90's and it's still holding, so IMO these are good master cylinders. It has a somewhat shiny and silver in color, special anti rust coating on it, and should brighten up the engine compartment a little more. Hopefully it'll stay this way for a long time. Looks better than the black paint on the OEM one , I think.

I will have to swap my 1991 triangular/with fluid level wires/sender OEM reservoir, onto this master cylinder though. This new MC has the older 240 style rectangular one. Shouldn't be a big deal IMO. Pics below:

While I have to admit this is turning out a bit colorful, I just figured the finishes on the blue IPD parts, was most likely more durable than any paint I could apply to them afterward.

And most of the parts are/remain in, the color they were painted by the manufacturer(such as the IPD parts & Bilstein HDs) So other than hose clamps,the IPD sway bars(originally gold cadmium plated) & brake calipers, I haven't really painted much of anything else. The blue susp.parts came that color

So I just went with what color they were. And bought/painted, or modded, a few other small/minor parts to match/blend with, the IPD ones, such as the hose clamps and oil dipstick handle. Then finished the blue theme with the IPD Silicone hose kit.

I figured that at least it would have a "color theme" instead of many different colors for each part, and it would look better this way, rather than 14 different colors, or all painted black. Plus the blue is one of the colors used in Volvo's logo. At least it'll be different.

I am applying undercoating to most of the rear suspension bolt heads & nuts, so they won't rust, and re-painted the four sway bar mounting bolts, on the "sway bar side" to better match the sway bar's shade of blue.

After looking at a lot of pictures of Group A 240 race cars, and other 240 race going cars, I noticed they usually had a "color theme" of some sort. And I was going for ,somewhat ,of that appearance, and the appearance of a "what if Volvo had made a n/a R Sport 240 version".

Though it might not be to everyone's taste, at any rate, I am having fun, and I am modding the car as I want. And I feel that is the main objective of modding one's car, and what it's really all about.

At least it'll look somewhat sporty. This car has huge sentimental value to me as well. And has a interesting story behind it, on the drive home after purchasing it, which if I was to share with you, you most likely would not believe .

I've wanted this 244, since the first day I laid eyes on it, when it was new, in 1991.

8/11/11

I sprayed some 3M undercoating into a empty cake icing container, and used a modeling brush to apply it to most of the bolts/nuts/large LTA bushing's sleeves, and diff's brackets. This to circumvent them rusting.

I then decide to paint the 2 bolts & two nuts that hold the rear sway to LTAs with Rustoleum Sail Blue to match the sway bar.

The other day, I ordered the 1 3/4" round Volvo R Sport decals for the Virgo center caps from www.davebarton.com. They arrived today,thanks to Dave Barton, for his always speedy shipping!

I applied them to the rear & front sway bars. This in keeping with my "R Sport n/a 240 theme" that I'm doing to this car. I like the look it lends. I will probably apply one to the front strut to strut brace also, later on.

Yep, I know the 242GT was all that was offered for "hi perf" n/a 240s, but I'm doing it my way....

Hopefully the rear brake calipers will be dry/hardened enough to install late this evening, or tomorrow.

8/14/11

OK, rear calipers on axle & loaded. Front calipers touched up on inside edge immediately behind pads, where I previously neglected to paint them. All 4 calipers now match in appearence..

Also touched up rotors on outer edges and front's "vents" are now fully painted as well. Also painted all four "wheel alignment pins" that screw into rotors/hubs yellow, for easy ID during "on side of road" tire change due to flat, and painted frt "rotor securing" bolts. Pics below:

Next part to install is Brake Master Cylinder. Then bleed brakes.

I removed the old ATE Master Cylinder, rinsed out the triangular reservoir with some new, but old/opened Castrol DOT 4 fluid until all the sediment was out of reservoir & it was clean again. Dried it off, cleaned up all the fluid residue with GUNK brake cleaner fluid on a rag. Got reservoir's exterior spotless.

Removed triangular reservoir from old MC, removed rectangular reservior from new MC. Then they swapped places.

I then bench bled the new Master Cylinder in the vise , and used the ATE Racing Blue Dot 4 Brake Fluid. Bled it until absolutely no bubbles were seen.

Placed a ton of paper towels in the area under the MC, to catch any & all spillage. Then installed the new master cylinder, wearing the original OEM Volvo triangular reservoir w/ fluid level sensor, onto the brake booster.

Removed the plastic bleed plugs, one at a time and threaded on each line, one at a time. MC is now on the car, and I'll begin bleeding the entire brake system tomorrow.

I spent the rest of the day, going through all my wrenches, and organizing them, as well as sockets, rachets ,extensions and all other tools.

Having used these tools and having them scattered to hellenback, for over a year, had gotten me to the breaking point.

It was way past time to put unneeded things away, and get my tools back in order. Would you believe it took 6+ hours? I'll spend more time working quicker now, because I don't have to hunt for 15 minutes to find something. Nothing bothers me more than that.

I'll post pics of MC install after I bleed the brakes tomorrow. But the silver finish on it does look nicer IMO.

The hard work is done, and it should be easy & all down hill from here. That is definately something to look forward to, as I've worked my everlovin' ass off up to this point. WORD.

8/16/11

One has to realize I used to work on new in showroom, and customer's custom Harley Davidsons, and I've built a few bikes that appeared in shows to boot. Sometimes the customer was a 1%er Club member, so I always did my best work . I guess the habits of that remains instilled in me & still shows in my work. Even on a Volvo 240 build.

,Today I took a razor blade, and an Exacto knife, and scraped/cut the paint on the bleed valves off , so the clear hose would slide on easier. Then cracked open all the bleed valves to free them of the death grip the paint had on them.

Then I commenced to bleeding the brakes................

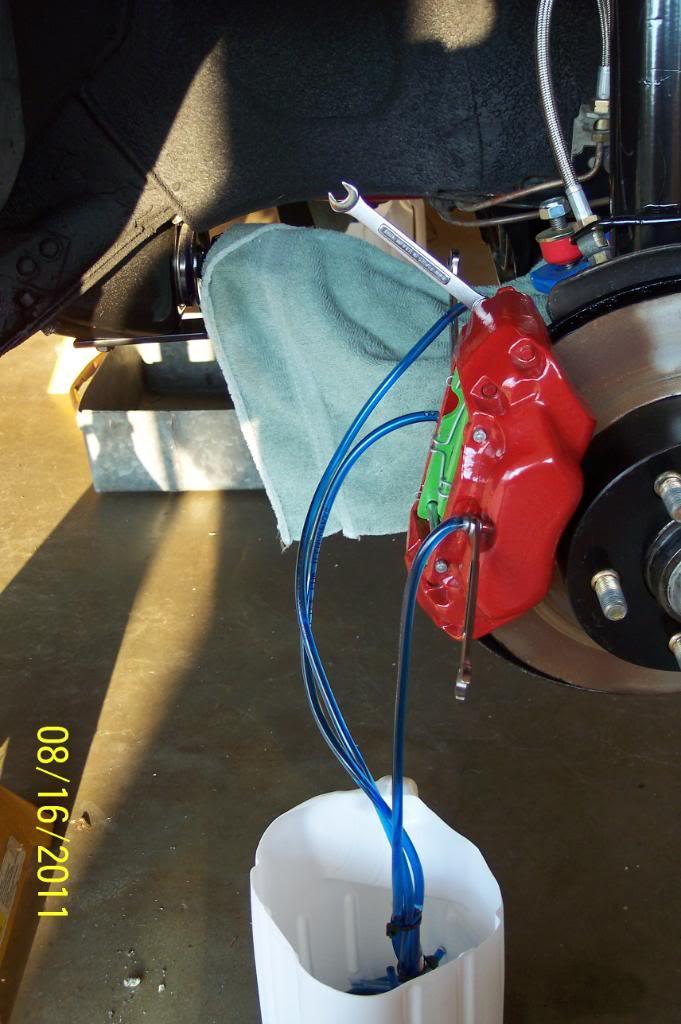

FWIW, I just thought I'd share how I actually set up for bleeding the brakes. Doing it this way keeps from ruining the newly painted calipers, and keeps from making a big mess to clean up. ..

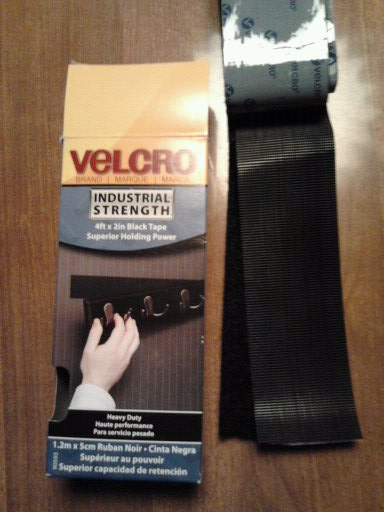

Ya need ...........

Eight(one for each bleed valve) ,8mm wrenches(1/4" IIRC for early 240s)

4 empty milk jugs with top cut out,4 rocks in baggies(to keep jugs from blowing away due to wind /to view how dirty old fluid was)

Clear 1/4" sink tubing from Lowes, say maybe 1.5 ft per bleed valve(8 of them)

8 tie wraps,

4 bolts to tie wrap to the bottom of the lines, so they will not curl up.

And 3/16" clear line will work, but is easily made to leak if you're not careful. The 1/4" clear line requires more finagaling to get on the bleed valves, but is more secure. Let it sit in the Sunshine before slipping on the bleed valve helps.

This has always worked very well for me, and is worth doing if you've painted your calipers. I didn't spill a drop on the carport floor. And disposal of used brake fluid, read burned, was much easier.

I also cover up around the MC area very well, in case I spill brake fluid. It's very overdone because, I did not want to take any chances of ruining the lower control arm's paint job, as well as the inner fender's paint.

Notice that's ATE Super Blue Racing Brake Fluid DOT4 in the new master cylinder. Ha Ha, more BLUE!

I've been busy bleeding the brakes. I have new fluid running out of all bleed valves & with no air & a good,firm pedal.

I then tapped on all the brakes lines their full length, with a hammer handle. I'm going to let it sit a few hours, then check the pedal & bleed all bleed valves one more time,just to be sure/positive.

I don't want to do this again if at all possible.

Ooohhh ......almost forgot.. pic of pretty blue brake fluid, to match the IPD Susp. parts

The entire brake system is fully bled & now brake system is correctly & fully functional. In other words, I have good brakes.

Close ups of Master Cylinder......

And how it "blends" with rthe est of the engine compartment..........

8/19/11

Went to A/Z, bought two pair of 18mm "Spark Plug Nonfoulers" for less than 10 bux. Then ,I cut a flange of an OEM Volvo cat I've had since 1997. Dressed it a bit, and had local muffler shop weld new straight pipe to it. Then muffler shop cut a hole & welded the bung in the header pipe.

Muffler shop also happened to have an old,used,what looks to be, "Orange Peeler" glasspack muffler. No rattles inside it.Quieter ,I suppose, than the proposed small round Thrush muffler (I call 'em Woodpecker muffler") I had intended to use, so for 5 bux i bought it.

Spent $35.00 for muffler & having an OS bung welded into 9:00 position of old downpipe and welding on flange, plus the 33" piece of new straight pipe.

Ran outta time, so will return Monday/Tuesday with car, to properly place bends in straight pipe, and weld hangars on glasspack, then weld on glasspack to bent straight pipe. Will run catless to Raleigh.

Hell, this seems like a helluva lot of work & $$ ,just to have a not so cheap, temp exhaust , only for the 70+ mile trip to RJS Custom Piping in Raleigh NC, to have the 2.5" mandrel system made. Gotta pay to play I guess.... I can always use it for similar tasks in the future....

I did bolt it all up, & just slid the muffler on. Hell it points straight at the "diff's hog's head".

Then I cranked engine & let it reach operating temperature. Did this 3 separate times. I looked for water & oil leaks all around the engine bay...and.....found NONE. Whew!

From sound of 1 glasspack, I'm thinking I'll need another muffler of some type, to run with the planned 2.5" in/out 6 round x 18" long MagnaFlow muffler ,when 2.5 system is on. I'll be shopping online for those tomorrow I suppose.

After I welded my header pipe bracket back on the old header pipe, I repainted it for the 3rd time with DupliColor Engine 500* Ceramic Paint in black.

Painted welded on flange of straight pipe, and bolted all these parts on. Aims straight for hog's head..again.

I sanded the 5 bux Cherry Bomb, and painted it with some red caliper paint, I had left over. Damn thing looks new now.

Gonna have muffler shop put some bends in the straight pipe, weld on two round rod hangers then weld on the Cherry Bomb, add some pipe to run it just under the axle and weld on a turn down tip on end.

I figure I can use this set up, later, on another of my 240s, to get it to a muffler shop if /when, I have exhuast system failure. Like I doin' now.

I don't want to chance breaking studs off of ex. mani with a half assed temp exhaust system. That woud be a large can of PITA at this near to being finished.

In the last pic, you'll see why I'll have to remove the straight pipe nd have local muffler shop put a few bends in the pipe .

A FEW PICS...

Either the exhaust pipe will hve to double time it as a drive shft, or vise versa,. I think I'll just have a few bends put in it.

8/21/11

So. I pulled the stright pipe off today. I'l have to drive it to muffler shop with "open header".

Once pipe was out of the way, I installed the newly rebuilt driveshaft. Flex disc, U Joints, center support rubber, center support bearing ....all of them new. And DS/Ujoints are all painted of course.

Pics........

8/23/11

I did some touch up painting of nicks/scratches on driveshaft & painted it's boltheads today. Also touched up some ugly scratches on subframe rails under the hood, at bottom of inner fenders.

And I removed the hideous clamp originally for ,the now absent, preheat pipe. Also painted the preheat pipe clamp's retaining bolt, and reinstalled the bolt to fill the hole there.

Amazing how removal of one ugly clamp makes it appear so much cleaner looking. See pics at bottom of post.

I went to replace the new, but cracked in 4 weeks MTC breather/flametrap hose(made in India), with the original 20 year old hose(hard, but no cracks), and the new MTC flametrap's small vacuum nipple broke right off. Cheap **** IMO.

So I ordered new OEM Volvo breather hose, flametrap , and BB hose from FCPG. Should be here by Saturday.By God that should fix it.....

I also ordered a new OEM Volvo clutch cable from Maxwell Volvo, to replace the cheapo aftermarket one I installed when I replaced trans after C & PP install. It turned out that I happened to have a cheapo CC as a 'in trunk spare", so I used it until I could get the OEM one.

Also ordered 8 new caliper bleed valve rubber covers to protect the bleed valves. These should arrive next week on Tuesday.

And....I finally decided,for better or worse,what mufflers to use in my custom 2.5" SS mandrel bent exhaust system. I had already bought the cat, and the tailpipe tip.

Summit Racing says they'll be here, also, by Saturday of this week.

For all these mufflers & exhaust parts, Good Grief... there went a little over $265.00....and no pipes have even been fabbed/mandrel bent yet....Happy Happy, Joy, Joy.

I'm going to have RJS Piping in Raleigh NC, cut off the new Starla/OEM type header pipe's 2" collector , then,lengthen the secondary pipes to maybe 30-36" and then weld on a 2.5" collector onto the header pipe's seconday pipes.

Here's the part numbers & descrips, of the MagnaFlow exhaust parts, for other's reference.

MagnaFlow cat (same shape/size as OEM only 2.5" in/out, so fitment & ground clearance will not be an issue)

p/n 53006

Inlet Quantity One

Inlet Diameter (in) 2.500 in.

Converter Inlet Attachment Slip fit

Outlet Quantity One

Outlet Diameter (in) 2.500 in.

Converter Outlet Attachment Slip fit

AIR Tube No

California Legal No

Converter Case Material Stainless steel

Converter Substrate Material Ceramic honeycomb

Heat Shield Yes

Converter Overall Length (in) 13.000 in.

Converter Overall Thickness (in) 4.000 in.

Converter Overall Width (in) 5.125 in.

Converter Style 3-way

GVW (lbs) 4,250 lbs.

Quantity Sold individually.

Notes Round body converter.

p/n 12646 MagnaFlow muffler (will be mounted in rear muffler locale)

Case Shape Round

Inlet Diameter (in) 2.500 in.

Inlet Quantity One

Inlet Location Center

Outlet Diameter (in) 2.500 in.

Outlet Quantity One

Outlet Location Center

Internal Construction Perforated stainless tube with packing

Muffler Material Stainless steel

Muffler Finish Natural

Case Length (in) 18.000 in.

Case Outside Diameter (in) 6.000 in.

Overall Length (in) 24.000 in.

Outlet Style Standard, without tip

p/n 12866 MagnaFlow muffler (will be mounted in resonator locale)

Round

Inlet Diameter (in) 2.500 in.

Inlet Quantity One

Inlet Location Center

Outlet Diameter (in) 2.500 in.

Outlet Quantity One

Outlet Location Center

Internal Construction Perforated stainless tube with packing

Muffler Material Stainless steel

Muffler Finish Natural

Case Length (in) 14.000 in.

Case Outside Diameter (in) 5.000 in.

Overall Length (in) 20.000 in.

SS tip

Inlet Inside Diameter (in) 2.500 in.

Tip Shape Round

Tip Outlet Size 3.000 in.

Tip Quantity Single

Tip Installation Weld-on

Tip Material Stainless steel

Tip Finish Polished

Overall Length (in) 12.000 in.

Tip Cut Slant

Tip Edge Style Rolled edge

Resonator No

Pics of subframe clean up...

8/24/11

I removed the front mudflaps to get all the grit,rocks, and dirt out. Washed hell out of them. Then,I decided to spruce up the appearance of the plastic front inner fenders. They looked like hell.

I washed them with 93 octance Amoco gasoline on a rag. Then with Brakleen on a rag. Dried them off. Then applied some "Forever Black" black dye on 'em.

Some of the dirt staining just wouldn't come off, and I did not remove all the road tar either. But the places that show the most, came out pretty good, so I'll call it "good enough" for now. At least, it looks a helluva lot better than it did. I have more "Forever Black" left if I decide to remove the road tar..

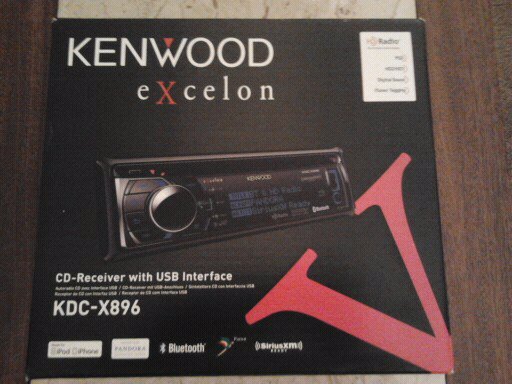

And guess what came on the Big Brown Truck today.. only took 2 days to arrive.. man that's fast!

And guess what came on the Big Brown Truck today

I think my neighbors may learn to hate me.........can you say "straight through muffler"?..

8/25/11

Today I got to thinkin'. (rare I know) Hmmm, the "bolt on" straight pipe exhaust idea didn't work out as hoped. Needs bends in it to fit right. Too close to driveshaft at diff.

That leaves me with exhaust gases blowing all over my newly undercoated floorpan, on the way to local muffler shop to get the straight pipe fitted, next week.

Wow, the old OEM gutted Volvo cat still has a flange left on the other end of it....hmmm. After a visit to the local muffler shop in borrowed car.,I came up with this. I figure I can have fun with it on another 240, later on, too. At least it'll help keep from blowing exhaust straight onto the undercoating. Should throw a little fire out at night, I do believe.

After that I eyeballed the front caster/camber/toe in. Adjusted the tie rod ends, and tightened them in the spindle arm. Will tighten the lock nuts in a little while.

Still need to adjust the Kaplhenke Adjustable Tie Rod End Links. After that, I will adjust the IPD Adj Panhard Rod ,& , if needed, the IPD Adj Upper Torque Rods.

Also,FCPG /UPS says my OEM Volvo Flame trap housing, & both the short breather box hose & the flme trap to intake hose/breather hose will be here tomorrow. That is only thing holding me up from cranking it again. Had a bad vacuum leak, due to smallest nipple on flame trap hsg broke off.

The air box bracket that holds AB to rad support did notmatch the radiator ones, that I painted black. So I painted it black to match today, & it's still drying. That's why it's absent in pic below.

I'll go for a ride around the neighborhood for a "shakedown run" tomorrow...if things go as planned.

I did get the IPD Strut to Strut Brace & the YoshiFab Firewall to Strut Braces on today.

The air box bracket that holds ABox to rad. support did not match the radiator ones, that I painted black so time ago. So I painted it black to match today, & it's still drying. That's why it's absent in pic below...sorry, but rice is white...LOL.

8/30/11

I have the temporary exhaust in place now. Pipe from header pipe to a ,what I think is, a Cherry Bomb glasspack., then to under & past rear axle, and turns down just behind axle. Doesn't sound too bad, but is loud with resonance inside the car.

Car/engine seems to have a little it more HP, but maybe it's just the added sound that makes it see that way, dunno.

This makes me wonder what the cat, 2.5" system & two MagnaFlows are going to sound like & if they'll have resonance inside the car. I hope not...... I'm wanting a little sound on the outside, but no resonance on the inside.

Then I had Maxwell Volvo align the front end. I always get good service from them on alignments. I also bought an OEM Volvo clutch cable, and it had come in also. Those are Great Guys there at Maxwell Volvo/Subaru.

I have a new license tag on it now, and been driving it a little for "shakedown runs". Seems I have no engine/coolant/transmission leaks, and so far, no major problems elsewhere.

I think I need to adjust the Kaplhenke Racing adjustable front sway bar end links some more though. And I need to adjust the rear panhard rod another 3/16th to driver's side for perfect alighnment.

I've worked too many days to the tune of 15-20 hours at a time. I got some rest last night. Might tackel the CC, end links, and panhard rod tomorrow & take it easy today. I'm not exactly a spring chicken anymore.....LOL

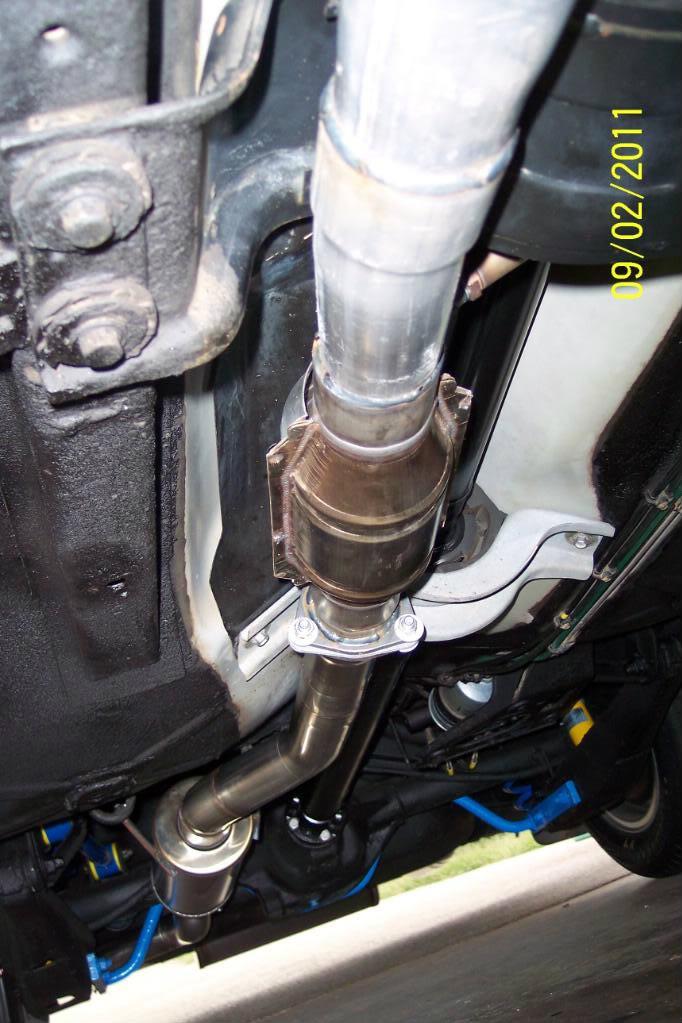

9/2/11

Well, Ron at RJ's Custom Piping,(3813 Capital Blvd, Suite 104, Raleigh NC, 27604) is one helluva good SS mandrel bend exhaust system welder,& fitter.

He began work at 10AM when I arrived. Worked straight through, no breaks, no lunch, no dinner, until 6:45 PM. He saved me a drive back the next day to complete the system by doing this.

He is the only exhaust system installer to ever put an exhaust system on volvo 240 for me, that did not hit anything under the car, clunk,or leak, and that fits snugly to the floorpan with great ground clearance, first time out, with no needed adjustments!!

Not even 1 leak or clearance problem ! Other shops I've tried, I've been back as many as 4 or 5 times to fix problems, and had to let another shop ,fix the 1st's one time.

Ron did the 2.5" header pipe collector mod for me, and TIG (oh yeah!) welded the entire system. I was impressed by the way he made the half moons ,that the 1st muffler(OEM resonator location) hangs from the o rings in. He's the 1st installer to ever do this for me. All the others, just let the rod hang from the O Ring & that way kills the o ring fast too. And impressed by the 2nd muffler's hangars as well.

FWIW, I find the rumor that 2 MagnaFlow mufflers are still too loud UNTRUE, IME & IMHO. it's just a slight tad louder than an OEM turbo muffler, but not a PoPo calling stereo system by any means.

I hear just a little exhaust note inside the car, but no resonance at all, & a little more exhaust note outside the car. I can hear my stereo just fine, at level 13. The exhaust note outside, is not too little, not too much..it's just right IMO. I'm quite happy with the sound of the system as well as it's better performance. It's sounds sporty without sounding like a busted muffler.

Ron is quite an accomplished welder, & fitter. I'd say the best I've ever seen or met. I highly recommend RJ's Custom Piping.I'm 110% satisfied & then some...oh, and any antifreeze/coolant you see is because I'm changing the 88C*T Stat. I don't like it.

I'll let the pics say the rest...........

New, Starla stock header pipe...

Cut the header pipe past the bracket flange, made them longer, & they now merge into a 2.5" collector. Looking up the end of collector showed me a much more open secondary pipe where they merge together. As it came from Starla ,they were quite small. Better flow there for sure. This is in aluminized steel here.

Actual collector is where the SS begins.

Collector dumps into a 2.5" MagnaFlow (9"body, 13" overall long x 5" round cat.

Cat back to the first 14" long x 5" round MagnaFlow SS muffler

First muffler.. Notice the half moon hangar in 2nd & 3rd pics...and the first "sleeve" disconnect..

Went with under axle pipe

Around the gas tank & into the 18" long x 6" round MagnaFlow second muffler. Used SS sleeves to join the pipes together here, for easy removal if needed.

How he made the second muffler's hangars, mounted with new rubber hangars.

From rear of car...

Exiting the 2nd muffler..

Some more complete views...

SS MagnaFlow 2.5" exhaust tip...

Some rear view with car sitting level on ground...

Well, I double, triple, & quadruple checked the 2 piece DS alignment arrows. They look to be in line correctly. Although it's hard to tell with a 1991 with only the 2 u joints on rear DS, as I'm more used to the 3 u joints DShafts. I pulled a string on 'em. looks to be AOK. I'd rather check 'em on a lift though. Maybe next week I will. I think they're right though....

However the adjustment I had, on the IPD Adj Upper Torque rods was 4 turns too long to be stock length. So I adjusted them to stock length.

The noise/vibration I had is now gone....and now it's much smoother. I am however wondering and still learning, just how much rear axle/diff vibrations/noise ,the IPD Aj Upper Torque Rods are now transmitting through the car's chassis. Mine have the (harder durometer than blue poly) yellow poly in them.

I've not ridden in a 240 with the IPD Adj Upper Torque Rods w/yellow poly in them, before that I remember.. so I don't have a point of comparison.

I do hear gear whine/backlash sounds that weren't present before the susp build. But nothing that I'd consider "not normal" for such stiff durometer bushings. Actually I think it's less NVH than I was really expecting. So I think that is all/what I'm hearing/feeling now.

I do get a bit more engine vibes with the 240 OEM Diesel MMs than before also. But again nothing obnoxious.

And my dual Cold Air Intake mod makes a little more "GM QuadraJet 4 bbl sound" too. Tee hee, it makes me grin ,combined with the new RJ's Custom Piping made, 2.5" collector mod & mandrel bent 2.5" SS/MagnaFlow exhaust system sounds.

Car runs much better/faster in 0-100 mph acceleration & 60+ roll ons on the test track.. Scats pretty good for an otherwise stock 91 b230 n/a too, IMHO.

Hhmmm, Now I just need a good bumpstick to compliment these current mods.... That'll be the icing on the cake, so to speak.

Car also handles like it's on rails now. I'm totally satisfied with ride quality, how it tracks flat & surefooted. it's now a "no lean machine" in the curves & corners.

I'm also quite satisfied with the amount the IPD Sport Springs lowered the car. I don't think I want it any lower. It suits my tastes & preferences as is. I shouldn't have a lot of problems with ground clearance either.

Now, if I can figure out how & where, I want to mount my Sun 2 5/8" tach, and mount my rear 6 x9 speakers in a custom made platform on top of the rear package shelf, with the 6 x 9 speaker boxes mounted underneath the speakers, on trunk side of package shelf, and refurb the OEM Volvo rear window louvers & install it, I'll be even more happy.

The engine is running a little warmer than I'd like with a OEM 87C* T Stat. My Blackstone radiator, may be slowly becoming a dead player. I'm currently checking into that.

9/5/11

I've ordered an OEM Volvo 82C* T Stat from FCP. It should be here Tuesday or Wednesday. I'm going to try the 82C* and see if WT gauge reads what I want t to read. I'm shooting for 185F* hot & running, as i have VDO Vision F* WT & OT gauges, as well as , OP,VM and Vaccum gauges too.

I took some pics of the car today, showing the ride height. here are those and a few others......

9/8/11

Well, today I decided to tackle the HL lenses install. Followed TrickMick's method of a "ground to fit lense channel on hsg pocket screwdriver" to dislodge the existing Volvo sealant. Worked like a charm. I removed all traces of the OEM Sealant too.