You must be logged in to rate content!

8 minute(s) of a 758 minute read

1-22-2013

Well here is todays body work up date, and it seems to be flying along.. I sure wish my guy wasnt making an occupation change, because it is hard to find dedicated and quality body men willing to take on the classics in a timely manner..

I thinking the work on the gapping is really starting to show now, and the flares are really starting to blend nicely.. I know you cant see it in the pics, but there has been alot of hammering and dolleying done here, and most all the little dings have been hammered out enough that they can be block sanded out in the primer stages, rather than just filling and working them with glaze... The whole center of the drivers door had to have a bondo patch removed, and all the metal shrank to give the sheet metal its strength back, because it just kept flopping in and out from being stretch by the hidden damage.. There is alot of work that can be saved with just a bit of hammering/shrinking, instead of glopping layers bondo on, and then trying sand until it looks right.

1-24-2013

With these Classic Volvo builds I have found area's in the car that have no drainage at all, and that normally causes major rust or leakage issues with the trunk area for the P1800, along with several other areas in both the P1800/Amazon.. The P1800 Volvo has a top only trunk lid, where the trunk jamd doesnt progress to the back panel for natural drainage, so the trunk weatherstrip jamb acts as a trouph.

From my experience with weatherstripping, and from what I have noticed through the years of restoring various models of car, it is the trapped water in the channel that allows the dirt and residue to stick for deteroiration to continue. And another thing that people dont really consider is, most of your typical trunck/door/hatch weatherstrip is actually a sponge, and the pores will hold moister for quite some time.. The more surface area that has water contact, along with amount of time with weatherstrip/water contact is allowed, the more moister the weatherstrip will store. That ratio only amplifies when you take into account the harm from the addition of layers of sediment and residue from the previous trapped water. If you can keep the water level low, and cut away from the time to obsorb, the more it will keep the rusting affect at bay.

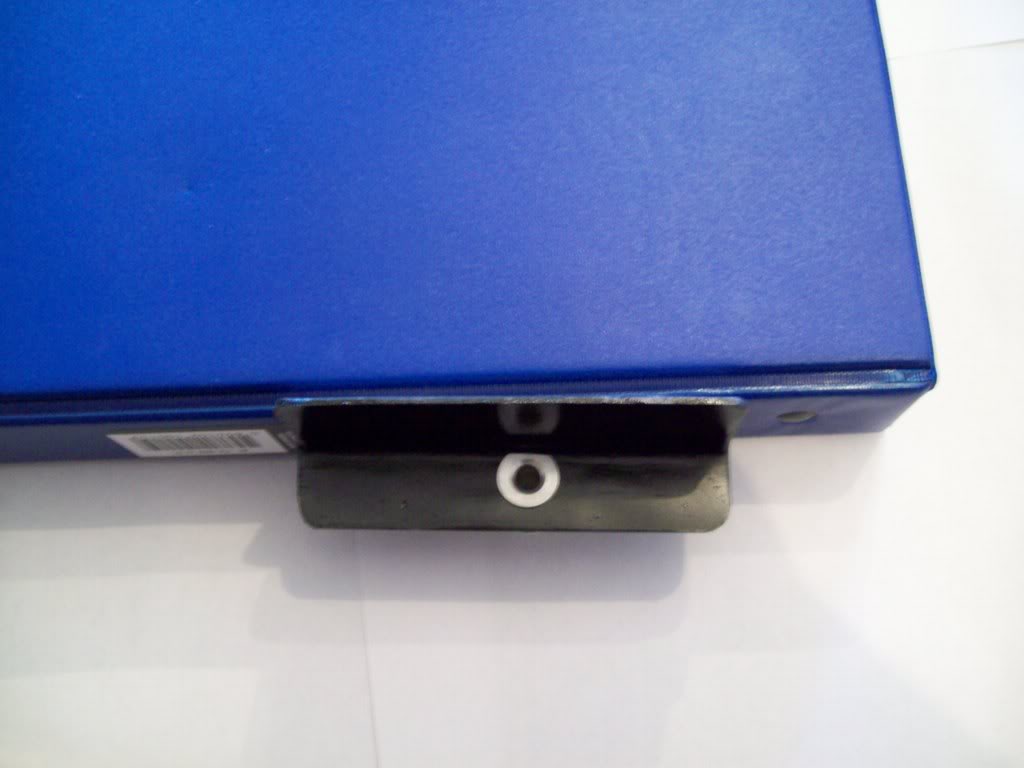

I have two sizes that are being made for me.. The pictured is a 1/2" head, and takes a 3/8" hole, with a 7/32" drain hole. I have another that is a 5/8" Head, and takes a 7/16" hole, with a 5/16" drain hole.. I had these made for strategic areas of the Volvo body, and the drain holes are larger than what most Oem featured body drains are. The flat spot on the head, makes it possible to get the drain hole as far inboard as possible, so it leaves virtually no water puddle.

In the pictures below, the black bracket only represents the trunk jamb, and is not part of the kit at all...

Well I received the custom headlights I have been working on today, and they are not what they are suppose to be, so I am a bit surprised.. I objected to the "SICK" logo in the last batch of updates, because they were to in your face, and not the best word to be the focal point at the front of the fenders.. The previously purchased and showcased lights did not have the etched logo, and these lights were being made to my design and specifications, so I dont understand the bold in your face logo. This light version was suppost to be the same basic setup as the previous pictured lights in this build thread, with the exception of a new seperate Turn/Park lamp at the bottom of it, and they were suppose to be the same clear outer lense.

With what I recieve, he apparently put a fluted outer lense on it, to hide the SICK logo, but that wasnt suppose to be the case at all. To make matters worse, the fluting actually conflicts with the position of the Projector Lense, so it all just seems out of sorts. I was told that this was his only solution to the matter, because to remove the logo involved destroying the whole light assembly, and there isnt any returns.

Here are some more body work updates, and I tried to highlight a bit of the gapping work that has been done so far. These are still bare metal gappings, so you can see it isnt just a build up of bondo or some other material.. You should also be able to see that the raw metal on each panel is level with the corresponding panel, and that is without bondo or glazes also. There still a bit more to be done, but they are really starting to shape up..

I have also tried to take some pictures that would show how the flares look proportionally to the body, but that is hard to do.. Even with the rear flares , the front end body work is still wider than the rear of the car.

Nice details!

Posted by Diggymart on 7/15/19 @ 1:21:16 PM