You must be logged in to rate content!

11 minute(s) of a 758 minute read

12-29-2012

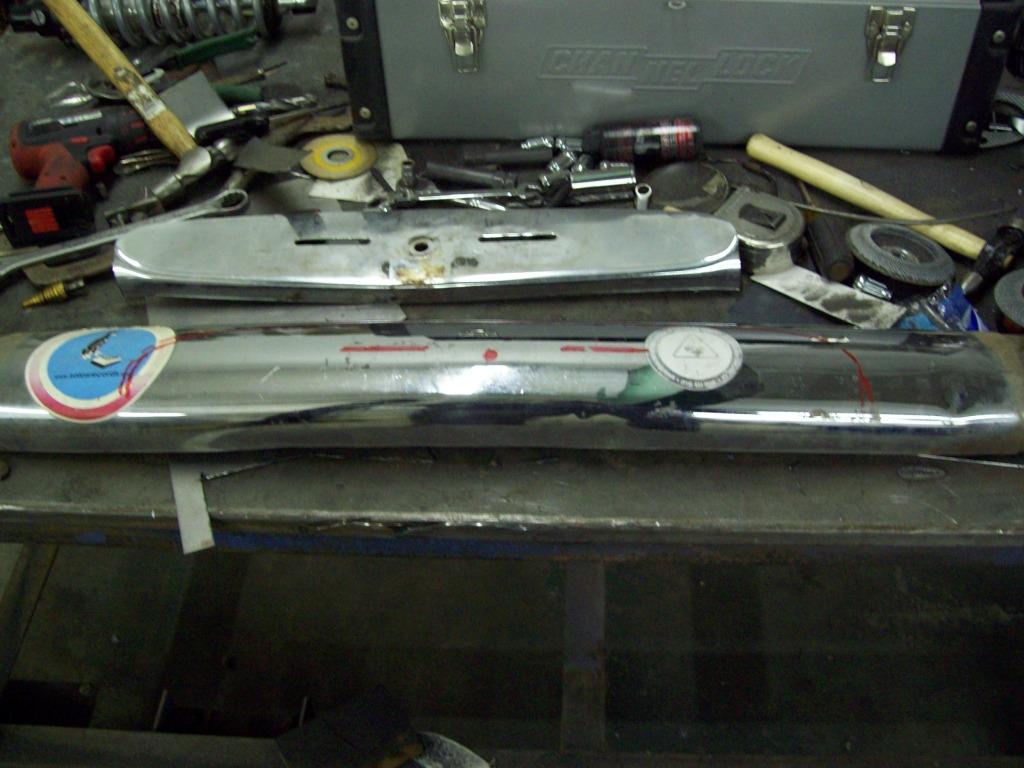

I am trying another rear bumper license plate mounting setup, and I am actually using the front bumper license plate relief.. In order to have it flow correctly into the rear bumper, the mounting angle is just a bit much, but I wonder if I can source an early chrome style license plate frame from some where? I had a PV that had a nice American license plate housing/mount, and I have seen something similar for the Amazon's.

I am also experimenting with rear mud flaps, and I am trying to use an altered version of the front mud flaps.. I think they will come back and out just a bit more, but they should work out.. It is Volvo styling, and I like the benefit I should get from them, when it comes to chipping and Tire Abuse. I havent trimmed out the spare tire sump, but it will be reduced to be abover the lower quarter panel, so it will not be seen when all is done.

The bumper will be made into a one piece bumper like the front, and all the mounting bolts will be hidden on the back side, but this will give an idea of what the overall bumper will look like.

I am really gravitating toward this option, and I think I will make it drop down anytime the ignition is on.. I can hide the whole plate behind the bumper, and in the body work, so none of the mechanism will be seen at all. If I do this set up, I will have a perfectly smooth bumper, with no reliefs of anykind, and that would be as clean looking as is possible.. I think this is the direction I am going to go for sure, but I am waiting for it to come in, so I can make sure there isnt any reason it cannot be used for the rear? It seems to me, that the front mount would be alot harder on the structure of the unit, due to the direct air force, but there may be a reason why it wont work hanging down from the rear?

Here is a Youtube link to a modified Show and Go hidden plate unit.. It is typically used for the front plates, but I can easily modify it for a rear application..

The first video is of how the Show and Go works without modification, but you can see the mechanism below the body, which I dont like.

This video is of a modified Show and Go, which allows the plate to drop straight down, so all the mechanism can be hidden in th body work.

12/30/2012

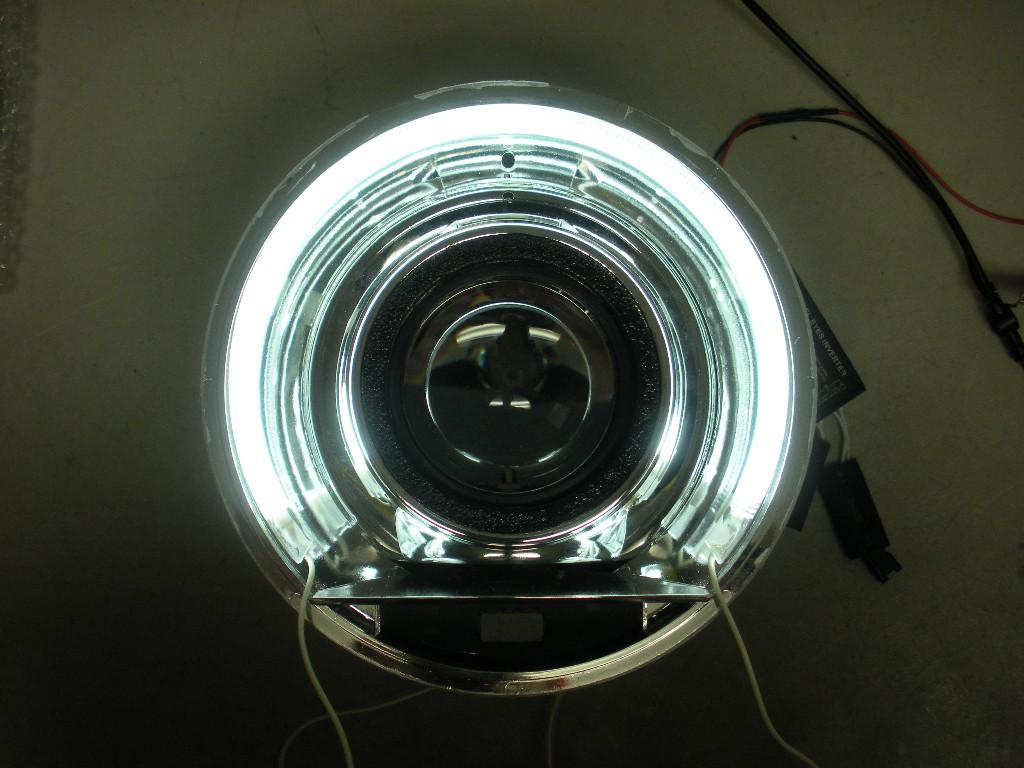

Here is a little bit more of the headlight building process, and you can see where the turn/park lamp will be placed, along with the new Halo placement..

12/31/2012

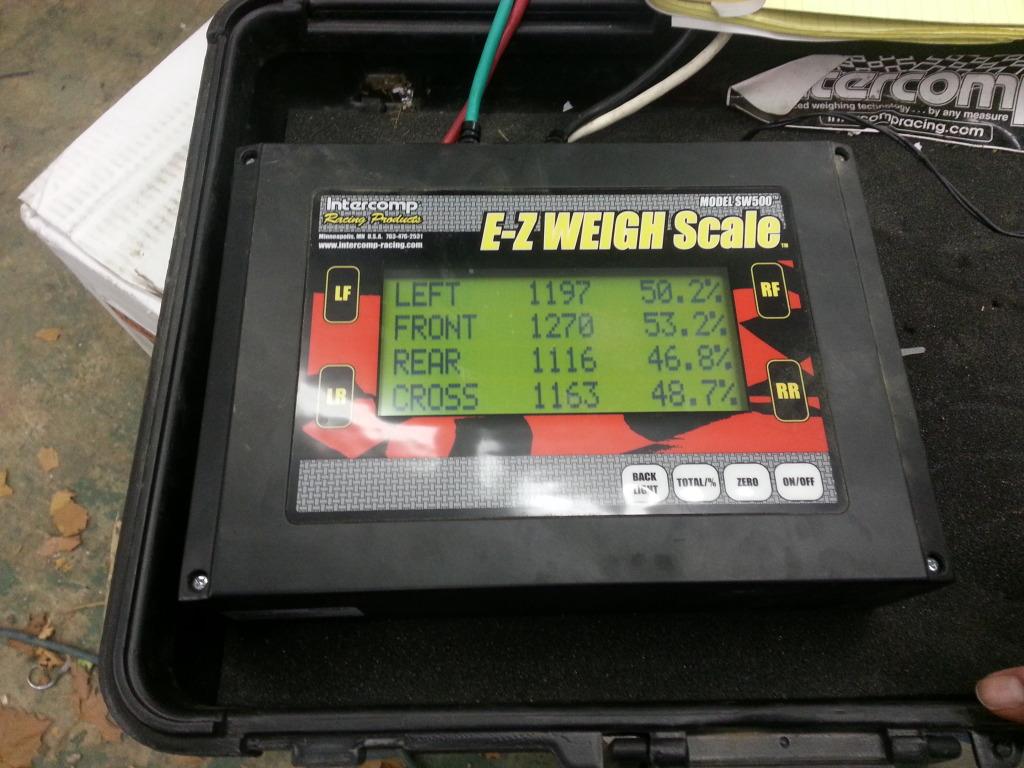

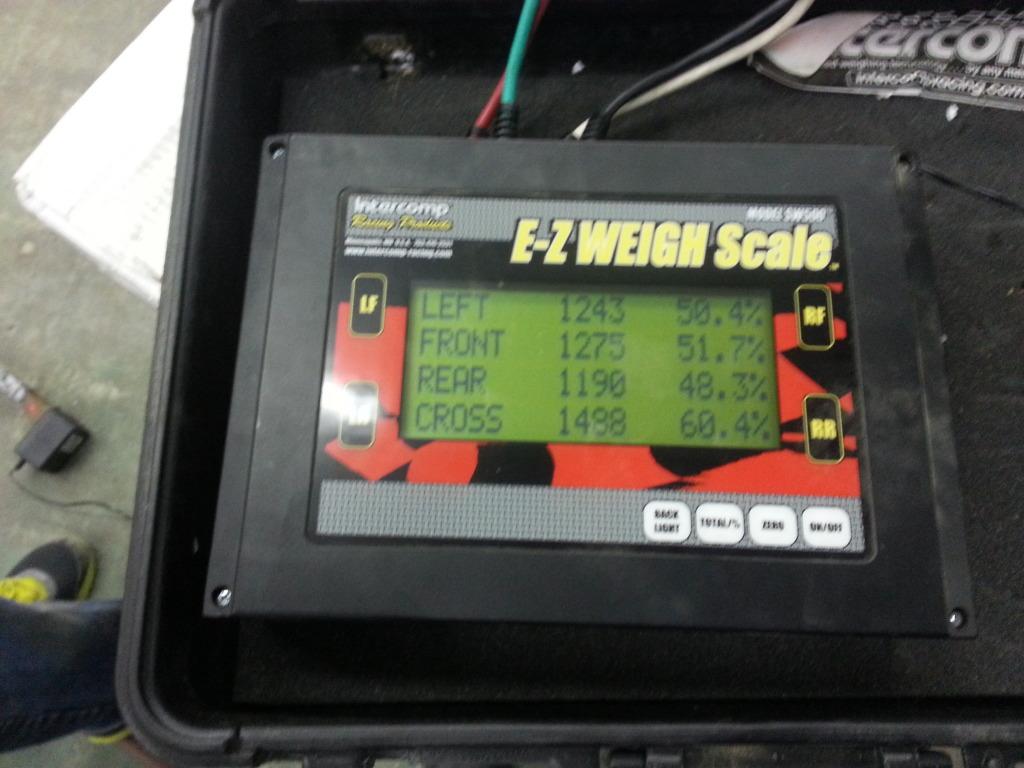

Well I have some preliminary weight figures for Volvo X, and hopefully that answers some of the questions some have had about the weight affect of the V8 and extra performance components. As a comparison to stock, I also have some figures from a 39,000 mile original car, so we should get a great preliminary indication here.. I must say that I am very pleased with the outcome so far, I think this car is going to hit the mark I was shooting for..

With these weight figures, I have an all original car first, and it is as stock as you can get, so this is a great comparison car.. Volvo X has all its running gear in the car, simulated Fuel weight, seats, complete suspension, Steering Column, Guages, bumpers, ect.. It is really only missing the basic wiring, windshield/back glass, insulation and carpet, so we should be in 200-300 pound difference margin for the added accessories. We are figuring that, by the time we add the missing weight of the missing interior/insulation components, Windshield/Back Glass, HVAC to the central part of the car, that will actually get the Distribution ratio even closer to 50/50

Original Car ________________________________Volvo X

Total Weight 2386lb_____________________________Total Weight 2465lb

Front Weight 1270lb________________________Front Weight 1275lb

Rear Weight 1116lb________________________Rear Weight 1190lb

Weight Distribution___________________________Weight Distribution

Front 53.2% Rear 46.8%_________________________Front 51.7% Rear 48.3%

I had a problem getting Volvo X totally level, and that is why you will see the variation in the cross weight, and that is cause by the floor affecting the contact points on the scales.. It was way to cold to switch the cars around, but I will definitely do that on the final weigh in..

Something to consider in all of these figures, is that I have added additional weight in areas like the wheels and tires, along with some heavy duty parts like the rear end assembly and other items, so I think a major achievement was made here.. Keep in mind we are at 540 horsepower, with a V8 and heavy duty trans/Rear end assembly.. Also I am running 14in Front and 13in Rear Brake assemblies, ect, so we are gaining alot, with minimal over all weight difference. On the next weigh in, I will probalby put some original style wheels on the car, along with a few other less bulky things, and I think we will find that there really isnt any notable overall gain in suspension and drivetrain.

1/4/2013

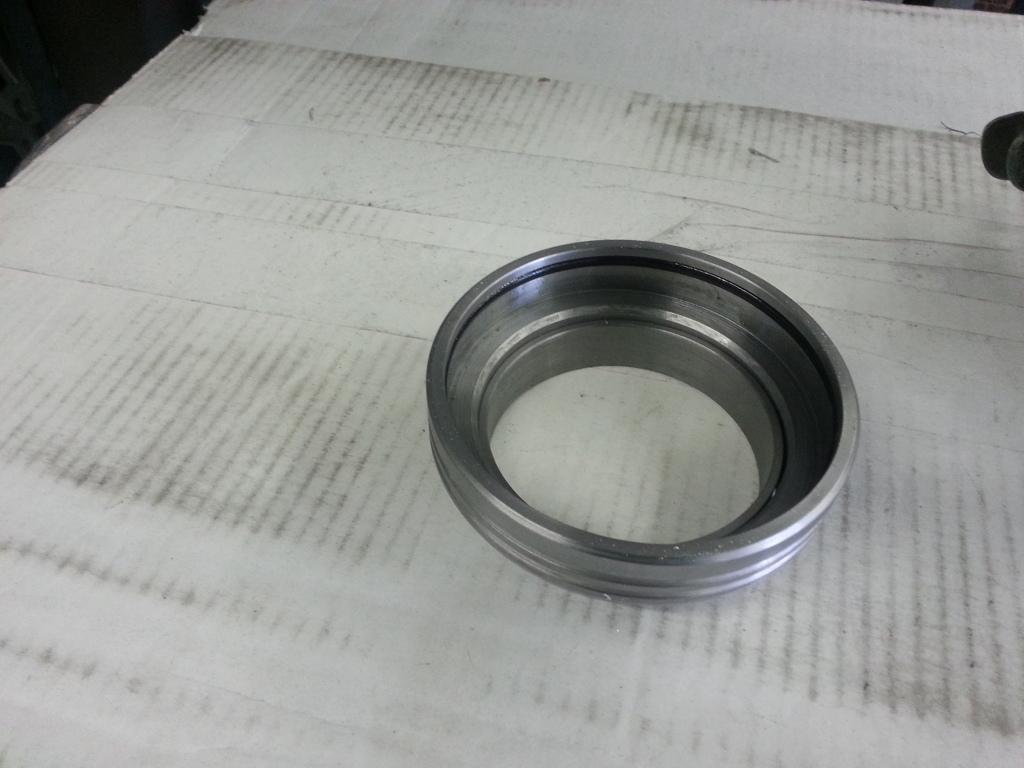

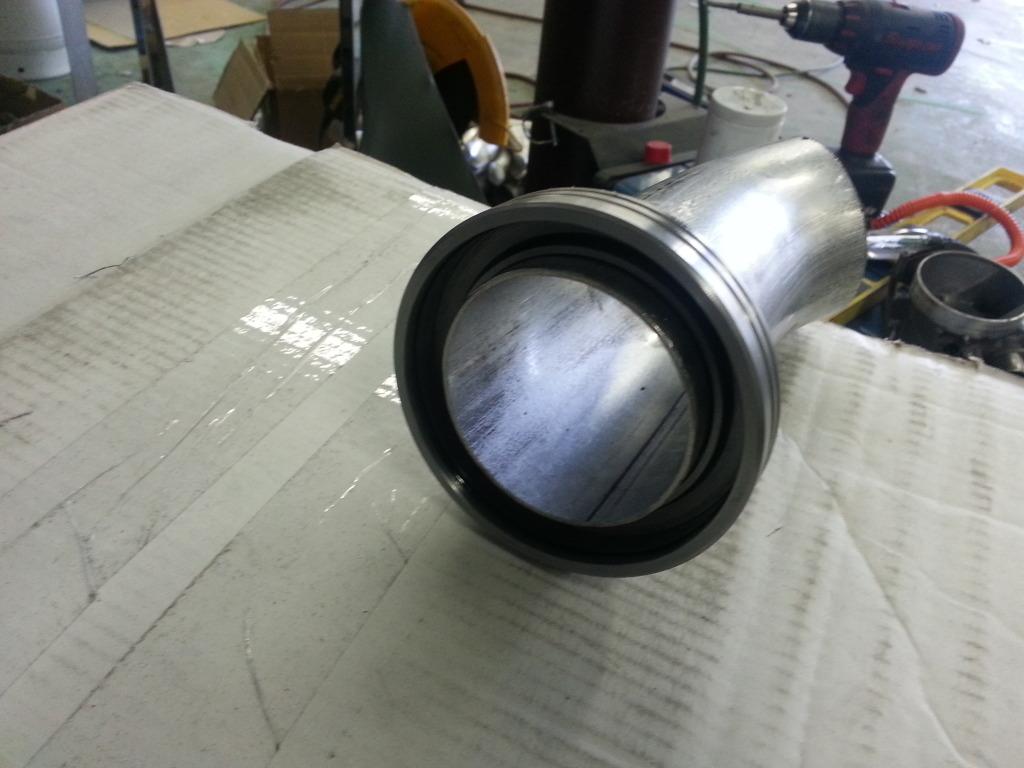

Here are some pics of what I have come up with for the intake/throttle body attachement, because I dont want the typical rubber boot and clamps you see. This collar welds onto the intake tube, and has a machine fit for tight tolerance, along with an O-Ring gasket setup. All the welding will be done from the inside, because I didnt want to have to worry about finish grinding on the curves, so finish product will look just as clean as it appears in these pics. This particular intake will be solidly mounted to the motor, so the O-ring should work out great, and I am sure this style collar could be used on other intake runner setups.. Hopefully it will be little items like this, that really make the build of this car planned out, rather than off the Ebay page or off the shelf.

For the other version of fabbed tube intakes, this collar could still be used for a free standing style system that doesnt have attachment points on the body of the car, because the tubes would be supported with hidden brackets to the motor.. I just really wanted a clean look, and couldnt find anything else out there for a factory style throttle body, so I had to make something for atleast my car.. These can be made in Steel, Stainless, Aluminum, Plastic, ect, ect, so I suppose they could be made to work with what ever material tubes you wanted to run.. I didnt make these to sell, but if anyone would like some, I can ask my machine guy to pop some out, that way he get a bit more out of his cnc programming.. LOL

1/10/2013

Well Volvo X is leaving for body work on Monday, which will be about 3 weeks of dedicated body shop time, and I will have updates of the process.. This car is not be done as a routisserie build, because it is going to be used and abused, but it will still be a very nice quality.. We are taking the extra time to weld up all the edges and gaps, so this car will be straight and precise looking..

I have locked on a solution to my rear license plate bulk issue, and I think this is going to work out just fine, along with look very minimal and clean. This set up is normally used for a front plate application, and it is on a Key Fob remote operation set up, but I am wiring it up to a timer relay for ignition Off/On operation. By doing that, I take the Key Fob operation out of the equation, along with the chance of forgetting to put it up or down. Here is the basic set up, and it is actually a very easy system.. I wanted to have it drop straight down, and be hidden in the body work, but there really wasnt any good way to do it with the body space I had available..

In order to get rid of the small reciever hitch look of the bracket below the bumper, I am thinking that all I will have to do is paint it a fairly close grey color that will match the new finished brushed/satin bumper.. Worst case scenario would be to have the metal track also put through the plating process, and that should help hide the overall appearance.

Nice details!

Posted by Diggymart on 7/15/19 @ 1:21:16 PM