You must be logged in to rate content!

5 minute read

Oil Pan Removal '86 528e

Compliments of Gold86Bimmer @ www.bimmerfest.com

Oil Pan Removal: '86 528e ( 6cyl ; auto trans ) MFD: 4/86

Safety first!! Take all safety pre-cautions when working on and under the vehicle.

This 'how-to' is meant to be a supplement to other work manuals and shows more specific details about this particular vehicle.

Tools: a) basic car tools; jack and jack stands

b) wrenches - 17mm; 15mm; 13mm; 10mm

c) sockets - 17mm; 13mm; 10mm

d) 'Torx' star socket – E10 (10mm)

e) torque wrench

f) break bar (optional-for extra leverage)

Oil Pan Removal:

Step 1) Raise and support vehicle.

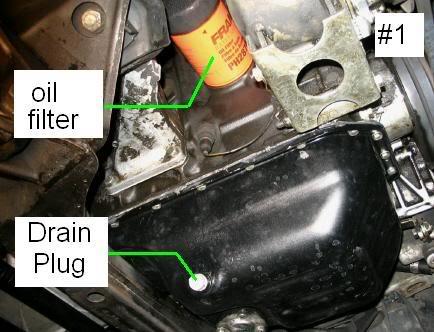

Step 2) Drain oil and remove oil filter.

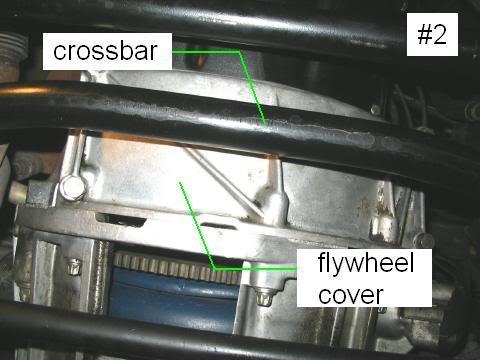

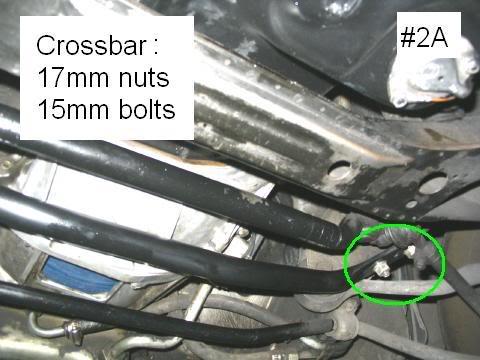

Step 3) Remove crossbar.

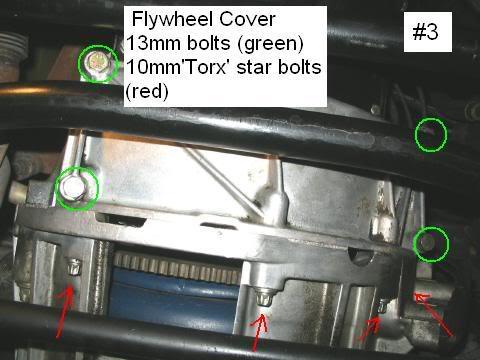

Step 4) Remove flywheel cover ('bellhousing reinforcement plate***8217 .

.

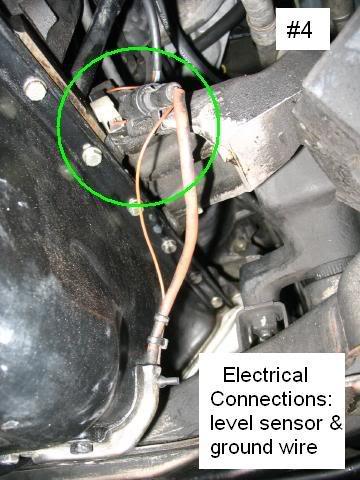

Step 5) Disconnect electrical connections (oil level sensor and ground wire).

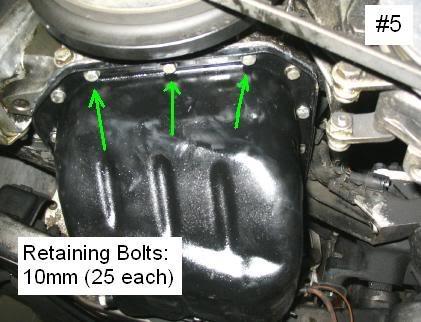

Step 6) Remove oil pan retaining bolts and lower pan until….

Note: oil pan can not be fully removed unless oil pump is removed also.

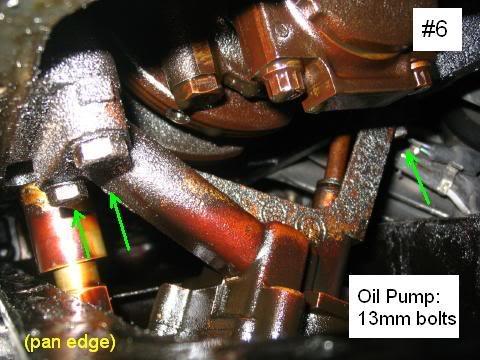

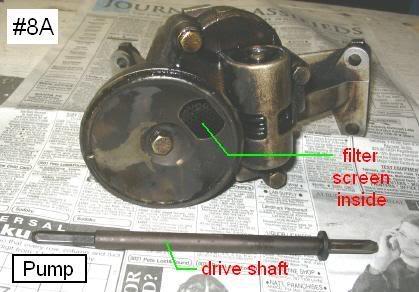

Step 7) Remove oil pump mounting bolts.

Note: tilt and move oil pan side-to-side to access bolts.

Step 8) Remove oil pan with oil pump.

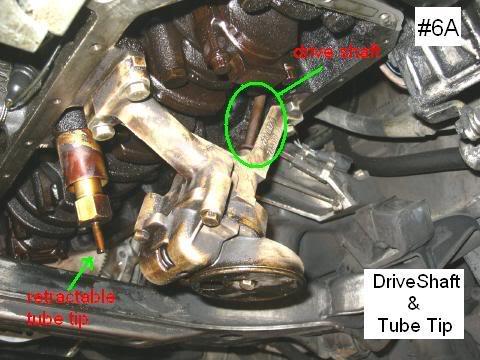

Note: there are two obstacles that keep from easily removing the oil pan even

after the pump is un-bolted.

One: the pump has a thin pencil-like drive shaft that sticks up too high and

the pump needs to be carefully laid down on its side (in the pan) in order to

clear the engine.

Two: a cylinder tube tip points downward into the pan and the small tip is

retractable. You will need to 'wiggle' the pan around while pushing up on the

tip in order to clear the brace/bracket that is in the pan. You will need to do

this task again, in reverse, when re-installing pan.

(Pic#6A-pump is re-attached without pan for illustration purpose only.)

Step 9) Re-install by reversing removal process.

Step 10) Replace oil filter and re-fill oil. Done!

Suggestions and 'Tips':

1)Use 'Seafoam' treatment in motor before old oil is drained. This way if the oil

pump filter gets 'clogged' then you can clean screen filter of pump after removal.

2) Replace old drive shaft with new one ($20).

3) Make sure drive shaft is properly re-inserted in hole of engine block before re-

bolting pump, starting with the single bolt bracket end.

4) Jack car up with plenty of space to work under…..safety first!!

5) Use a light layer of RTV silicone glue (gasket maker) with gasket to provide better

seal.

6) Use rubbing alcohol on gluing surfaces of engine/oil pan before re-attaching.

7) Brake cleaner used on inside components and engine degreaser for outside

cleaning (as well as 'dishwashing' soap).

8) Allow weekend (at least two days ) for proper cleaning (and painting ?) of parts

before re-installing.

Additional Pics:

![]()

Good one!

Posted by Diggymart on 4/1/20 @ 6:01:27 PM