You must be logged in to rate content!

32 minute(s) of a 68 minute read

12-28-2020

IT HAS BEYGON! My 1.8T swap assembly

Compliments of talx @ www.vwvortex.com

8/10/05

Ok this is the update you have all bin waiting for the assembly

To those of you that have not bin acquainted with my project hear is a link to the initial thried

http://forums.vwvortex.com/zerothread?id=1207423&page=1

Last week I toad the car down to the performance shop I have started to work at in my free time well that actually means im there from 9:00 to 18:00

So finally ange has an adequate home that stands up to my expectations and all her needs no more ghetto parking lot working in 38^c

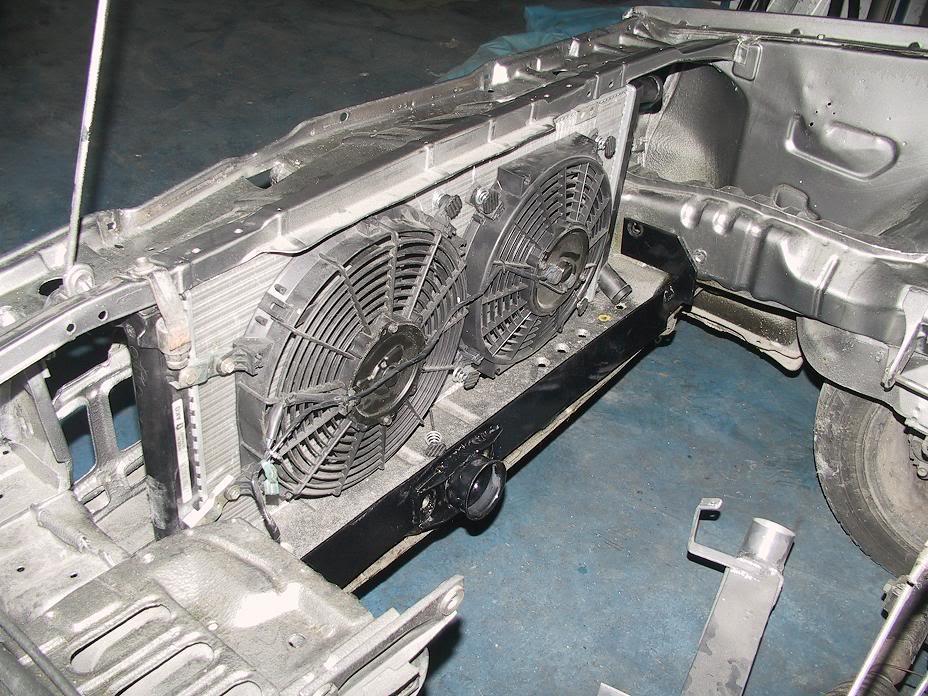

Started of with locating the radiator drilled to new holes to locate it further back on the front member to clear a bit more room in the engine bay and there is still more than enough room for the intercooler a huge one actually 24X11X3.5 core still waiting to have end tanks assembled later on

You can also see the front member reinforcement bar I built soldered to the front engine mount and connects to the bumper bolts

This is a very important bar if you don't want to shear of the front mount when pushing big hp

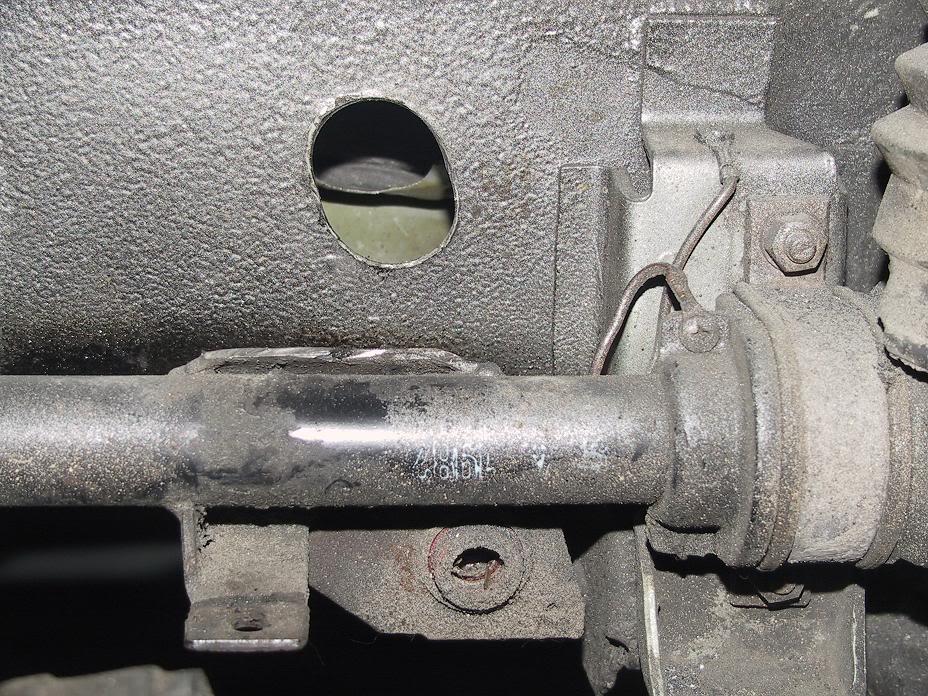

Before installing the engine I drilled two holes in the fire wall for the shifter cabals to go threw I needed to cut a bit of the old shifter rods assembly that is located on the steering rack to drill the holes but no bigy I am going to disassemble the steering rack any ways when I get the polyurethane mounts I ordered to be refurnished and shave of the shifter rod assembly

lucky me just next-door to the shop is a metal works shop that can do practically any job I have grounded some good relations with the owner because of the work he dos for us at the shop so I had the flywheel shaved for free to take of some weight should weigh just about 10 pound now

bolted up the clutch and fly wheel to the motor pay no attention to the clutch it is a used clutch that did only a few km of work and will be changed since the engine will be pulled out again to be fully built just as I finish the project and have don a few mills of driving to see that every thing is working in order I will take that chance to change the clutch

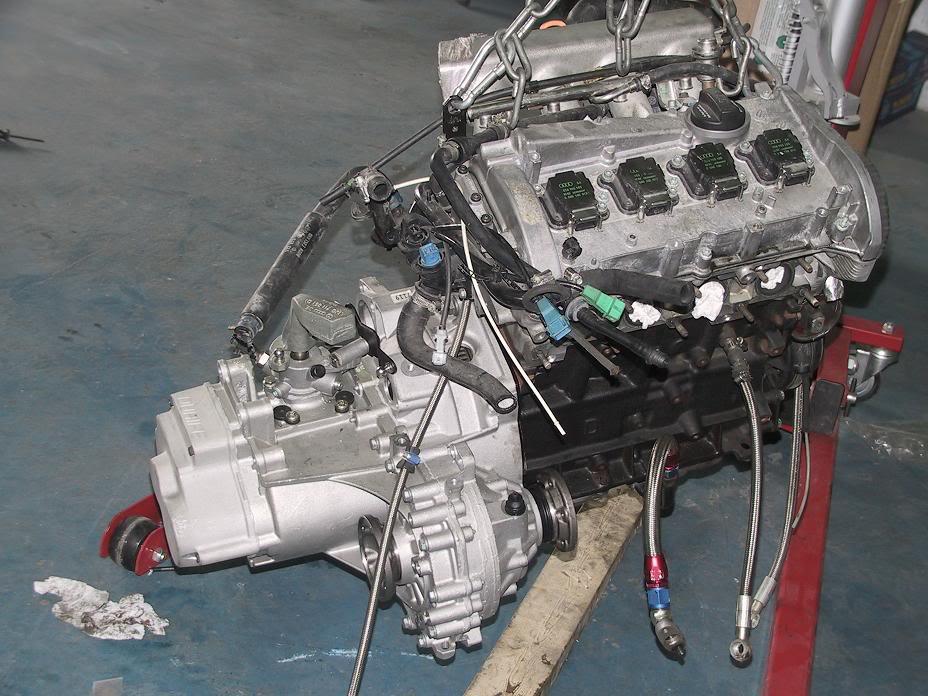

ok bolted up the Quaife to the engine all the mounts have bin assembled to be cheeked from my experience it is easier to first mount the engine in the engine bay with only the passenger side mount then mount the driver side mount, rear mount and front mount when the engine is located in its place

engine is in after more than two years finally again a request pleas pay no attention to the filthy engine bay the body shop that panted the car was requested by me to spray some wax in the engine bay on all of the joints but for some reason he just sprayed the hole engine bay so after about a year it has gotten all filthy

I have a big job ahead of me to clean everything up its going to be hard to stand up to funcksolekitty and polov8 Cleanliness of the engine bay they have established the standards of cleanliness on these projects and it is up to me to with hold it

O rear wind shield is in

Well that's just about it for today still much more work to be don

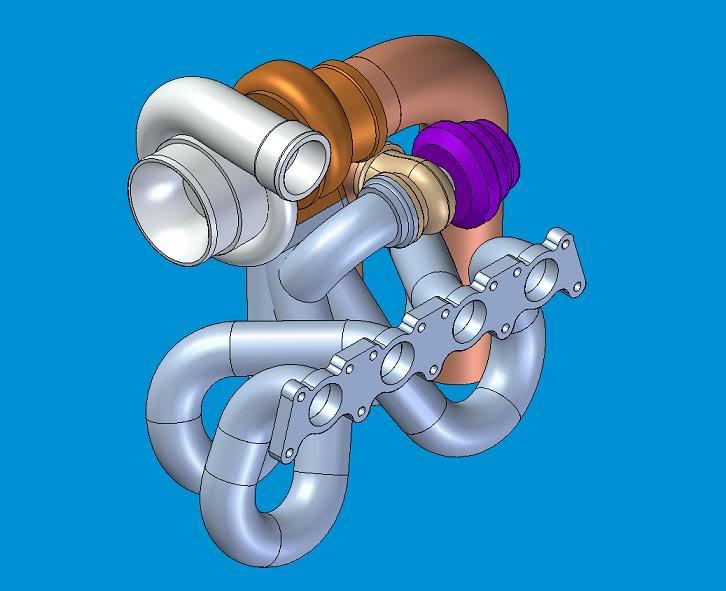

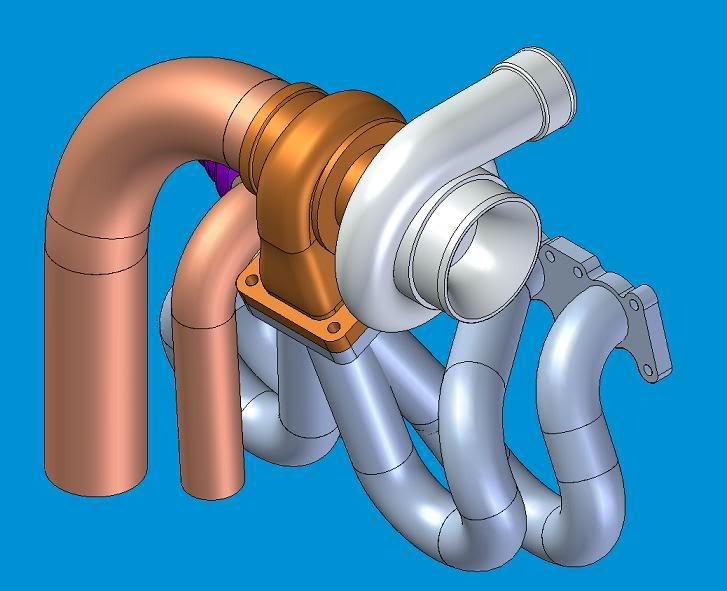

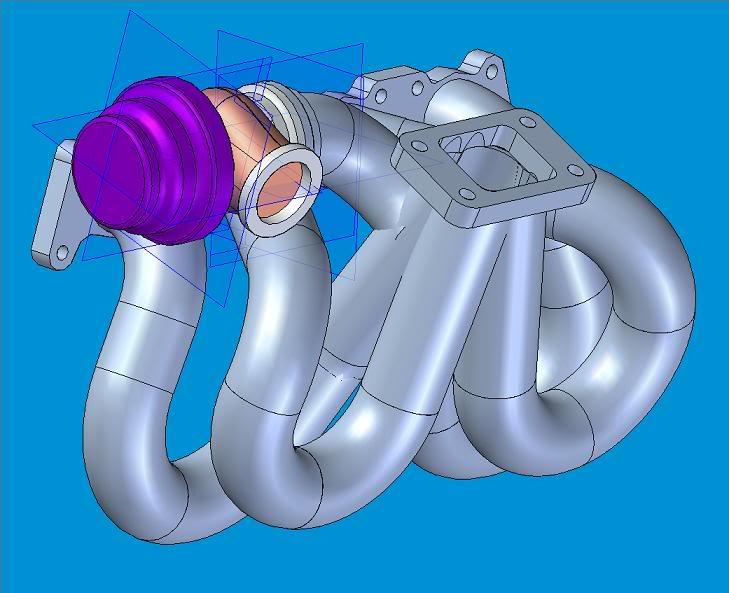

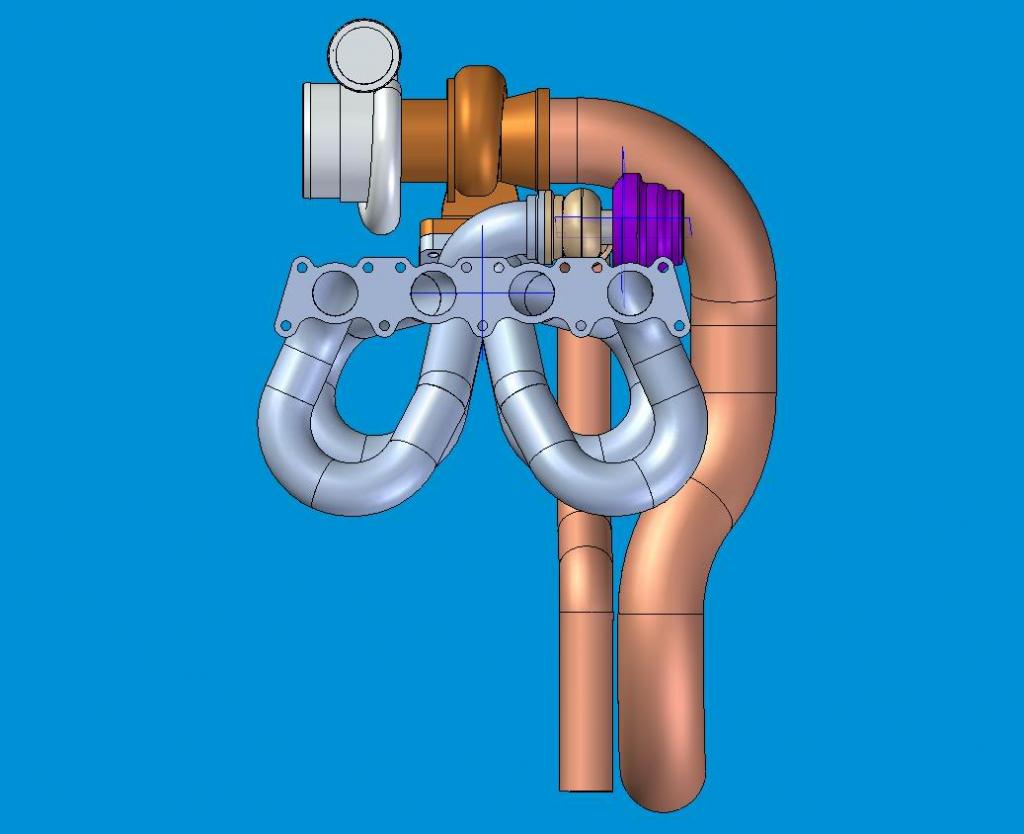

I have started to sketch on CAD an equal length manifold for my GT35/40R using calculations I have don before the engine was mounted so tomorrow I will re check my calculations for the clearance of the turbo and manifold to see if they are correct and if not change the design of the manifold to fit

A few CAD pics of the manifold

8/12/05

Yes I do should I singe you on for one Andy?

Actual as I have seen an interest in the manifold I am going to start to build them

Problem is I need at least 3 people that are in interested not including me to make it worth wile and inexpensive

All though the SS in Israel is actually surprise ably cheap compared to the rest of the world I would like to build them out of ss321 or 310 problem is I can only get it on special order and there is a minimum quantity that I can order

The manifold is intended for a GT35/40R but will fit any smaller turbo considering the GT35/40R much larger and with a touch of a button I can change the manifold to fit any ones requirements

Ok to my project put the door windows on today yes yes I have windows woooooooopy and rear spoiler just look at that sexy bum on Ange prrrrrrr

On Sunday the rear windows and front windshield will go in with the head liner upholstery yup that will be the start of putting together the interior

To my first problem installed the shifter cable gear leaver fingymbom ore what ever you would like to call it an all though it actually sits just in the position I would like it the blessed thing sits to hi up with no purpose at all and will stick out of the center console

Well thing is it's out of an Ibiza only reason I actually wanted to use it is because I hade it left over from a 1.8T Ibiza I purchased as a parts car for a 1.8T corrado I had built

I'm going to see on Sunday if I can exchange it for one out of a MK4 golf that I know dos fit the difference between them as you can see is that the base of the Ibiza shifter is much taller

Actually at the end of all things this is what my little hart desires but will just have to wait to later on

By the way it's an mk3 dash out of a golf VR6

Pics are still up on the second page

No pics of the finished dash because first I need to build mounts and a frame for it to hold the glove compartment only then will I install the upholstery

8/23/05

Have bin working more ore les on the interior getting the dash ready and fabing all its mounts I got some 15x15mm square bar to build the frame for the dash to make it extra strong and hold all the parts together + a shelf instead of the air bag for the DTA P8PRO wind band and built in computer

Next I dismantled the mk1 steering stacks and installed mk3 ones instead

I needed to use the mk3/2 steering lock to mount the mk3 stacks to do that I shaved the original flange because the space for the mk3 one is different that on the mk1 steering not only that I used the mk3 sleeve so I can mount a mk3 steering wheel and have no movement of the steering shaft

Next I started on positioning the Audi TT cluster well ended up needing to shave the cluster and the mk3 cluster trim to give a perfect fit that was a bit of a PITA to give the cluster a good angle so it could be easily seen not only that I also needed to reposition the dash a bit so I could actually see the cluster threw a small steering wheel (the one in the picture is only a peace of $hit demo)

Actually most people doing this swap cut the steering mount and build a new one so they can sit the cluster deep in the dash but I did not want to do this and because the TT cluster is slimmer and I did want it less deeper in the dash it turned out perfect for me

Mounted a seat and vwala only need to extend the steering wheel distance using a 60mm spacer in the end it should all be positioned beautify at first I was under the impression I will need to lower the steering wheel a bit to give a good driving position and a good vision of the cluster but no need for that apparently

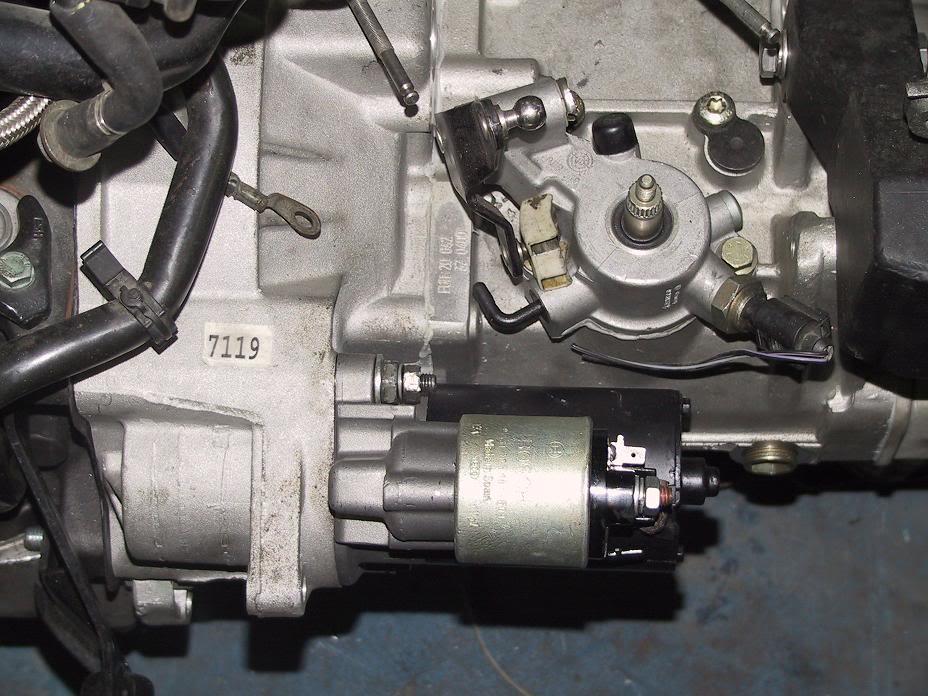

Next my friend finally delivered me my new starter courtesy of his starter/alternator rebuild shop he has

Well all of this + tracking down some parts I needed has more ore less taken up my time it's the small details that take the most of it

Tomorrow I hope to finish with the dash frame etc so I can take it home and cover it with the Alcantara trim I did for it

Next on my list will me installing the roof trim which has bin delayed because I couldn't fined any fin sponge to cover the pilers (seams to be a shortage in my area)

That's about it I am sort of stuck with the progress I'm still waiting for my new control arms and polyurethane total kit to arrive so I can start on the suspension and mount the brakes

And from next week I will not have much time on my hand to work on the car any more because im starting a new job which is good because im going to be working at a salvage yard as a sale representative so lots of cash to spend on the project and all the second hand parts my little hart desires

8/31/05

So I have installed the roof trim in the car Actually not such a hard job to do but if you want to do a good job its going to take time and pacians to stretch it to a perfect fit Well the roof trim I sowed about a year ago and finally got around to putting it in as you can see I got some 5mm sponge to cover the side pillars to cushion the trim and give it shape Then I started to stretch the fabric using the old rear seal that I cut up into peaces and used as pegs to hold the trim in place will I stretch it then after stretching it from all angels I removed a section of pegs and applied contact glue first started with the trim that goes under the rear windows so I can install them to hold the trim in place then moved to the trim that sits under the rear hatch seal then the doors and finally the front windscreen But I have bin having a really bad week and everything seams to have bin going wrong I asked a friend of mine to help me install the windscreen next thing I know he tries to press it into place and brakes it obviously I am really pissed of after mentioning to him that this is a very delicate job and if it brakes I cant get a replacement one in Israel and telling him only to hold it do not do anything ell but breath and stop doing that as well when I tell you Well outcome is my wind screen is broken making me one very upset and depressed young lad see the problem is I cant get one in Israel

because the car was never actually imported so I tried at the dealers and they want 700$ for a new one even with all my connections I got it down to only 400$ Well I am looking for one any where in Europe that can ship it to Israel all the places I found will not all the places that install windscreens I cheeked in Israel will not even agree to import one for me So if any one knows of a place in Europe that will ship me a wind screen for a reasonable price pleas help me out before I drive my self off a cliff O and for any one that's interested pics of the work know im going to berry my self under a stone

p.s

I hate my camera it makes the color of my beautiful Alcantra look different that what it actually is because of the flash and because it's a peace off $hit of a camera It's actually a much darker color like in the first picture

11/4/05

Some progress not much but every little thing counts I guess

I over come my windshield problem and managed to track down a local company called OSG that makes windshields for world wide distribution I guess lock is on my side because they got a request to build scirocco windshields for the European market so after forking out 220$ I got me a windshield

Any body knows of them? Thing is from what I understand anew windshield goes for just about 100$ in Europe so I really don't understand why I need to pay twice as much for it when they are built in my home land of Israel

Got my self a set of prothane total kit mounts to go all around dismantled the rear axle cleaned it up and put a fresh coat of paint on it Mounted the new mk4 brakes but I still need to get my hand on pads and hand brake cables that will be long enough to reach Although like usual I always have a change of mind I got my hands on a set of rear ventilated brake from a golf V5/r32 for well practically nothing I just love working at a salvage yard and all the perks that come with the job The calipers will mount up on the Ibiza axle's and a set of 4X100 10 16v front discs are almost an exact replacement for the 10Â discs that are 5X100 which won't work for me only difference is the width that is 2 mm smaller which is not a problem because the offset is OK

Some new door handles that will get painted and that's just about it I haven't had much time to work on the car like usual but have placed a big order for some parts including turbo waste gate turbo accessories fuel rail fuel regulator injectors and a few other things that should bring the project ahead I've also decided to stick with 1.8 and not to go 2.0 so im getting a set of Mahle forged pistons that will be ordered shortly to go with my Pouter rods Well next on the list is to replace the control arms mount all the new bushings and do the steering rack

11/5/05

The rear stub axle is from a 00+ Ibiza (polo) it mounts up exactly to the original axle beam holes on any mk1/2/3

It utilizes a hub unlike earlier models that the hub is part of the rear disc this means you get a beefier bearing which has its obvious advantages and you don't need to change them every time you change the discs + no need in spacing

If I am not mistaking (I have yet to check this The V5/R32 calipers should mount up to the Ibiza stub axle since the mounting point to the axle on the non ventilated caliper careers is the same like the ventilated ones only differences is in spacing to accommodate the bigger discs

I am not quite sure why I want to have rear ventilated discs ore if I really need the stopping power but I guess that in the end it will just look really cool Well much cooler than an UZI anywise any one that did 3 years of service can tell you that an UZI cant hit **** for bricks a MAG would be much more affective and practical

11/20/05

Just a picture of the R32/V5 rear caliper's

Now what do you guys think should I paint them in red to match my 4 pot Brembo's up front?

11/22/05

Well since a few people have approached me in IM asking how im doing the R32 brake swap I have decided to elaborate on the swap

For this swap you are going to need rear hubs and axels from an Ibiza 20vt

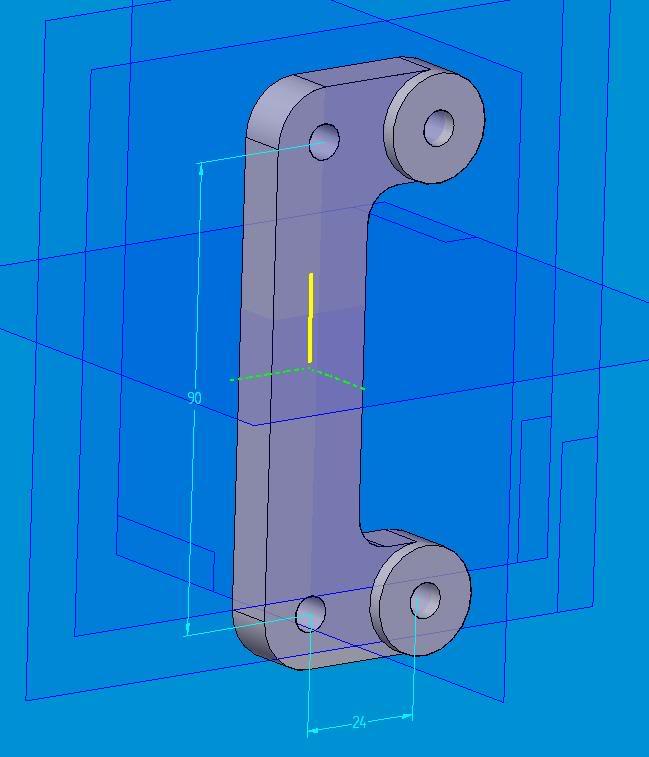

First of all it seams I have jumped the gun and after checking things out im going to customize a mounting bracket for the R32 calipers to fit

I have added a few pics and a cad sketch of the final bracket I will be fabricating to help understand what I am doing

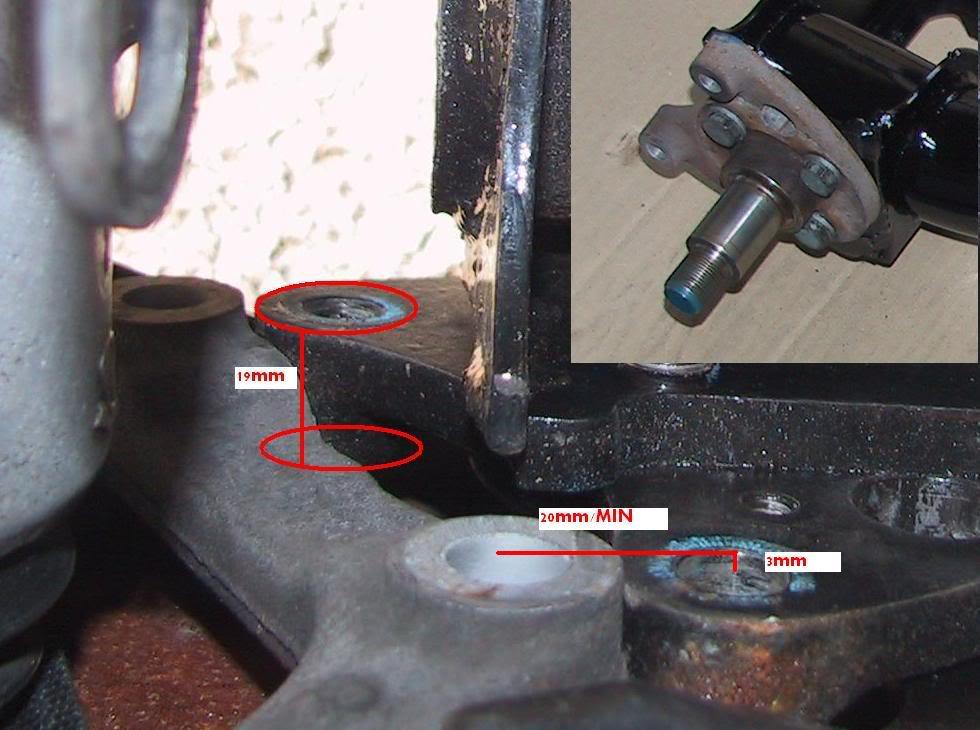

Now down to measurements:

Distances between the mounting points of the carriers to the axle is - mk4/90mm R32/90

Distance between the mounting points on the caliper to career is - mk4/118mm R32/118mm

Distance between the mounting points of the career to the back side of the disc is - mk4/13mm R32/35mm

This means I will need to offset the R32 caliper 22mm towards the inside

The width of the axel mounting ears is 19mm

Original caliper carrier is mounted on the out side of the axle mounting ears

by using a mounting bracket on the backside of the carrier and backside of the axle mounting point I will need an additional 3mm spacer between the mounting bracket and axel to compensate the 22mm offset needed since mounting the carrier to the backside of the axle only gives me 19mm

Because of the need to offset the caliper the career ears are now parallel to the axle ears this meaning there is a minimum distance between them which is around 20mm

Meaning I can't use 256mm discs because with an extra distance of 20mm minimum disc size will me 272mm since the mk4 disc is 232

Radius of a 232mm disc is 116

Radius of a 256mm disc is 128

128 -11=12

Meaning there is need of a bracket spacing an extra 12mm between the carrier and the axle

But as I mentioned there is a minimum distance of 20mm because of the interference between the carrier and the axle

So next best thing is a 280mm disc

Radius of a 280mm disc is 140

140 “ 116 =24

So the mounting bracket needs to be 24mm between each of the bolts

Now to the discs

Mk4 Ibiza discs have a 34mm height between the back side of the disc to the mounting point on the inside

After checking a 280mm front disc from a corrado has a height of 34 mm as well

Meaning they will fit beautifully Since there width is 20mm And the R32 discs width is 22mm Which is not a big difference and should not cause any problems

11/30/05

Well my dad was in LA and picked some parts up for me from ATP which is one of the mane suppliers of parts for my project and being distributed by a my fiend and associate in Israel for performance upgrades

I was actually going to join my Dad for the trip and com to the GTG but couldn't get time off of work to make the trip worth wile but on the positive side that means I now have some cash put aside for my solid lifter head kit

12/23/05

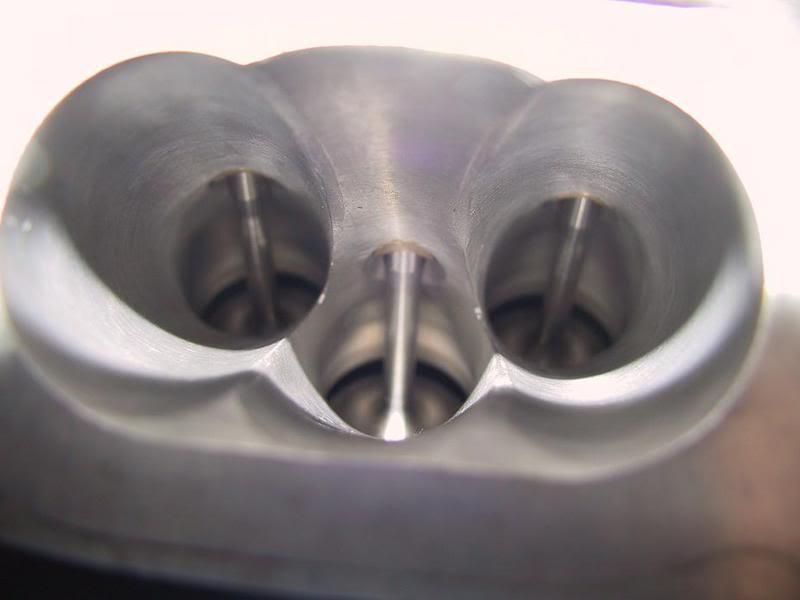

So pistons look beautiful pornolishis and thanks to bobqzzi for the grate deal!!

Well not much can be said about them except the fact that they are probably the strongest pistons on the market made Mahle seam so too because they mention that very fact in the manual

Pistons seam to have a gray coating I don't know if it is ceramic based ore not but looking at a F1 piston picture of a Mahle piston it seams to be the same coating and quality of piston

Unfortunately I will not be installing them in my engine just as yet because I first need to finish my project on the car before I can be worried on building the engine

They will be going in with a set of Pauter rods I have forged crank Race ware studs big port cams solid lifters etc etc....you know all the usual

1/6/06

Just a few more parts came in

ADR big port head flange to for my intake manifold I will be building soon with velocity stacks

Exhaust and T3 flanges from 304ss bar for my exhaust manifold that I should start working on around next week when some SS321 pipes come in

And Raceware head studs because you can't ever be too safe

More to come

Its bin raining so i haven't worked on the car for more than a month but hopefully some work in progress updates soon

3/2/06

Intercooler has arrived!

It's a HUGE B****!!!

Spearco Wave technology core 24X12X3.5 with 3Â in and out pipes

One good thing about the MK2 is lots of room for a healthy intercooler

Although I did do my homework and measured then measured again and to finalized it by...... measured once more I had my worries it wouldn't fit because the pipes mite hit the tray support pillars

But in the end it's a perfect fit and has good clearance I test fit it with the radiator as well which sits perfectly in the pic its leaning a bit forward because there is no support but actually the intercooler sits quite snuggly under the tray

Getting it in was very tight and on the edge I needed to take the air temp sensor of to be abele to slip it in actually I thought at the beginning I would need to take the intake manifold off which didn't really worry me since I am building a custom manifold with shorter runners anyways

That's it I have don some progress on the car but nothing interesting since it has bin cold and raining all winter so it took my inspiration away to work on the car

4/5/06

So I went to do sum shopping yesterday for Ange and ...................

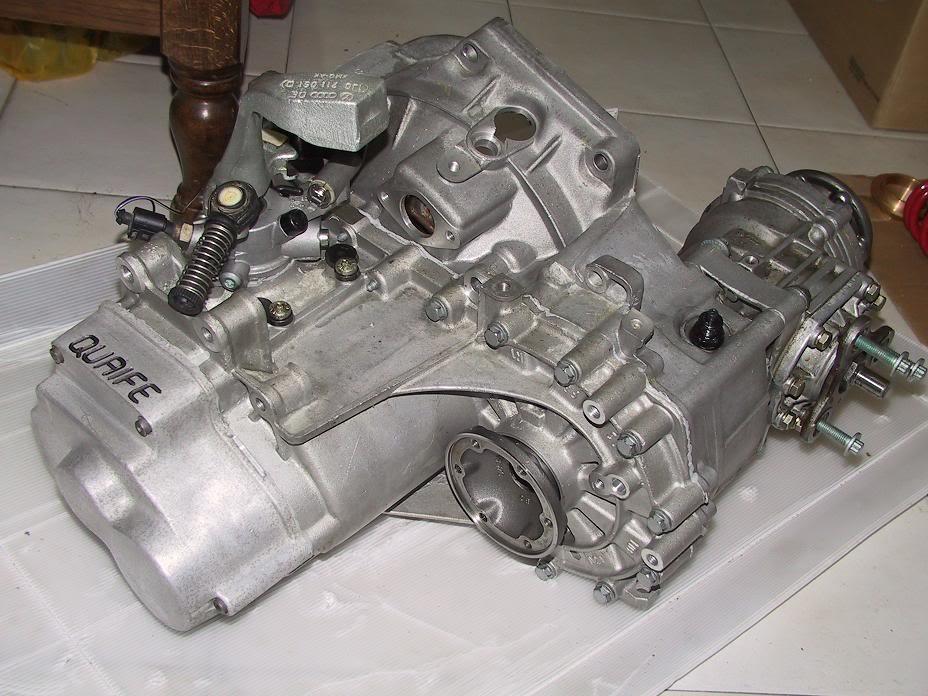

Ange has a complete Haldex swap now

It's a Golf VR6 rear end with 40.000 Km and a Skoda 4-motion 02J tranny with 10.000km which means it has a transfer with the ratios needed unlike the 02C trannys

And I can swap my 6-speed Quaife set into it with Peloquin diffs front and rear

Damage to my pocket wasn't that bad actually only 1500$ for it all and I have 2 ½ sets of drive shafts to go with it which means lots of spare couplings

My mom told me when I got home and I quote "maybe if you spend all the cash you waste on you car on a good psychologist you mite have some hope in hell to torn out normal"

me normal is that posibal

4/8/06

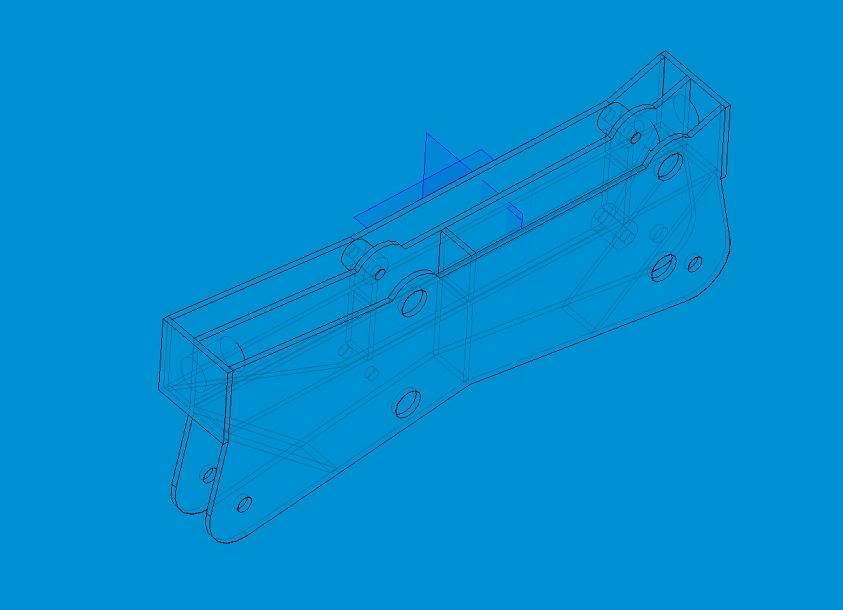

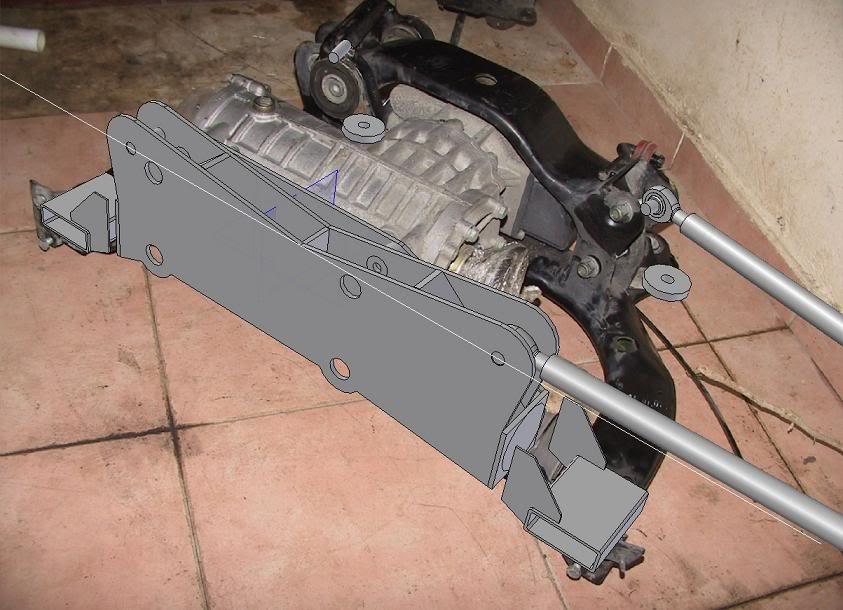

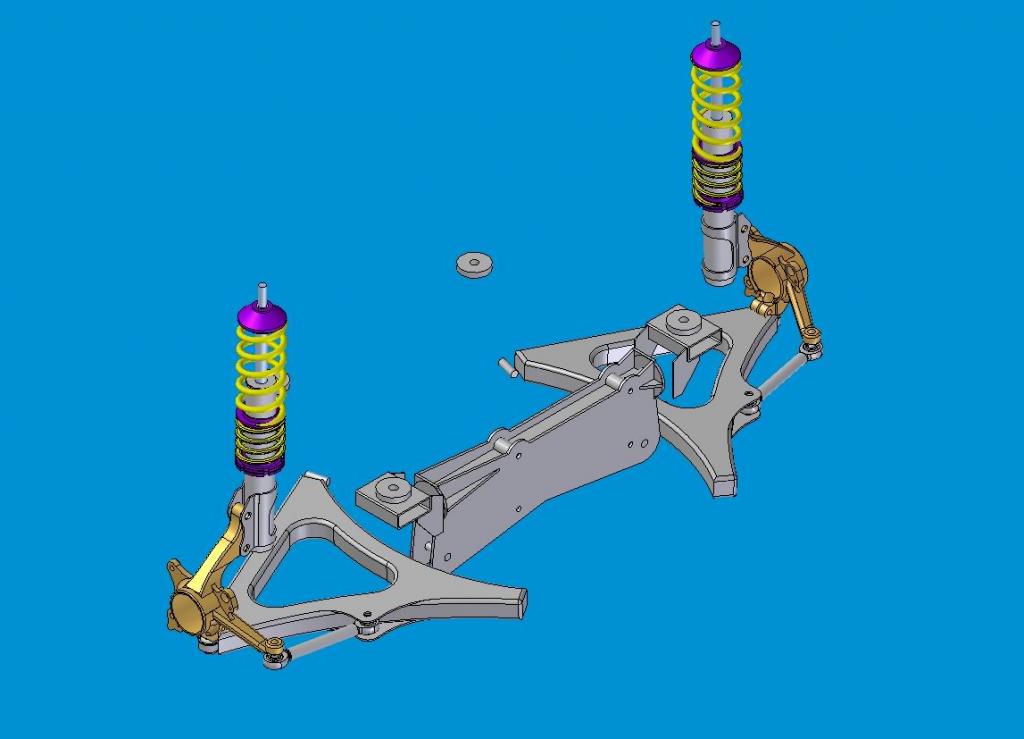

Ok I have bin working on sketching a rear sub fame assembly to replace the original aluminum bridge that holds the differential on the rear sub frame

The reason for this is to add two points for the assembly of the link rods of the rear suspension

This makes the swap quite simple because im am using the 4-motion sub frame which means less fabrication this also make the mounting of the sub frame quite easy only need to add a second cross member in the rear to get 4 mounting points for the sub frame

I will be using 3 links two traditional links from the sub frame to the wheel hub carrier's and one longditional link from the hub to the mounting point of the original sub frame

In conjunction with golf mk2 front wheel hub carrier hubs and coilover struts

I'm lucky the tranny came with the front part of the drive shaft because it seams that the 4-motion 02J coupling is different from the 02M coupling

All though I will not be using the 4-motion drive shaft because it is impossible since the transfer sits of center you most use a drive shaft with 2 joints to accommodate for the stray

I will use a Rallye drive shaft shortened in the rear and change the front and rear couplings of curse I will take it down to the local drive shaft shop to have the work don and the shafts balanced

I have also decided to get a golf Rally tunnel this way I won't need to lower the engine and make new mounts also this way everything sits much better positioned

I'm probably leaving a lot out but I will update with in length descriptions of how to do this swap

now for pics of the rear subframe i have bin working on

O!!! and a COOL! new trki i learnd on CAD

7/25/06

Updates and as usual it always gets me excited

Well Just a few simple parts like GT to V-band 3<4 for the 4 DP

And few silicone hoses for the charge pipes

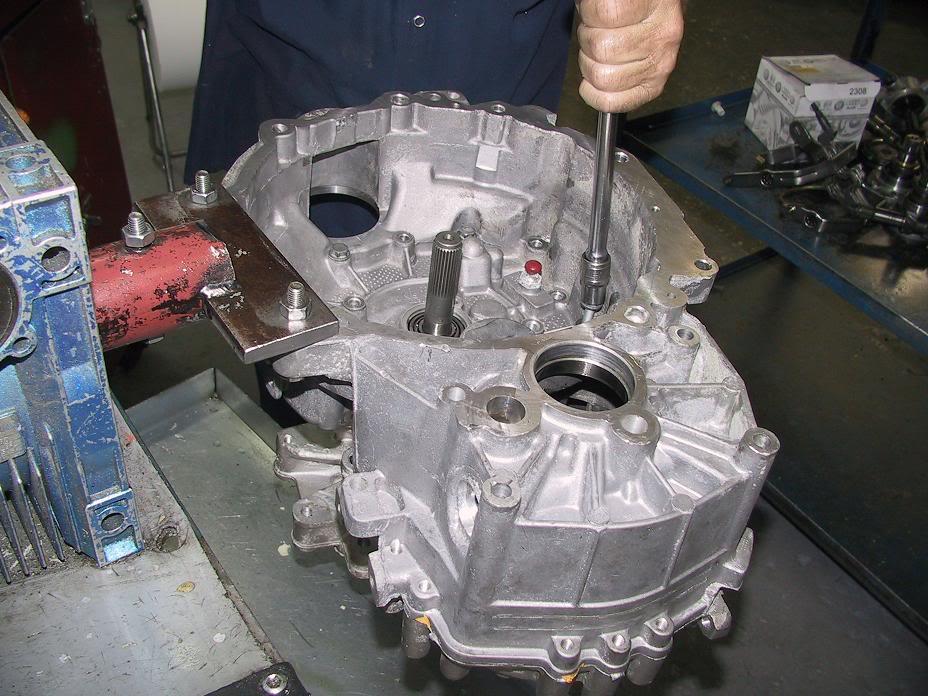

Peloquin front Diff has arrive so it was also time to take booth my tranny's apart the 02J 6-speed Quaife and the 02J/C Haldex Tranny

02C/V bolt in flange diff and boy is it Pornolishis

Basically what I did was change the bell housing on the Quaife tranny for the 02C bell housing and transfer and installed the Peloquin diff

Of Corse the differential pinion and mane shaft where balanced and clearenced in the new casing even though this tranny wasn't ever used I changed all the oil rings in pored in new original VW tranny oil

final drive was heatid and instaled very important

Even though im installing a solid lifter head and will be pulling to 9000 rpm I decided to keep a 3.388 final drive

Which give me @9000 rpm shift the following

Gearbox:- O2J Quaife 3.388

Tyre:- 215/40/16

-------------------------------------------------------------------------------------------

Top Gear gives 24.952 MPH/1000 RPM and a top speed of 224.568 MPH at 9000 RPM

Engine speeds in top gear:-

30 MPH = 1202 RPM 40 MPH = 1603 RPM 50 MPH = 2004 RPM 60 MPH = 2405 RPM

70 MPH = 2805 RPM 80 MPH = 3206 RPM 90 MPH = 3607 RPM 100 MPH = 4008 RPM

Top Speed in 1 gear = 65.880 MPH

And changes into 2 gear at 6366 RPM dropping 2634 RPM

Top Speed in 2 gear = 93.134 MPH

And changes into 3 gear at 6998 RPM dropping 2002 RPM

Top Speed in 3 gear = 119.770 MPH

And changes into 4 gear at 7200 RPM dropping 1800 RPM

Top Speed in 4 gear = 149.712 MPH

And changes into 5 gear at 7170 RPM dropping 1830 RPM

Top Speed in 5 gear = 187.923 MPH

And changes into 6 gear at 7531 RPM dropping 1469 RPM

Top Speed in 6 gear = 224.568 MPH

************************************************** ***************

Ok im still working on CAD designs for the rear suspension just a small glimpse of what im working on when I finish I will post the full design CAD sketches!!

1/7/07

got this Tial 50mm BOV what can I say pure CNC porn

Haven't worked much on the car well not mechanically im still working on the rear suspension layout on CAD which is on top of my list to get finished

Got a few new parts that should arrive in a few weeks first is a Dahlback full race solid lifter mechanical head and may I say YHEAAAA BABY!!!!

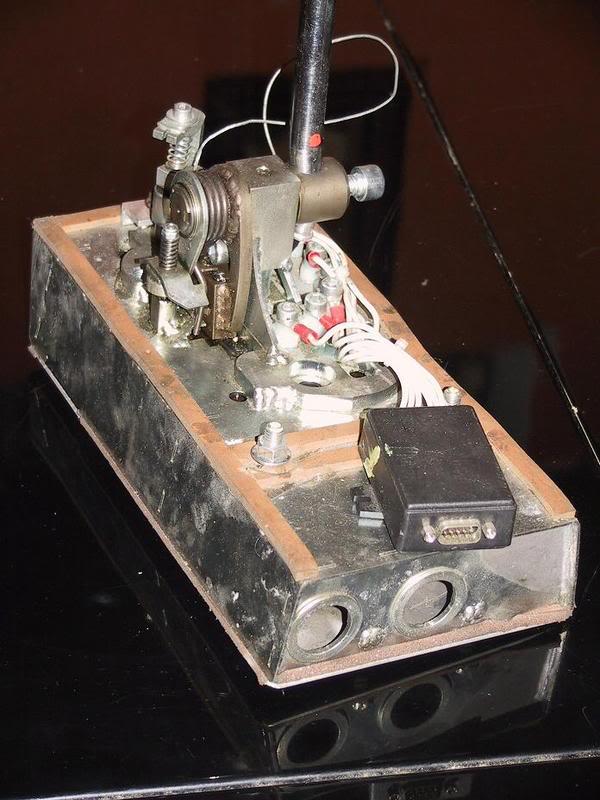

Second is a SQS sequshift sequential 6 speed shifter for my Quaife

Im very exited.. very exited

3/17/07

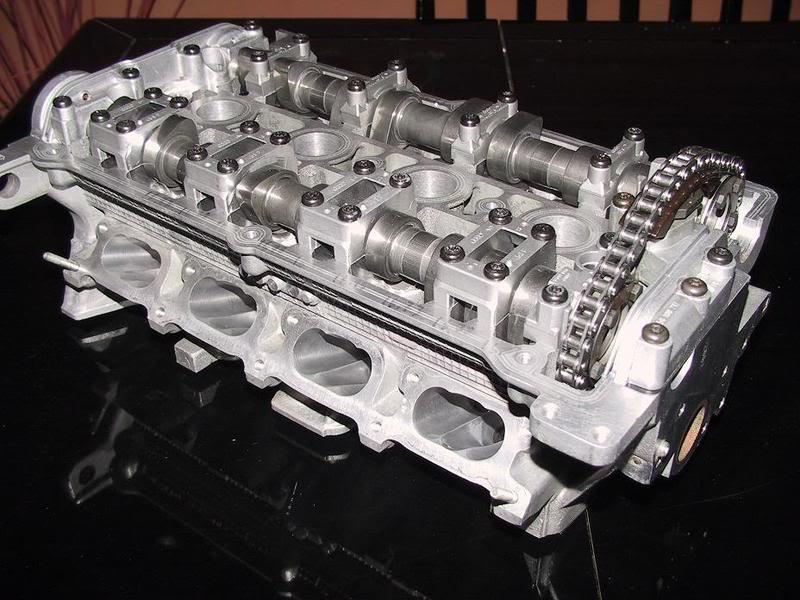

Ok head has arrived

Port and polish complete Schrick solid lifter conversion including upgraded springs titanium retainers seats lash caps and ferrea intake and exhaust valves

I'm not sure what im doing with the block yet mite just ship the crank pistons rods FW and pulley to the US to get balanced

Also got an SQS Seqshift sequential shifter

This baby will help with shifting as well as give me gear related boost it comes with a gear position display but ill just have it hooked up to the DTA which will feed the G-dash with the info

Work on the Haldex is to begin in the summer and hopefully finish it as well

I have don som renovations and will probably use Audi TT spindles in the front and back because I don't like the idea of using brackets to lower the control arm pivot