You must be logged in to rate content!

11 minute(s) of a 249 minute read

9-14-2010

Worked on the cooling system, the turbo cooling lines are a PITA, ran out of parts so headed to the junkyard.

Didn't find the coolant parts that matched what I needed, but I did get some other decent stuff:

Mk4 gas pedal and throttle cable to replace the DBW setup:

Throttle cable bracket for mounting on the intake manifold, that I'll need to fabricate a bracket for:

All sorts of assorted crap that might be useful, such as the bolts needed for the radiator support:

A bunch of coolant lines from my own collection, I'll make something work:

Mk4 fuel line protector - might be useful with the turbo and the currently unprotected fuel lines..

So this is the stock pedal setup. The firewall hole for the throttle cable is behind it, and has a grommet blank on it.

It's held on by two bolts. I finally get to use the flexible angle 1" extension that I knew I'd need one day, along with the weak but useful angleable socket allen:

The old pedal and the new pedal. The new one looks so much more race'y:

I guess I forgot to snap a photo of it all installed. Sorry!

Off to the Home Depot for some more parts for the cooling system.

Just finished running all the coolant lines to the turbo, heater core, water pump, cylinder head and coolant reservoir. One involved a trip to Napa for a random hose from a 2000-2003 Ford Focus that happened to work well for the spot. I had to use a universal piece of hose for the coolant reservoir, until I can find something from another car that has the correct bends.

The only other coolant lines I need now are the two radiator hoses, but I will have to wait until I bolt the front end again.

Next.. Boost lines and fitting a intercooler, and swapping the oil pan / pickup / welding the oil return.

Fitted the radiator and support back on to line things up, got the bottom hose sorted from one I had laying around. Top hose will need to be found, but it doesn't look too difficult.

Started to work on the throttle cable holder for the manifold.

Ben came over and helped try to bleed the clutch slave. It didn't work. It's been years since I've bled one from empty, and I seem to remember that doing it with the same method as a brake caliper doesn't work. Need to work on that again tomorrow.

Tomorrow's mainly going to be boost lines and a intercooler setup.

Need to take care of some axles..

90mm Polo axles cross reference to match every O2O transmissioned Golf/Jetta mk2, but the only cross-reference I can find for 100mm inner joints are to a 1989-1995 Scirocco/Corrado, which I assume ETKA means Corrado by.

Hmm... Not sure if I should get 100mm axles for :

a) Scirocco 16v (short)

b) Corrado G60 (medium)

c) Mk2 Golf GTI 16v (not sure the difference between that and G60 in size)..

9/16/10

So here's where we're at, in a simple air/fuel/spark sort of way, before we can get the car running at least to test it :

Air : need to get harvest MAF, install with cone filter. Simple*

Fuel : In-tank pump in, but not wired. Need to choose external pump pump and install in engine bay. Something cheap, common and simple - Ford Mustang FI pump? VW Fox external pump?

Spark : Need to harvest ICM from on top of airbox, sort final few unknown engine connectors.

Water : All hoses done except radiator upper. New (backup) radiator on its way.

Oil : All lines finished, need to pull oil pan / mark new one / weld new one / install new one, new oil filter on already, need to buy oil.

Boost : Which bring us to the intercooler and charge pipes;

I thought this was going to be a nightmare. The polo is short on room at the front, I don't want to (further) destroy any bumpers, there's no room behind the grille, and moving the radiator back is not a good option as it takes away what room there is back there. This, and limited time and budget, made me think about trying the stock Passat and Golf/Jetta sidemount intercoolers that I had sitting around. Not ideal for big power, but with the stock turbo and light car with no A/C, PS etc, it'll match the rest of the setup and won't be a bottle neck.

So I tested fitted the Passat one first, fearing the worst and imagining some horrible 180' tight turns in pipes etc...

With a little bit of clearancing on the frame rail it will fit like it was from the factory. I refuse to cut framerails lightheartedly, but again, everything is better than expected and the closest edge to the intercooler on the rail is just a thin piece of metal that extends out from the actual box section, so I'm going to angle it down slightly and not cut it at all. This will give me a few mm clearance on both sides, that I'll also use foam between to further protect both metal pieces.

For the upper boost tube, to the throttle body, a Golf/Jetta stock one should work fine once trimmed down a little bit:

For the outlet from the turbo, the stock G/J pipe is great. The next one will need to be spliced or welded to extend it, but the bends are nice. The next two turns might have to be chopped up a bit, and... I'm probably going to have to use that stupid pancake pipe, blah. Still.. it should all go in tomorrow with any luck.*

At this point, rain and not having the car up on ramps stopped play. But I have time to harvest the airbox for parts, and also snap some photos of some unknown connectors.

Inside the Passat airbox, the MAF:

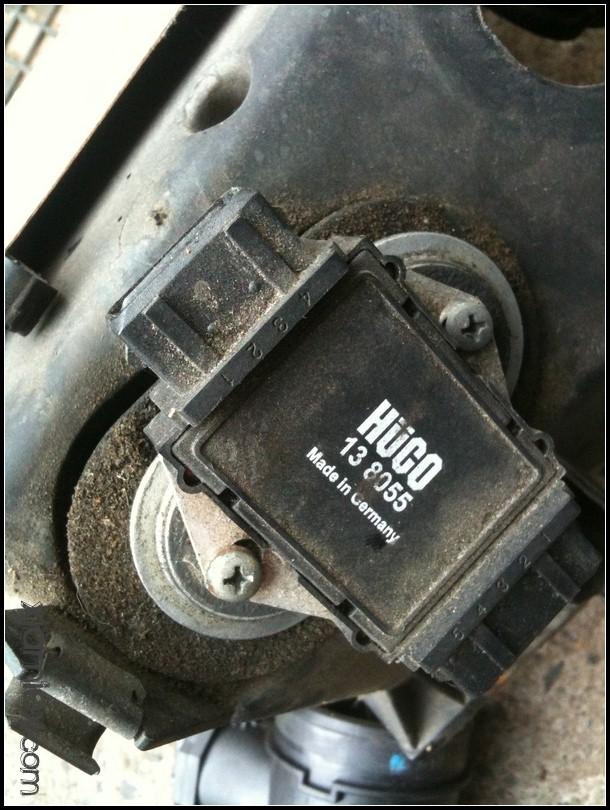

And on top of it, the ICM:

Removed, the rest of the airbox is junk. The MAF goes on the factory G/J Intake tube, with a cone filter on the other side. The ICM needs to retain its heatsink, and be installed somewhere relatively safe. For all the upsides of using the AEB swap, the ICM is a downside.

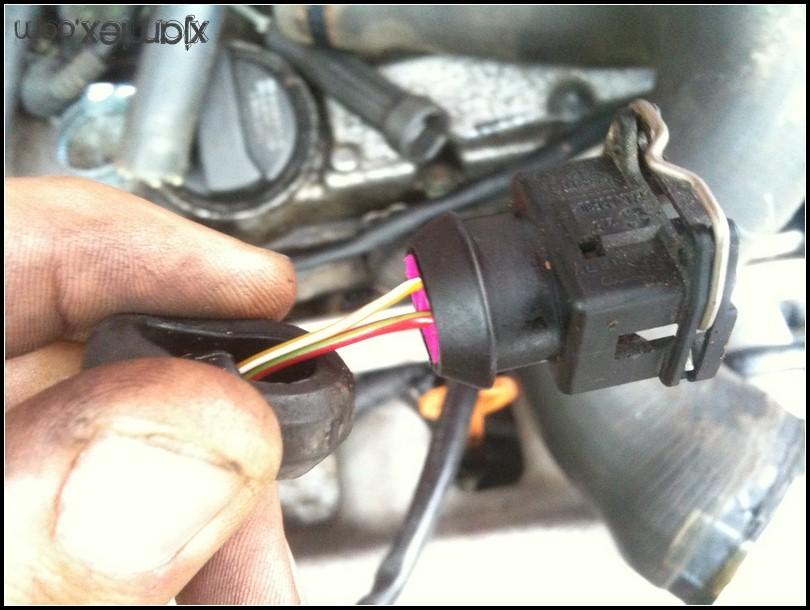

And finally three unknown items..

The first I guess is a ambient air temperature sensor:

The next time i'm not sure. Ones wiring is yellow/white & red/yellow, and the other is violet & red/green. If it keeps raining i'll check my wiring notes for the answers..

*knock on wood.

9/19/10

Too busy workin' on it!

Friday: Prep work, nothing amazing.

Yesterday:

Ben, Eric and I working again, starting early at 9am and working until sunset (with time to eat tomato pie and Rita's Water Ice). Can't say thanks enough to these guys for their help and support.

Installed new mk2 axles. They are the correct size.

Mocked up intercooler piping - found someone selling new aftermarket pieces on craigslist only 10 miles from my house, so went and bought them. They'll work.

Removed Passat oil pan.

Cleaned, marked and drilled mk2 16v Golf oil pan.

Welded two nuts inside oil pan for oil return from turbo.

Installed shorter mk2 16v oil pickup, and oil baffle. Welded used oil pans makes some crazy smelling fumes. Cough.

Cleaned both gasket surfaces for oil pan gasket (using thick rubber/metal one instead of awful sealant that gets sucked into the oil pickup).

Tried to install oil pan - bolts are too long for the steel pan.

Installed more sensors, moved some wiring

Went to warehouse at 11pm to get shorter bolts.

Removed interior to access fuel pump wiring.

While the seats are out Eric vacuumed and cleaned a bunch of the interior. Amazing, because I hate detailing.

Test fitted mk3 G/J seat base. They fit, so the car's likely getting some special front seats.

Removed the intank pump to verify the depth of the pickup compared to the diesel pickup - the gas pump is actually slightly deeper than the diesel one when it has its filter installed, so no problems. I was worried it might be significantly shorter and therefore mess up fuel levels.

and finally, went to Walmart at 11.30pm to get Mobil 1.. which means it's getting serious!

I'm probably forgetting a bunch of other things, and the photo taking rate has really dropped off as the workload has sped up. I'm hoping to get the car insurance and pay for the annual years registration tomorrow, so hopefully today will be a big day of progress. If it's not at least running for a couple of seconds by tomorrow, it's unlikely to be driven to the show at the end of the week.

There's a hole in the fuel tank. It doesn't have a drain plug, it has a hole that someone [damn you Danish worker who stripped the car!] drilled in it and then stuffed a random 10mm bolt in.

Here's how we found out:

Got the final radiator lines sorted.

Fixed a issue with the alt.

Hooked up the belt for the alt/WP/crank.

Temp. connected the MAF, sensors, wiring etc.

Put 2 gallons of gas in tank. Tested in tank pump, cleaned fuel line.

Connected fuel lines.

Put oil in car.

About to start car.. and notice the huge puddle forming under it.

Damn.

I'm not dropping the tank. I'm going to buy a bigger bolt, with matching nut, fender washers and rubber washers.

I'm going to weld the fender washers to the bolt / nut, to seal that joint, and then fit the nut through the hole from the outside, using a spanner to hold the nut on the inside. My hands are too big to fit inside the fuel pump opening, so i'm looking for volunteers (my wife should be home shortly)..

That should just about solve it, in a pretty permanent way. I think this is a better option than trying to plastic weld it or glue it shut.

So.. Home Depot Motorsport hardware. Zinc Coated:

I don't fancy breathing in zinc fumes while welding (after yesterdays breathing of old oil fumes while welding, plus todays covering of gasoline), so gave them a quick shot:

All ready to weld:

Start welding and.. ran out of wire.