You must be logged in to rate content!

5 minute(s) of a 127 minute read

7-14-2019

Abit of an update, made this water pipe, goes from the heater outlet to the lower section of the radiator with a T off to the coolant res, made out of 20mm galv conduit with a sealed T connector, threaded in place then welded

shown in place at the back

couldnt get anything to flare this small and thick of a pipe so blasted it with some high power weld to put a lip around it

shows routing around the front, i did have to remove the engine mount to fit, there is also a mount to the engine to take its weight

boost pipes, ive turned around 4.5m of 3" tubing into cuts so far i have around 2 hours cutting and almost the same in deburring

turbo outlet 2.5" v band to a 3" adaptor

these are going to be mixed up abit due to amount of pics and it being 0030

2 parts of intake and 2 halves of boost pipes for the first lot of welding 54 pieces in that pic

showing post intercooler with silicone hump joint

later stages of intake double flange and joint, mount made so it could be held correctly with a spacer as left flange is higher then the other

intake and post intercooler

pre intercooler

another intake pic showing its shape

hard to see but intercooler lower brackets made out and painted etc

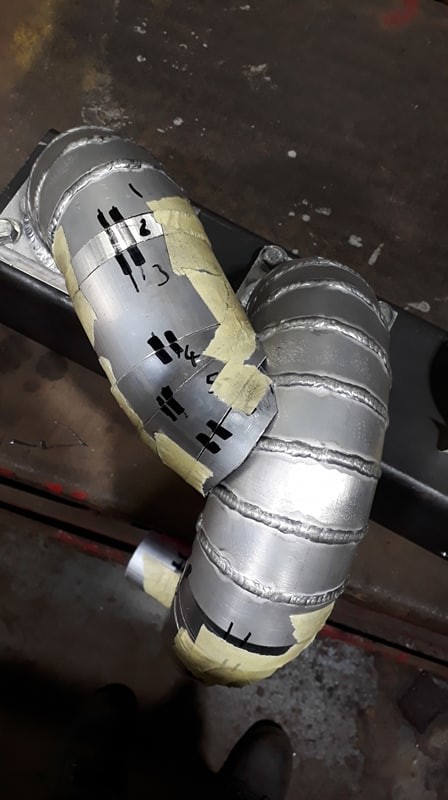

bungee cords and rubber washers to hold it all in place for figuring its routing out

another simple job, literally a case of making it upside down and wrong way around, selector is of a LT77 gearbox, bought an adaptor to use it on the daf 45 box, only issue is its too short and when used the H pattern is the wrong way (as the selector housing is rear facing oppased to fowards like on a land rover) way to overcome this is to flip the pivot point like below

cutting out the plate to essentially make a flat version of the right

rough cut to flip the pivot to underslung

alot of head scratching to get to this point, need to get selector welded to plate and some repair work to selector ball housing as its wallowed out, you can kind of see this below the centering spring as the peg is offset to the slot, i will also have to flip the selector stops after abit of welding

2 hosuings made into 1 and new rod machined to suite, i did have some alightment issues, basically fling sanding polishing and using valve lapping paste to get a nice movement

you can see some of the heavy wear on the shorter rods due to there shine

finishing off the fuel line mountings, no space to run the lines side to side on the chassis leg so spacer with a p clip top and bottom to get it all nice

similar spacer jobby for the pas lines that run out of the way, i was short of 1 spacer so i drilled out a socket and used that too

Comments

I bet the purists probably don't like this, but screw them! This thing looks like a blast!

Posted by stevegolf on 10/22/20 @ 11:15:40 PM

This thing is insane. Definitely not a swap I would think of doing, but it looks like it will be a blast to drive. I like the mad max look you have going too.

Posted by MPower on 10/1/20 @ 8:26:26 PM

Wow thanks for sharing!

Posted by Diggymart on 9/20/20 @ 2:50:40 PM

This is my kind of build right here. Very nicely done!

Posted by Squonkwerkz Garage on 9/28/21 @ 2:07:53 AM