You must be logged in to rate content!

6 minute(s) of a 643 minute read

1-6-2013

Better photos of the tint (20% all around).

I had an interesting issue today. I'm not sure if it's common or not, but I did a search and didn't come up with anything, so I assume it's fairly rare. My clutch linkage broke!

I was driving to a family get together and I pushed the clutch in and it went straight to the floor and stayed there! I ended up in neutral at the time so I coasted along until I could get it into 1st gear and then I managed to pull into a gas station.

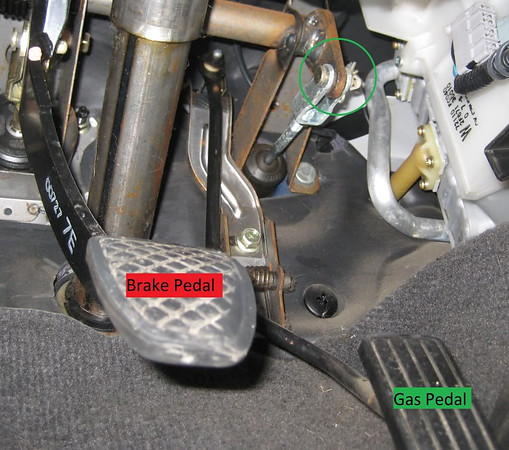

I really had no idea what had gone wrong so I checked the slave cylinder (no movement) and then started to follow the clutch pedal along it's path and eventually noticed that it was not connected to the master cylinder at all any more. The linkage is usually connected with a rod that is held in with a cotter pin and then a plastic cap on the end. Here are the best photos I could find online:

I looked around my floor mat and luckily found the rod that had fallen out. I also found the broken plastic cap, but I could not find the cotter pin. Looking at the rod, it appears the cotter pin broke off inside the hole. Unfortunately this meant I couldn't just shove a new cotter pin in there. Here's a photo of my broken linkage piece:

I ended up sticking the rod back in, without the cotter pin at all, and friction seemed to hold it in well enough to drive the last few miles to where I was headed (and drop of my wife and baby). Then I borrowed a car and went out to the hardware store to see what I could find to repair it.

From what I could tell the OEM part is 8mm in diameter. The only shoulder bolts they had were SAE so I got a 5/16" shoulder bolt that had a shoulder that was the same length as the OEM part. I also got a locking nut and the necessary tools (wrench and allen key) to install it. Here's a stock photo of what I bought (not the same dimensions):

When I got to putting it all back together I found that there was very little space to work in there (and it was dark, I was out in the street, and I was using my cell phone as light), but I did determine that the linkage (the U shaped portion, not the rod itself) was bent about 45 degrees off from where it should have been. I think this has probably been broken for a long time and finally worked itself free.

The lack of space and the bent linkage made it very hard to work, but I eventually got the bolt in and tightened down. The 5/16" diameter is just a hair small, but it's a pretty good fit. The shoulder section is much, much longer than it needs to be. Overall I think this connection method is better than the cotter pin, but I need to get the right length bolt so there isn't so much side to side play.

Once I got home I bent the U linkage back to being straight, but it's still much wider than it originally was. It is all aligned so it is pushing straight on the MC rod, so I'm pretty happy with it, but I'll have to squeeze in the width once I get the shorter shoulder bolt. Here are some photos of how it currently sits:

So now I just have a few questions/concerns:

- Any possibly issues using a should bolt and nut instead of the cotter pin? I will use a locking nut and not over torque it so it impedes rotation.

- Is it possible that my MC was damaged due to this issue, or over time? Is there anything I need to check?

- It appears that the locking nut on the MC rod is not tightened to the U bracket. I will have to go tighten it, but how do I know if it is adjusted properly? I don't know if the rod has moved over time, or just the nut backed off. I do know the my clutch engagement point seems fairly low compared to most others.

That last thing I wanted to note was that I had my MC replaced by the dealer about 2 years ago (when the car was brand new). It was making a clicking noise (an issue some other newer cars have had). The new MC fixed the clicking, but I'm starting to think that their install may have been the cause of this failure (2 years later). No real way to prove that or get them to do anything about it I fear...