You must be logged in to rate content!

17 minute(s) of a 190 minute read

5-6-2012

Fuel Pressure regulator bracket got coated and baked today, and warranted a few photos. Fuel pressure gauge is taped so I dont whack it with something.

I'm debating bead blasting my AC / Alternator / PS pump pieces and doing those too.

6/4/2012

UPDATE! Been almost a month.

Motor is and has been done sitting in my living room, All that is left on that is to solder on my new connector for spark plug and to get my spacer that still hasn't been made yet.

Went to Toronto to buy my transmission from gtasti. Nice guy and had no issues dealing with him. Buddy and I tried poutine. (salty cheese curds and gravy over french fries). It wasn't that good.

Put my axle seals in my trans for the 05+ Axles and began the trans install. It was a fight, because I did it by myself, but I finished the install tonight. Have a torque solutions trans and pitch stop in place, pretty nice pieces. My shifter has every TiC / Kartboy bushing made and it felt really nice once I got it into place. I wanted to rake the gears pretty bad, but with no fluid in the trans, I figured confirming it went into every gear would be the best idea.

Changed out my clutch line late tonight also, that wasn't fun and as always with those little lines, nerve racking, one slip and you have a nice kinked hose. Used a flare wrench to bust it loose, then it was cake.

Finally, I went to connect the electrical portion of the trans, and for the first time of the night, I was stuck and bummed out... Can anyone advise about the NSS and the back up lights comign out of the trans? I dont know if I am going to need a new connector on one end or the other or what, but I couldn't seem to get any of the 2 extra plugs next to the dipstick to go anywhere. I did have the plug for the Vehicle speed near the dip stick, but nothing else.

Any help , much appreciated!

6/9/2012

Well, today was going to be the day to get the driveline back together. Or so I thought.

First started out by replacing ball joints. Old ones came out fine, but the ones I bought at Advanced were too big, so I'm going to take those back and try some others. My thought was to get some to get me by, and once I get some coils, get the whiteline tie rods / ball joints for having a slightly lower car, wont be hellaflush by anymeans, just a nice drop.

Then, since I canned that idea for the time being, I thought it would be a good time to throw on that DSS Aluminum shaft. I knew some minor adjustments would be made so I got out the grinder, plastic mallet and started. Had to grind the front of the rear sub frame, hit where the e brake cables go into the cabin, and it one of the rivets that has a bolt on it for tightening down ebrake cables. Wasn't that bad. I think I will get a utility knife and lob off the corner on my rear shifter bushing cause there is a small small rub there also.

The real problem is the fitment of the shaft. It might be okay... But It seems iffy.

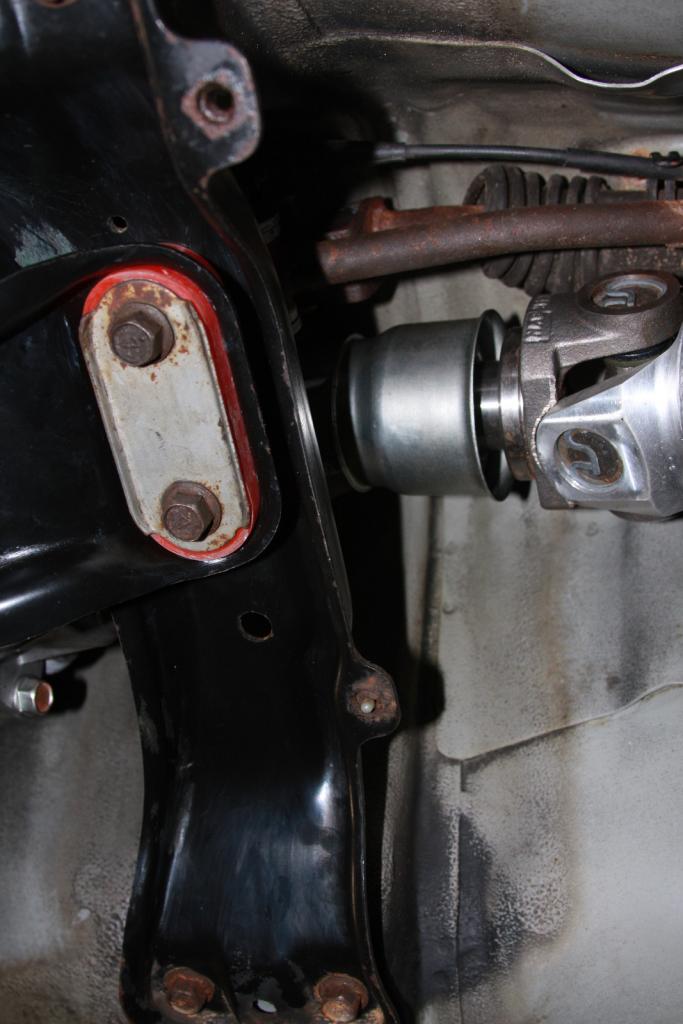

This is with the shaft pushed in as far as it will go.

This is once I suck it back out to bolt up the DS to the rear Diff.

I know there is a seal there, but I think that the boss'd part of the splined piece is supposed to be fully seated is it not?

... Without asking the guy I bought it from, I'm guessing that this shaft is for a different impreza than what mine is or something. It was on this transmission at one point though, so thats why i'm hoping it is fine.

Layvon

6/14/2012

Called and talked to drive shaft shop today... explained the situation and they said that if it was pushes up against the output shaft it would bind up an break.things. the dust shield is nice to have but note entirely necessary. This weekend ill get out the grinder one more rime cause its running rear shifter bushing a bit, and that will be that.

Onto bigger and more fun things.

90% im Ditching the EFR. Really don't want to.. but I just feel that every two months, 2 weeks before BW is supposed to release them, the date gets pushed back. ... I won't have all my money saved by the end of august, but at the end of august if the EFR isn't available .. I'm going to the gtx35 or a PT 6262 or something similar.

Just not loving the idea of all the perephenilia you have to have with them. Exhaust plumbing and bov.

We'll see... still two months away.

6/18/2012

Got sick of waiting and liked the thoughts of only pushing 23-25 psi vs 27-29 on the EFR.

Have a PTE 6262 with the ported inlet and billet wheel, ceramic bearings on the way. T4 .84 trim. Should spool up decent with the smaller AR and still being twin scroll.

Losing some of the fun factor of having something "new" but I guess we can't all be paving the way. jsard proved this turbo a while ago and my setup is quite similar to his.

Getting a 46mm PTE EWG with it and just putting the two scrolls to one Wastegate. Turbo and EWG were still 250 less than what the EFR was going to cost. I already have a boost control solenoid so thats not an issue, and I need to find a BOV worth putting on which will make it about even compared to the EFR. (ANY SUGGESTIONS? Thinking TIAL)

Hopefully will have turbo by July 4th weekend... depends if I still get any bday gifts that cause me to ... accessorize and spend money haha.

6/25/2012

Well... Got the fuel system setup tonight, at least the pumps and FPR.

Calibrated the FPR to about 43.75 psi if I really squint at the gauge, and confirmed that added pressure / vacuum changed the pressure. So that was a bonus.

I bought the lines to this system used and put in new pumps. Talking with the previous owner, he ran both pumps 100% of the time, which is what I'll do initially to eliminate variables. I'm curious though... What is the general consensus on throwing a check valve in front of one of the pumps, and putting a pressure switch on it so that it only comes on with boost?

Thinking something like this

http://www.summitracing.com/parts/EDL-72214/

At 50 PSI, it woudl be coming on at about 6psi of boost. My thoughts are to save wear and tear on that pump. I'm not 100% opposed to leaving them on 100% of the time, but just want to know what is a good / bad idea when it comes to these pumps.

Another option would be to use a oil pressure safety switch that activates at 5psi, but using air instead. This would be easier and cleaner to plumb.

Thanks again fellas!

7/15/2012

Drilled hole in my spacer today. Was aiming for 62mm. Got close enough with a 2-3/8" hole saw and used a 2-1/2" flap wheel to get it the rest of the way. Then finished with 1500 grit sand paper.. Motor will be hopefully 100% ready to go in tonight! Going to keep it in my living room till I have my Turbo and exhaust back so that it can keep the dust out of the.motor

7/18/2012

Well ... time to complain about that drive shaft again. I thought I only had a little nit of grinding to do to finish up, but ended up needing to cut a good sized chunk out of the rear subframe to get it to fit with some clearance.

Then I noticed it was rubbing on my rear stay bushing on the shifter, so I used a fresh blade on the utility knife and shaved a bit off that. . . Then, I had drilled my rear diff out previously because DSS decided that they would use bigger bolts than what is on the diff, so that had been done... but I didn't think about the collars on the bolts being a bit bigger than the threaded shank, so I need approximately a 25/64" (10mm) bit to drill out the holes the rest of the way.

Mike at built industries is about 2 days away from my last payment ( I think) on this build. Turbo and assorted fittings will be paid for on Friday. I'm going to have the Turbo sent straight up to "Fobia" to get my twin scroll setup made. In the process, ill be getting my vipec situated. Waiting to gear back from a few people I've been talking to, or trying to talk to about tuning the vipec.

On a side note... the new AMS intake manifold looks sexy as hell. Hoping Ty will let me be the GD demo cause other than I don't have stock rails ... I'm exactly what he's looking for.

7/19/2012

Paid for the Turbo today and Candy at Built hooked me with shipping to fobiawrx so I'm hoping that will be there next week.some time so he can start on my exhaust the following week. In theory that will be here by the end of August.

Also drilled out those holes today. Put in the front diff cover and there was only a little bit of grinding necessary for that, I just took out the metal guide on the bottom cause it was hitting the u-joint.

Gave it a minor rust protection and finally done and bolted up. Added some fluid to the trans and didn't see any leaks. Next week ill fill er up. ... I'm broke right now.

In the interim between now and ordering my vipec I need to get a map sensor, and an IAT sensor so that I can 100% finish my motor. Had to do some minor grinding on the alternator bracket this weekend. Not positive it will fit once its assembled but I can always take more. A much simpler solution would be the kstech 9.5mm intake manifold spacers cause that is about all I need. The 8mm don't have quite enough to get.over the alternator with ease. If any vendors are reading I feel a 12mm would be the perfect size to avoid hitting the bracket and to keep clearance on the hood.

8/12/2012

Well, small update, but an exciting one. Through the work program for my truck, I get paid around $0.31 a mile, and last month when I went on storm work in West Virginia, I drove 5,000 miles. Between that and selling a few things, I'm going to pay FobiaWRX the rest of the money I owe him Friday, and Send Mike at Innovative money for the Vi-Pec Next week once that check for the fuel comes in. Very excited!!

I'm trying to get my car running at least enough to go up to Matt Markers Memorial Cruise in Elk Rapids, so I would like to have my car able to turn on the weekend before, so I can owrk out some kinks during the week, and do my 50 - 100 mile oil change. I am very excited to be able to say this, because my time line just got pushed up by 2-3 weeks, which is a big bonus to my personal morale.

I've got the IAT wired over onto the drivers side of the trunk, and the Signal Wires from my gauges over to the computer area waiting for the Vi-Pec to arrive. WB02 should be easy, and so should the Oil pressure. I have not confirmed this yet, but I would imagine I can use the stock wire for the oil pressure signal and configure what to do with the pin out. Same thing for the WB02. I am going to rely on Mike @ innovative and possibly bug kelly again since he's been a huge help so far on questions with the Vi-Pec

8/13/2012

I was talking with Mike at innovative tuning today, sounds like I've still got a long road ahead of me. Plan on having the vipec here by the end of the month, but then ill have to get my car to new York for a base tune, which is a day and a half ordeal. Trailer it back home, break in for 1000-1500 miles then trailer back it there. Sounds like a good time to take a couple days off from work and familiarize myself with some fun roads.

Don't think I want to go for a trip and get broke down in between A and B.

I've got nearly everything dongle that I can before my exhaust comes. Don't think ill make it to Matthew Markers Memorial cruise in my car, maybe a buddies.

I cannot hardly stand it I'm so close, not with excitement either. All I can picture is blowing up on the dyno and having to start all over. About the only critical.steps I've done that would really affect much is install my heads and timing belt, which I'm fairly certain head studs went in fine once I figured out where the torque lube went and I had an exhaust cam that didn't want to rotate as smooth as the others, so I tried an exacting knife and some steady hands to deburr an edge. All of the buckets and valves and all that jazz were setup from the Guy before me, and he had no issues so that leaves timing.belt. . . Which I can give that a visual at any time.

Whew. Still a nervous wreck.

9/9/2012

Bump for boredom.

Fuel system is all set to go, just need some E85 to test things out and pressure check.

What's the longest you want e85 sitting in a tank for? I'm hoping to be running base map by end of the month.

We'll see though.

9/24/2012

Got my fmic pipes all fabbed up yesterday, glad to have that monkey off my back. I have to finish trimming bumper to fit the FMIC behind it, and it'll start to look like a car again.

Can someone measure the OD of a stock MAF Size short ram? I'm hoping I have a coupler, but cannot find what size it is for some reason. Excitement is building now, Oil, coolant, PS Fluid, Trans fluid are all being purchased this week. NEVER know, next weekend could be the start up if the moons align properly.

Truly the only things left to do are:

Install all FMIC pipes once Rich welds on the coupler beads.

Re-install the MAF connector wires

Tighten down suspension components in the front

Fill all fluids mentioned above, and snag some E85

Flash Break in Map

Prime & Pray

If anybody has an AP V2 that would work with my car, and has their car out of commission right now, I'd really love to use an Accessport for break in, but I don't want to shell out the coin, cause quite frankly, I don't have it right now. So a 4-6 week rental would be sweet. I dont want to deal with romraider again, but I know how to use it so I will if I have to.

I got my JDM V8 seats monday, and thought it was a little intriguing that the drivers side had ridges in the bolstering to hold the driver in a little better. Didn't matter to me too much, since I'm getting a Carbon seat for my side of car for track days, passenger can have the height adjuster i suppose.

9/29/2012

Getting everything buttoned up today, will be waiting on my break in map for next weekend!

Added some blood to diff / trans / motor. Might seem goofy, but is it advantageous to pour oil in thru the head breather on the passenger side to get some oil over there. I doubt it is practiced often, but just something I was thinking about last night as I poured the first two quarts in.

10/6/2012

Well, patience paid off. Got it primed, reinstalled spark plugs and prepped for start up. Have a super small fuel leak, which I will fix with a new AN fitting.

The main issue I have is the wastegates. They are tials with the 5lb spring for break in. At idle they are open and blowing everywhere. Scared me $hitless at first when I started and heard that.

I initially thought I hooked up hoses wrong, ie switched top / bottom ports .. so I changed that, still no luck.

In a last resort before I left for family function, I hooked the top ports right to Turbo... still letting exhaust out.

Meanwhile, idling afr is 14.5-15.0 . Though I don't trust it because I have to believe that the wastegate taking most of the exhaust would.change something.

Any ideas fellas?

10/7/2012

Well, Day two of motor being alive has been interesting. Trying to figure out why everything is so noisy on the exhaust side of things. Not the tail pipe either.

I'm thinking I have a combination of a leak (fish eye in a weld) and new exhaust ringing. Buddy suggested that it was new and that there isn't anything to stop the echoing, but my gut tells me otherwise. I hope he's right. My first thought was that it was the throwout bearing not clipped in and the fingers on the pressure plate hitting it, but I put a stethoscope on the bell housing and couldn't pinpoint it. I installed a ACT Streetlight flywheel and 6 puck clutch, so I was expecting some noise, but not this much.

In other news - I have an AEM Wideband, and am having one heck of a time getting it to communicate with romraider. Any tips?

**Edit - I was doing a couple investigations about the USB - Serial Adapter that I have, and it turns out that if you get a yellow ! and a code ten, it isn't any good. I've been trying to get hyperterminal to work and fighting it and it is a darn hardware problem. The worst kind. Thankfully Amazon came through in the clutch, and I'll have a good one here tuesday.**

Thanks fellas for reading my pleading for help.

Wow nice

Posted by Diggymart on 4/3/20 @ 2:24:09 PM