You must be logged in to rate content!

8 minute(s) of a 264 minute read

1-6-2012

Bit more work carried out over the last couple of days.

Coils mounted behind RH headlight. M400 and unfinished harness dummied in. Control panel moved. New suede covered steering wheel.

Also just starting on the oil lines to the tranny. Find that the oil return line inlet is only -4 which seems way too small. I've sent an email to CMS but does anyone have any idea why they tapped it this size? From the outside it looks to be -8an but the inside has a tube/tunnel which looks like it's designed to go through the rear bearing instead of return oil in front. With the metal plate, glue, and grub screws there seems little chance of that rear seal blowing out if we make the hole at least -6.

Any opinions?

1/7/12

We've decided to retain the rear oil return with the spray bar as supplied by CMS. Part of the extra cooling mods to the internals were to have all the shafts X-drilled and this will help supply oil from 3rd-6th gears. We will also run a line into the oil filler and T it off to the rear.

Thanks Bruce and others for your continued enthusiastic replies. As we all realise these projects take a lot more time, money and persistence than you ever anticipate and it's quite easy to get a little lost and dare I say it, a bit discouraged at times. The posts and support from others are really appreciated.

Besides which, I love reading about Bruce, Tony, Sid, Joshua, Gustaf, Chris, Thom, Tom, Tim, Darwin, Ollie, Jason, Frederik, Sean, Paulyy and all the others guy's builds. (Apologies to those I've missed but you all know who you are) We have a small community and even smaller one that pushes these cars beyond their original design brief.

There are a couple other projects or people that I've not mentioned but there will be one or two more surprises emerging in 2012.

1/8/12

This is currently how the 3L motor has been setup. Of course there will be some changes. I've also included a pic of Thom's very nice engine/bay showing his CnP (Coil near Plug) setup. Not entirely sure how we'll setup the 3L when it gets here.

What I don't quite understand is the point about if you go for COP you can eliminate the distributor etc but while these motors are CnP they still have no distributor. If the setup on my 2.5L has 4 individual coils (located a bit further away), why can't I also remove the distributor? Sure, the leads will be longer on my 2.5L but isn't it essentially doing the same thing as these 3L motors? Sequential CDI.

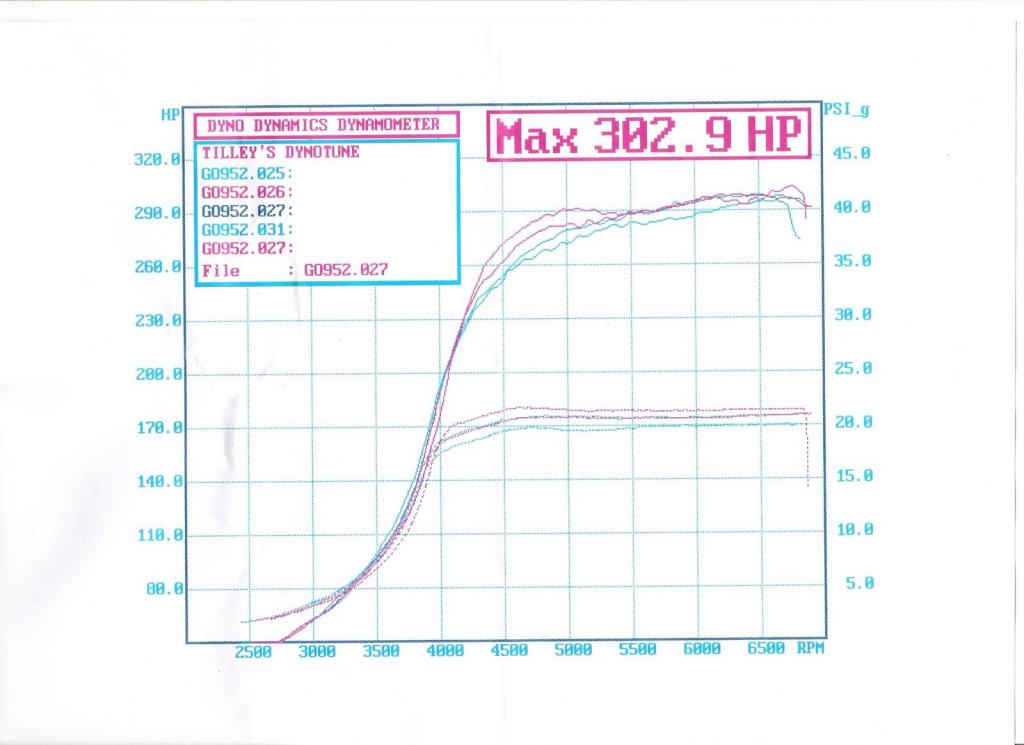

btw...any guesses what differences we'll see with the 2.5 tuned with the new system vs the old setup. The old setup was the Vitesse V-flex on E85 at 22psi on the E85 race image.

1/21/12

While there has been a fair bit of progress, I haven't taken heaps of pics lately. Mostly making brackets and mounting either hardware or lines. Lots of fiddly stuff.

Had to include some of the mounting bracket that they made for the trans oil cooler. Also showing where the oil cooler w fan is going. They'll run ducting via the rear left hand 1/4 window and Naca duct. Like Dubai's car I believe. All the temp, steering, brake sensors are mounted too. With the rear brake line being brought inside. Super neat. I'll get some pics of all this next week.

I was speaking with the owner of Fuel Control yesterday. They supply the E85 for the V8 Supercars, Carrera Cup etc. It is a control fuel at a constant 85% / 108oct year round. It's been found to be the best in the world by the fuel testers in Paris. The ethanol is 100% Sucrose based unlike some others. Cane sugar in other words. Anyway, I'm going to use this for the tuning process on another Dyno Dynamics workshop, but will go back to our one with 'normal' E85 from the bowser just to see the differences. Should be interesting.

1/23/12

The trans oil pump is this...with blurb.

Mocal

MOC 13530-SL

Heavy Duty Oil Scavange/Circulation Pump

When high temperature and continous duty are required: this pump delivers! Designed from the ground up to handle the toughest automotive racing applications for transmission/differential fluid cooling (circluation) and turbocharger oil drain (scavange) applications.

Key features:

- Continuous use circulation/scavenge pump.

- High temperature capable.

- Specially designed with emphasis on turbo charger scavenge applications.

- Low noise and vibration.

- Can be mounted -/+ 3 feet above fluid level.

- Military specification fit and finish at an affordable price.

Specifications:

- 3 GPM @ 60+ psi

- 350f temp rating

- self-priming

- quiet low vibration operation

- 10,000 hour rated bearings & motor brushes

2/10/12

Not too far off the dyno now. All things going well, end of next week. Fueling is pretty much finished. Just need to mount the Ethanol sensor. All the pumps / filters are mounted. New CEP billet fuel rail with the latest Bosch Motorsports 1200cc injectors. CEP Cam syn trigger mounted. Lines in the front with FPR and heatshield in. All the electronics mounted and removed from direct heat and vibration with some nice little brackets. New suede steering wheel with the scroll buttons. Wheel angle sensor also mounted. I think this week we'll get the dash covered in suede too. Liked the idea of Alcantara but it's double or more the cost. Windows and doors to go in also. Just in case it rains on the way to the dyno on the back of the truck. Some new calipers and floating rotors going in too. Got some 997 Cup calipers for the front with a 355mm rotor. Going to stick to the stock sized rears for now. They're 300mm and 4 pots. Front and rear brake pressure sensors with all new brakelines.

Wow great build!

Posted by Diggymart on 12/28/20 @ 2:54:22 PM