You must be logged in to rate content!

5 minute(s) of a 264 minute read

10-23-2011

Well my intention was to build it to race in Prod Sports which has a limitation of 44" all round. I didn't want to go 10"s/12"s so I came up with the odd sizes. If Fikse were a little bit closer than Canada, I'd consider sending them back and changing them. Funny thing is that Broadfoot say they use 11"s on the front with those flares, but only 285mm up front. As you can see a few pages back, Tony G fits 315s on the front under OEM looking fenders that are only 1" wider. His offset has a very small margin between wheel and spring. I took a few pics recently to try and get an idea of the space I have. Seems like I've got some margin up front. I'm sure in the rears too. All I really want to do is get the car back on the track sooner rather than later. Might have to make some changes next year to the wheels.

12/23/11

While there has been a few weeks work done on the car lately, it's mostly wiring and mounting of sensors. Didn't bother taking too many pics of those just yet. Wait until it's all rewired and mounted.

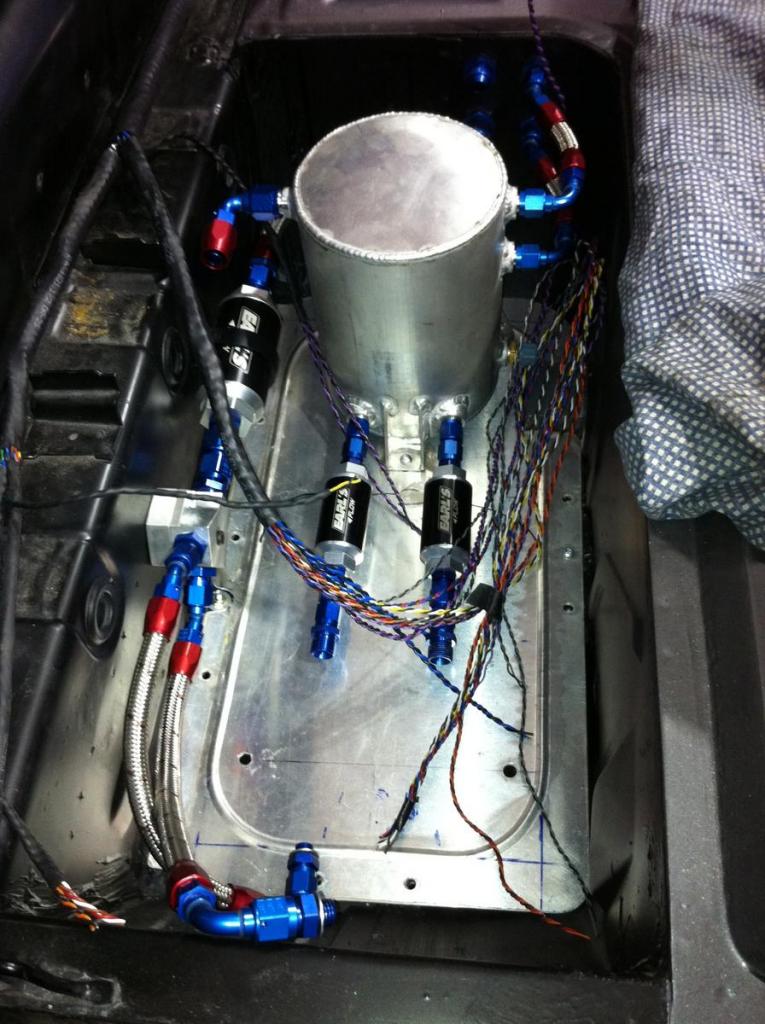

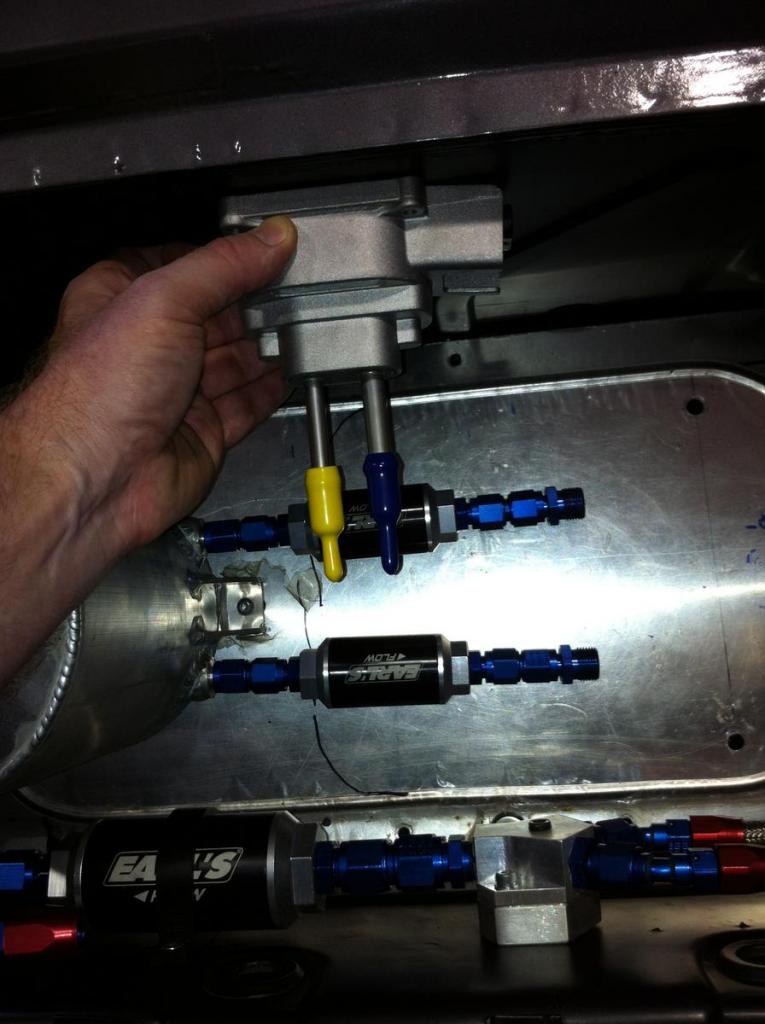

Thought this pic showing rare access to the turbo etc while 2.5L motor installed in car might be a bit novel. Won't be quite the finished article but you get a good look at it now. Also converted the rear wheel well for fuel system. Ethanol sensor to also get mounted in there.

I'm essentially just following advice. With the car changes which will increase lateral loads a decent percentage (I hope) then this is a fuel starvation prevention issue rather than running out of fuel issue.

12/24/11

In regards to the amount of fuel pumps, the guy doing the wiring works on a lot of top end racecars down here and assumed that I'd be running 30psi regularly. One of the Evos he worked on with the last Superlap down here was running 30psi in the corners and 40psi on the straights. All running at least 3 pumps. I suggested that we won't be doing that sort of thing so I'm thinking 2 044s will be fine.

1/4/12

Not a lot of work over the last few weeks with the Christmas break. While the wiring is being done on and off site the sensors are being mounted, control panel moved to in front of the gearstick for passenger safety, mounting of the Ethanol % sensor that just arrived, internal fuel hardlines.

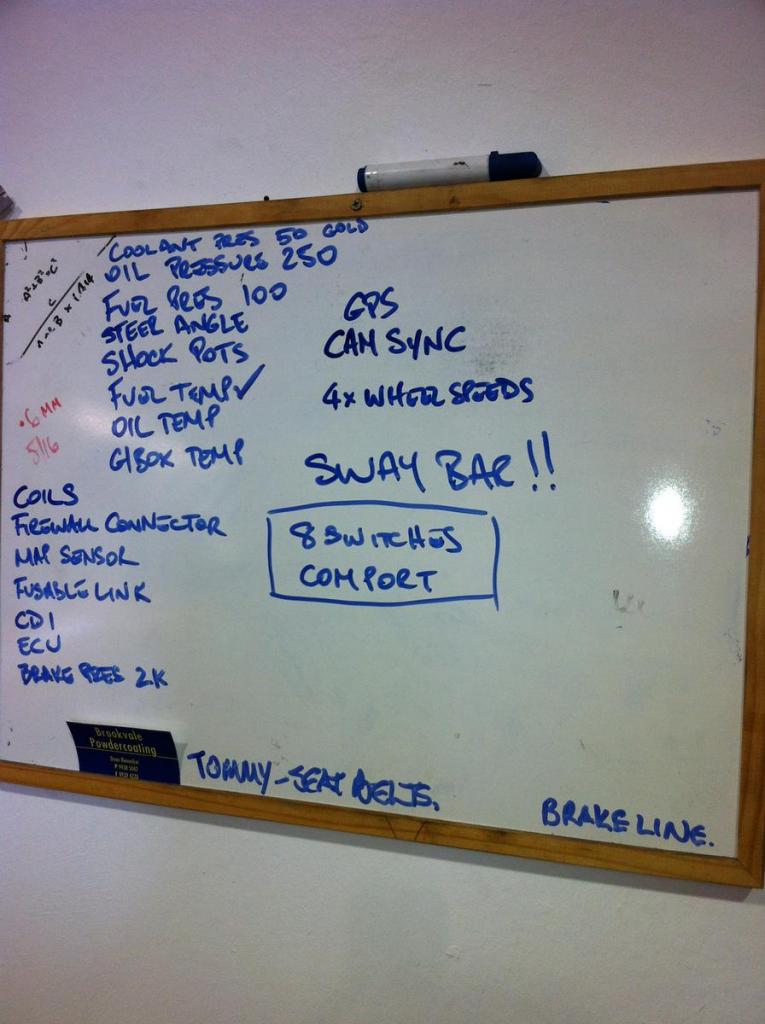

Whiteboard showing current schedule. Much of this is being done in regards to the next motor. So in effect the car is being 'future-proofed' as much as possible now so we don't have to go over things again later. Things like using the Milspec firewall connector for the engine harness means that a different motor will be easier to install.

Wow great build!

Posted by Diggymart on 12/28/20 @ 2:54:22 PM