You must be logged in to rate content!

127 minute(s) of a 264 minute read

12-25-2020

Patrick's 1986 944 Turbo

Compliments of 333pg333 @ rennlist.com

9/24/11

So here are the specs so far. There will be the odd change made to it but essentially this is it currently or being completed now.

D9 GTS lights replacing the stock pop up system.

A couple of different splitters to choose from.

993 Oil cooler.

Custom front mount intercooler.

Engine bay seam welded and repainted.

Full carbon fibre hood with D9 vents.

A/C & heater removed.

Smaller alternator w/ CEP bracket.

Custom SFR 3.5" - 5" S/S exhaust.

Moton Clubsport 2 way adj coilovers with OEM torsion bars removed.

Motons:

The full race setup as suggested:

160 kg/cm front springs + 30 kg/cm tender spring

200 kg/cm rear springs (torsion bars deleted) + 40 kg/cm tender spring

Big Reds on CEP full floating slotted rotors.

Racers Edge A arms, billet hubs and solid bushings all round.

Tarrett adj swaybars front and rear.

LR Semi solid engine mounts.

All the stock brake system removed.

Stock fuse box removed. Replaced with Motec PDM30. Very slick and programmable way of getting rid of fuses and relays. http://www.motec.com/pdm30/pdm30overview/

All the stock wiring and harness removed. Replaced with Milspec wire.

New heated windscreen.

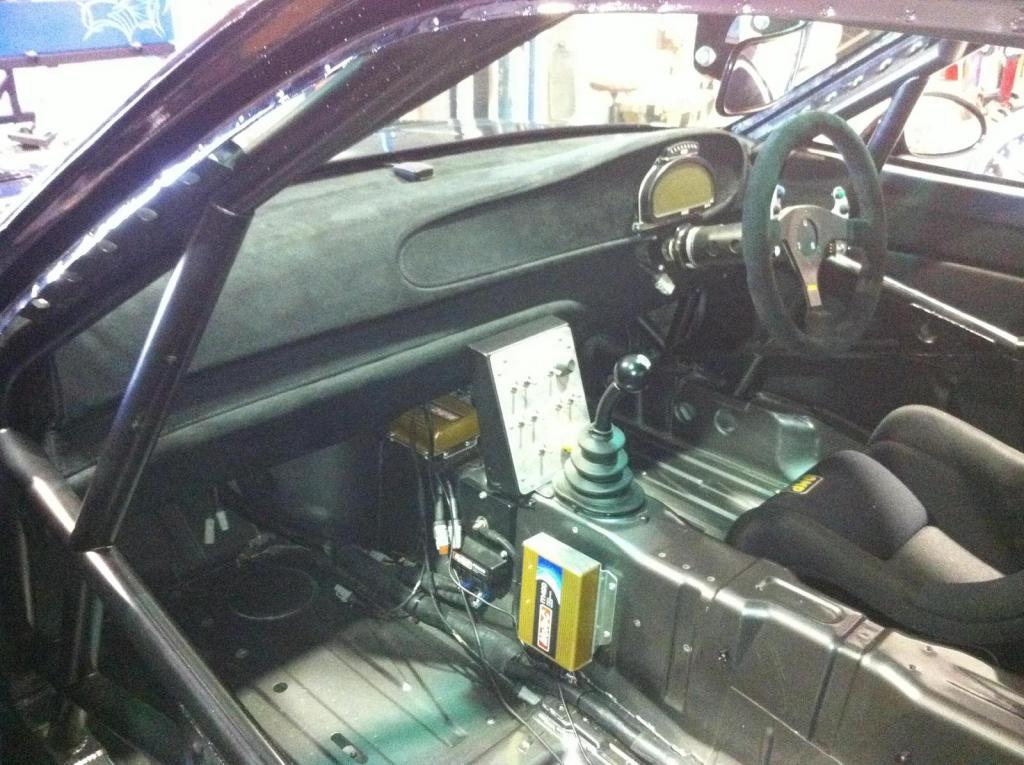

Full fibreglass dashboard with all the OEM 'stuff' underneath removed. (big weight saving)

Motec SDL3 Dash and SLM programmable shift light module. These are all my gauges! http://www.motec.com/sdl3/sdl3overview/ http://www.motec.com/slm/slmoverview/

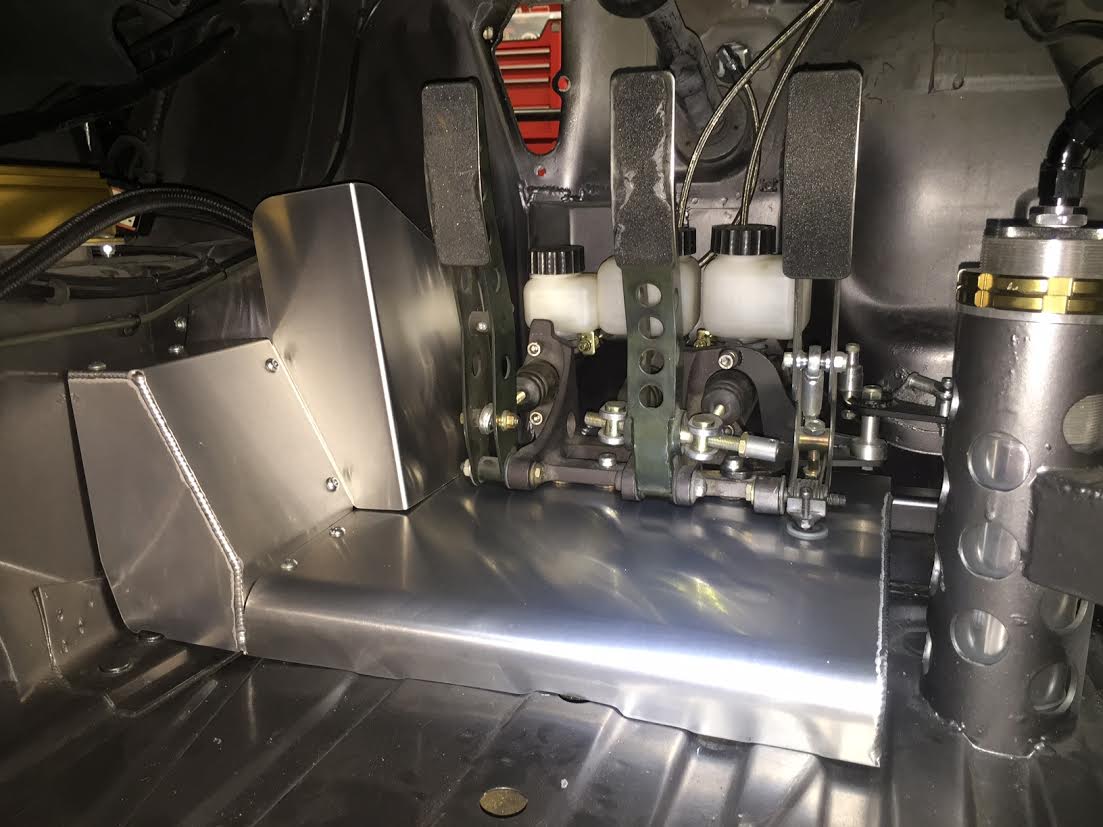

Tilton floor mounted pedal and dual m/c setup.

Extended Steering wheel boss with quick release hub.

OMP raceseat moved back and down with welded in reinforced runners.

Custom control panel within reach. (Now being moved re passenger safety.)

RSR Carbon doors. These weigh something like 2-3 kgs with lexan windows installed. (not sure if these are going to work just yet. Had to have them ‘repaired’ once they got here.)

Fully stripped and caged and repainted interior. In a metallic silver. Cage goes through to front strut towers.

Stock roof with hatch replaced by single skin unit. Good gain in headroom.

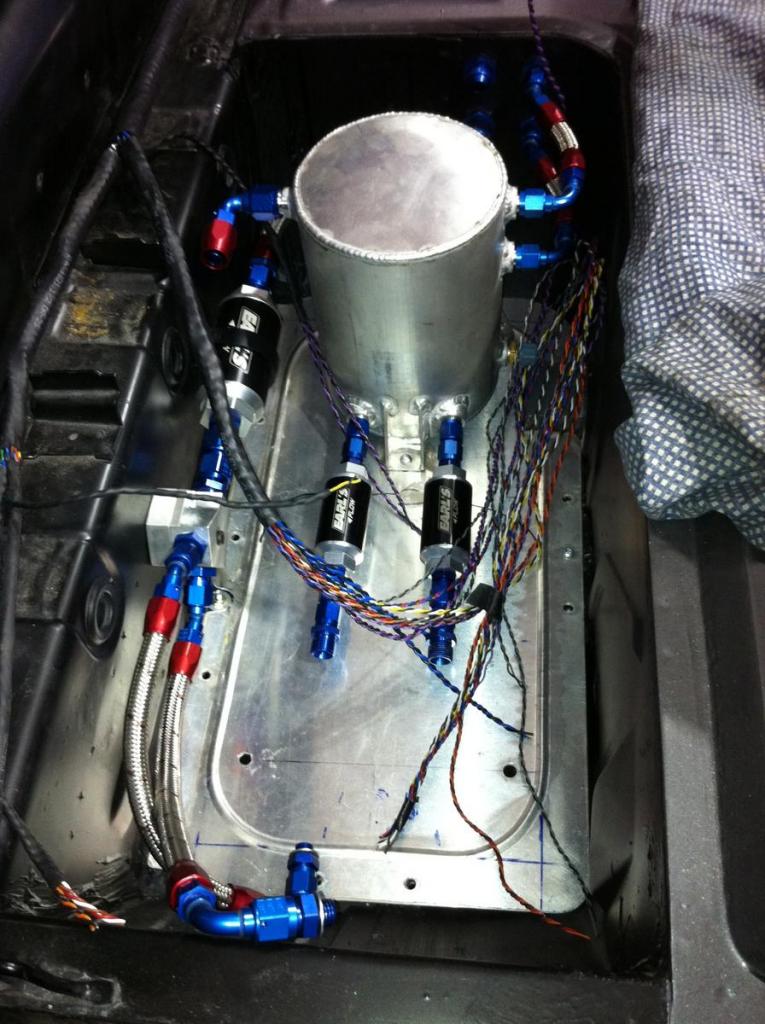

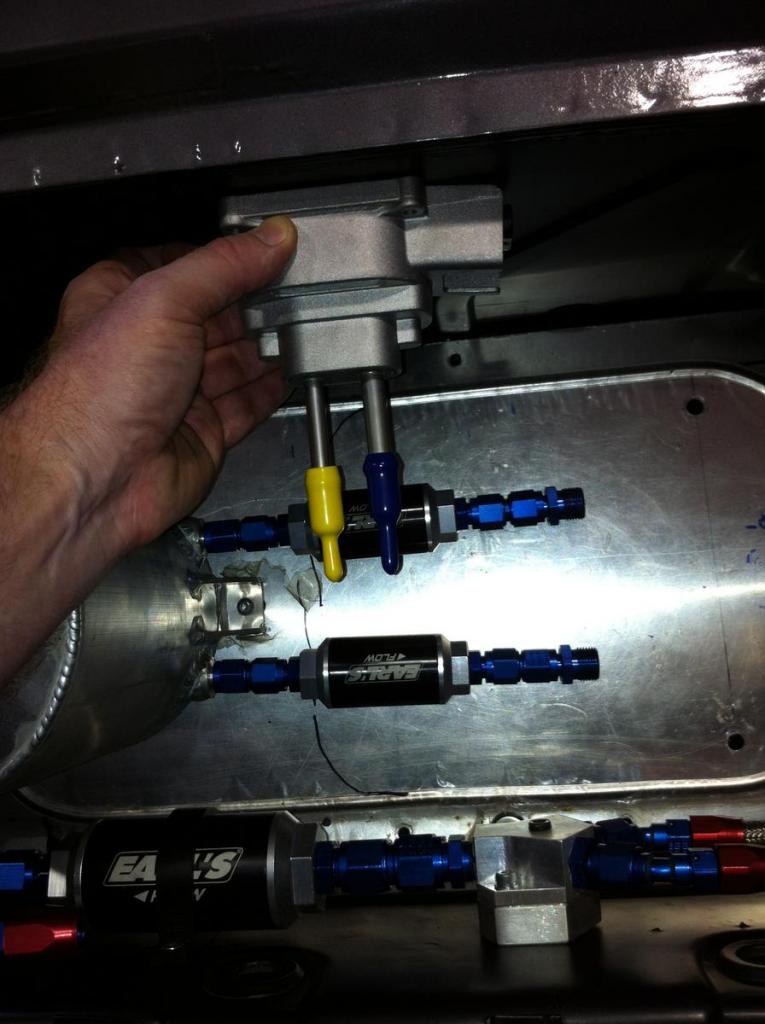

Spare wheel well modified to be shortened by removing about 10cms off the base. 2x 044s and Surge tank to go in there.

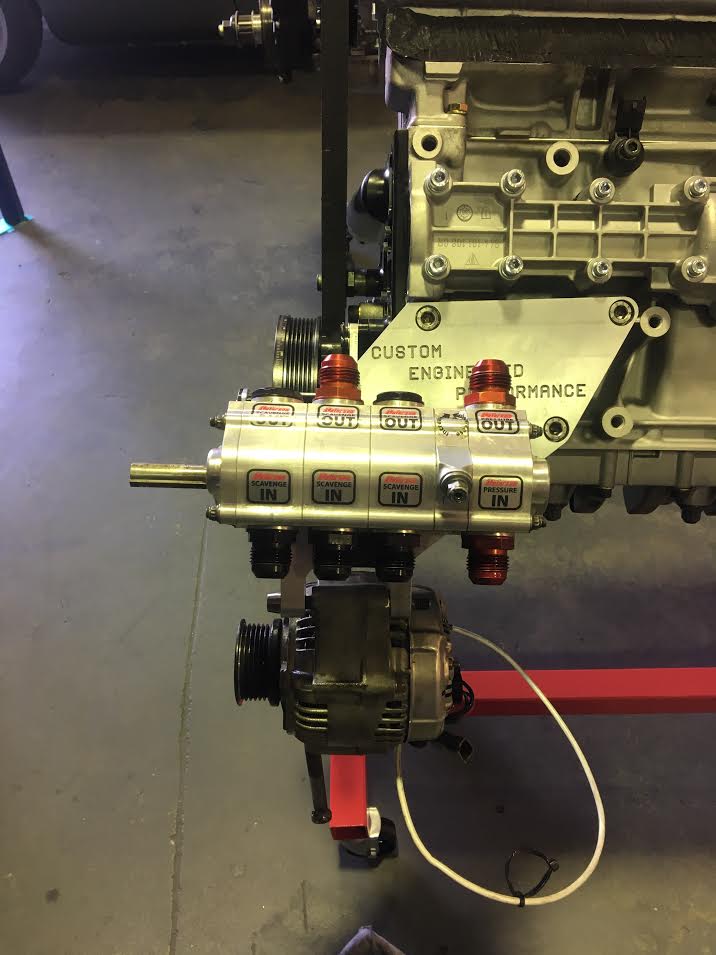

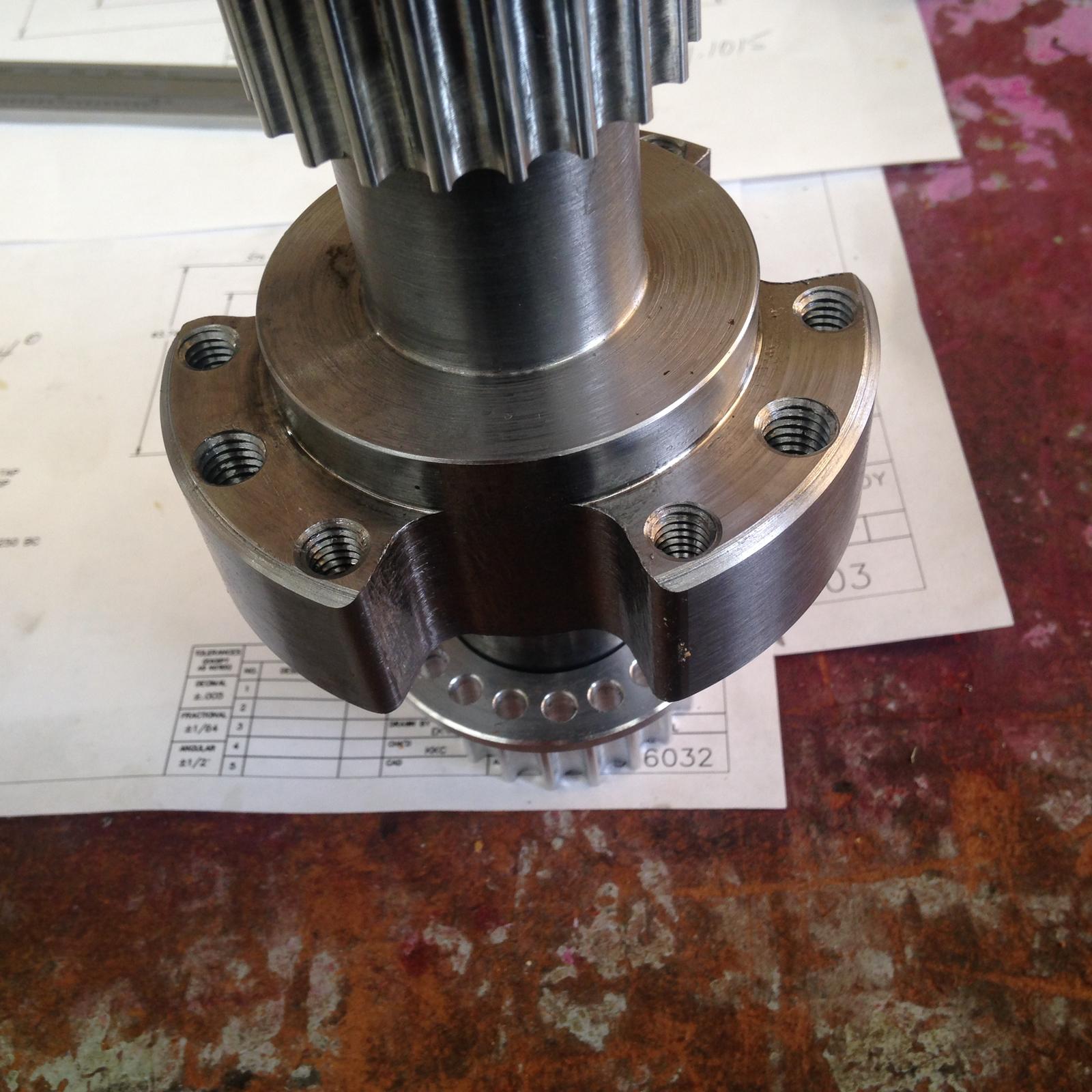

Fully rebuilt and customised by California Motorsports 968 6 speed. Strengthened and increased cooling being the mods. See the custom billet sideplate in pics. Stayed with the stock gearing for now. KAAZ 6 plate 45/90 LSD.

LR race axles and CVs.

OEM Mo30 rear brakes for now.

Full lexan rear hatch.

Dual element rear wing from DJ engineering U.K. (Simon McBeath is a very accomplished / published aerodynamicist)

Wheels are 10.5" and 11.5" x 18" Fikse Mach V all black anodised. Either 315/18" Nitto NT01 on all 4 corners or Hoosier 305 / 320 R80 full slicks.

Broadfoot GT2 widebody flares.

Not far off:

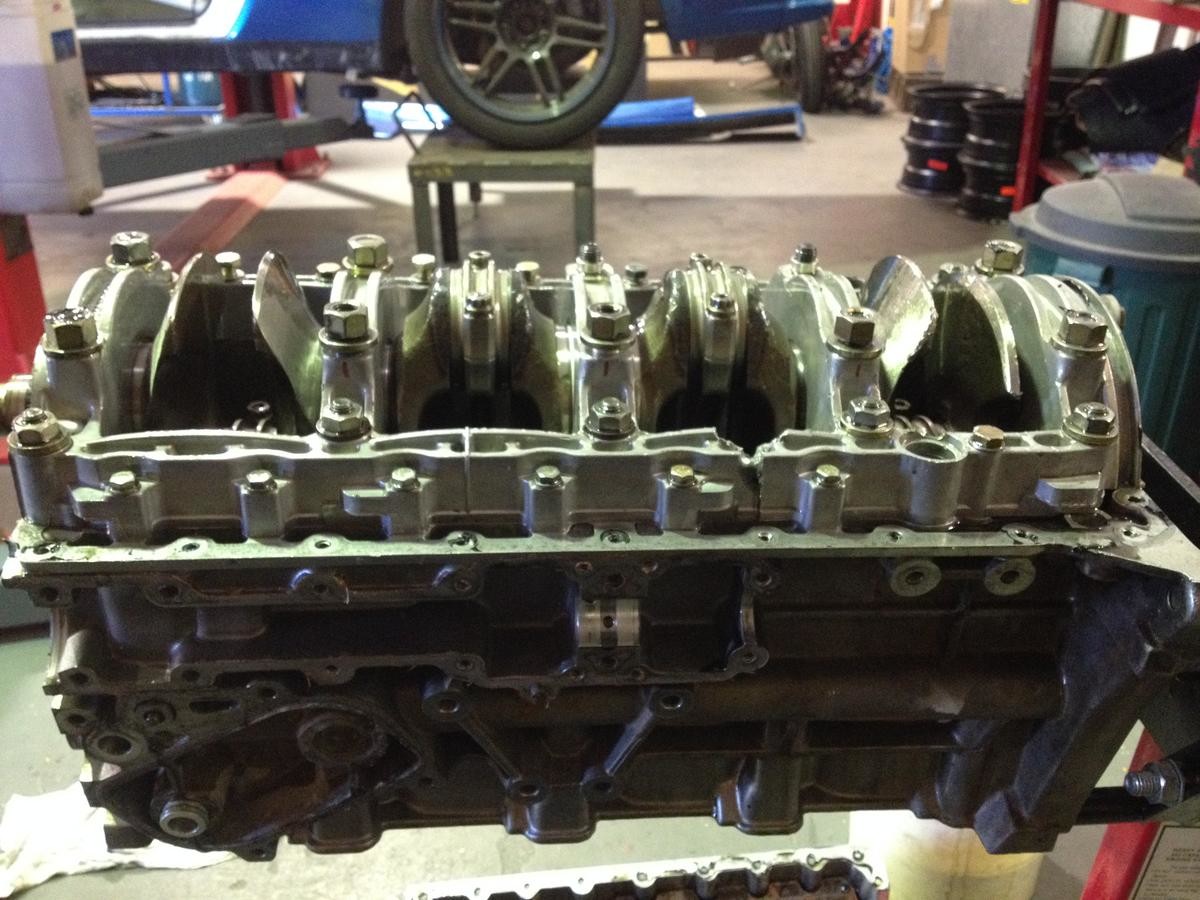

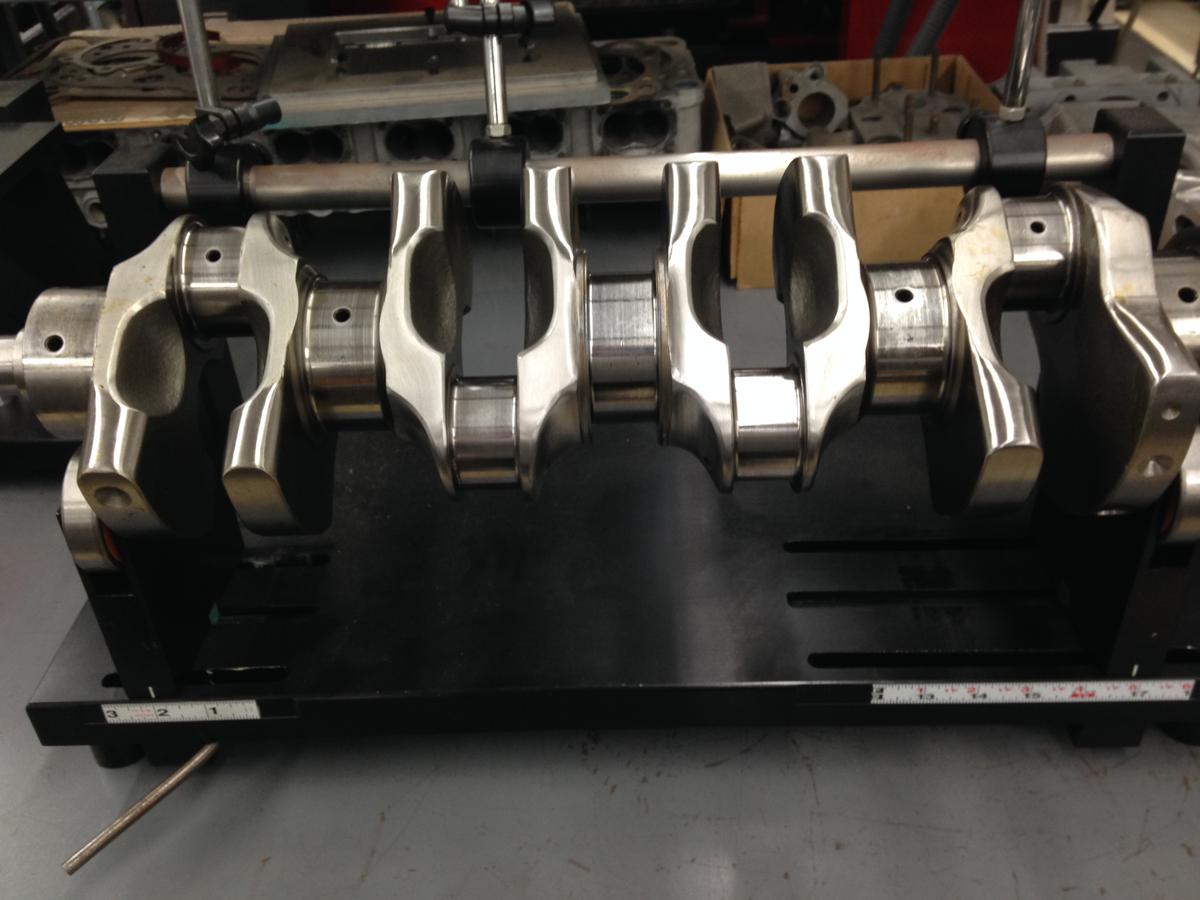

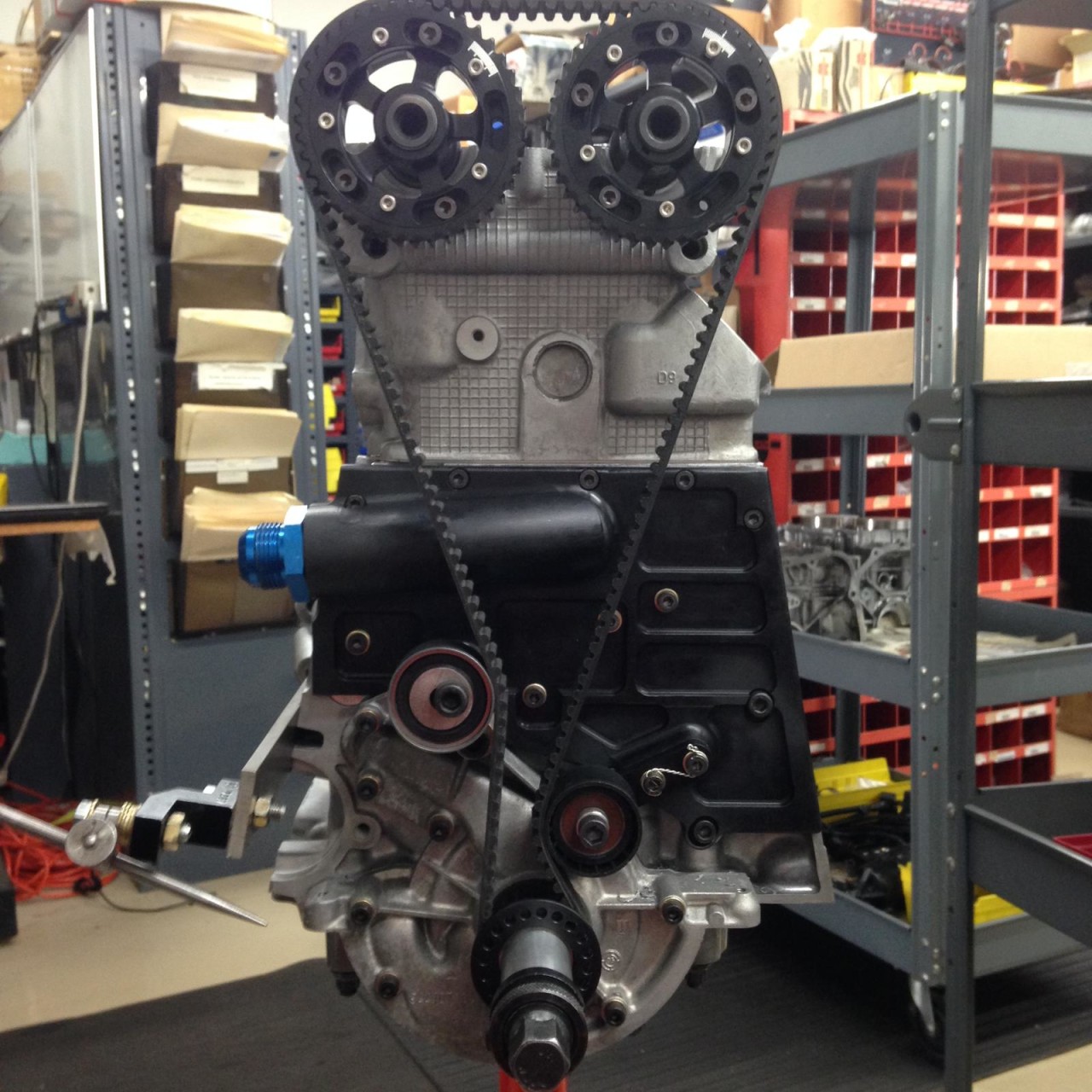

Dry sumped 3L 8v racemotor. Motec or LINK ECU.

Any guesses how much the car will weigh?

Unfortunately probably going to move the control panel as it really doesn't work with passenger / instruction.

9/25/11

It's an '86 with all converted '89 running gear. I'll see if I can't get some idea if we have others like this over here.

We had to modify the wheel well to make room for the oil cooler fitting.

I know you see full Cup Cars in the Group ahead of you and maybe earlier ones in your class. What about road going GT3s converted for track use?

9/26/11

We did a BMW / Porsche club challenge a week or so ago. 3 BMWs were involved in accidents. One of them a pretty bad roll where they had to load the car on the towtruck upside down as it was mashed pretty badly. Some of our cars are much quicker than this one so I feel it's time to get safer. With the cage, harness, HANS, and now a lot more headroom from the non sunroof conversion, it feels like there is a lot more margin to walk away from a bad one.

Not sure which pic you're thinking of Bruce, but the car is Black, Black, Black. Actually I'm very happy with the paintjob considering it was cheap for around these parts....well cheap-ish...

As for getting back in the car soon...I guess it's not too far off being driveable. The DJ Engineering wing has arrived so that will take some work to figure and fab it to the car. Want to lean it back a bit, but am a bit concerned about too much understeer / lift as it can provide a ton of downforce. We're going to run some ride height sensors to do some data logging of the aero and suspension.

It will be very similar to the wing shown here in a local Beefy R34. I'm not looking at going up to such a large splitter...I hope!!!

Eventually I want to work on a flat bottom setup with diffuser.

Noted on the wing. We will run ride height sensors and obviously have to play around a bit. If you're interested, I asked questions on Pelican about aero. Got some interesting answers.

http://forums.pelicanparts.com/porsc...-out-aero.html

9/28/11

My fronts are 10.5" but 18". Wouldn't have thought 18" is a problem though as the OD is about the same.

Even with stock fenders you would think that the GT2 flares would be large enough and cover about the same as yours from the front angle? I'm really curious just how much space I have on the inside. Car is in another shop getting the body wired. I'll have to check once we can get it up on the hoist again.

The rears are very tight too. That's with 320/645 slicks on there. I wanted to lower the car a bit but it's not looking possible.

10/15/11

My Broadfoot nose piece turned up last week. They were sincerely apologetic and offered a discount. I didn't take the discount even though it was well earned. I feel that despite the hassles involved, these small operators need to be kept in business. It's all we've got and should be thankful for them....warts and all.

The 944 / US market is a twin edged sword. Due to the population cars are very cheap in the US. So college kids can afford to buy a Porsche. Problem is that they often don't have the money to upkeep it, let alone modify it. So you have very few aftermarket options. The people that do give us choice are almost running charities in some cases. Mostly small profit margins and low turnover. Makes it a very tough field.

It's a shame that there have been some feuds along the way, but we should be very thankful that there are any options at all for us. I certainly would hate to see any supplier shut up shop on our little corner of the automotive world.

10/21/11

Took a couple of Phone pics of the Techart knockoffs. 10"x19" fronts 11" rears. They weigh a ton but for the occasional road use I think they look ok.

This is a custom SFR exhaust. The fart can thing is really only a nod towards silencing the noise. Would it sooth your sensibilities if we put the chrome tip that came with it on there??

Prefitted to George's car too.

Kinda sounds pretty good to me.

The body bits were actually mounted by the guy that did the cage and other parts. He made the nice control panel in the car which unfortunately we're going to move due to it just not working with a passenger in the car. Shame.

In actual fact I've just seen a pic of the car which makes me think that the rear flares need to be moved forwards a little but I don't think there is a lot of margin to do this as I assume the bolt holes will be revealed. The shadows make it look worse than it actually is. He also made up a small plate to on the rockers as to move the front flares forward for better wheel room. It's all still a bit tight.

I'm happy with the all black look for now. It'll possibly morph into something else in time.

In truth, it would probably look better with smaller wheels and higher profile slicks like the GTR featured elsewhere.

Hope this is what you'll be seeing next season!! It's going to be fun with Rod's new 3L competing as well. Can't wait!!!

10/23/11

Well my intention was to build it to race in Prod Sports which has a limitation of 44" all round. I didn't want to go 10"s/12"s so I came up with the odd sizes. If Fikse were a little bit closer than Canada, I'd consider sending them back and changing them. Funny thing is that Broadfoot say they use 11"s on the front with those flares, but only 285mm up front. As you can see a few pages back, Tony G fits 315s on the front under OEM looking fenders that are only 1" wider. His offset has a very small margin between wheel and spring. I took a few pics recently to try and get an idea of the space I have. Seems like I've got some margin up front. I'm sure in the rears too. All I really want to do is get the car back on the track sooner rather than later. Might have to make some changes next year to the wheels.

12/23/11

While there has been a few weeks work done on the car lately, it's mostly wiring and mounting of sensors. Didn't bother taking too many pics of those just yet. Wait until it's all rewired and mounted.

Thought this pic showing rare access to the turbo etc while 2.5L motor installed in car might be a bit novel. Won't be quite the finished article but you get a good look at it now. Also converted the rear wheel well for fuel system. Ethanol sensor to also get mounted in there.

I'm essentially just following advice. With the car changes which will increase lateral loads a decent percentage (I hope) then this is a fuel starvation prevention issue rather than running out of fuel issue.

12/24/11

In regards to the amount of fuel pumps, the guy doing the wiring works on a lot of top end racecars down here and assumed that I'd be running 30psi regularly. One of the Evos he worked on with the last Superlap down here was running 30psi in the corners and 40psi on the straights. All running at least 3 pumps. I suggested that we won't be doing that sort of thing so I'm thinking 2 044s will be fine.

1/4/12

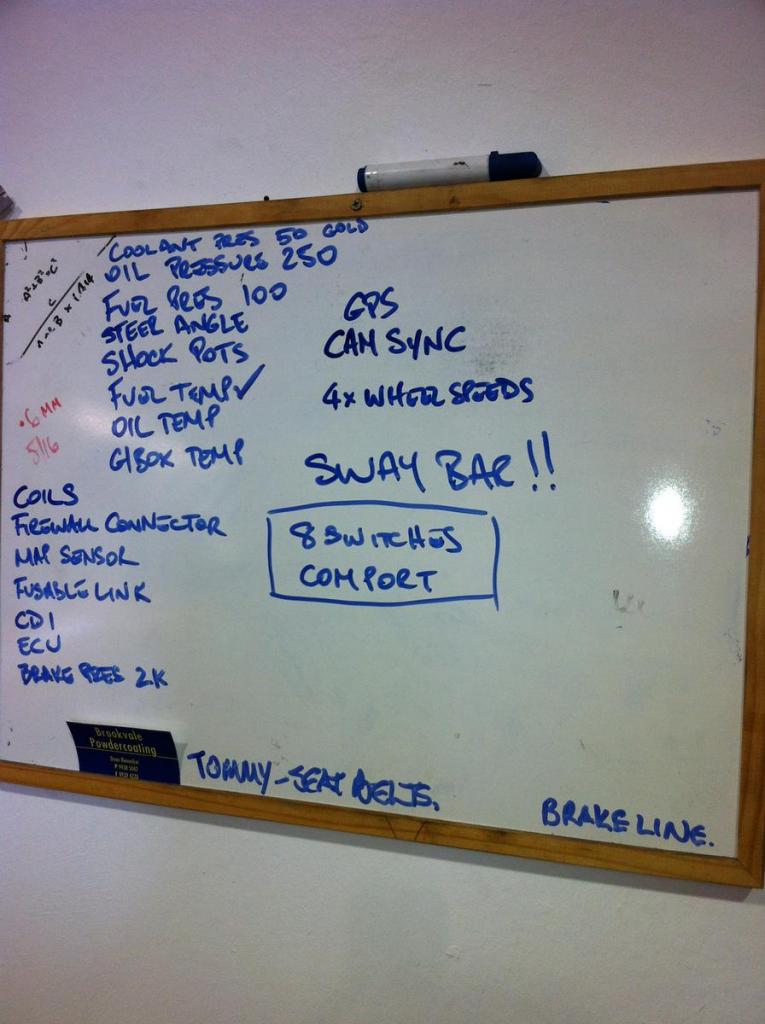

Not a lot of work over the last few weeks with the Christmas break. While the wiring is being done on and off site the sensors are being mounted, control panel moved to in front of the gearstick for passenger safety, mounting of the Ethanol % sensor that just arrived, internal fuel hardlines.

Whiteboard showing current schedule. Much of this is being done in regards to the next motor. So in effect the car is being 'future-proofed' as much as possible now so we don't have to go over things again later. Things like using the Milspec firewall connector for the engine harness means that a different motor will be easier to install.

1/6/12

Bit more work carried out over the last couple of days.

Coils mounted behind RH headlight. M400 and unfinished harness dummied in. Control panel moved. New suede covered steering wheel.

Also just starting on the oil lines to the tranny. Find that the oil return line inlet is only -4 which seems way too small. I've sent an email to CMS but does anyone have any idea why they tapped it this size? From the outside it looks to be -8an but the inside has a tube/tunnel which looks like it's designed to go through the rear bearing instead of return oil in front. With the metal plate, glue, and grub screws there seems little chance of that rear seal blowing out if we make the hole at least -6.

Any opinions?

1/7/12

We've decided to retain the rear oil return with the spray bar as supplied by CMS. Part of the extra cooling mods to the internals were to have all the shafts X-drilled and this will help supply oil from 3rd-6th gears. We will also run a line into the oil filler and T it off to the rear.

Thanks Bruce and others for your continued enthusiastic replies. As we all realise these projects take a lot more time, money and persistence than you ever anticipate and it's quite easy to get a little lost and dare I say it, a bit discouraged at times. The posts and support from others are really appreciated.

Besides which, I love reading about Bruce, Tony, Sid, Joshua, Gustaf, Chris, Thom, Tom, Tim, Darwin, Ollie, Jason, Frederik, Sean, Paulyy and all the others guy's builds. (Apologies to those I've missed but you all know who you are) We have a small community and even smaller one that pushes these cars beyond their original design brief.

There are a couple other projects or people that I've not mentioned but there will be one or two more surprises emerging in 2012.

1/8/12

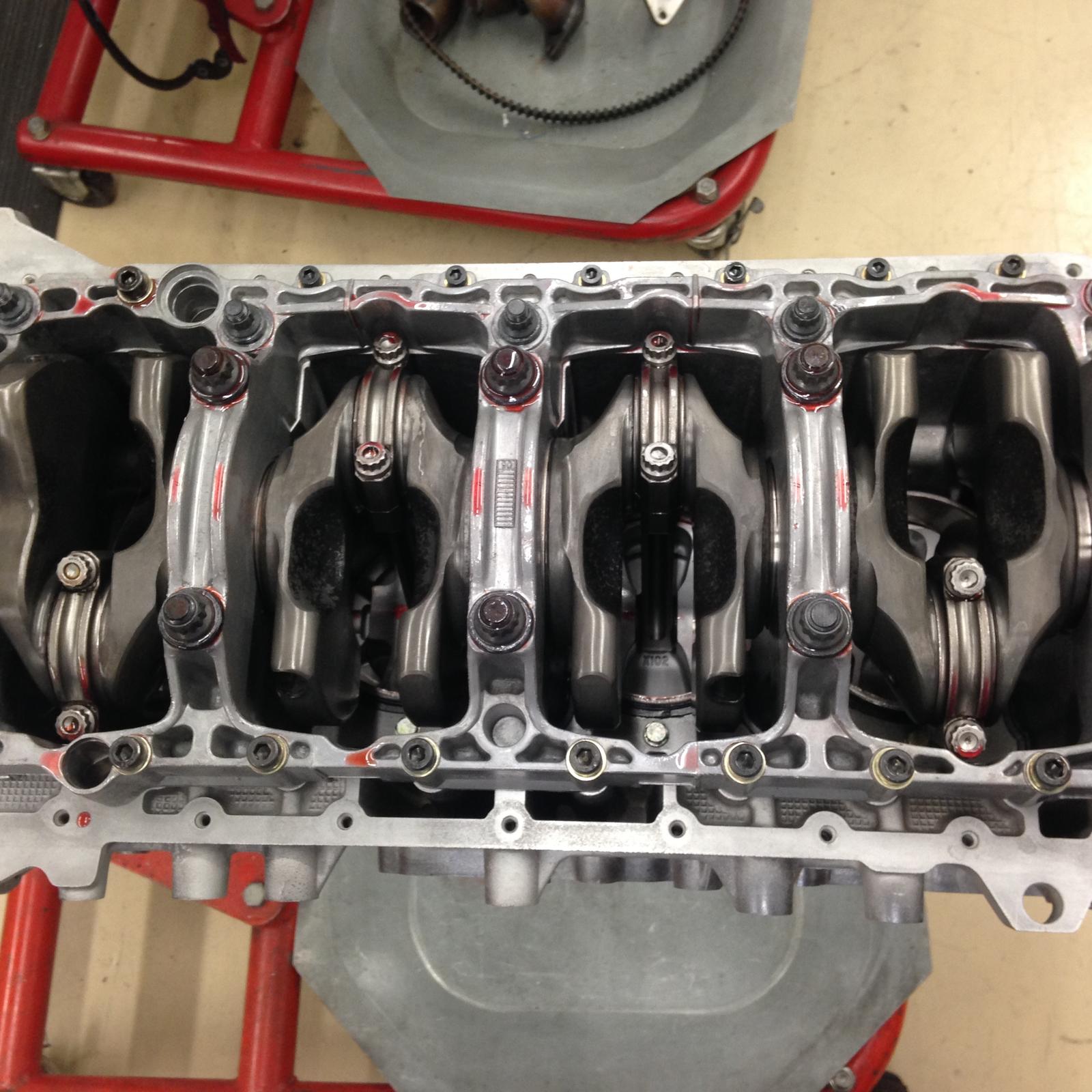

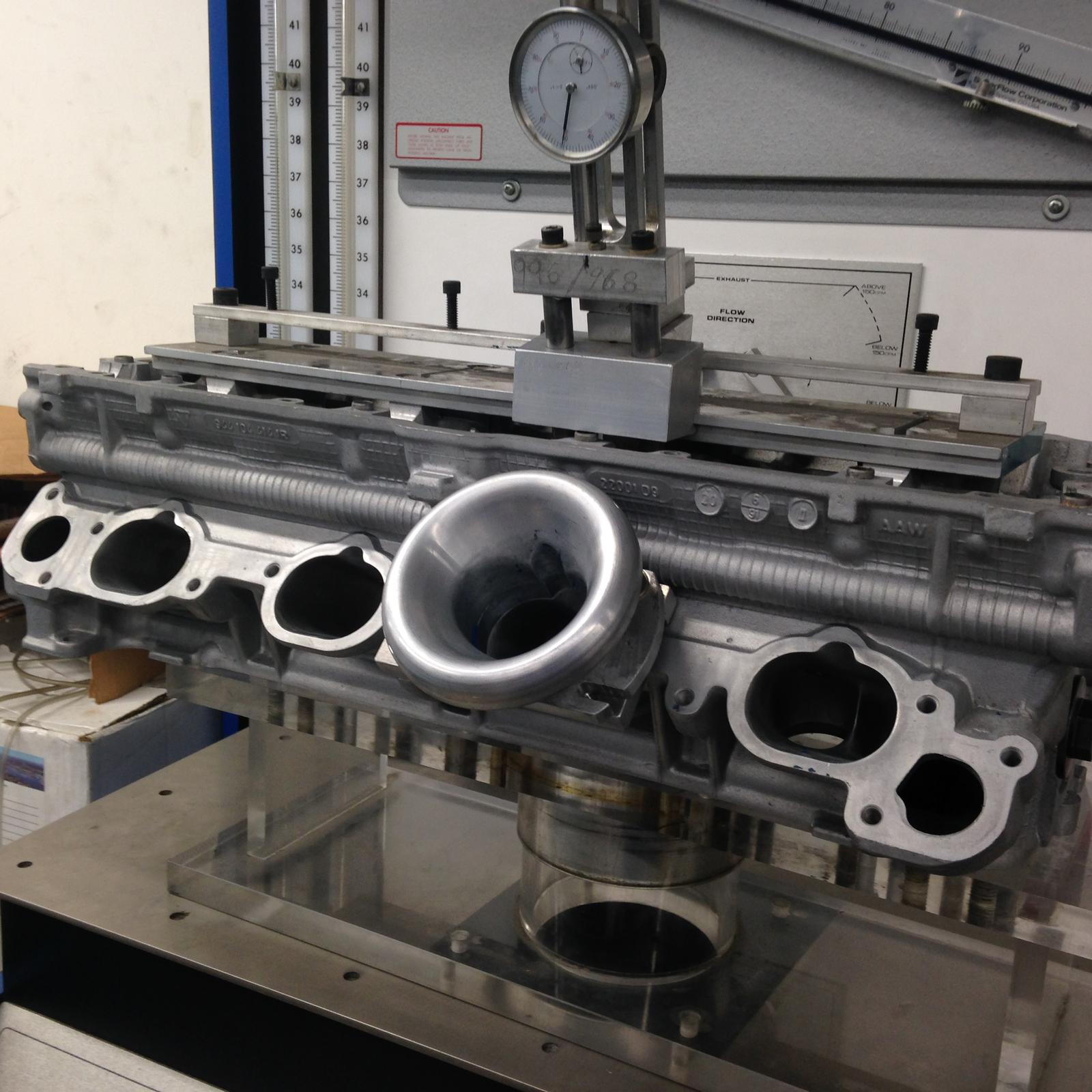

This is currently how the 3L motor has been setup. Of course there will be some changes. I've also included a pic of Thom's very nice engine/bay showing his CnP (Coil near Plug) setup. Not entirely sure how we'll setup the 3L when it gets here.

What I don't quite understand is the point about if you go for COP you can eliminate the distributor etc but while these motors are CnP they still have no distributor. If the setup on my 2.5L has 4 individual coils (located a bit further away), why can't I also remove the distributor? Sure, the leads will be longer on my 2.5L but isn't it essentially doing the same thing as these 3L motors? Sequential CDI.

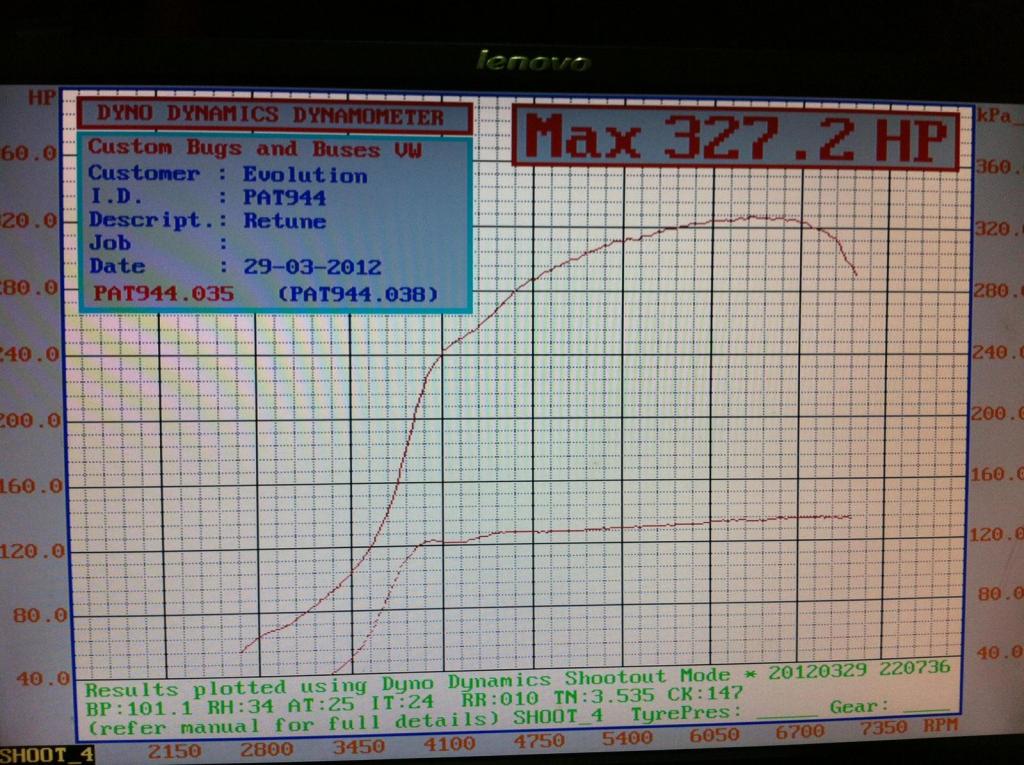

btw...any guesses what differences we'll see with the 2.5 tuned with the new system vs the old setup. The old setup was the Vitesse V-flex on E85 at 22psi on the E85 race image.

1/21/12

While there has been a fair bit of progress, I haven't taken heaps of pics lately. Mostly making brackets and mounting either hardware or lines. Lots of fiddly stuff.

Had to include some of the mounting bracket that they made for the trans oil cooler. Also showing where the oil cooler w fan is going. They'll run ducting via the rear left hand 1/4 window and Naca duct. Like Dubai's car I believe. All the temp, steering, brake sensors are mounted too. With the rear brake line being brought inside. Super neat. I'll get some pics of all this next week.

I was speaking with the owner of Fuel Control yesterday. They supply the E85 for the V8 Supercars, Carrera Cup etc. It is a control fuel at a constant 85% / 108oct year round. It's been found to be the best in the world by the fuel testers in Paris. The ethanol is 100% Sucrose based unlike some others. Cane sugar in other words. Anyway, I'm going to use this for the tuning process on another Dyno Dynamics workshop, but will go back to our one with 'normal' E85 from the bowser just to see the differences. Should be interesting.

1/23/12

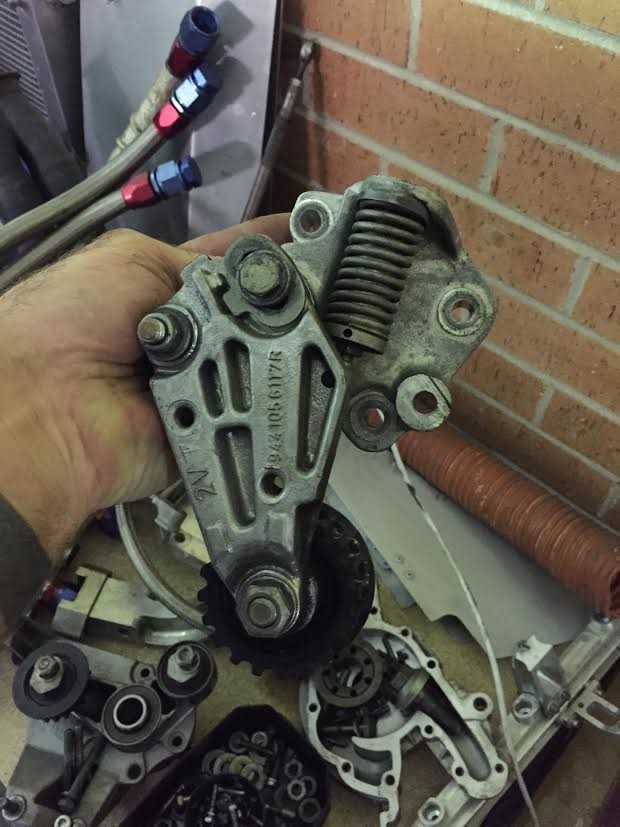

The trans oil pump is this...with blurb.

Mocal

MOC 13530-SL

Heavy Duty Oil Scavange/Circulation Pump

When high temperature and continous duty are required: this pump delivers! Designed from the ground up to handle the toughest automotive racing applications for transmission/differential fluid cooling (circluation) and turbocharger oil drain (scavange) applications.

Key features:

- Continuous use circulation/scavenge pump.

- High temperature capable.

- Specially designed with emphasis on turbo charger scavenge applications.

- Low noise and vibration.

- Can be mounted -/+ 3 feet above fluid level.

- Military specification fit and finish at an affordable price.

Specifications:

- 3 GPM @ 60+ psi

- 350f temp rating

- self-priming

- quiet low vibration operation

- 10,000 hour rated bearings & motor brushes

2/10/12

Not too far off the dyno now. All things going well, end of next week. Fueling is pretty much finished. Just need to mount the Ethanol sensor. All the pumps / filters are mounted. New CEP billet fuel rail with the latest Bosch Motorsports 1200cc injectors. CEP Cam syn trigger mounted. Lines in the front with FPR and heatshield in. All the electronics mounted and removed from direct heat and vibration with some nice little brackets. New suede steering wheel with the scroll buttons. Wheel angle sensor also mounted. I think this week we'll get the dash covered in suede too. Liked the idea of Alcantara but it's double or more the cost. Windows and doors to go in also. Just in case it rains on the way to the dyno on the back of the truck. Some new calipers and floating rotors going in too. Got some 997 Cup calipers for the front with a 355mm rotor. Going to stick to the stock sized rears for now. They're 300mm and 4 pots. Front and rear brake pressure sensors with all new brakelines.

2/17/12

Ahh, couldn't resist taking pics of the latest stuff.

Got the f/glass dash covered in Black Suede complete with stitching around the old gauge panel. Looks pretty nice and no glare.

New gearshift complete with Rodder 8-ball ha!! That was done as a bit of a joke but it actually feels really nice so I might keep it. Also got the Ethanol sensor mounted so all the fuel system is plumbed in.

Getting close to going to the dyno with the 2.5L motor. Hoping to sneak up to an Aussie 350whp. Probably more likely 330whp with stock head. Should be ok in a lighter, stiffer, grippier car I hope.

2/18/12

The guys had to fab up an assembly to work the accelerator cable from the pedal. Seems very strange that Tilton doesn't offer some generic setup like this??

Nicer pic of dash. We will cut down the shifter a few more inches too. The throw isn't too bad but it's a bit long.

2/25/12

Getting closer now. Wiring almost finished and off to dyno this week. Always a few more things to be done but aiming at being back on the track early March.

Oh, and we shortened the gearshifter. Bit nicer throw now. Not that you can tell but these are a different 'Clubsport' door card. So no armrests and winders. For now the window motors are still in the doors and still working. What they've done is run the wires into a couple of nuts and put them just under the latches on the inside of the doors. So you attach power to both terminals and with the polarity on one way the window goes up, and the opposite happens also. So that's kinda cool for now.

3/15/12

Never been so happy to see my car on the back of a truck!! Off to the dyno. Hope to have some results by tomorrow this time...maybe early next week if we hit a glitch. Trackdays booked for the end of the month. Looking just a little bit forward to this.

3/20/12

Minor glitch. When we started the car in the shop and checked all the reference signals etc, all was well. Then it was started again at the dyno just to check that there were no signal corruptions. Again,100% fine.

So I drove out to the dyno on the weekend (over an hour away) and he was just strapping it up and starting the tune proper. Signal errors. D’oh!!! The Motec unit is really precise when looking for clear signals and the 132 tooth is just too blurry. I actually went back and looked at your thread Bruce where you customised your alu Flywheel to run the 60-2 teeth. Pretty smart. Are you still using that setup? Did you ever get to test it yet? Almost wonder why someone hasn’t done a production run of a custom flywheel for the 944/951? So we’ve got a Clewett setup on it’s way here. Should bolt right up and we know they work. Just another delay. A bit costly too by the time we towed the car 1.5hrs either way…let alone the frustration of losing another 2 weeks…cancelling another 2 trackdays booked…missing out on the shakedowns before the 2nd Club event which means my season is toast yet again. 3rd wasted season. Gotta love it!!!

3/31/12

So after a very long 2 weeks which involved 3 long trips to the dyno late into the night. Heat issues, wastegate issues, rogue sync signal issues...we finally got an ok first tune. Picked it up yesterday morning from the dyno and went straight to the track which was chock full of cars practicing for the NSW Motor Race Champs Rnd1. They chucked us in with Improved Prods. So the builder goes out in the car 1st as I felt he would be more objective than me. Stoked to see it finally getting back on the track first time since 2010...not so stoked to see him pull into the pits after one lap and saying there's some ign cuttout going on. So we go back to our shed and plug in the laptop. Damn...the rogue sync error is back. It's appearing all the way from idle up through the range. At 540 btdc. So they check the gap on both cam and crank sensor. Disconnect the knockbox. Swap ECU's...still there. Damn!! They keep playing around with filters hoping to disappear it. Not having a lot of luck. When 2 guys who have worked on literally 1000's of motors look at you and say "Hmm, never seen this before" it's a bit disconcerting. Checked out the stock cam wheel to see if there's anything that could be creating a reason for this extra signal trigger. Can't see anything at all. Could a blind bolt or dowel behind it have become magnetised over years of having a distributor in front of it?

So they've done what they can and he says, you may as well go out and see what happens. So in I jumped and hastily made my way down to pit lane. Sitting there I was feeling pretty excited...but also fully expecting to be back in next lap after the ign cut persisted. So off we go. All sorts of cars in this group. Commodore V8s, RX7s, Nissan Silvias, Civics, Old Holden HQs, Toyota Sprinters...So I go down into T2 car seems fine. Out of 2 into 3..still fine..down the hill. Seems kinda nice. Feels much lighter and directional. Lots of weight has come out of it and stiffness gone in. Around 4 and 5. Yep, I'm liking my 'new' car already. Hmm, what happened to T6? Somebody took it. Around 7 and up Corporate Hill. Car feels responsive and quite toey. Down the hill and into the hairpin. Plenty of turn in. Great! Up the hill give it a squirt. No sign of ign cut. Yay! Into 10-11-12...line up a Silvia and plant it. Whooshka...past him pretty easily. Nice. Down the main straight. Motor is revving nicely. Quite a bit of chop though...front to rear. Tippy toeing around T1 and into 2 again. Toss some salad while searching for the right gear and proceed around the track for another 1.5 laps before Red flag out. Everyone back into the pits. Damn again. Some one had put themselves off right at the top of T2 and onto the Grass. Seemed safe and easy to move him...but it took forever. By the time they finally waved us back out we did one more outlap and they flagged the session. Arghhh!!

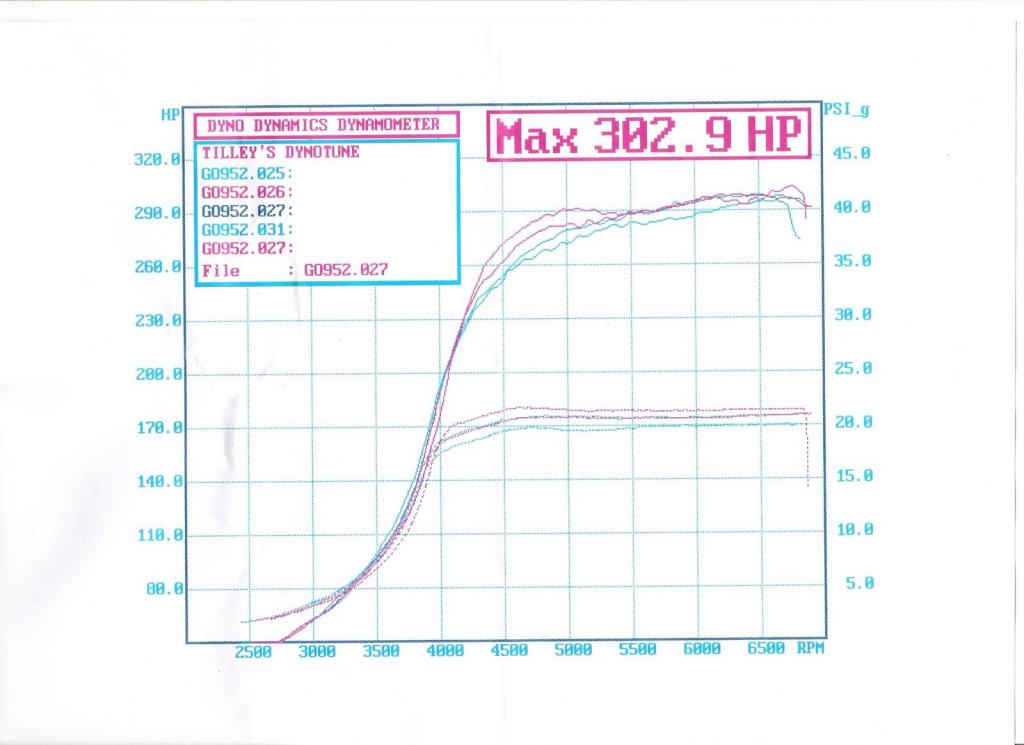

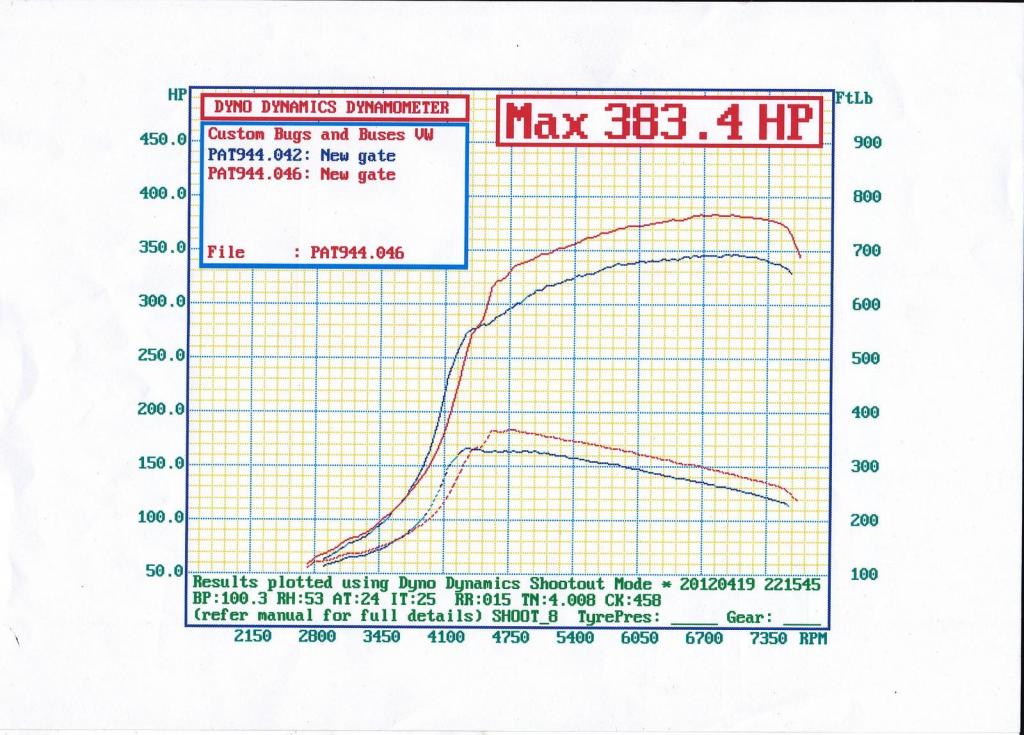

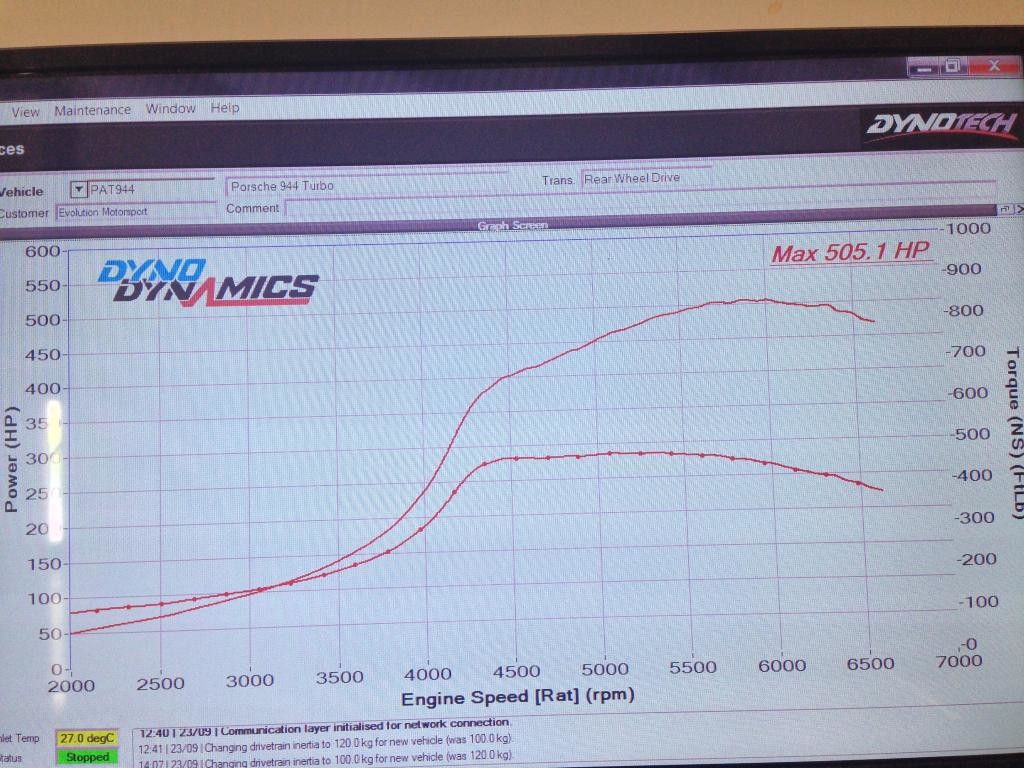

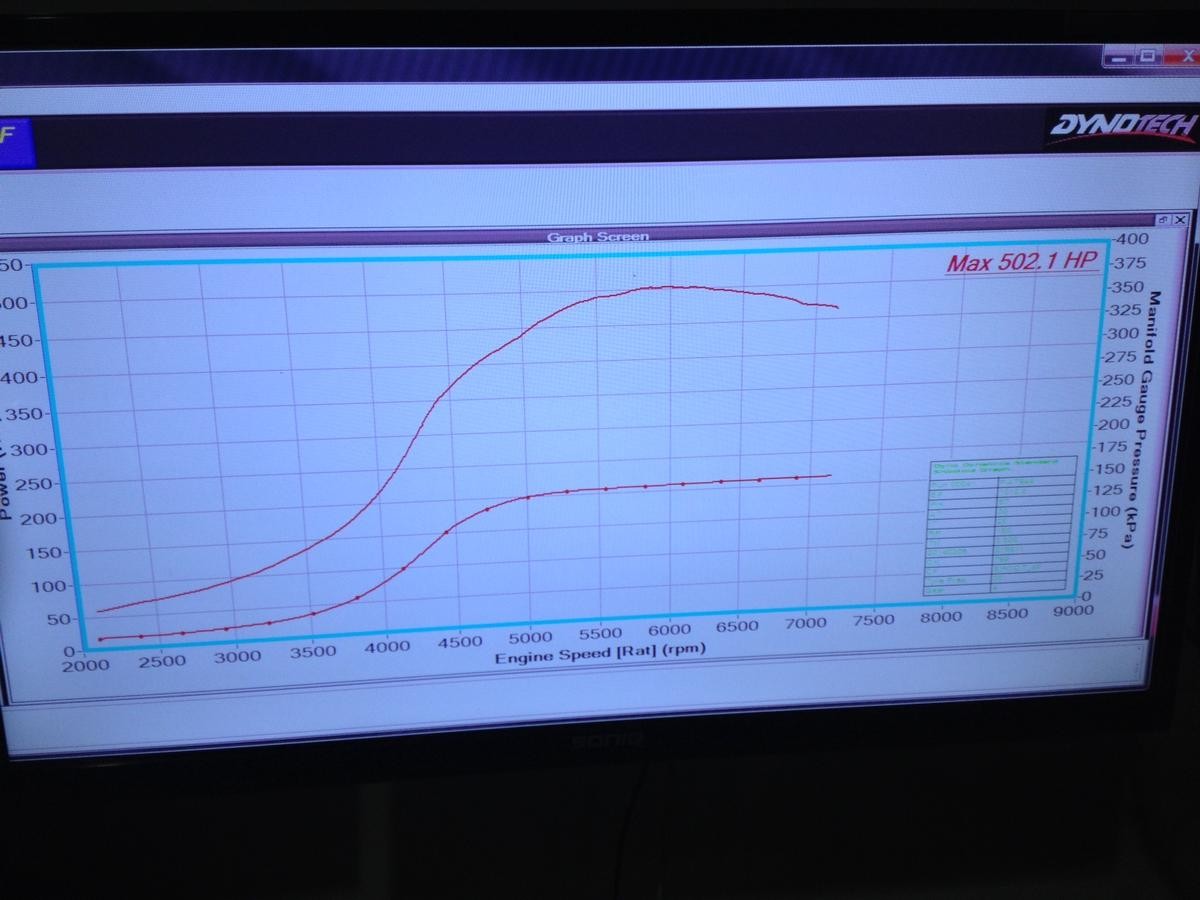

So all in all, the car felt great. Would have loved to do more laps but it was late in the day and I let Paul (the builder/racer) out in the next session. He concurred with me that the suspension was way out of kilter. The back end wanted to step out too easily and the porpoising was bad. He still managed a 1:43.8 which on old tyres was pretty good all things considered. Here's the most recent dyno chart. We will replace the wastegate and go back to the dyno. He will screw more boost and ign into it. Not sure if they've actually cured the sync error or just fooled it. That's what filtering is for but I'd rather know what's causing it too.

Here's the only film we got. This is basically with a stock internal motor (except for bigger cam). This is Paul driving, not me.

Am hopeful that with new w/gate and sync error cured (fingers crossed) that we can put a little more boost into it and get a bit more out of it. The suspension needs to be setup half decently too. Add the wider new slicks, traction control and the wing and I think there is another couple of seconds to come out of the car.

4/16/12

Few more bits and pieces. Got the car weighed today. 1197kgs or 2630lbs and that's with OEM doors (stripped a little) and glass hatch. So a bit more to come out of it but wing to go on yet.

Replaced the wastegate with a locally made TurboSmart version. Couldn't believe how much smaller it is compared to the LR modified stock version. When the builder took off the LR one he thought that it was a strange way of installing it as the exhaust gas push against the w/gate piston instead of blowing through that when it opens. Seems odd to me too. Note the welding skills. Few more shots of some custom pipework he did on one of his bikes. Those pipes took 3 days.

Also decided to modify the front hubs to run the wheel speed sensors to give a cleaner read. Front shock pots on now too so we should be able to get some reads and dial in a bit of T/C.

Found the rear RHS Banana arm bushing to have a bit of looseness in it. Does anyone know if you can just buy the inner part?

First event this Saturday. They're predicting a heap of rain this week. Hope we at least get some dry laps with the new wider rubber on this week.

Don't have enough time on it yet to tell if it's over or understeering. Literally had a handful of laps without any proper shock settings. In fact thought they were all on full soft the other day but it turns out that they were except for the rear RHS...which was on full hard! So that wasn't helping any. To add, we only had 10" wheels all round with 265 / 285 older slicks on. So no real test. More just to see that nothing fell off or any leaks. As it turned out we had an electronic glitch for most of the day, hence the lack of laps / feedback.

Now switched to 10.5"/11.5" wheels and 285 / 305 new slicks and set the suspension up half decently with a corner balance, so things should improve drastically from the last outing. Just hoping we have a clear day on the weekend. Tony, I don't have the corner weights to hand. It only got done late yesterday. I'll post when I have them.

I ran a staggered spring setup previously with square or square-ish wheel/tyre combos and didn't suffer too much oversteer. As you say, there is sooooo much to take into consideration. Even the size of your s/c pulley will have an effect. We can only try these ones as supplied by Moton.

Interestingly, the engineer knew of the Motons even though they're hardly heard of out here. He said that while they were favoured in the U.S. he found them only 'ok' and that they'd take a little longer to setup. I've had them put on a dyno and while not totally conclusive, he did say that they had some good and not so good results...but all could be worked with. He is not a vendor for suspension.

4/19/12

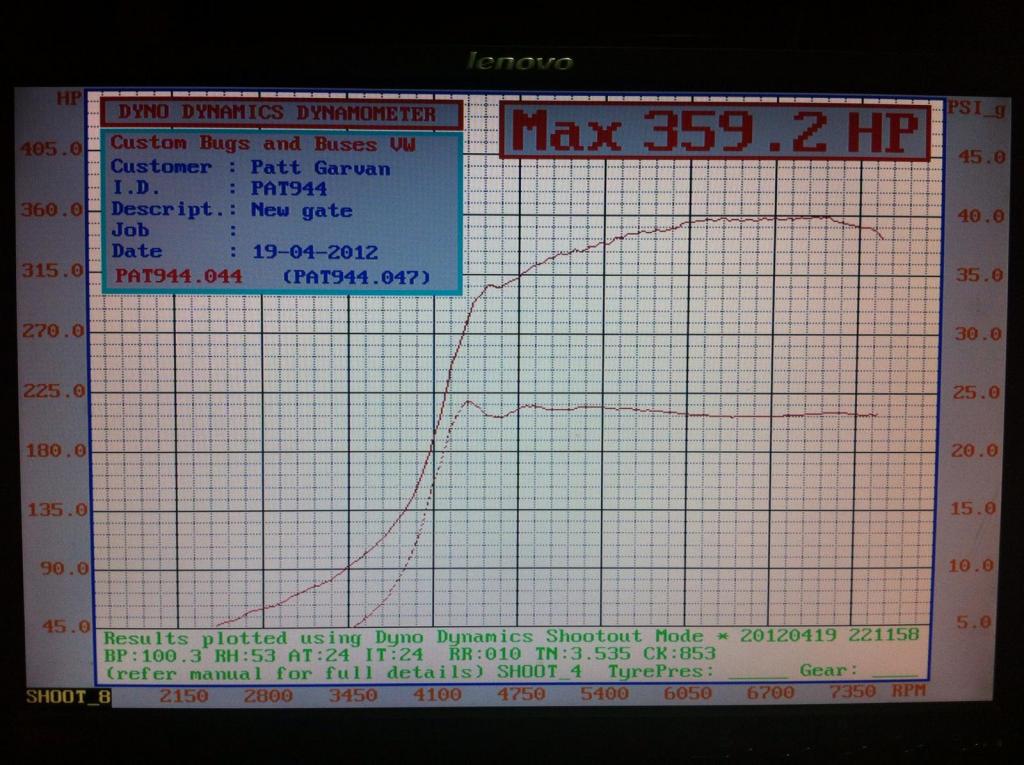

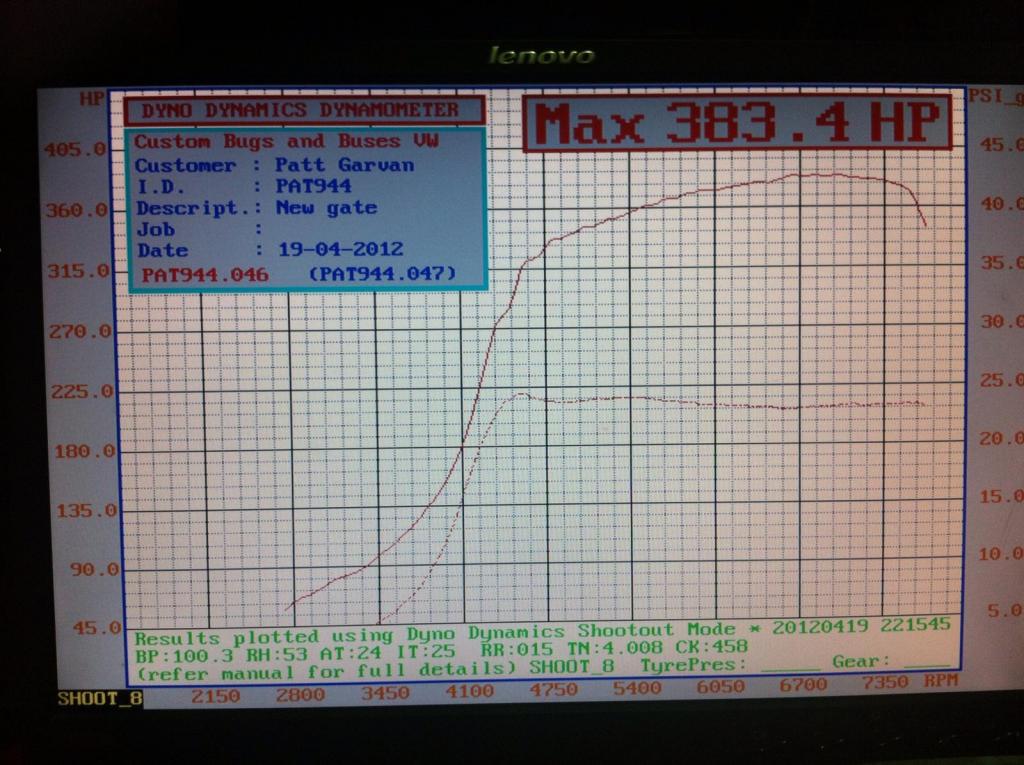

So went to the dyno again with the new wastegate. Got some basic charts back. Included is a back to back run with the ramp rates changed just to show how you can pick up instant hp without doing a thing. This is still on a conservative brand dyno compared to others so we could bump 400whp if we wanted to post a number.

4/21/12

Sorry to say but I had a pretty decent off yesterday at the fastest part of the track. Met with the tyre wall at a reasonable pace. At this stage it looks fixable but won't know until all the panels are stripped off. Fingers crossed. Pretty sure it wasn't entirely my fault. It looks like there was something on the track that caused me to lose traction very rapidly. Oil or marbles. Hit the wall quite hard. Feeling pretty sore but I'm ok. Ribs are very sore and to make matters worse I have a cold/cough...OUCH!

I have copy of the video which I might post up. Not for young viewers!

4/22/12

The day was going pretty well but the car felt a little taily and sort of darty from the outset. So we took the rear sway bar off completely and changed suspension settings a little. Car felt better. Engine felt strong.

Well here's the video. This is on the new short North track at Eastern Creek.The new flip flop is quite challenging and quite a bit heavier on the brakes than I anticipated. I was behind an 'interesting' car. An AlfaSud....Sports Sedan. Mid engine 13B with GT35. Pretty fast in a straight line but he was holding me up in certain sections. So having fumbled around trying to create 3rd gear from 5th at the top corner (to date, this refuses to comply) I set sail after him and was quite deep before shifting to top gear. Car just seemed to get a bit light initially and I corrected but then the surface just felt like it was pulled out from underneath me. All I could think of was not to over correct too much and snap back onto the inside left wall. Seen this happen quite a few times and it's not pretty. Totalled cars are the norm, roll overs not rare. So I just had to sit out the ride across some wet grass and through the gravel. Even had time to downshift. Managed to scrub off a bit of speed but as you can see, the impact is still pretty solid.

Ribs are sore and to make matters worse I have a cough which kicks in at night as you lie down. Tore the muscles even further in a very painful bout last night.

Got the car back to the shop and on the hoist. From appearances it looks like the frame is ok. Roof and windscreen are straight. Whole left hand side it damaged but from underneath could only see lh tie rod bent. Will have to slowly build up an inventory of spare parts and put it back together again. That's the risk with this hobby.

ps...if you really want to feel sorry for me you can all join in and sing Happy Birthday! haha...too funny.

Yes still a few more things to be done when back again. I do have a Hans but we just ran out of time to fit the Helmet fasteners. Stupid really, but HANS won't help so much in lateral incidents, more front to rear movement. I'm sure it would have been better to have it than not though. Neck is sore. Didn't get knocked out but the helmet actually hit the GoPro behind me so quite a bit of head movement. Might have to get a seat with a Halo I think.

A few things to take out of this. If I get this all back together it won't be without net, hans and halo seat. I count myself lucky to have only sustained the injuries that I have. Going to get them checked out this morning.

My recollections of the moment were that I felt an uncertainty of traction. The correction 'seemed' pretty mild and I felt as if on edge. Sort of tip toeing through the corner. There are a series of bumps through that corner that can also assist in unsettling the car. We also noted that the rear right hand bushing that holds the banana arm to the torsion tube carrier had a little fore/aft movement but couldn't replace it in time. We felt that under compression it would be ok. Perhaps it was a combination of a few things but I have to say that loss of traction seems the main culprit. Not to assuage my ego, merely examining the event. The car in front seemed to have stuff billowing out so much so that I thought I was behind some Dragon car on a Japanese kid's show. I also noticed the shifter moving sideways. Not sure quite why that is the case? The car has all new mounts in it. Have to check into this as well.

As Chris notes, I did downshift. This was a deliberate attempt to scrub off more speed. Sitting on the sidelines as a Monday Quarterback, it is doubtful that this did much to slow the car...but I didn't have many options at my disposal. Wonder if yanking on the handbrake or just jerking the wheel suddenly sideways would have helped? Rotate or Rollover??

Well the ribs are fractured and while the neck is pretty traumatised, it's not in any danger of further damage by way of X-Rays. Now that the adrenalin has worn off, things are tightening up and starting to tickle.

As for the corrections and discussion, well don't worry, I am happy to have people's opinion and don't take it personally. Of course an event like this dents the ego and confidence as much as the panels, but I think in my 'defense' I have to point out that there were two mitigating circumstances going on. One was the absolute conscious thought of not letting the outside tyres get onto the grass and causing a rapid hard left hand turn to the inside wall. This was a very clear and pervading thought as I was going through this. We have seen plenty of video or been at the track when this has happened. Generally presents a worse result than the one I experienced. So as I started to lose it to the right I was very much trying to straighten the car up. Of course this may have produced an over reaction based on my concerns of the inside wall. I'm sort of happy that at least I was thinking while this was all unfolding in beautiful 'Surround sound You 'R' There 3-D'. You can throw in 'Scratch and Smell' there too if you like!

The other thing was that previously when I've had a loss of traction on the circuit due to too late braking or just too fast into a corner you have the advantage of all the friction between tyres and tarmac. With this one I had grip, then no grip. So there was very little chance of keeping it on the road surface. I'm sure a pro would have handled the situation a lot better than me, but it's only when you get into these situations that you are confronted by whatever is in your artillery. If you don't have the moves then it's hard to consciously pull them out. Instinct is ok but experience and knowledge is better.

To add, with the extra rubber and springs when they do give away it's just faster. (900/1100) If I'm honest, I wasn't entirely convinced that we'd got really close to setting the car up yet. All we'd done is go in with certain bump and rebound settings, taken the rear sway off as the car was too taily with it. We'd made some minor adjustments to the rears and went out again. The car was feeling a little nervous or jittery even in a straight line in the morning. It was a bit better during the ill fated session. There was still a lot of work to be done.

Just a damned shame to get this far and bin it first time out. Took a lot of time, money, effort and now we're back quite a few places. Like playing Snakes and Ladders!

Onwards!

4/23/12

Wish I had of had a bit more tarmac and friction to utilise. A slow spin is fine if you have a straighter bit of track. This is at the fastest part of the circuit and a long 90o bend. I was a fair way into 6th gear and probably doing 110mph+ through there. A lot of momentum wanting me to go to the rhs of the track, especially with a sudden slippery surface. I think the only thing I could have done in hindsight would have been to pull the wheel hard left as to rotate the car. When it let go there really just wasn't time to straighten things up on the road with little adjustments or by pushing down on the gas pedal. I was going off to the right hand side no matter what. What I'd like to know is what would have happened had I rotated the car? That's the uncertainty in my head and obvious concerns about flipping the car. These are the things that should be taught as much as car craft etc. To add, they are spending what amounts to no small fortune on this track however I suspect that they will leave changing or upgrading the known areas of concern either to the end or not at all.

To be honest and this isn't to make any excuses, but the car is very different to what I was used to. Don't get me wrong, I love it and can feel the potential. Missing 3rd gear selection a few times has me irked. I never missed in my old box. The brakes are very different but I was growing to like them. Seating position is different. Motor felt good though. Having a guy on the sidelines very calmly analyzing everything that the data produces is great, but also slightly distracting. Still, it was great feeling like there was sooo much more to learn.

Anyway, time to put it behind me and get over it. Life goes on.

4/24/12

Just to answer a few questions.

These are the details I have on the Motons:

So the fronts are 160kg w/ 30kg tenders and the rears are 200kg w/ 40kg tenders. I'm not sure if the tenders are counted in the overall spring rates. My logic tells me that a spring is a spring and therefore can resist pressure and should be counted? However I've heard other people say that they are just locators. So approx 900lb front and 1100lb rear. Steve, you may well be right. My builder and very good driver * wants to take some rear spring out. We had them set at 9/15 bump and 7/15 rebound all round. We then knocked 2 clicks of rebound out of the rear when we took the rear sway-bar off. The car did seem to handle a bit better after that but was it bar, shock or both? I also think that having virtually no rear downforce might have been an oversight. We just didn't have time to put the big wing on and there seems to be enough advice to suggest you need more power to drive through the aero drag. Might have to wait for the next motor.

Hans, halo and netting will be in the next version.

* A quick little montage that the builder Paul put together. This was with him driving it after bar was off and shocks were adjusted.

Thanks again for all the positive support by all. Much appreciated.

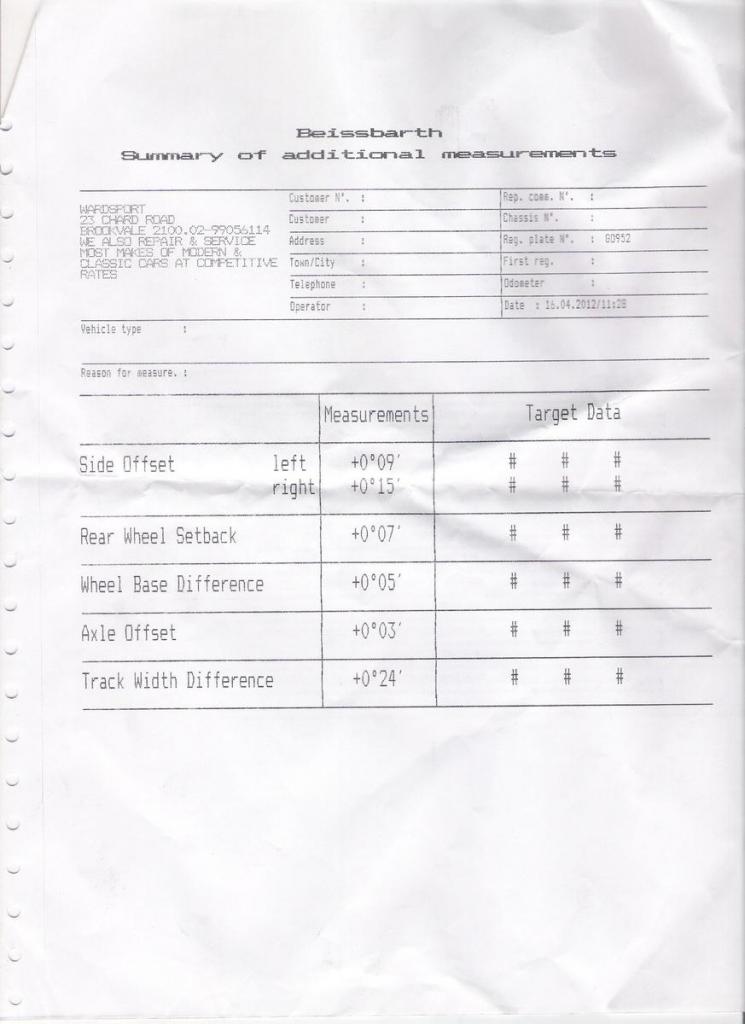

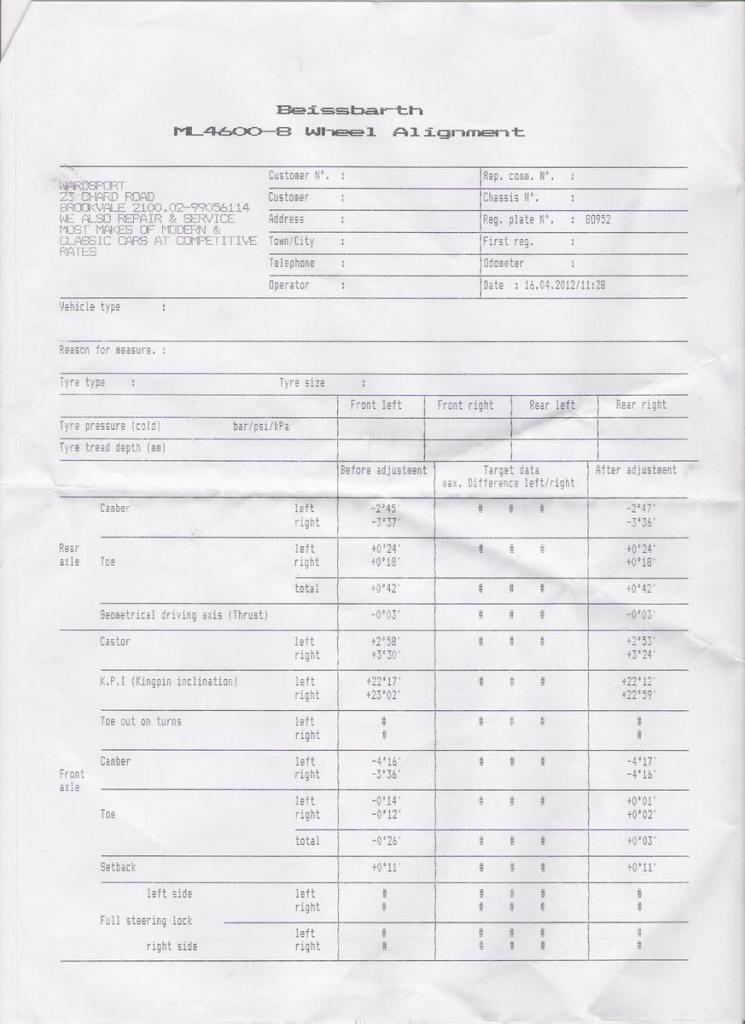

Here are my geometry stats:

Well if the tender is completely 'flat' or compressed under the weight of the car, is it doing anything or is it just sort of acting as a bump stop and locator? Or even though it's compressed 100% is it still part of the quotient just because it has a rate?

Another thing to consider is that I'm rusty, virtually everything in the car has changed and I'm getting driving coaching by the engineer based on data. I did feel like I was very slowly getting my head around the car. In some ways it felt awesome, yet in others I can see that I'm driving with caution compared to the previous incarnation. I don't have the data yet but I have to assume that I was going fairly quickly when changing into 6th gear not that far from the braking point. Maybe I'm imagining things, maybe the old rear wing did exert some downforce. When I showed the cross section template to Simon McBeath he kind of laughed in a polite way...so who knows.

I'm going around in circles a bit here guys. Vascillating between beating myself up then feeling like people are saying I'm to blame and it was an amateur mistake. I know I've driven around that track enough times and while I'm certainly no pro I have faith that I'm an ok driver. The feeling of lack of control when it happened reminded me of two other times. One when I hit a rain storm while driving on fully worn R specs with no tread, and the other time was when a slick had deliminated and threw me off the track. I had zero control and can't believe many others could have saved the situation.

Nevertheless. It is what it is and I have to get past it. Sick of hearing myself write about it and think about it. Extremely frustrating to get the car to this point and have this happen 1st time out. Sure it's just a car, but damn...I've had a LOT of problems over the last 5 years and am certifiably stupid for persisting. I wish I had another pastime that I was so passionate about because I'd be turning my efforts towards this about now. I do appreciate all you guys and your input. Just wrote to the organisers of SuperLap to withdraw for the 3rd time! Extremely frustrating and embarrassing. This is a very limited event and we were finally back in the field with a car I felt I could be proud of.

4/25/12

Steve, I'm sure you're right in what you're saying and thanks for putting that all down. Here are some observations from the engineer to add to the mix. I knew something was up....

"Hi Patrick,

I’ve been analysing some of the data in more detail and what I have discovered is the following.

We have been using 45mm of rear damper travel at the track. This probably equates to around 70mm of wheel travel.

Unfortunately the car needs to have more droop travel through some of the higher G force turns. The inside rear wheel is lifting off the ground, this is the jacking effect that Paul was talking about, at the time we thought it was being caused by too much rebound damping and we removed some.

Factory setup have the droop controlled by the bolts retaining the outer torsion bar bush, your application probably has the rear droop controlled by a spacer above the piston within the damper so some damper or rear suspension setup mods will be required before the next outing.

If you look at the data particularly suspension position [position each corner in a new graph on the page] you will see that the lr suspension pots flat lines during some corners at around -22.

At this time the rear wheel is starting to lift of the ground and the rear will start to become unstable.

Your video also confirms this as you have to correct your line on entry , you were travelling 16 klms quicker than the previous lap and the gpsmap shows you wider on entry before the apex which all added to the event.

The rear end appears to be rolling more that the front but a more accurate measurement of motion ratios would be required before you could call this a fact.

Everywhere that the lr suspension starts to bounce off the full droop point is where you were complaining about a lack of rear grip so we need to rectify this before next outing.

If there are no spacers within the damper then we may need to get extended rose joints, Im a bit surprised that this has occured given that you bought the dampers to suit this application.

Mark

Rsport Race Engineering"

I also wonder about the rear inside lifting. Perhaps he means on the track that day as opposed to just at that corner before the crash. However even if that was the case it may mean that the inside wheel was not actually lifting off the ground but still could have been getting pretty light. Also, as has been noted, I slip initially and correct before the main 'let go'. There are also some bumps through there which could have easily unweighted part of the car. Not everything has been discovered yet I feel. I want to resolve this before taking to the track again. Collin, I don't have the ride height but it was not slammed low at all. I suspect it wasn't all that much lower than normal ride height but don't have the actual measurements.

4/27/12

Going to inspect a shell we have to see what other parts we can scavenge off it. There's not a whole lot left. Kinda like going back to that chicken in the fridge for the 4th time! Doors and rear 1/4 panel I'm thinking. Most of everything else is already gone...even the 1 piece roof!

5/5/12

Still not sure yet what lies beneath but from what we can see it 'appears' to be mostly surface or panel damage. The shocks look straight, the shock pots didn't break, the wheels look straight, the roof is straight, windscreen intact...tie rod bent and sway mounts seem to be the most obvious undercar issues. Might just have been really lucky and hit the tyre-wall at the perfect angle.

Also note the shot of the rear rh wheel. I hadn't paid much attention to this in the past but the builder and engineer are very much convinced that there is not enough droop or suspension travel. Bit hard to compare with the body kit on there but in the flesh it certainly doesn't look like it drops down much. What would 'normal' travel be? 5"...more, less?

Does this rear 1/4 panel look usable in terms of the cuttoff point?

Oh, got a basic torque read too. Doesn't cross at the normal 5252rpm. Guess that's just a scaling thing. Not sure if it can be re calibrated to the 'normal' position or if it would change the actual curve. Looks like about 365ft/lb on the 'optimistic' pull. Doesn't seem a great deal of tq either way. I suppose that's also just dyno to dyno.

5/8/12

I just don't know and it's driving me quite a bit insane not knowing what the definitive cause was. I'm still thinking it's more than one reason but can't claim to know the exact combination. Going to be a few more weeks before work even resumes on the car. More time for it to rattle around in my head for days/weeks on end. More YaY!!!

5/12/12

I'm kinda sick about the whole thing tbh. Took so much time and money to get it there only to have that happen. Not knowing the full cause and quite possibly never will further exacerbates the frustration.

Now I have a guy in the UK who is a cage builder saying that I should probably not re use the cage in my car even if the chassis/body is repairable. I don't believe he is trying to sell me anything, merely pointing out his observations. Said that in super slow motion video cages deform and can go back to 'normal' without being recognisably affected, but he says the metal can have fatigue or weakening.

So either I'm faced with fix body but cut out cage and start again. Or body no good & re-tub. Realistically a painful and expensive process down here. Or just a plain old rebuild a totally new car. None of these options appear attractive. Could fix body and turn blind eye to possible cage issues which doesn't sound smart. Not sure how to test if cage has been affected? If floor, mounting points and suspension pickup points all look good perhaps it's ok? Just have to wait a few more weeks until panels stripped and assessment can be made. Frustrating and daunting.

I'd like nothing more than to do this and halfway done already. Just not going to happen like this just yet. My builder is super busy at the moment so work won't start for another week or 2. I will put to him concerns or questions about re using the cage. I am pretty sure he'll agree with you, but are we all being a bit ignorant and maybe the cage guy in the UK knows more than we do? If the cage happens to be visibly deformed I'm not sure if you can replace certain parts or have to start from scratch? Because we haven't pulled the panels off yet I don't think I can make a call on the overall outcome, but I do have parts heading this way already. Looking at seats now but want to wait to hear outcome of damage first. Re tubbing is not easy even though you've mentioned it. Building a whole new car is not an option right now, so just have to wait to see how this one looks underneath.

5/13/12

Just to clarify, the seat is an actual OMP raceseat. Not a stock road style thing. Had a full 5 piece harness on too. I tend to agree that they should be ok but for the price, not worth skimping on. I'll replace them. As for the seat, I want a Halo, but there are some that have a open part to the Halo which I'm sure will make life a lot easier. The downside to these is that they somehow 'appear' flimsier. Any thoughts or experience?

5/14/12

We will do all the measuring once stripped down. It doesn't make sense if this will be the case though, unless they sold me the wrong shocks by mistake. I did have them dyno'd and they were described as being pretty good in most readings. I'd have to dig up what was said but they were deemed as sufficient for the task and we could tune around them. Not sure that this covered potential droop issues though.

We also have the actual data from the suspension pots which is why the engineer is sure it’s to do with the rear droop and lack of shock travel. To counter this it does seem strange looking at the type of constant radius corner and how little I was loading the suspension? Having said that, I was going pretty fast and perhaps there were other mitigating circumstances which when added to the suspension travel caused the sudden loss of traction. Having watched video of a few different tracks I’ve driven on and seeing how it doesn’t convey things like speed and road camber / conditions, I also think that perhaps this might cloud the issue when dissecting the incident off video alone.

5/15/12

Oh, just to add to this. There is a particular fast road/track 951 which was put into the hands of a suspension analyst who suggested to go with the 850lb front springs that he should increase the rears to 1200lbs and even 1400lb on certain tighter tracks. I believe it was largely based on matching front and rear spring rate frequency (which as most readers would note doesn’t get much of a mention in these pages). This was not on a race car but as I said, a fast road / track weapon. No aero to speak of and running on R spec rubber.

It will be interesting to see how this progresses.

6/23/12

Just a bit of an update. Things have been moving slowly for one reason or another but we did some basic measurements today. Putting all the 'stuff' in a pile, shaking it up and seeing what results, I think the reason I came off the track was due to the inside rear wheel having minimal or no contact at times during some cornering. This I believe was due to a sort of domino effect. Bear with me.

So back when we decided to change the car from a road / club car to pretty much a race car I flip flopped about trying to decide what to do with the bodykit in that I wanted to go up to a wider track. So in the end due to not a lot of choice I went with the B/foot GT2 kit and as things happen, I also sort of ordered the Fikse wheels at the same time as they were running a special on them through B/foot. My intention was to do some door to door racing and I was restricted to 44" total wheel width. So I went for 10.5" / 18" fronts and 11.5" / 18" rears. Fikse said fine and that they knew the right offsets as they'd worked with B/foot before. B/foot says that you can run 11" / 12" with their kits also. So anyway fast forward 18 months and we're readying ourselves for the first track outing. The builder had done his best to get clearance for the front wheels and in the end had to raise the ride height a little in the front. So of course the rears got raised similarly to maintain balance. Anyway, enough backstory.

So today we measured the ride height and rear travel from resting ride height to jack-it-up droop. So the droop was only 15mm or 0.6". To me this seems very little but I'm learning that we work in smaller increments the more race oriented suspension we move to. We also found out that my car was sitting 170mm off the ground at the front (measured to midway through the bolt connecting the A-Arm to subframe) compared to JET's 145mm. The rears were 275mm from midway through the bolt connecting the trailing arms to the T-tube carrier compared to Sean's at 245-250mm. He also said that his similarly measured droop is 25mm.

So...I know it doesn't sound much different but it would seem that due to not having the clearance for the front wheel/tyres to turn sufficiently at a more desired ride height, we had to raise it and ergo, wheel lift. Tough lesson!

So, my next choice is how to replace the body work. I have bought another set of B/foot GT2 flares but there's no point repeating the process. I'd like to go for a more complete widebody but it just doesn't seem like there is a good quality off the shelf kit available. Waiting to hear how Tony G goes with his new kit that he bought from B/foot. I'm tempted to go for some of the same front fenders that he used from A.I.R. that are an inch wider and then put the GT2 flares on. The rears could do with a little padding too but I don't want to have the flares on the front only. I actually quite like the look also. So we might massage the rear metal guards before putting the flares back on. Anyway, I'm seriously hoping that the extra clearance will allow us to drop the ride height and regain sufficient droop.

6/24/12

Prof Fred (industry lurker) requested a pic of where we were taking the rear ride height measurements from. Fronts were mid point of the bolt that joins the A Arms to the sub frame.

Be interesting to know other people's ride heights??

5/30/13

Plenty going on at the moment but nothing to say just yet. As opposed to releasing weekly (+/-) updates I’m just going to wait until it reaches a point where it looks pretty smart. It will look very different to the last iteration though. Besides, my build pales into insignificance against Tony’s & Dukes amongst others. Nevertheless, hope to have something to show by about end of July which is when we’re aiming to be testing. Fingers crossed!

I think the only stock panel on the car will be the roof (which has a slight alteration), pillars and rear licence plate/lights panel (whatever that part is called). While we've added a few bits and pieces to the car, we've also removed quite a bit also. The old car weighed just over 2600lbs wet with no driver. I'd guess that we can get this down to 2500lbs, maybe less. Not as light as some but getting down there.

9/21/13

Hi All

It's been sometime since I've made a post in here. Sometime since April 2012 that I had that crash which at the time and for ages afterwards really got under my skin for a number of reasons. So now we have GO952 v.4

Well it's only GO952 in name as the car is clearly not a road registered vehicle anymore. Just to touch briefly on the accident as it ties in with the current version, apart from any driver faults, fluids on track, bumps, lack of downforce...whatever...the main reason was that we ran out of suspension travel in the rear. The inside rear wheel was lifting off the ground and the car was super twitchy. So we knew that we needed to get the car lowered and for that to happen we needed more wheel/tyre clearance. So I went through quite a long process of talking to Mike from I.F.C. who produced the new front 1/4 panels. This not only allows us to lower the front of the car (which obviously gives us more rear travel as we can now drop the rear also) but allows heat and pressure to escape through the top and rear of the panel. Win on all levels.

I also wound up using some rear GT Racing fenders which are 2" wider than stock. So we have tons of room for most size rubber. To add, we have added a bump steer kit which has helped us a lot with the front geometry. Also we have the 95ONE rear T-bar delete bracket (2" x 3" version!) for the rear which also affords us a better roll centre with the raised pickup points...well that's the theory.

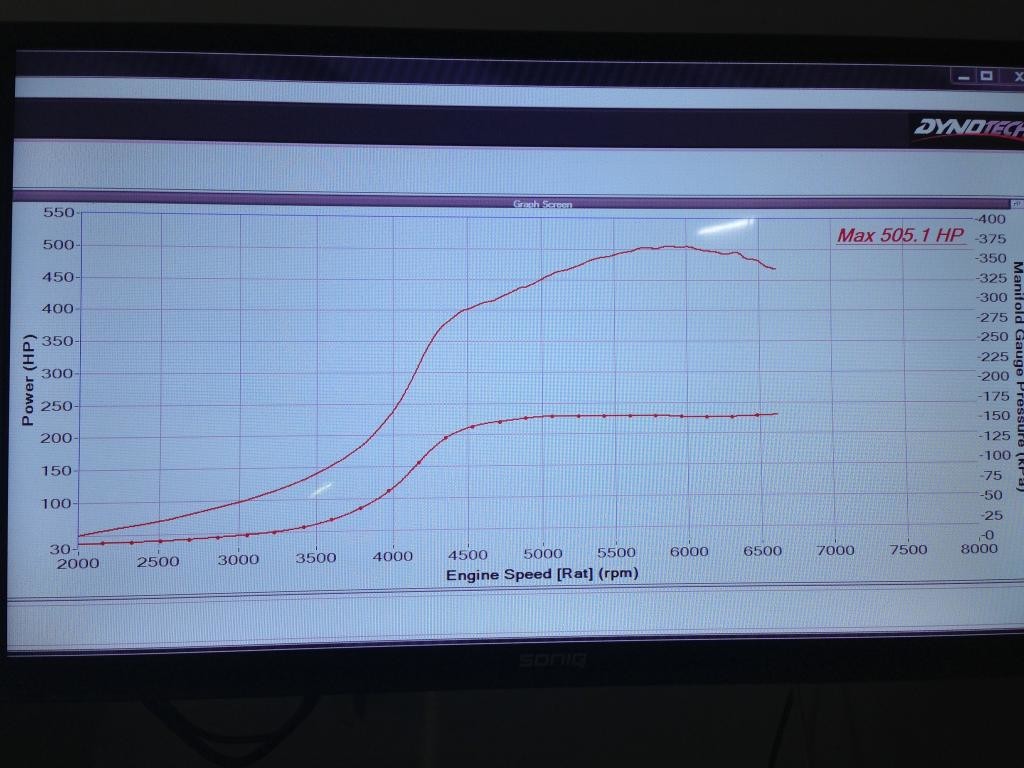

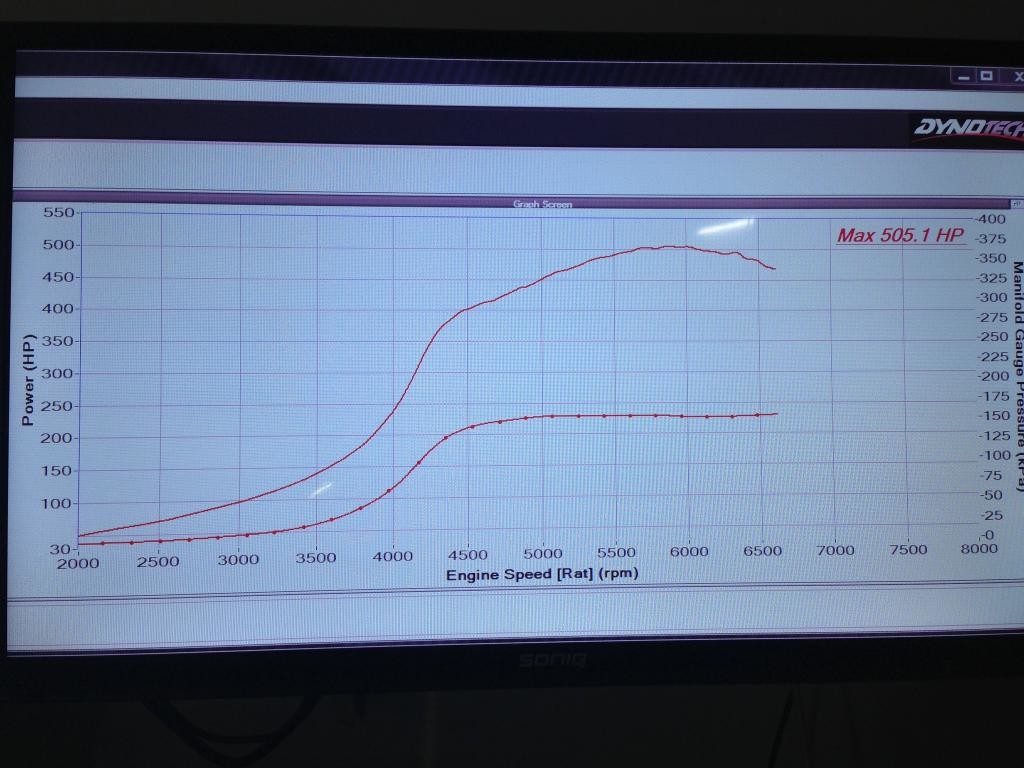

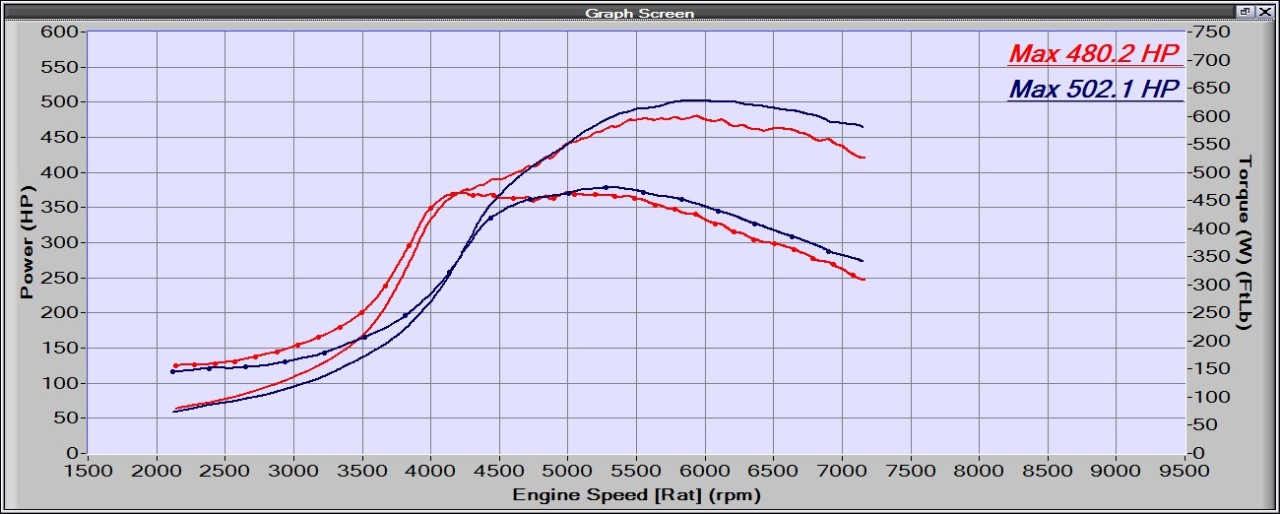

So much has changed in this car even since last year. Perhaps a list might be in order but it's going to make this first new post too long. I think a few pics and video might do for now. Remember this car has been built for Time Attack. So it's all about downforce. We are off to the track on Tuesday for the 1st shakedown. It will be a chance for us to start sorting through the new chassis changes, aero, springs and new horsepower/torque. Ahh, yes, I didn't mention that we finally have the 3.1L 8v motor in the car now. We've only just done the first tune and while they're hitting a brick wall at about 6000rpm, the power to weight is going to be quite sufficient for a rusty driver.  With a bit of luck we will have a new intake on the car before the event in mid October. We feel that the stock intake is really holding the head/cam/headers/turbo back. To think that we haven't even tapped the sweet spot in this motor yet is pretty cool. From 6000rpm to 7500rpm this motor will shine. All in all 505whp at 22psi isn't to shabby for a starting point. I don't have the tq or ign charts yet. Once I do, I'll show them too.

With a bit of luck we will have a new intake on the car before the event in mid October. We feel that the stock intake is really holding the head/cam/headers/turbo back. To think that we haven't even tapped the sweet spot in this motor yet is pretty cool. From 6000rpm to 7500rpm this motor will shine. All in all 505whp at 22psi isn't to shabby for a starting point. I don't have the tq or ign charts yet. Once I do, I'll show them too.

Anyway, I hope some of you guys enjoy it in it's latest version.

Oh, here's a bit of a walk around.

Still waiting on the Tq and ign Sid. We're hoping to put together a new intake before the event. Am looking at Corleone's for inspiration and packaging. This turbo is pretty big so we have to work around it a little to get the stock intake to fit. Going with a re design with the centrally located entry should work pretty well I believe.

For the record. The car last weighed in at pretty much right on 1200kgs / 2640lbs wet. Since then we've added dry sump system inc all the plumbing + tank & housing, rear wing/struts/internal bracing, front splitter w/ thick alu supports, rocker panels, roof scoop, air jacks and plumbing, and all the custom front end cooling system. Not insignificant additions as you can imagine. However with the removal of all the underbody insulation, addition of carbon fibre doors, lexan rear hatch and removal of all the metal quarter panels and replacing them with f/glass...we are now down to 1140kgs / 2500lbs wet. Considering we've also lowered the car a lot...incorporated longer A Arm pins plus bump steer kit and replaced stock torsion tube housing with the 95ONE 2" x 3" version. We should have way better geometry and we've gained a lot of droop (which is the main reason for all of this!). On top of that we've added a 3.1L racemotor in place of the former 2.5L mostly stock motor. When I look at the old video of the car back in 2012 it was still pretty damn quick in a straight line. Disregard the suspension issues, it moved forwards at a decent pace. Now we've improved everything (except the stock intake) so I imagine that this car should feel somewhat different yet again!

Shall report back.

Video from April 2012 session prior to crash. The car is pretty fast and it only has 360whp. I can hear/see now why I came off the track back then but I remember how it leaped through the gears. Brain is doing somersaults trying to imagine what it will be like now!

Thanks for the kind words guys. For some reason I've been inspired by these forgotten little cars that not many are aware of and even fewer care about. Have been inspired by many on this Board and hope to fly the flag for the front engine transaxle water pumper for some time to come.

A real photographer is taking some pics this week.

First track day tomorrow. Stomach is currently in permanent Butterfly mode...

We’ve basically just gone up about 230lbs in rate both front and rear. So the ‘feel’ should be the same. Bit of guesswork in terms of specifying the new springs based on the extra downforce. The issue we had before was of the inside rears lifting off the ground. I mean, perhaps the setup was taily as well but I don’t believe the springs were why I came off the track. I will be taking things slowly and Paul will do the first session. He’s an accomplished driver and will be much more efficient than me dealing with the setup. Whereas I anticipate going down the straight for the first time and feeling 500whp kicking in, screaming like a little girl and covering my eyes with my hands!!

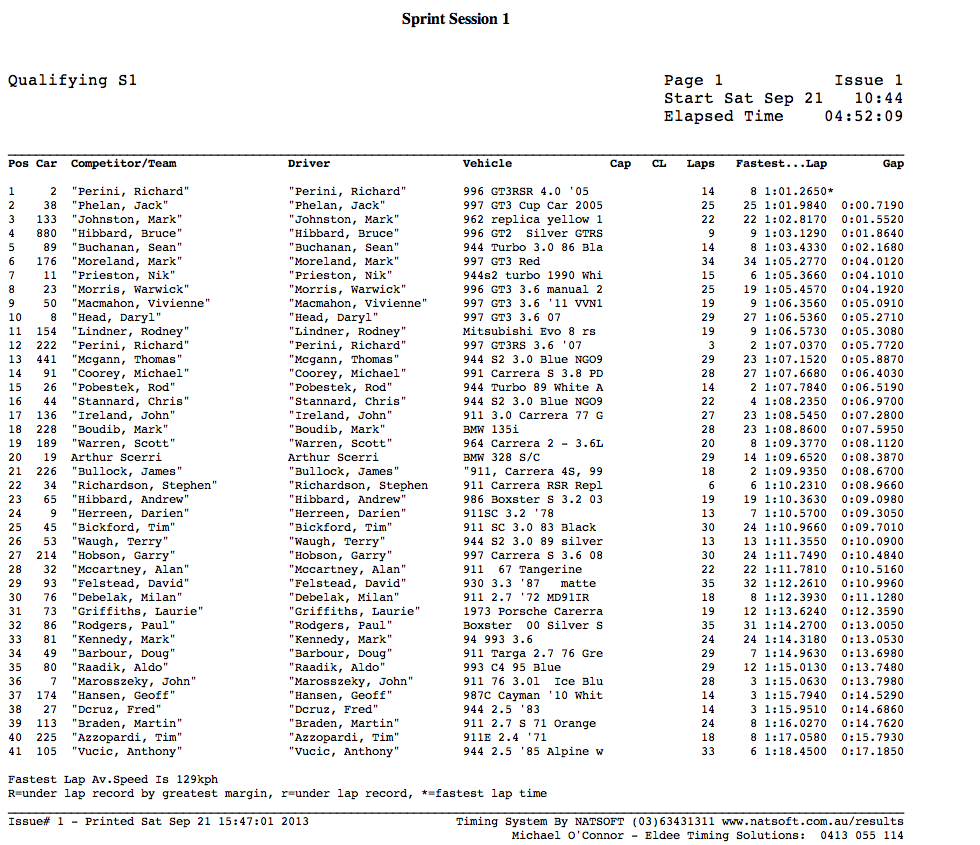

9/24/13

Well the good thing is that the axles and CVs stood up to today's first shakedown for the car. We turned the boost down to about 19psi for the day. Best thing was that the car ran pretty faultlessly. The only time work was carried out was when the throttle cable was a bit grabby and we discovered that the outer shielding for the cable had in fact melted around the firewall. They think this could have even happened on the dyno. So we are very happy that so little extra work was needed for the day. Bit of a slow day as there were plenty of cars/groups today. Anyway, Paul, the builder went out first. Only did 3 laps as the cable was not right. Even so he managed a 1:03.4 which was very impressive. The car looked really quick down the straight and we were right on pit wall. He's a very good driver and is quick straight out of the box. We missed the next session but he went back out in the 3rd session and managed a 1:01.9 with an eclectic of 1:00 flat! I hope Sean doesn't mind me pinching the pic of their recent trackday at the same track to illustrate the times. Similar weather and conditions for a fair comparison.

Also a couple of pics/videos. Sorry don't have any in cabin vids yet. Just a couple more Ipad snippets. Watch in HD format.

Well you might be asking about my turn...So I went out after those first 2 sessions and...(I'll make my excuses now  )...there were some V8 Supercars in our Group and a few slower cars. Without any wing mirrors I was spending more time looking in the internal mirror trying to stay out of people's way. Not easy! I was soooo rusty and not a little daunted by the car at first. You could have timed me with a Sundial. So I did a 1:12 first session. Managed to bring it down to a 1:06 after that and there's plenty left as Paul ably showed!

)...there were some V8 Supercars in our Group and a few slower cars. Without any wing mirrors I was spending more time looking in the internal mirror trying to stay out of people's way. Not easy! I was soooo rusty and not a little daunted by the car at first. You could have timed me with a Sundial. So I did a 1:12 first session. Managed to bring it down to a 1:06 after that and there's plenty left as Paul ably showed!

So all in all a really great 1st time in a totally new car. We were on Medium compound R spec Yokohama rubber for the record. Going back next week. Hope we get the same weather.

Oh and here's the tq as well. Clearly not in the same scale as we're used to. After having driven the car today on lower boost, I'm not sure how much I need the new intake just yet!

Yes, guys. As I said, that was the timesheet from Sean's trackday on the previous weekend. Just wanted to show you as a comparison. I'd like to also say that Sean doing a 1:03 is extremely fast considering his car is a daily driver. Much heavier than my car without any Aero. So his time is even better than ours if put into perspective. However, I wasn't really saying that our time is the be all and end all, more that we had a very successful 1st shakedown. Usually these are spent doing a lot of work in the pits fixing things that are failing or loose or whatever. Gives me confidence in the builder. Have to also thank Sean for helping us out when we had a last minute Oil pressure issue with the motor. Only last week it had to be pulled out and torn down for some unforeseen changes to be made. Sean who works a few miles away was able to help us out and go and do the tear down/reassemble in quick time. Many thanks to Buchanan Automotive for their continued help and friendship!

Sorry guys, I didn't have the cameras in the car. Paul did and he will upload them in the coming days. Put some Go-Pros in some interesting positions so there might be a little delay due to editing. Don't worry, I'm really hanging out to see them too.

Tim and Fredrick

The car has been designed to compete in World Time Attack. While not door to door racing (I don't have the money for that) it is a very fast growing format of essentially qualifying for 2 days. In other words, fastest lap wins. There are 4 different classes and some extremely fast cars. eg a Cup car will generally do this track in 1:31-1:32, maybe a bit quicker if a Cup 'S'. The Aussie Supercar V8's fastest lap is a high 1:27 from memory. Last year's winner of W.T.A. did it in 1:25 flat and the car was not long finished before the event. This is also all on R spec rubber! So as you can see, they're very quick cars. The fastest cars in my group will do it in low 1:30's I'd say. We are hoping to get under 1:35 this time around but who knows...The front fenders and rocker panels on the car were developed by Mike at I.F.C. via many emails back and forth. The bumper is Broadfoot. Nose panel from Belgium and rear fenders from GT racing. The lights from D9 and the hood from Van Zweden!!!! In other words...it took a hell of a lot of time (money) to get this all to work.

I was actually feeling really tense prior to doing the Shakedown the other day. Both for expectations of how the car and me would react. The car won on the day! Now I’m just really keen to get back out there and try and remember how to drive. As I said elsewhere, one failed trackday in 3.5 years doesn’t make a Champion! The track that we’re testing on is quite different to the one that we need to be fast on in October but testing anywhere is better than not testing at all.

Here’s a little edited Video that Paul made. It’s him driving. I think he left the music over the motor due to Go-Pro’s poor sound. Not sure. Hope to get some more with better engine sound soon. From outside the engine makes a sound unlike any 951 I’ve heard before, especially on backoff. Just a straight through 3” with no muffling or anything.

9/26/13

Had some Pro pics taken last night at the workshop. I wasn't there but this is a sneak preview of what he did. Apparently the car will be going in a few Mags and on Internet sites. Who'd a thunk it from such humble origins as a pretty battered 1986 951 when I bought it in about 2009.

I have to say sorry for the overindulgence of the last few days. Don't mean to be flooding the forum with pics & posts. It's just that it's been a long time coming and accompanied by a lot of heartache along the way (strictly car heartache that is, nothing really serious) so to have it finally appear in this state is quite surreal. I have felt like I'm in a dreamstate all week. Right up to the last days we had some quite major issues and had to suddenly pull the motor out and down to fix some oil pressure issues. That was a real pisser and cost many thousands for the privilege. Wound up being an issue with the piston squirters leaking past their sides. So anyway, forgive the over enthusiasm and I'll try to keep the 'baby photos' to a minimum!

Here's some Hand held video atop a little stand. Bit windy so pretty shakey but you get the picture. I really like the beginning when the car is waiting to go out. Sparkling and new. I think you'll agree that this thing sounds unlike any 951 before. At first I thought it was an exhaust leak but as Sean pointed out, probably just due to the straight through no muffler setup. Paul asked if I wanted to change it but now I think I'll stick with it. Sounds menacing like a War Cry! Now that the car looks like going quicker than we projected we might as well make them look over their shoulders!!

Thanks guys. Very humbling. To be clear, I'm just a working schlep so I do very little in terms of what physically happens on the car. Of course I pay for it but if any plaudits are to be cast in my direction it would be for planning, talking, conceptualising, dealing, pestering, cajoling, pleading, remonstrating, crying, kicking/screaming, thanking....etc...all the people that I've involved in this build. There have been quite a few different people/companies that have their mark on this car but I have tried to stay true to the cause and am glad some people like the result. I do.

The builder, Paul doesn't read forums so he won't see this but he has been great to work with and has given me reason to be calm at times when things have been somewhat frantic. His fabrication and vision have been such a bonus and now I'm equally lucky that he has great skills behind the wheel to help set the car up and achieve some great times in it. I am planning on closing the gap brick by brick but can't see myself beating him just yet...or ever. Also have to thank Bruce and Sean Buchanan, my mechanics. They have remained great friends even though this car moved workshops and continue to assist when they are called upon. Even last week Sean performed an emergency tear down and reassemble in short time. Very grateful for their continued help and work during this project.

Hope we can do some damage at W.T.A. to fly the 951 Porsche flag. I can say with surety that nobody was expecting to see this car at this event and it will create a bit of a stir in an otherwise 99.9% Japanese car field.

10/1/13

We have only been running 1.3 bar for the moment. The car is pretty quick as is. There's a lot of room for improvement too. I always like that feeling as we know there is more potential to eek out in the future.

Great to see these cars still getting built in all corners of the world. How good would it be to bring them all together one day.

Here's another recent video of Richard in Holland. That car looks pretty nicely hooked up....well except for that little glitch that just cost him the win!

10/3/13

Did some more testing yesterday. Amongst other things we found that by increasing the angle of the 2nd smaller vane on the rear wing we gained top speed down the main straight! Riddle me this?

Pretty much spot on Colin. Better exit from preceding corner. I don't have all the stats to hand but that's the gist of it. The corner speeds were pretty low too. The one leading onto the main straight is very tight and also bumpy. So it's really easy to not get quite right. Map is kinda wonky but you get the idea. Track runs Clockwise.

Not the track we will be running on in Competiton in 2 weeks. That is faster and more flowing.

Drag and downforce would have increased with the more aggressive attack Elliot but as there was greater corner exit speed, this overcomes the extra drag.

The difference between the 1st test day and yesterday was that we raised the the front ride height a little as the springs had settled. We have to be 65mm above the ground at resting ride height. We knocked a little bit out of the front camber so it’s back to just over -3^. Raised the rear ride height a little yesterday and wound in some rear sway bar. The corner speeds were quicker which translated to the improved straight line speed. The only thing I didn’t confirm was how it changed the downforce at the same part of the track.

3/18/14

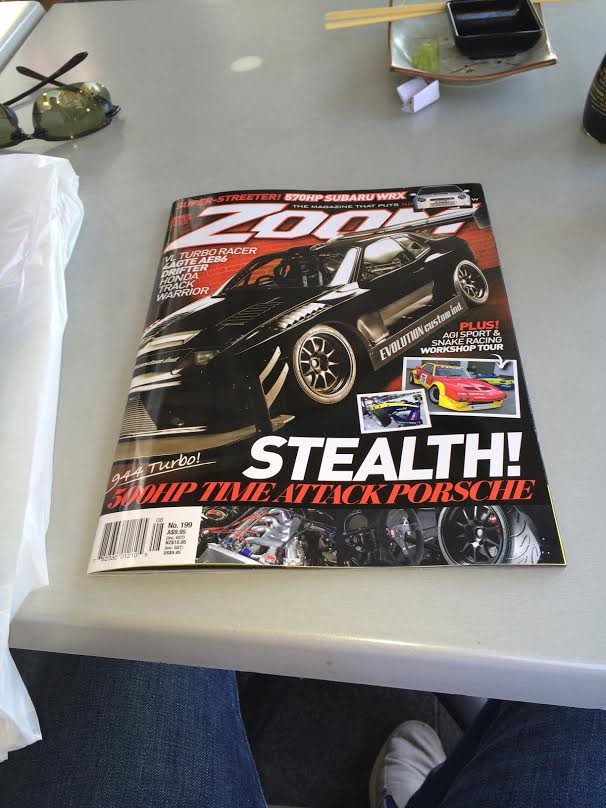

I know this car has had saturation coverage and had to think before posting but I guess it’s worthy of another one. Apologies to those that are over it!

Got it covered in a local car mag down here. (No, it’s not a Mazda magazine!) Got a nice article and the ‘Centrefold’ too.

As it’s taken some time to finally hit the stands there has been some changes already to how it appears in the article. Gone are the ‘busy’ dive planes and we’ve also cut away at the rocker panels.

Another recent article on the Time Attack website.

http://www.worldtimeattack.com/index...nues-to-amaze/

This was all done very recently and haven’t tidied it up yet. More to come as we’ve had a 2 day consultation with a well-known US Aerodynamicist, the aptly named Andrew Brilliant. Very interesting stuff indeed. Amazing how some seemingly insignificant changes can create big gains in downforce. We are going to nip away at the changes over the year with the WTAC 2014 being the objective. At the end of the main straight in the event in 2013 he calculated our car was showing over 1000kgs downforce on the rear while we had -90kgs lift at the front! Yikes! Makes me shudder thinking about that considering the little incident I had in 2012! He was actually highly surprised that we even got the times we did under such circumstances. So the whole emphasis is on increasing frontal downforce for this year. This will be achieved through changes made to the splitter, end plates, rockers, fenders and some more venting on the hood. To achieve some of this we will actually shorten the radiator at the base, remove the large air to oil cooler and convert to water to oil and move the enclosed air filter higher. This will allow us to create an actual working or active splitter with diffusers that will create a lot more downforce than our current slab of wood. He is confident that we can improve our laptimes significantly. Even with the minor changes we were able to do some improved times 2 weekends ago at Wakefield Park which is a short, tight track. Car also feels a lot more alive with the smaller more efficient GTX3582 and a change in fuel. Hopefully some more improvements are not too far away.

Not a great video but it certainly looks faster up the hill and along the back straight. Was a fun day as I am starting to get more comfortable in the car again. Managed a 1.02.9 myself which was a 4 second improvement from the last time I was at this track. Paul was super close to breaking into the 59 sec barrier which carrys some kudos. He did a 60:00.7 and was showing 59.6 on the predictive timer with 2 corners to go. We had a few minor glitches at the end of the day which prevented us going out again which was a shame. The bolt in our RH engine mount broke and Paul suddenly had some interesting steering changes! Something to aim for next time though.

3/19/14

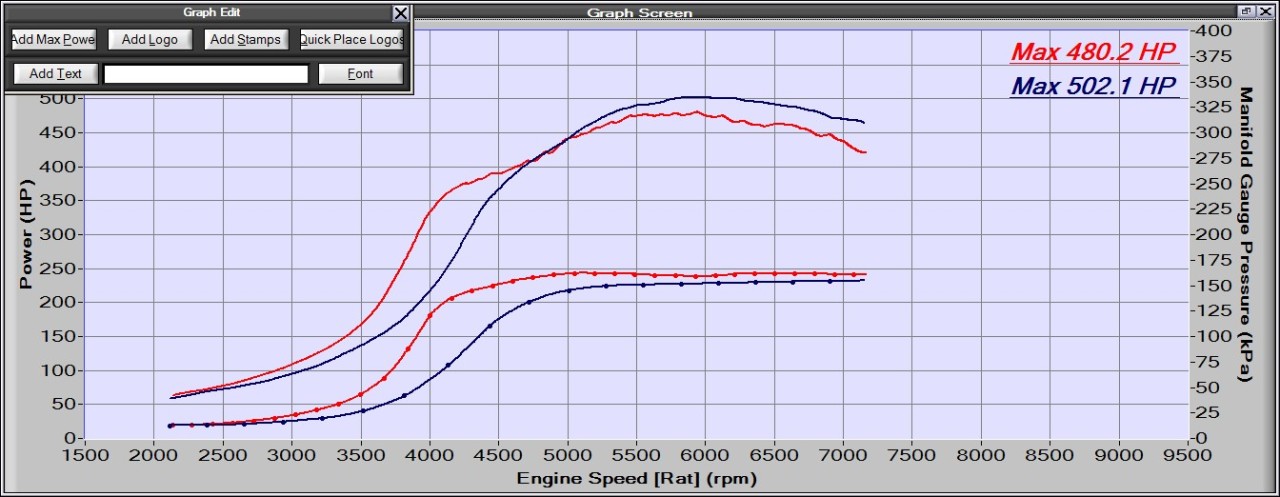

Sure. I thought it was posted elsewhere. Unfortunately the dyno chart isn't of much help as it was done on a different ramp rate according to the operator.

I don't quite understand but from what he said (briefly) he loaded it up really slowly to get a better tune. Said he got more timing into it as well. The chart looks slower than the previous turbo which doesn't make sense as I know it's more responsive.

1st one was the BW hybrid. 2nd is the Garrett.

I wish I could get more info out of the tuner but I can't ask him everyday for the maps/charts. He's a really nice guy when I see him but just seems to be super busy and often working well into the night so it is what it is. As mentioned, I don't think we can compare the charts completely apples for apples due to different ramp rates and possibly temps. He also said we had problems with wheelspin due to the slicks turning to mush at some stage this time around.

I guess apart from the coolant issue, we have a great motor for the time being and the bottom line is laptimes. Having the fastest RWD T.A. car at the shorter track is a sign of things to come. We've got more improvement to come which is exciting.

Colin, the calcs were done on the car as it was in 2013. With the splitter and dive planes. I was amazed and couldn't believe with our fairly significant dive plane 'extravaganza' that we were still showing lift!

From what I've heard, read and seen, Diveplanes/Canards etc are not what they appear. Unless you did some pretty significant aero work yourself, I'd not go there. At best you'll get some downforce but with that will always come drag. At worst, just drag and possibly lift. Perhaps those really small ones that Tony G had on his Red car might be worth a shot. I think they were off a Cup Car. I've seen a lot of people removing their Diveplanes so it's not all as obvious as it would seem.

Ok, finally some more info. Interestingly the boost comes on much earlier when comparing these two pulls.

Here’s a bit of an explanation from the dyno operator:

“I have attached 2 files. The 1st is boost. 2nd is torque. These overlays are at different ramp rates. This shows the problem we are faced with turbo cars & ramp rates.

The higher horsepower reading is in shootout mode which is the correct ramp rate to show the correct horsepower/ torque readings. Unfortunately this does not allow the turbo to spool so therefore shows the boost coming in later. The slower ramp rate also overheats the tyres causing wheel slip. “

So this makes a lot more sense in terms of what we’ve been ‘feeling’ by the seat of our pants. Very different curves and response rates. Going to get the Ign map too.

5/22/14

A few updates occurring right now.

We discovered the last time out that we were running out of front brakes. They were Big Reds on 2 piece floating/slotted 332x32mm rotors. I had purchased a 2nd hand set of 997 Cup Calipers that were repainted and refurbuilt in the US some years ago. Due to various reasons they hadn't been sent down to me until recently. I had also wasted quite a lot of time and money trying to source some larger 350mm rotors to fit with the Mo30 uprights but that just didn't work.

So we then decided to go with the later sized Cup rotor of 380mm / 15" but that was going to be a really tight squeeze in under our 18" wheels. Finally we decided on ordering some custom rotors and hats from Coleman Racing which were 375x32mm. These finally arrived (although they made a mistake when converting mm to inch which resulted with the inner face being 9mm shorter than we ordered) and we went to fit the Cup Calipers. Unfortunately they had been put back together incorrectly which resulted in the Ti pistons being damaged. Further investigation shows that it would cost something like $1500 to rebuild both of these calipers and also the more I read, the more I found out that the Cup Calipers aren't viewed as a true race quality version. Race teams have to run them but they probably toss them away after each meeting as they're subsidised when buying them.

So, after more frustration and wasted time we decided to ditch the Brembos and go for some 6 piston Alcon calipers and make up the adapters here. These are the same calipers that were used on the Aussie Supercar V8's for many years so they are well regarded as being of stout quality. Interestingly when we compared the previous rotor and caliper vs the new larger setup, the new one is slightly lighter which is a bonus! Another thing was that these calipers have much larger piston area so we've had to change the master cylinders to adjust for this. The Cup calipers have 28,30,32mm pistons vs 30,35,38mm pistons for the Alcons. Which also means that the piston area covers all of the pad. Incidentally I had also bought 3 sets of pads to work with the Cup calipers so have learned that it is possible to cut them down to fit the Alcons but Paul will be coughing up some interesting substances today!

A further change to the car involves the front sway bar. Due to changes we are going to be making to the splitter we have to make room. One of the things that had to move was the front sway bar. So we've made a pretty trick custom setup which has it positioned behind the front Axle line. In addition we get less drag with it more out of the airstream too. There are blades on each side of the cromoly bar and it will have in cabin adjustment via the control unit pictured. Both these new additions plus a new wider version of the front splitter with new end plates (all the dive planes have been removed) will be tested this weekend at the track.

The next steps will be to shorten the radiator from the base upwards, change the p/steering pump to electric and convert the large air to oil cooler to a water to oil version. Both these will be moved from the front of the car. What we are chasing is better front down force and to do this we have to make significant changes to the splitter and also reduce frontal drag. Clearly the rear wing is overpowering the front and we are concentrating on removing as much underhood pressure to do this. The front of the rocker panels have been modified and we'll be making more changes to increase the release of this pressure. Aero is way more important than extra ponies at this stage. Amazing how some apparently minimal changes make a difference too. Angles of vents, panel gaps etc...Aero is King!

Pic of brakes under 18" wheels.

5/23/16

We moved from the big 993 oil cooler when this particular version of this car was 'unwrapped' last October. However it was too small and we were seeing temps over 110c. So put in something that was as big or bigger than the 993 and the temps dropped to about 90c peak. With the car primarily used for short bursts we think we'll be ok and have been recommended this path by someone with a lot more experience than me. Looking to use one of these Thom. http://www.laminova.se/