You must be logged in to rate content!

8 minute(s) of a 264 minute read

3-12-2015

Some more work being done prior to the new long block arriving next week. New coat of paint underneath. Newly built torsion tube carrier. Made out of thicker sheet steel to survive the loads that the last one didn't. We were initially going to go back to the stock piece but it's so heavy and doesn't offer the advantage of the raised pickup points so it was decided to make a new one. Sandblasted and fitted new Racers Edge bearings. Fitted new drive shaft bearings via Constantine. They look more sturdy than the stock ones. Fitted all new rear axles and CVs and rebuilt front and rear wheel bearings.

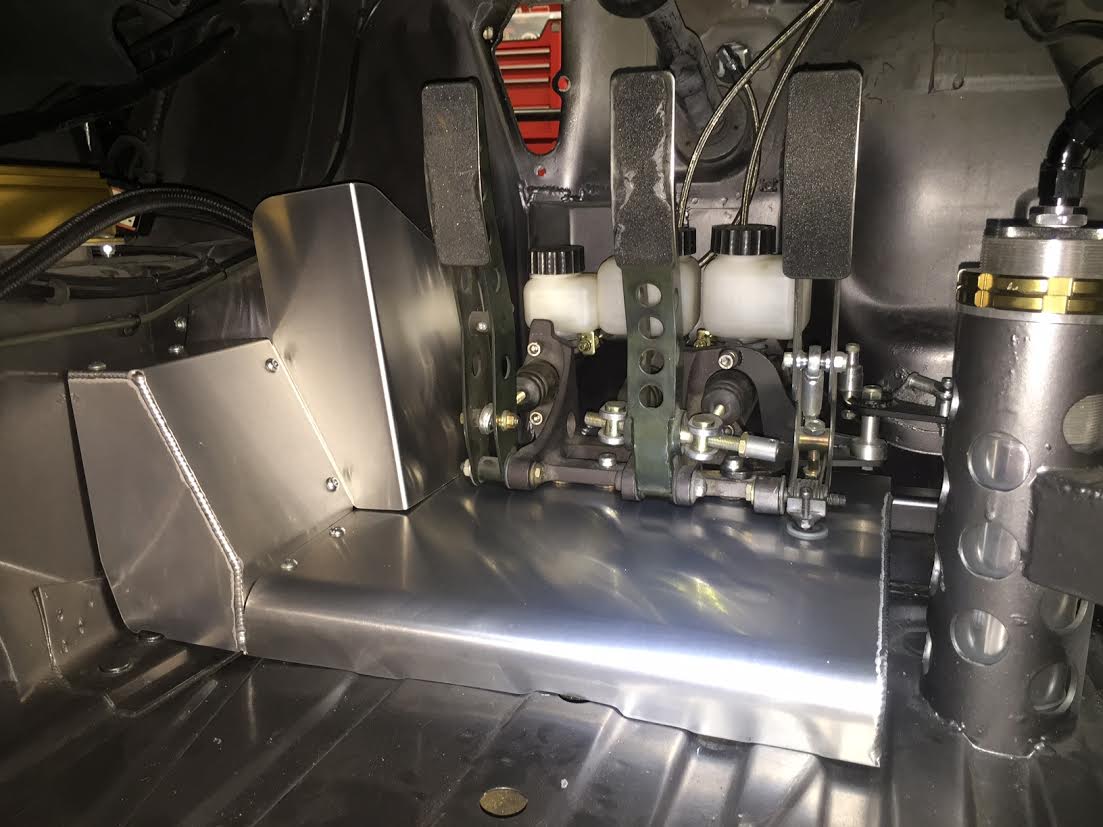

Paul has also repositioned the pedal box to be higher and further away from the seat. This will create a more 'open wheel' leg extension which is ergonomically superior.

The long block is on it's way. This is the 2.5ltr 8v not the 16v motor. Really looking forward to seeing how different this 'little' motor is compared to the last. Once it gets here we will O ring it and have the same sealing rings and copper gasket made up. Trying to get another intake that will be more suitable for this head/cam arrangement but may have to use the current one initially.

10-22-2015

Thanks! We were really pretty close to being quite a bit higher than 4th but others might have the same story too. You get so few laps that they really count. If you get baulked by another car or a session gets Red flagged (which happened to us twice before we could turn a lap) it really reduces your chances of a good time drastically. On our fastest lap Paul got a long brake pedal coming into T2 where you are going over 140mph about 130yards out from a twin apex hairpin. When that happened we lost .5 of a second just there. Another few tenths later in the lap with oversteer and that's a 1:30.7 which was same as 1st and 2nd placed cars. Oh well.

Here's the incar video fwiw. Best thing about this little 2.5 motor is it's rev range. We lose torque and the broader curve that the 3.1 motor had. Plus the old H pattern gearbox doesn't help it. Loses too much boost and power each time we shift. Nevertheless, a great little motor.

https://www.youtube.com/watch?v=iPPn2N7WQ04

10-23-2015

That was actually 26psi Thom. So about 520whp on the dyno. While the dyno was a warm morning, this was a warmer day so lets round it down to 500whp. I think we could certainly tinker more with this motor. The GTX series seems somewhat inbetween for a 2.5 8v. I'd like to see it with a Borg Warner EFR twin scroll turbo. Might be able to get some more driveability out of it without compromising top end too much. Pretty good thing nonetheless.

4-5-2016

Been quite a long time between posts on the 16v motor. There have been a few design changes and part delays along the way also.

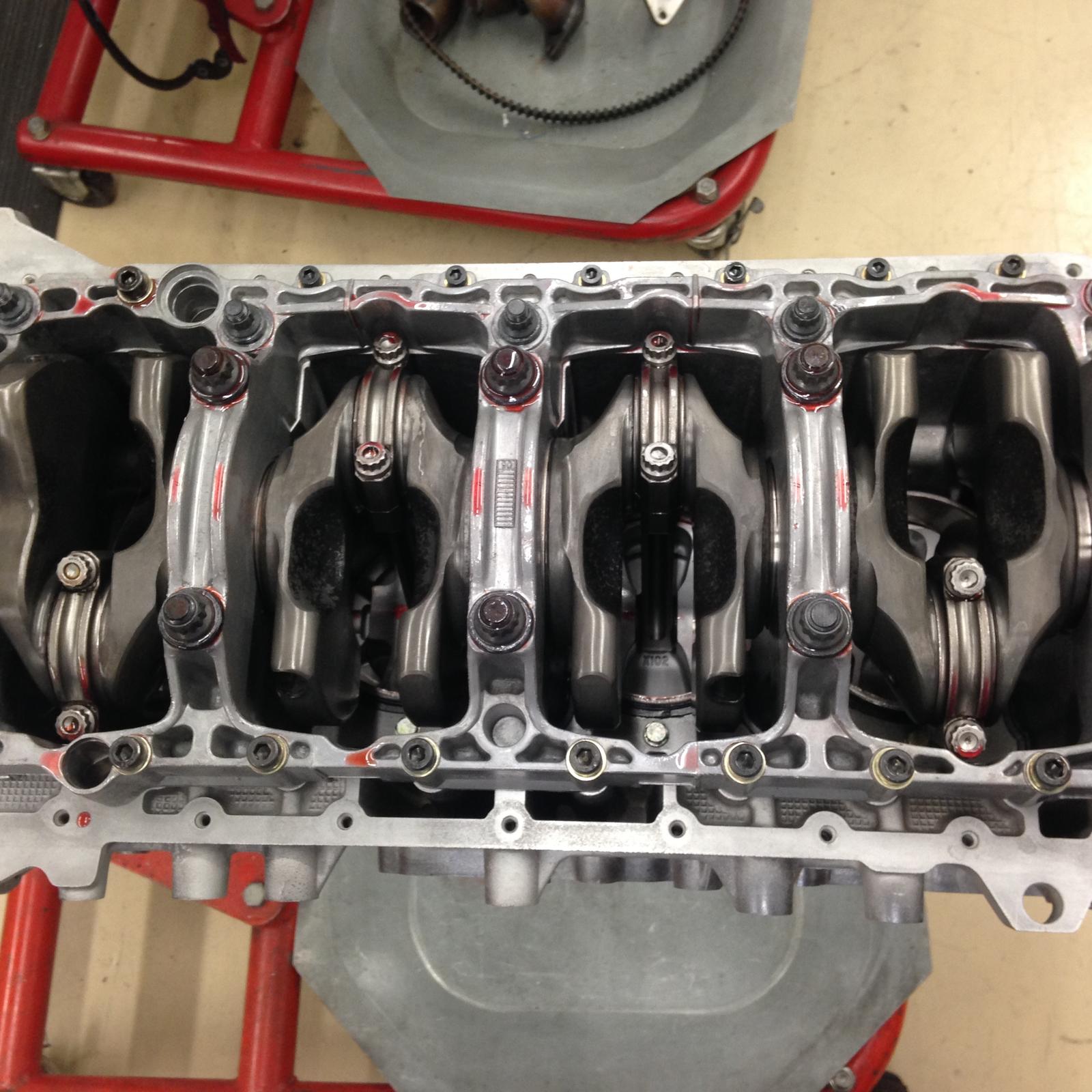

Block has been Nikasil treated for extra hardness. The main studs holes have been additionally strengthened by a version of a Time Sert. With the extra torque loading on these 25yr old blocks and larger headstuds it was deemed a worthwhile modification. We did something similar down here with the 2.5 8v racemotor.

Certain parts such as bearings and rings have been coated with an anti friction coating used by Honda in F1. Ultimately we would like to use a custom crank but at this stage it is a stock crank with some lightening (approx 6 lbs I think) and has been modified to a 94mm offset grind to enhance torque. The main issue we have with our car is the stock Syncromesh 6 speed vs competitors with Sequential Transmissions which are a massive improvement. So we need to maximise torque to give us a lot of drive off the corners and possibly reduce the amount of gear changes. The old 3.1 8v had about 720Nm of tq to the rear wheels which is a lot. Hopefully the 16v motor can give us something similar.

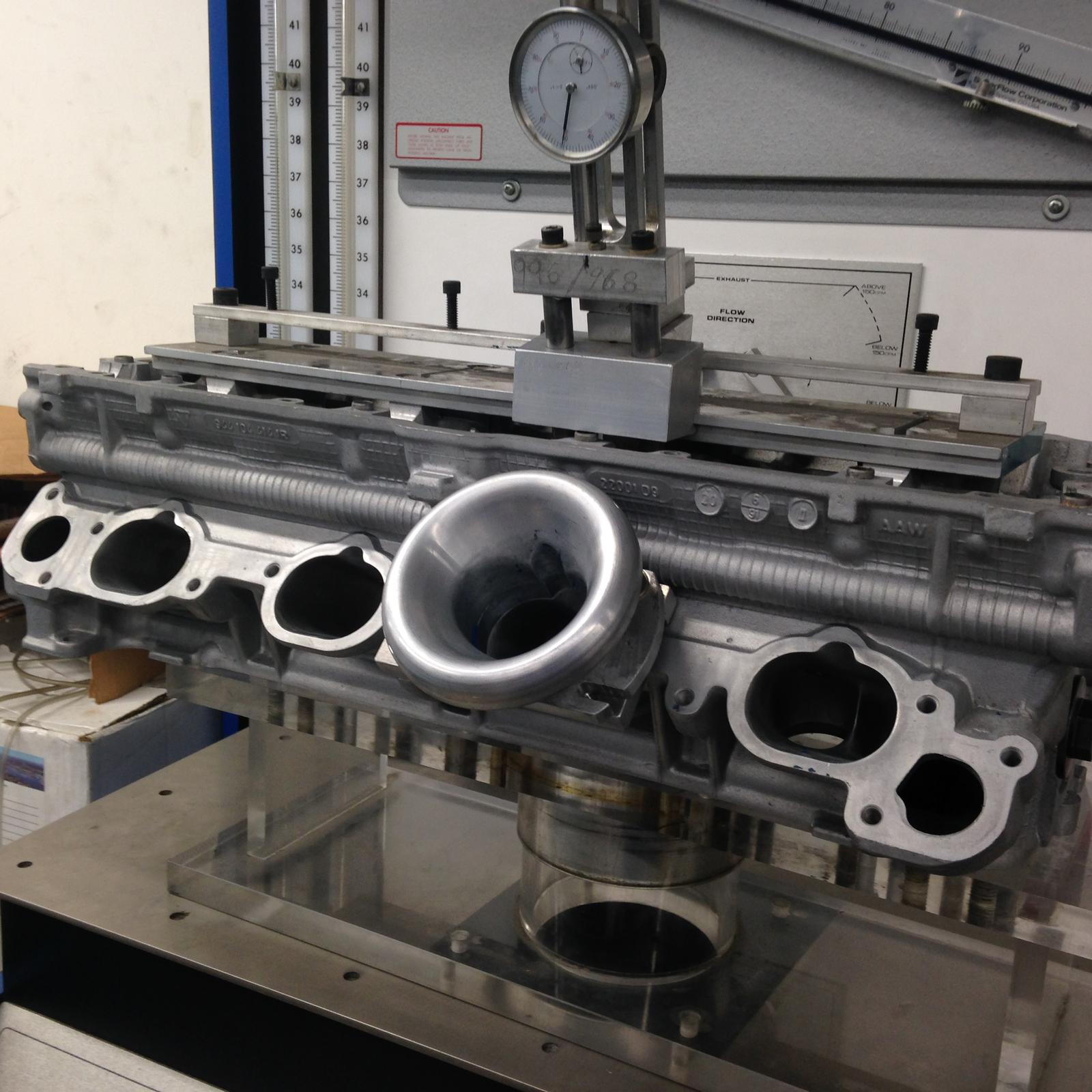

The cams are being ground now and they've been designed more around mid range than totally upper rpm. The valve train will be capable of spinning out to well over 9000rpm but we'll not get up that high. Not quite sure where we'll set the rpm cut. Perhaps around about 8000rpm and a soft cut rather than the hard cut we've been running on the previous motors. Just a bit more friendly to the components. The head was flowed to a max of 370cfm at 25". It was decided to not go overboard on the exhaust side to try and induce more rapid response both on and off boost. Potentially the superior head and 3.2 capacity should ensure that we can reach similar power (say 550whp) at lower boost than before therefore enhancing reliability. It will be running adjustable twin cam wheels at the front of the motor with a modified tensioner to increase belt wrap on the custom crank pulley.

There will be a custom ATI damper to quell harmonics but also incorporate a pulley to run the alt belt off. The idea is to shorten the parts hanging off the nose of the crank to further reduce the possibility of crank distortion which we felt was the likely reason for the failure of the 3.1 motor. The balance shafts have been removed. We felt that the main purpose for the balance shafts is to deal with harmonics in the mid range. In addition, they were designed and built with the stock motor all those years ago. With every single part in the new motor changing in weight, size, balance etc it was felt that they were almost redundant.

The head will be sealed via a custom Cometic gasket designed to run with custom Garlock sealing rings. Due to some changes in their company structure these Garlocks have taken many months to procure. Hopefully they do the trick combined with the possible lower boost needed.

I went down the path of changing to a Borg Warner twin scroll EFR turbo. I would really like to change to one of these, however budget is tight and this would have added about $10k to the build with changes to the headers, X overs, turbo and I would have also changed the exhaust to a larger than 3" straight through system. So reluctantly we decided to keep all the externals that we have and at least we can compare this motor to the 2 previous ones apples to apples as such. We will move up to the largest turbine housing for the GTX3582r and therefore our setup will be quite similar to Gustaf's motor which achieved very good figures on the dyno. I'm not expecting quite the same figures on the basis of expected pessimism but even 80% of what he got will be very pleasing. The main difference will probably be the length of inlet runners. His are quite a bit shorter. Due to budget and also packaging constraints I have decided that we will probably just modify the intake we have now. Enhancing the tq with the longer runners won't be such a bad thing.

The rods are custom design Carillo and pistons are short skirt CP. Obviously considerably lighter than stock.

The stock water pump is being blocked off and we will be using a Davies-Craig electric product.

The block and head will be sent down to us within the next 10 days. We can start working on fitting the motor and rejigging the headers and inlet. Also fit the water pump. The cams and drive pulleys plus tensioner will follow shortly afterwards. Hopefully not too long to get this motor in the car and tuned. More pics to follow.

Wow great build!

Posted by Diggymart on 12/28/20 @ 2:54:22 PM