You must be logged in to rate content!

4 minute(s) of a 264 minute read

12-14-2014

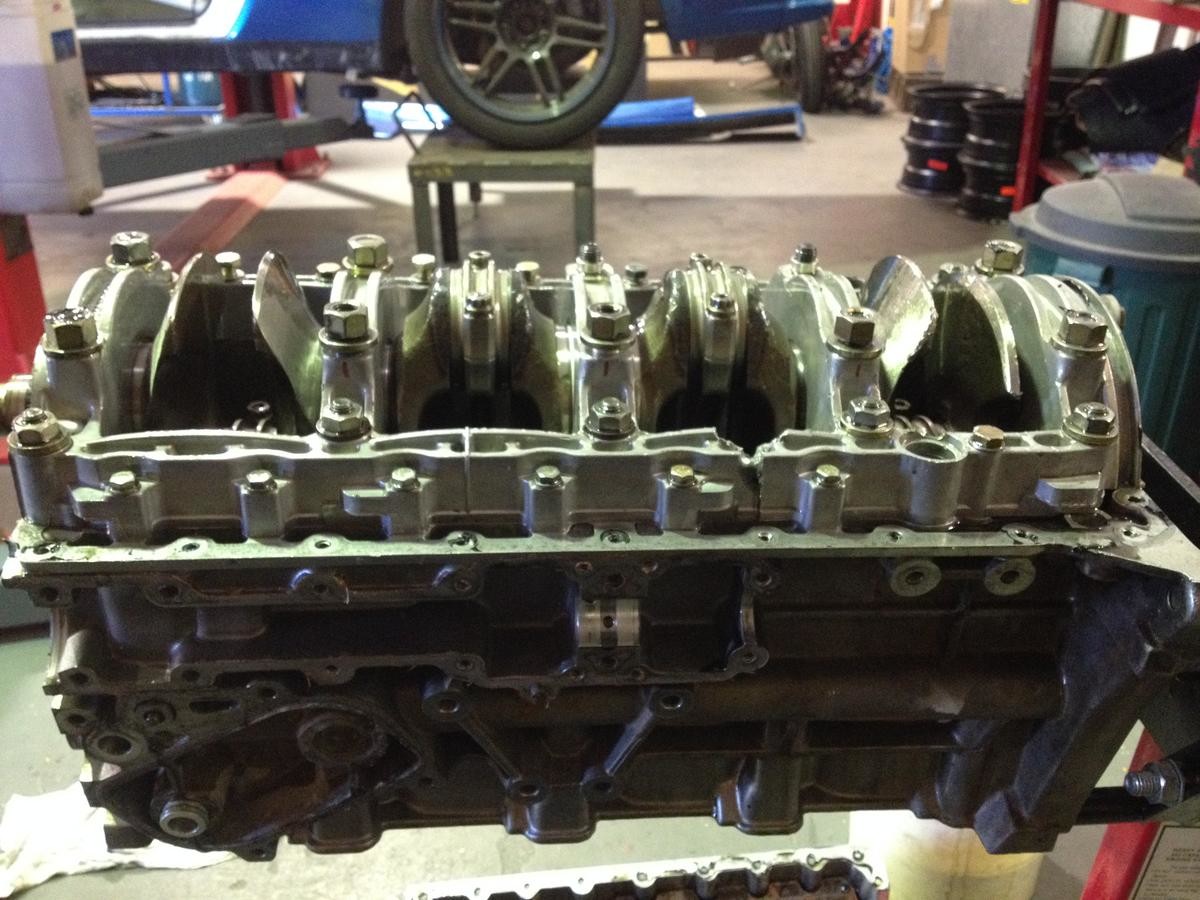

Pulled rest of motor down to find this. Now is Toast. Yay! Whatever led to the failure had a resounding success through the whole motor. Not sure of cause but plenty of symptoms. Pity....

Neeeexxxxt!!!!

Not spun bearing. Big harmonic issue. Somethings have come loose and caused massive vibrations which in turn saw parts break off the front of the motor. The first signs were the dry sump pulley shearing in half. Once this part was replaced with something more solid, the balance shaft main pulley sheared in a very similar way.

Yes, Mike. All those nuts were loose as marked by the texta on the cradle. Somewhere along the line there may have been crank whip but very difficult to determine what started this whole procession of failures. I very much doubt we will do any forensic analysis. More a bit of guesswork. Too many possibilities.

Now we will just have to bring forward the 16v motor. All the same, shame to lose this one so catastrophically. The interesting fact is that the two pulleys failed at almost the identical part on the track. Higher loads on motors are sometimes caused during backoff rather than full load. This might be one of them as the place on the track was through a fast turn following the main straight.

Hard to say if it was cause or symptom, just like a bunch of other things that failed.

Order of events were that when Paul went out on the brand new (treated [shaved/heat cycled]) tyres he came straight back into the pits after thinking that the vibration might have been loose wheel nuts. Assured that this wasn't the case he went out and did one hot lap. He came back in and the next session he went out on supposedly less affected tyres. The CV broke straight away and he came back in. We cobbled together a replacement setup and waited for the next session. He then had the first motor hardware failure which was the dry sump pulley. So he drove back to the workshop and made a whole new one out of a block of alu. Came back and fitted this and we thought we were going to be ok but had to come back in immediately after that when the b/shaft pulley sheared in half. Oh, and there was also a big crack in the intake which we also attribute to this high vibration / harmonic issue. We didn't discover that the rear suspension X member was also bent badly to such a point that the car actually had really high rear wheel toe out. It's easy enough to pontificate about what might have been the first domino. I am still not so sure it wasn't issues at the rear of the car that might have transferred down through the torque tube into the motor. There has been a big evil harmonic that has affected many parts but what caused it to start when we seemingly had none of these problems throughout the year. I say seemingly as there would appear to be evidence (metallurgically speaking) that the b/shaft pulley didn't break in one event. It looks like there are different colours in that break which might suggest it was stressing prior to failure.

12/15/14

Crank before and during engine assembly over the years. Old pics so it was like that from when I took possession of it. Definitely something 'odd man out' with the furthermost counterweight.

Wow great build!

Posted by Diggymart on 12/28/20 @ 2:54:22 PM