You must be logged in to rate content!

7 minute(s) of a 286 minute read

1-8-2012

Happy 2012!

After a 3 week trip in Taiwan, I'm back now and put a little time in on the car today. I located and welded in the hoop supports as well as cut holes in my inner fenders for clearance. I've roughly shaped patch pieces for the fenders, and will weld them in as soon as I get the chance.

1-29-2012

Thank you, everyone! Finally, I was able to get a full weekend in on my car. It's the first one of the year, and the first one within the past 2 months. I was having withdrawls...

Anyways, On Fri I was able to patch the holes I made on my inner fenders and spent yesterday and today by starting to mock up the cage in my car. Since this car will see the street I don't want the cage too close to my head, nor do I want to always wear a helmet while I drive. I know this won't pass NHRA tech because of that, and that's OK. The purpose is to provide more rigidity and a bit of safety than Pontiac provided in 1967.

My plan is to build a "6 point" style cage. I'm making my own so I can fit it where I want and how I want. I'm going to have this fit up as close as possible to the body so I can attach it to the body in various locations for additional strength.

I made some rough estimates as to where I'll be sitting and how much room I need (hence why I put the wheel and pedals back in) and determined that the main hoop can be exactly where the ashtrays used to reside on the rear seat armrests. This is cool as I can reuse the original vinyl from them. Of course, the arm rests had to be trimmed down to clear the inner wheel tubs.

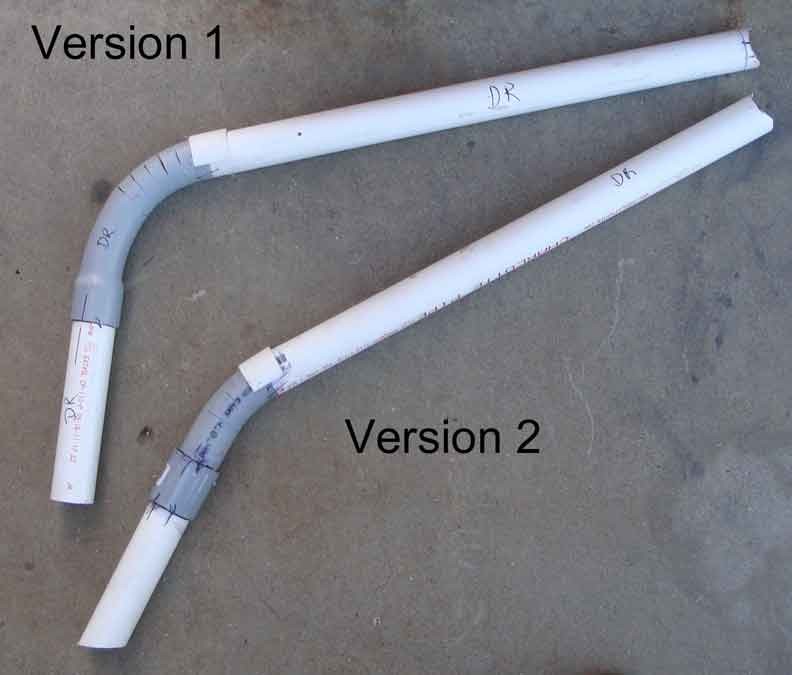

I made two versions of the rear down tubes and decided on the "version 2" as it is a less severe bend and should be a little stronger for that. I'll also add gussets in critical areas as well as plates on the rockers for strength.

It seems like I don't have much to show for a full weekend's worth of work, however, one benefit to this is it's a lot easier (and cheaper) to cut and grind plastic than it is DOM steel. Plus, I can see it, and change it if I don't like it. Next weekend I'll work on the bars that run along the doors. They'll fit nicely underneath the "deluxe" armrests on the '67 Firebird.

2-12-2012

Ok, I had some time to work on my car this weekend. First pic I have is actually from last week- I had only enough time to make a mock up of the side bar that will run along the doors. The cool thing is the door panel armrests have a nice radius that will allow the tubing to tuck underneath it. The only downside is they are not truly parallel (they angle up towards the front) So, this gives me a choice of either running the bar equal to the arm rest (which would have it angle upwards toward the front) or keep it parallel to the rocker panel. I'm choosing the latter to keep more legroom for ingress/ egress.

After making this model I ordered the DOM tubing from a local metal shop (they cut down the 20' lengths for me) and picked it up after work during the week and I thought I was all set to start bending tubing on Friday. I was wrong. My economy Eastwood bender just wasn't up to the task. The u shaped bracket wasn't strong enough. It didn't even have a chance. Trying to bend the 1.75" tubing ripped it apart like aluminum foil. So I spent the rest of the day building a new one out of stronger metal only to discover that even with that, the jack wasn't strong enough to bend the metal. So now I've used the thing 2x, and it has broke 2x. not happy.

Fast forward to today (Sunday) my neighbor Brett (Fab 53) was able to save the day. He helped bend the tubing for me with the proper equipment. It looks beautiful! I also had enough time to make some base plates for the rocker panels. Next weekend I hope to work on trimming the tubing and work on getting this thing installed.

Wow excellent!

Posted by Diggymart on 9/23/19 @ 1:21:32 PM