You must be logged in to rate content!

7 minute(s) of a 224 minute read

6-14-2009

.....and a few steps back today.

First thing today I installed the new flexplate that I bought to replace the Corvette flexplate that will not work with a standard drivetrain. I took the opportunity to test fit the YANK converter snout into the back of the crank, all was fine.

The converter was then primed with fresh trans fluid, I was able to add less than a quart. There was plenty of fluid already in it since the converter and trans were tested together on a transmission dyno.

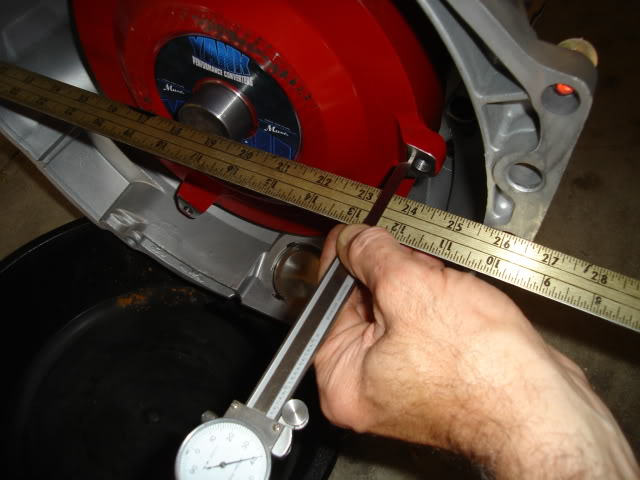

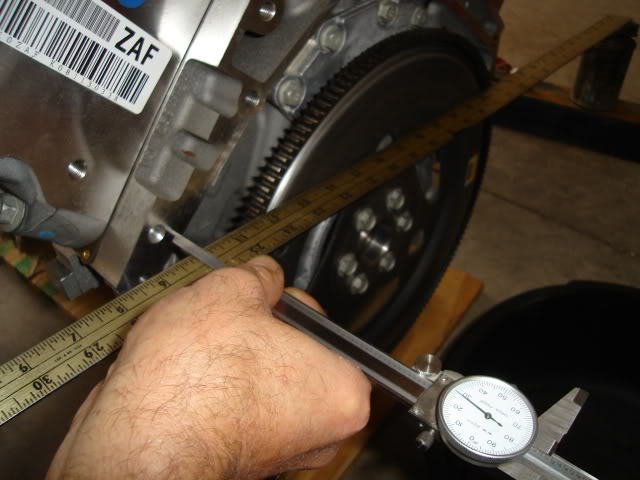

I then measured the distance between the converter mounting lugs and the mounting flange. I did this partly to make sure the converter was seated all the way (it wasn't, it went in another 1/2") and to calculate the need for any shims between the converter lugs and the flexplate.

Next I measured the distance from the mounting flange on the block to the face of the flexplate. After doing a little math I found that the converter will need to be pulled towards the engine by .250" in order to mate up to the flexplate, a little too far.

It's best to keep this distance between 1/8" and 3/16" (.125" to .1875") to make sure the converter is engaged far enough into the front pump on the trans. I'll find 3 hardened washers that are exactly the same thickness to get it into spec, something between .060" to .100" thick will work.

Since clearance inside the trans tunnel will be very tight I removed the straight cooling line fittings and put in a couple of 90 degree fittings. I'll probably loop the trans lines rearward and down before bringing them forward.

Next I bolted the trans up to the engine, hoping that I could put them in as a unit.

Here goes nothing.

This is as far as it will go, the pan won't clear. The trans is stopped against the top of the tunnel.

Very close here too, it's time to remove the engine and trans and separate them and put the engine in by itself. I had read that the engine and trans couldn't go in together as a unit but I just had to see for myself.

Engine is back in and is now sitting on the mounts where it needs to be, time to pull it back out and drill some holes for the engine mount stands.

Mounts are now bolted in place on the crossmember and the brake line reconfigured to clear the new mount locations.

Engine has been set back in place on the freshly installed mount stands. I'll leave it supported by the engine hoist overnight with a floor jack under the back of the oil pan for insurance.

Tomorrow I'll mate the trans up to the engine and do any clearance work necessary on the tunnel (hammer time). I need to figure out where the trans crossmember needs to go, hopefully the original crossmember will work. I'll try to find some time to fit up the headers, I'm hoping they can go in place without removing the engine.

End of a very long, busy day.

.....that the trans crossmember can no longer sit on top of the bottom section of the frame 'C' channel.

I can't slide the crossmember back far enough to get the trans in the car because it hits the supports for the center body mount on both sides. There's no way to put the trans in first and the crossmember in afterwards unless I change the way the crossmember attaches to the frame.

The trans crossmember will need some mods done to the ends to keep the crossmember from sitting too low after I bolt it in from underneath the frame rail instead of having it sit on top of the bottom rail.

I will make a slice the pretty much right along on the black line at the bottom in the pic and bend the end down so it's even with the bottom of the crossmember and then add a triangular piece to fill the gap. Next I will slice it straight down along the other black line and remove that piece so the frame rail will clear, I can use a piece of 2" X 2" X 3/16" angle iron to fill the gap there. While I'm doing the mods to the crossmember I'll search out a transmission jack to get the trans into the car safely, a floor jack just won't do in this case.

I searched through my scrap metal pile and found an old radiator support crossmember that I made for an old project. I was able to use it as a rear engine support by making a couple of angle iron brackets that attach onto the rear control arm bolts. The oil pan rests on a wood block, this will keep the engine in place while I'm working out the trans fitment and other issues.

Finally the LS3 is sitting in the car.

That's all for this weekend.

The Tempest!

Posted by Diggymart on 3/26/21 @ 3:09:22 PM