You must be logged in to rate content!

9 minute(s) of a 390 minute read

11-3-2010

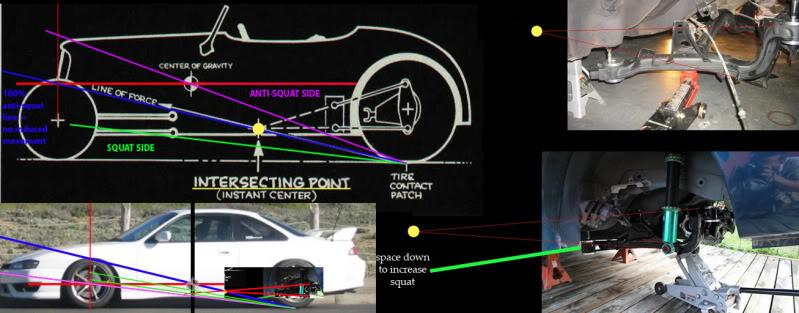

I've been working a bit on the rear subframe and thinking about squat. I've never seen anyone attempt to calculate what percentage of squat the rear had in it so I thought I'd give it a go. It looks like the S14 has about 200% antisquat!!! I misunderstood anti-squat before, as it's a little counter-intuitive. Drag cars like to have 200% antisquat, but the problem is, that can cause wheel hop on braking. So road race cars tend to have 120% to 150% anti-squat.

The pink line on the 240 represents 100% antisquat which = no effective induced force.

The blue line is where the line of force goes through the 240s instant center.

The two green lines represent 120% and 150% antisquat and conventionally if we could get the instant center to fall with-in range then you could seriously increase the rear brake bias, and thereby shorten stopping distances.

I don't believe that simple shims above the front subframe mount will be enough to get the anti-squat into a more road race like geometry. It's going to take lowering the front LCA mount, or raising the RUCA/subframe mounting location. If my drawing is at all accurate the S14 came from the factory set up like a drag car. And the S13 is set up to make no sense for anything.

11/18/10

So from all of my research the ideal antisquat for a roadrace car is 120-150%. Any more and you compromise braking performance, and on throttle oversteer. Any less and you're giving up some holeshot/corner exit traction.

Made some more of my own drawings and photographs. With my modified subframe bushings the rear is 0.160" from the frame, and the front is flush. I think I'm probaby going to grind the front down a bit. I can probably get the front another 0.100" up.

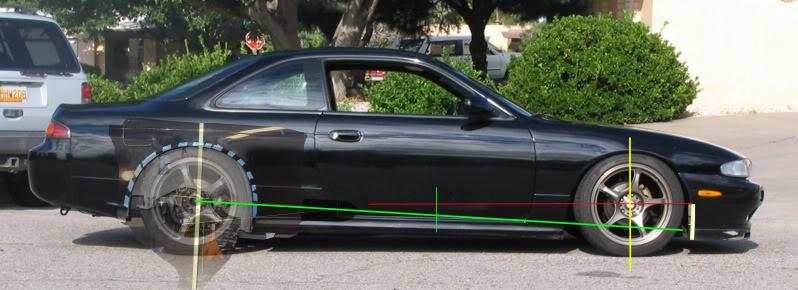

My S14

Ride height: 3.5"

CG height: 11" (presuming it's at the height of my crank center line)

Antisquat%: 56.40%

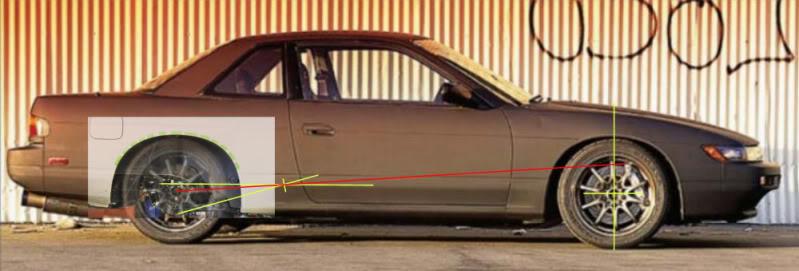

Most S13

Antisquat%: 151%

So basically the S14 has too little, and the s13 too much antisquat. I'l probably be relocating the traction or RUCA a bit.

Also continued on reinforcing the rear subframe

I was also a bit concerned about making my water pump outlet hose cross between the pulley and radiator fans... GM to the rescue!!! Found this add on ebay, ""LS3 WATER PUMP NEW Take off Corvette Cadillac STS" The offset is exatly the same as my old LS2/LS7 waterpump, but the outlet is on the driver side instead of the passenger side! Sweet.

Old Ls2 pump

New LS3 pump

1/13/11

I've been paranoid that something was going to happen to my radiator unless I got it mounted since I bought it. And I'm finally getting close to having it mounted. The stock LS waterneck that is on the WP inlet side (unlike on a gen I SBC) sticks out at about a 45 degree angle and was preventing me from getting the radiator as far back as I wanted. It was also much smaller in diameter than my 2" radiator outlet. I picked up a 2" 90 degree cast aluminum elbow on ebay for like $5. I cut off the offending part of the original water neck, ported it out quite a bit and LM24 in Deer Park, Long Island welded the two up for me. Boom! An extra inch or so of radiator clearance, and I can move my monster heavy Nascar radiator further back to improve weight distribution.

I also used a steering wheel puller to pull out the original stainless water pump outlet in the 2010 camaro waterpump and pressed in my -20 AN fitting that I also found on ebay.

1/16/11

My uncle Greg and I were discussing building cars to race at Bonneville. We both had been drinking I think, but I think the conversation turned towards he putting up the pink on a 78 GMC motorhome against my 240sx's pink if/when we ever make it to the salt.

I did a little research as to what the minimum horsepower to achieve 200 mph at Bonneville would be for both a Motorhome and the 240sx. And plugged all the numbers into a calculator on this sweet web site.

RSR Aero-horsepower Calculator

BELOW IS THE WORST CASE FOR THE 240. I can definitely get it slipperier than the stock .33 Cd, and smaller than the stock frontal area of 17.88 sq ft. But per the calculator I'll need at least 428 hp to hit 200 at the stock size and Cd. The fastest guy on the 240sx forums claims he did 167 mph with 500 rpm left to go before he chickened out. He did it with a nissan sr20det at 1 bar of boost (he should be right at or below 395 whp) in his 240sx.

We can't be pullin upto the Salt flats in a POS, slow motorhome. Uncle Greg informed me that the 1978 GMC was the most aerodynamic motorhome ever made, and I'm sure he could improve upon it's stock Cd and frontal area a ton.

Now the motorhome: All per wikipedia:

All GMC motorhomes (produced 1973 through 1978) are 96 inches (8FT) wide and about 9 feet (2.7 m) tall including the usually-installed roof air conditioner. Interior head room is 76 inches (190 cm).Gross vehicle weight rating for the 23-foot (7.0 m) coach was 11,500 pounds (5,200 kg) and 12,500 pounds (5,700 kg) for the 26-foot (7.9 m).vMotorhomes tested via a wind tunnel were reported to have a drag coefficient of 0.31, which is typical of modern sedans (although offset by the large frontal area).

Pretty sad that a motorhome has a better Cd than the 240sx (.31<.33) !!! But that frontal area gets ya.

This is me being extra nice to the GMC motohome. At 500 lbs lighter than stock and 2 foot shorter. It requires 1230 hp to hit 200 MPH per the calculator.

Not as bad as I thought it'd be! 1300 horse power shouldn't be too hard. Especially if we leave the stock (then turbo'd) 455 powering the front (The GMC was FWD!!!), and put a turbo viper motor layin it down out back. Easy.

2/2/11

Holly crap! Have you guys seen this stuff? HTS-2000

Aluminum Welding - Aluminum Repair - Aluminum Brazing - AluminumRepair.com

YouTube - HTS-2000 Aluminium Repair For The New Millenium

I want it.

2/4/11

The good news is the car is closer to completion, the bad news is that I'm down grading to a stroked L76 (404 ci) to make it happen, and am selling the LS7 heads. This should knock me down from about 670 hp to 600 hp. Not the end of the world. There's always forced induction if I need more power. But since I want to race in street tire classes, I probably won't need any more hp.

Out:

LS7 Corvette Z06 Heads with REV valves and dual springs - eBay (item 130482421966 end time Feb-12-11 18:58:58 PST)

In:

For those not in the know, an L76 is basically an LS2 4.00" bore block with LS3 heads. It was used in a bunch of Holdens, but only the Pontiac G8 state side.

Paying for the big bore block the LS7 heads require was going to slow me down too much, and I got a crazy good deal on the L76, so here we are.

I took some calipers to the ports on the LS3 heads and intake. The plastic intake was as small as 28.9mm accross in the smallest port while the head's port got as large as 31.8mm. It was probably a smart move on GMs part to make sure that there wouldn't be a step down going into the head's intake ports regardless of sloppy tollerances. But obviously there is room to improve by hogging out the plastic intake close to 1mm all around. Normally the LS3 intake uses a nifty re-usable rubber gasket o-rings. Not a lot of help for gasket matching the heads to the intake. I had been told that the carb spyder intakes for the LS3 had gaskets that were too big to be of use also.

I started a thread on the topic here:

Gasket Matching an L76 intake - LS1TECH

But I found a company called SCE that sells gaskets that are smaller than the head ports and are perfect for gasket-matching. The gaskets aren't perfectly square or perfect, but at least they aren't too big.

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM