You must be logged in to rate content!

7 minute(s) of a 390 minute read

2-17-2010

I had a long conversation with the tech guys at C&R radiator yesterday about how to plumb my nascar style radiator. Here's a couple things I learned.

1) Originally I was worried about the top being the input of the radiator because I was afraid it would push the air into the system. But there is a -4 port at the top of the radiator. Ideally this would be -6 and on the top/opposite side of the input. This port basically has the same function as the steam vents on top of the LSx heads: to allow air/steam to exit to the top of the surge tank.

2) The bottom of the surge tank should be connected with a -10 (but -8 will work) to the lowest point of the radiator near the radiators outlet. This recirculation line is supposed to help prevent pump cavitation.

3) Don't completely fill the surge tank. The air above the water in the surge tank acts like an air spring against expansions in the coolant.

4) I don't know how legal this would be in most classes of racing, but circle track guys sometime run the the overflow hose to spay on the windshiled instead of in a bottle. That'll get your attention!

I also had some interesting conversations with Magnafuel and Lonie at Lonnies Performance Automotive ---- Main Index in Perryopolis, PA. I had heard of guys running pumps capable of more than 700 hp would re-circulate so much fuel at cruise that the fuel vaporlocks. Lonnie's solution is dual in-tank walbros triggered by a hobs swithch on boosted apps, and by both an rpm and full throttle switch. Magnafuel reccomended against fuel speed controllers, as their pumps weren't designed to run under 12.5 volts. They said that the one time they heard of their pumps vaprolocking it was fixed with a fuel cooler. I'm probably going to install a fuel cooler under the car.

2/20/10

What is the first thing that hits and stops/limits bump travel?

I started working on the rear subframe yesterday. I have the ebay solid subframe bushings. I measured the stock bushings and they sit somewhere between 12.6 and 13.6 mm above the subframe. SPL wasn't kidding when they said that you can raise your subframe half an inch! It's like a free drop spindle mod! But my cheapo ebay bushings have a 9mm lip above the subframe . So here are my options.

1. Buy SPL bushings and use their shims to get back the squat that raising the subframe gives up.

This cost more $, but still a very fair price.

2. Use only the bottom half of the ebay bushings

I worry that there would be too much stess on the bolts that hold the subframe with the top half of the bolt unsupported.

3. Machine off the lip of the ebay bushings.

This is complicated. If I machine the 9 mm lip off from the side, and drop the whole top bushings into the subframe-cylinder it will not fill the cylinder to the top. The cylinders in the subframe are 56.5 mm tall. Here's how that measures up to the ebay bushings.

The lip

from SCC:

"...Unlike the front of the car, small amounts of anti-squat are generally a good thing for a rear-drive car since it allows for softer rear suspensions without the excess squat.

Cars like the Nissan R32 Skyline GT-R, Z32 300ZX and S13 240SX have a great deal of anti-squat in their rear suspension geometry. This makes them transition to on-throttle oversteer very rapidly because anti-squat, like anti-dive, significantly increases the wheel rate. This is why the S13 works so well for drifting.

Extreme anti-squat can cause wheelspin and rear wheel hop under power, which is why the Z32 is notorious for launching poorly at the dragstrip.

Rear-wheel-drive drag racers have made a science of anti-squat tuning to maximize rear-wheel traction. Drag cars often have so much anti-squat geometry that the back of the car actually lifts when launching, driving the tires into the ground. Drag cars have adjustable four-link rear suspensions,so this percentage is tunable for the amount of bite desired in different conditions (see sidebar on page 102 to learn how to calculate anti-lift, anti-dive and anti-squat)."

Fun with fire

Tuning with anit-squat (here's my understanding):

More anti-squat: More predictable handling/transition to on-throttle oversteer. Allows softer springs.

Less anit-squat: More rear weight transfer, and better launch. Requires stiffer springs.

from SPL

for their subframe spacers:

For maximum squat (eg. drag racing), rotate the instant center down by installing large diameter spacers above front subframe bushings and small diameter spacers below rear subframe bushings.

For slightly increased squat, lower the instant center by installing spacers above all subframe bushings.

For slightly increased anti-squat, raise the instant center by installing spacers below all subframe bushings.

For maximum anti-squat (eg. drift), rotate the instant center up by installing small diameter spacers below front subframe bushing and large diameter spacers above rear subframe bushings.

for their solid bushings

Our CNC machined T6061 aluminum subframe bushings completely replace the stock bushings to eliminate free play of the subframe relative to the chassis, reducing wheel hop and improving suspension performance. Our new version 2 solid subframe bushings is designed to allow the subframe to sit up to 1/2" closer to the chassis (raising the subframe), which will allow up to 1/2" compensation of roll center for a lowered car.

However raising the subframe will not just change roll center, it will also increase anti-squat. Therefore our subframe bushings include 1/4" slide in shims so you can quickly raise or lower the subframe in minutes, and adjust the roll center and anti-squat behavior to best fit your driving style! Our unique adjustable subframe bushings offer a completely new way to tune the suspension behavior.

from www.formulaindyracing.com

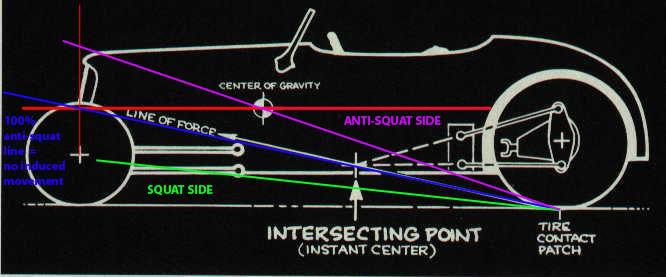

Chassis engineers talk about "anti-squat" at the rear on acceleration and use a traditional diagram to calculate "percentage of anti-squat" (see illustration next page). Because the weight (center of gravity) of a typical road car is supported by the front and rear wheels, engineers draw a "100-percent anti-squat" force line from the rear tire contact patch to the front wheel vertical center-line, at the height of the center of gravity. If the actual "line of force" for the car – the line from the rear tire contact patch through the instant center of the rear suspension – coincides with the 100-percent anti-squat line, then theoretically the rear suspension will neither lift nor drop, and the rear of the car will not rise or squat, as the car accelerates. That is, if the instant center of the rear suspension lies anywhere on this line, the car will have 100-percent anti-squat. If the instant center is anywhere below the line, the rear will squat (or, have a certain percentage – a fraction – of anti-squat). If the instant center is above this line, it will have more than 100-percent anti-squat, which means the rear of the car will be pushed upwards by the suspension links as the car accelerates.

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM