You must be logged in to rate content!

8 minute(s) of a 280 minute read

2-12-2011

Here is a version that has the sides of equal width...

And here is a version that shows the sides of the 7 narrowing a bit...

[

Josh&FD... The flash IS effecting the way it looks, but it was "soft" because I wasn't entirely sure about doing it at all. (I could have had him use the female mold and it would have been way crisper, but had him use flat rubber for the female and pressed the male into it with a 50 ton press. As I said to KKM, I may try adding a fairly thin and small 7 to the top of the embossed 7.) Right now, my car is badge-ess, so this is its current 7 badge, I suppose. ![]()

Josh, Thanks very much for the comment. Although I haven't seen it yet in person, I think it may be too soft. These two pictures may show that its a bit more defined and pronounced than the other pictures show it. My best guess from the pictures is that the 7 comes out about a half inch and the ange looks to be 65-70 degrees. So, I am somewhat hopeful still, but... ![]()

2-25-2011

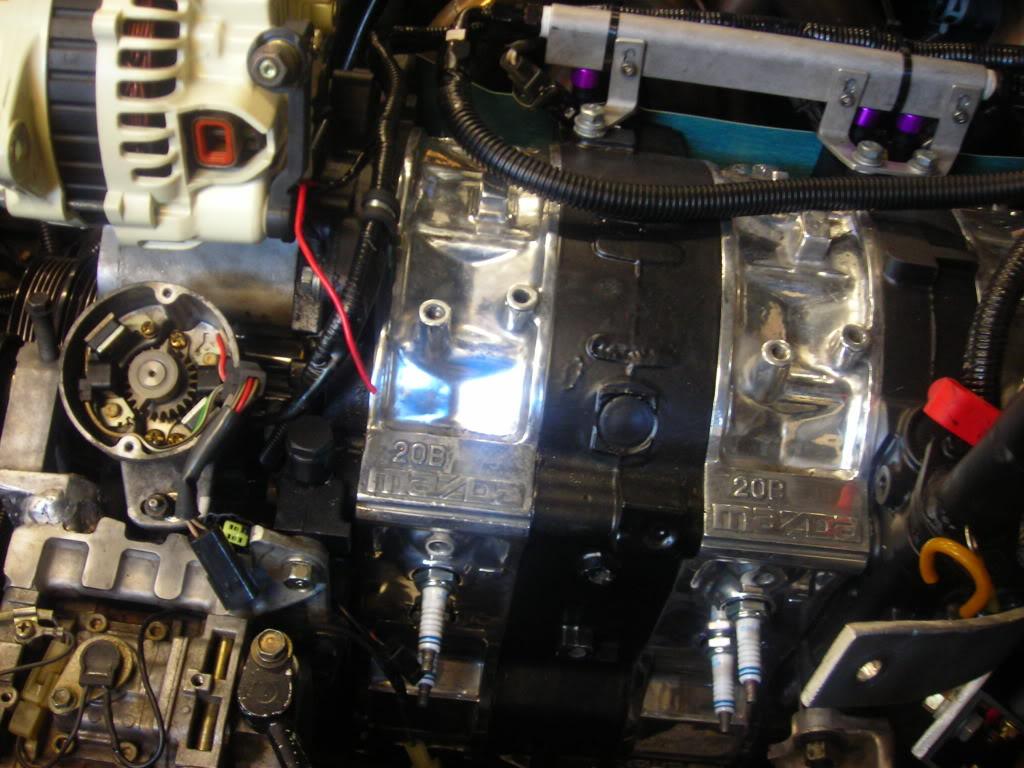

The headers were designed using state of the art formula and of course has a burns style collector, as did the old one. The math-derived lengths were then shortened a bit retuning them and running the dyno iteratively. The three header pipes each varies a slight bit from the others in length to accommodate the change in the speed of sound waves as heat increases and the three 20b rotors each have different exhaust port heat. Also, while I don't remember the name of the metal Logan used, it is not a common stainless steel. It has some mineral impregnated in it that in some fashion keeps the heat inside. An advanced header material. These are the second set of headers I've had made and if they do what I think they will do, I will either leave them as is or ceramic coat them and be done (I truly hope).

We haven't considered variable volume plenums, but have thought about variable length runners. We've thought a lot about the fueling issues from low to high rpm and, while our focus on this motor was the broad torque curve and peak power at 9,500 rpm, we are thinking we can balance things out with Paul Yaw's ID1000 injectors in conjunction with the high speeds the primaries should achieve through the taper and length. The biggest issue we had was the 90mm throttle body opening and getting the fueling when it opens to increase in lock step with the sudden gulping. Using one of Yaw's 1000cc injectors per rotor let's us achieve very accurate control over the entire rpm range. We also went from the 10:1 Rx8 rotors to S5 NA 9.6:1 rotors, because we are pretty sure that the physical squish area (or scallop or dish) on the 10:1 rotors is just so shallow, we think there was a physical fueling issue at higher rpm.

Its all down to putting it on the dyno on March 5th and seeing if all this accomplishes what we set out to do or if its back to the drawing boards. I've started writing the section on the engine and only have written about what I wanted it to be and why. What I've been trying to do, as I think you know, is build a motor that makes about 350 whp, has bags of torque everywhere, and makes peak power at 9,500 and goes strong to 10,000 rpm without either peripheral ports or individual throttle bodies. I am pretty sure that no NA rotary motor has done that before. Anyway, I am hopeful the new headers, and the intake will get me there.

I don't know if you've seen the new slide throttles that Logan has made for his car and Chris Walker's, but these are the state of the art and should be equally useful for 20b turbos and in 2 hole form, 12a's and 13b's. We are going to make up a variation on this new design for my car on the next plenum go round.

(I have been tempted to bump that 2008 thread "Predicting the future". While I was off about a year or so, Bernanke's intervention on the short end of the curve was unprecedented and delayed things. Combine that with Obama's masterful handling of the middle east and oil price increase and the related increases in the Treasury curve ensure high inflation. His masterful economic policies manage to increase the costs of doing everything and he scares the hell out of every sane businessman. Volatility thy name is Obama. Little or no GDP growth for the next two to four years. No job growth. Anyway, stagflation, late-ish...![]() )

)

3-25-2011

Some guys were over at SpeedOne (aka KD Rotary) sometime this week and took a few more quick vids of the car on the dyno with the new headers. (Everybody else gets to see it, but I haven't even had time to get over there. And, no. I don't know why the videos look a little green-ish...) Thought I'd just post them up. Nothing to report yet for numbers, since it now only has 21 dyno-miles on it, but I'm going to pick it up Saturday and put 200 miles on it to get the RA seals bedded in more. Its just too slow on the dyno.

Gordon

http://www.youtube.com/watch?v=ceOeV...eature=related

http://www.youtube.com/watch?v=NX-vq...eature=related

3-31-2011

We're still finishing up the engine bay and getting the powder coated plenum and runners, throttle body, and air intake back on over the next few days. Then, I finally put a few hundred miles on it and we tune it one last time before Deals Gap. Here's a few pictures showing the simplified wiring harness that really can't be seen and the relocated fuses and relays away from the driver's side fender. The shroud should be on and the coils relocated tomorrow.

Gordon

4-9-2011

Christ... Just trying to get the plenum and runners powder coated and painted was an odyssey. The guy said he could do it in 2 days and it took 14 to actually get it back. Hopefully the engine will be back together in a few days and the engine bay cleanup completed. Here's a couple of pictures of the plenum. I still haven't even seen the car with the motor in and together, though some people have posted some videos. Oh, well. Looks like its still done in time for DGRR.

Gordon

Nice job!

Posted by Diggymart on 3/13/19 @ 9:54:43 PM