You must be logged in to rate content!

12 minute(s) of a 390 minute read

11-18-2014

11-18-2014

Hey guys. Updates are coming! I will carry over some of the small updates from the other forum. My engine will be here soon and everything is falling in to place. I will back fill my new 416 stroker choice and where everything is at. But as of now, she is still on jack stands but getting closer. ![]()

Why the engine blew. I think this is speculative, but a combination of not enough meth, factory seals, and leanish AFRs (mid 11s). I definitely was pushing the setup by using a stock lower as well. The setup likely would have performed perfect if I had stayed at or below 500whp. It detonated for sure. 2 rear apex seals were in fact broken and the rear housing trashed.

Why I chose the V8? I have said it a few times but I guess I can reiterate. I have loved rotaries for many years and still do. I have owned 10 Rx7s in a 17 year period. But I have chose to move forward for a few very simple reasons: Time, money, reliability. Despite what any camp you belong to an NA large displacement engine will be more reliable than a turbo small displacement engine at the same power level, regaurdless of the design (piston vs rotary). It will make power with less stress, and more consistently on pump gas. Of course there are anomolies, but relatively speaking there is no replacement for displacement. As many have said, everything has to be just right with a high HP rotary. Some of the issues are builder induced, and some simply are not.

The rotary is a unique niche engine. ANY engine can make power with enough engineering and dedication. Many rotor heads look at other people as ignorant because their own setup has worked consistently or they have a large amount of experience with the engine, so they are somehow superior by their own learned mistakes. Either way, there is a reason why rotaries aren't in every major production sports car on the planet.

I am at a point in my life where I want to build a setup and have it last for 10 years, not always looking over my shoulder of the next possible blown engine. Take a poll of how many people are on their 4th, 5th, or whatever number rebuild. Despite the cause, it still happens. There is always a reason, and there is always a fix. Thus, propetuating the viscious cycle. This just isnt common place in other V8 communities.

As mentioned, I am still a big rotary fan. I love Rx7s and turbo brap. Much of the reason I couldn't transition to a Vette was the love for the car and how far it has come. Every person makes life choices for their own wants and life situations. Swapping in a V8 was mine.

Proper update:

Well guys, after 10 months of waiting for the LS7, I pulled the plug. In fact, I would have pulled the plug before that, but the "builder" didn't have the funds to pay me back. After that, he agreed on a refund and over a month later, still no money. So after being patient, and hoping that it wouldn't turn legal, I sent him a notarized letter formally requesting the refund and boom, I got $10,900 wired to my bank account.

So after everything, I was totally done. Ready to click the buy button on a GM 480hp LS3 crate from Jegs. But after a little more thought, I knew I wouldn't be satisfied. It is a killer engine and a good choice, of course. But part of this decision to go with a V8 was to make big power reliably, and 450whp felt like I would be compromising. I spoke with a few people I trust and I was once again recommended to Redline Motorsports (west).

With a solid reputation, and a seal of approval from a person I call a friend, I gave them a call to see what we would do. We came out with a solid game plan for a 416ci LS3 stroker. With a good street cam, it should make around 550whp. Which truly has been my goal all along. With a 4-6 week build time, a deposit down, and a bank account full of money, it was time to get started.....

My Samber kit and DSS drive shaft arrived so it was time to do something with them!...

I finally man'd up and bought a welder. I have been borrowing friend's and farming out little jobs for far too long. With my upcoming exhaust modifications, and needing to get the camber bolts welded, I knew it was time to pick one up. Weld shop was closed so I had to use flux core on the below. I will have argon for the exhaust work, and I will be backpurging. ![]() .

.

Samberg cradle is in, front suspension is assembled and everything bolted up well.

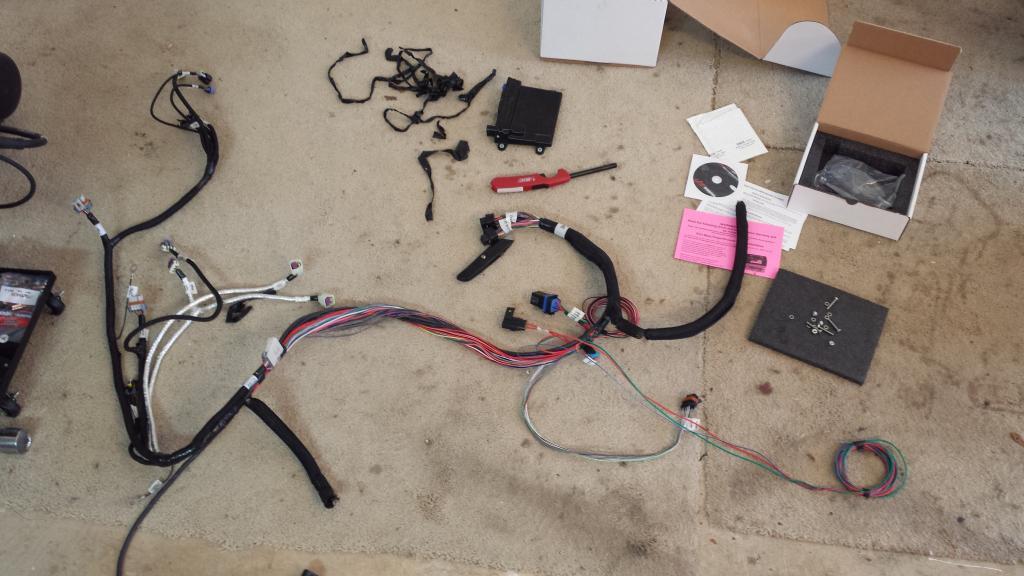

Holley HP EFI, Holley 95mm throttle body, Holley anodized black fuel rails

Some details on my engine.. I have opted to have the builder dyno the engine before shipping it. We discussed the option and I think it's worth it. This does a few things for me. First, it ensures the engine is broke in with no ring washing and, it will get broke in on the dyno. Next, I am shipping all of my injectors, rails, TB, ECU, harness, etc; so I am getting a very nice base map with my parts. Finally, it ensures everything on the engine is solid when I receive it. Though an issue isn't likely, it would be a pretty big hassle finding out after the swap IF there was an internal issue. This way, I receive the engine with dyno sheet, ready to rock. I think it's $500 well spent.

416ci LS3 Stroker being built at Redline Motorsports

New 6.2L LS3 Block and covers

Crank Callies 4340 Forged 4" w/58x reluctor

Rods Callies 4340 Forged I Beam with ARP bolts

Pistons w/ Pins and Rings 4032 Forged

Bearings(Main,Rod) King Extreme Rod and Mains

Pushrods - 4130 3/8"

Camshaft w/ Cam Plate Custom Grind

Lifters GM LS7 with trays

Lifter Trays/bolts - GM

Heads LS3 CNC Ported by WCCH, Stainless Valves

BTR Spring kit w/ titanium retainers

Comp Cam roller rockers

GM Head Gaskets

ARP Head studs

ARP Main Studs

Oil Pump Mellings

Timing Chain Set Billet Single Roller with Damper

Balanced rotating assembly

I will be running a BER ported factory LS3 intake with the Holley 95mm TB as well.

LS9 Injectors on the Holley rails

Mcleoud RXT twin disc

ATI balancer

PWR high flow water pump

Polished LS1 accessories

I chose a vertical surge tank and mounted it where my WI tank was. Samberg uses the horizontal tank in his kit, which works great. But for me, it was visually not what I wanted to achieve. Overflow line routed through the fender.

I had to make some modifications to the Holley harness. Though I am shipping everything to the builder for the dyno day, I did some pre-fitting to move things along. I also wanted it to be modular. There are about 6 loose wires that come off the harness to be wired to the chassis. I added weatherpak connectors and loom so it can be easily removed from the car if needed.

Below is my Racetronix dual fan relay harness. I could have made one but I just love supporting these guys. They have some great wiring solutions. All excellent quality. The Holley will stage each fan by temp while also dedicating one for independent A/C control.

We decided on the following specs with an all around good street cam in mind.

231/247 .617/.624 113

I will post up some more pics soon. Getting close!

I figured I would do a little sound deadening work while I had the time. I have some foam on order to help fill some of the space behind the plastics. The mat I used is "FatMat". It got good reviews and it is WAY cheaper then Dynomat. I know I know, it isn't Lizard Skin but I think it will do well. IF I have to pull the dash I will do the entire front of the car. I definitely plan to line the doors when I pull them apart for my alarm system and keyless install.

I got my relay boxes relocated to my liking. They are close to where they were but I had to move some of the mounting around.

The Samberg radiator kit didn't mount up around the bumper due to my Feed Type I wickedness. As such, some trimming was in order. Steady hand and a cutoff wheel got it done.

The lower lip lined up perfectly. I will be doing some more duct work.

I mocked up the Samberg radiator kit completely today. I had to tweek the positioning a little because of the way my bumper mounts on the top side. After getting it to my satisfaction, it was time to lay down some satin black. The fan wiring is also complete with independent control routed to the ECU. It is now ready for final assembly once the engine is in.

The car as it sits. Lots to do yet. I am taking a week of leave when my engine arrives. My last class for the year ends at around the same time so it's perfect. No students until January. It's game on! ![]()

![]()

![]()

![]()