You must be logged in to rate content!

13 minute(s) of a 484 minute read

10-12-2017

Now I deserve another smack, I have now discovered a new crack (air leak) in one of the inlet manifolds so I have now given up on them and have ordered a new pair from the Rapier Register "Spares". They have had a hard life & a ham-fisted owner.

I did (for about five minutes) think about fabricating a pair in steel tube but decided to just order them from the UK. This one of the really good things about owning a Rapier. The "Register Spares" can supply almost anything that you are likely to require "off the shelf".

10-13-2017

You are really on the ball this morning.

The manifolds that I am getting from the Register "Spares" are exactly the same as the ones that I fitted when I first restored my Rapier in 1978. The problem was that seeking to improve on something that was perfectly good in the first place, I had decided to incorporate a "Balance tube" as recommended by Phillip H Smith the author of several learned books on the design of Exhaust and Inlet manifolds. The problem arose in that the inlet side of my Rapiers engine is rather crowded with the ignition distributor tucked into the space between the carburettors. Then several people commented that it was no good having the Balance tube underneath the main body of the manifold as It would fill with unburnt fuel. Unfortunately in turning them over the Balance Tube fouled on the underside of the cam box. In the end I decided to abandon the Balance tube but this left me with two rather large holes. My first thought was to make two plugs and screw them into the holes securing them with Lock-tite. The next problem was that these were not a really satisfactory because of the wall thickness and the curved nature of the manifold "walls'. The next plan was to fill the holes with "plastic metal" but there was a lingering doubt that this would eventually crack and fall out. Finally I bought some "Magic" aluminium "brazing rods" to use these required heating the manifolds to a point where the rod would melt on contact. Then allow the finished work to cool graduallyThis seemed to work OK but after returning from the weeks drive around the Western District the motor would not idle properly and I diagnosed this as an air leak in the inlet side of things. After removing the carburettors and manifold I checked the repairs by pouring Methylated spirits (alcohol) over the repairs. This showed that there were microscopic holes around the repaired area. I treated this with a skim of the plastic metal. Re asembling the manifolds In an attempt to cover all possibilities I used some one millimeter thick sheet cork for the new gasket. After I tighened up the manifold securing nuts I started the engine only to find that there was a mystery high pitched "whistle" It did not take very long to discover that in the process, I had over tighened one of these nuts and as a result the cork gasket compressed and the flange on one end of the manifold had cracked. I did consider fabricating some new manifolds in steel by having the necessary plates laser cut and using some steel tube. Having got as far as doing the drawings for the steel plates I decided that doing this was simply creating another source of frustration and that the sensible thing to do would be to simply send an email to the Rapier Register "Spares" and order a new pair of inlet manifolds. These should arive in the mail sometime in the next week or so. I will not use the sheet cork for the gaskets next time but use the same side out of a Breakfast Cereal cardboard box that I have used in the past. The only other thing that I will have to do is to match the new manifolds to my (slightly) larger than standard inlet ports. The new inlet manifold I had bought "ticked" all the boxes having a balance tube incorporated into the design. The problem with this was that in doing so increased the distance between the side of the cylinder head and the carburettor by about half an inch, As a result the carburettors fouled on the side of the bonnet (hood). There were three alternatives, 1. To remove the bonnet side and secure the bonnet top with a leather strap. 2. To have a new larger"Bulge" made into the bonnet side, This would also involve having it repainted and 3. Continue to use the manifolds tha were already on the engine having modified them to in corporate a balance tube. Having failed with all of these for various reasons, I am now back to where I had started from, only several dollars poorer! One other alternative was to attempt to repair the broken flange using the same Aluminium Brazing rod.

I have already sold the "New design" manifold to another member of the Register who is building a "Special" and not so concerned about the cosmetic appearance of his car......

So now you know......

10-14-2017

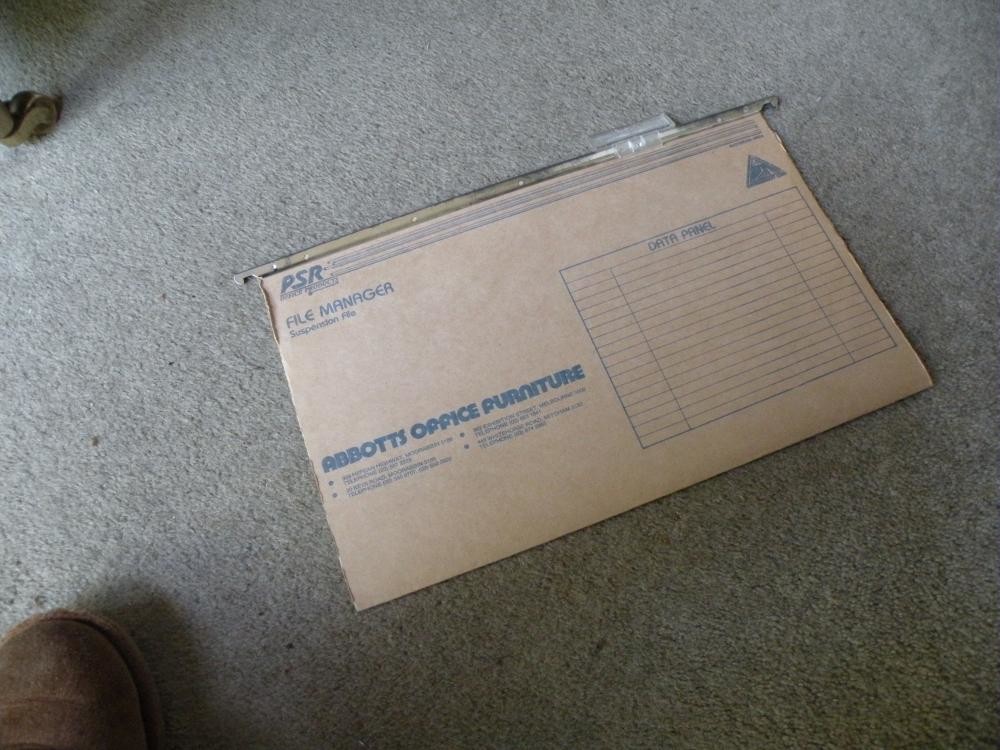

I must be more careful with what I say in future! When I used the term Cereal-box I was using it as a generic term to indicate the type of material. In actual fact, more recently I have been using discarded filing cabinet folders. The type with provision to hang them in a file draw.

These are made of much stronger card and have a minimum of printing on them. What printing there is, tends to be matt finish with little or no build up on the surface. The card is -1500 of an inch thick.

Rather than use a silicone base sealant, I prefer to use Permatex "Aviation" form-a-gasket. This comes in a little bottle with a brush to apply it attached to the inside of the lid. Used sparingly a bottle lasts for an extremely long time, It is essential that the lid is replaced firmly after use. Instructions say to apply a thin even coat and to allow to air dry for a few minutes. The bottle contains 2 ounces or 59 ml.

N.B. There is a warning on the back of the bottle expressly for residents of the State of California stating that it contains a chemical that may cause birth defects or other reproductive harm. At my age this is not thought to be significant. In addition perhaps as I live in Australia this may not apply.

I can not imagine how or for what other purpose, the residents of California are prone to use it ?

There is a further warning on the front of the bottle in red that it may be harmful if swallowed and that it may irritate if in direct contact with eyes.

Bernie j.

The bottle is made of re-cycleable plastic HDPE.

10-21-2017

I have just received an email from David Nutter the owner of an original Eagle Two-seater that had spend much of its life down at the bottom end of the South Island of New Zealand. He has now completed giving to a "big makeover" re-upholstering the seats and making a new hood and tonneau cover. He has also had the wheels rebuilt and repainted along with some new tyres.

But how many people noticed one major difference about Davids "Eagle". It has, along with just one other, also in Australia, full length

front mudguards (fenders).

For comparison here is a photo of our Rapier with the hood (Top) up. You will note that the main "bow" is further back and more upright to give much better head room and more useable space behind the seats. Unfortunately we do not have many other photographs of our Rapier with the hood (top) erected. I had to search back through the archives to find this one. We do have a pair of side-screens but it is so long since we used them I would have to search through the attic to find them.

10-24-2017

This one is for Paul

The new inlet manifolds (2) arrived from the UK yesterday. I still have to take then out to our son, Steve's to have him do a couple of little maching jobs before I fit them. The holes for the studs to secure the carburettors need to be drilled and tapped and the ports need some work to match them up with the ports in the cylinder head. these are slightly larger than standard. Fortunately I have kept the copper templates that were made when enlarging the ports in the original manifolds. I try never to throw anything like these away. Perhaps this is why I have "stuff" everywhere.

10-26-2017

Here are todays photographs of one of the inlet manifolds. One for each carburettor, these serve two cylinders each.

It may be difficult to see from the photographs but the opening for the carbs has been increased from 1 1/4 inch to 1 1/2 inch.

Like wise the openings on the cylinder head (ports) side have all been opened up by about 3/16 - 1/4 inch and carefully matched to the inlet ports.

Being two overhead cam there are four inlet ports on one side of he head and four exhaust ports on the opposite side.

Any irregularities inside the manifolds etc have been smoothed out and the internal surface given a light polish with a small abrasive "flap wheel"

You have to remember that this is a "limited production" (less than 400 in total) 1100 cc or for a small number of cars now 1500cc. They were all built between 1934 and 1938, most between 30 June 1934 and 30 June 1935. All over 80 years old.

Many are still driven in highly competitive "Vintage Motor Sport", Sprints, Circuit Races and Hill Climbs as well as Competitive Road Navigation Rallies.

Our car may look innocent enough but it has a long and continuous Sporting history dating back to the 1940s. The Chassis has been lightened and the 1500cc motor extensively tuned and modified. It will "rev" effortlessly to 6,000 rpm and is still capable of over 90 mph fully equipped and with two people (on board).

It has been timed over a standing start 1/4 mile in the mid 14 -15 second range.

10-28-2017

At last after a couple of hiccups KG is starting "on the button" and idling at under 1,000 rpm. Not too bad considering we are talking about an 83 year old car with an 81 year old owner/mechanic. I still have a couple of minor oil leaks to track down, wash off some of the oily hand prints and take it for a drive.

For the benefit of some of my American friends who still look at this, I am repeating a post I left on my Studebaker thread.

Many people are confused by the French sounding name for Lagonda. This in fact goes back to Wilbur Gunn's first cars and motorcycles in 1899. Wilbur Gunn was an American living in England. The Lagonda name comes from the Lagonda Creek that ran past his father's farm in Springfield, Ohio in the 1800s. To see just how far the Lagonda name goes back in the USA, look at http://lagondachapterdar.org

Now that the car is going again, the attached email : http://www.via-flaminia.com/enkele-rally/flaminia-classic-2018-may-3/ that was in my in-box this morning could be tempting, If only I could win the Lottery or at least back the winner of next months Melbourne Cup. Problem with either of those two thoughts, You have to be able to buy a ticket in the lottery and or place a bet with a Bookmaker to back a winner in the "Race that Stops the Nation."

Re:- Via Flaminia, In the past were have driven KG through parts of Northern Italy on two or three of our "holidays" but not through any of these parts. It looks extremely interesting but I am afraid it may have come to our attention just a little too late.....

The other thing that may tend to put us off is that there does not seem to be even one "Pre-war Car" entered. Just a lot of boring 1980s Alfa Romeos and Porsches. I am amazed that so many Alfas have survived the Italian sardine tin rust bugs. Perhaps they are all "plastic replicas".

A lot of the originals were made from steel that the Russians sent to Italy in exchange for those little 4WD Lada wagons.

I really don't know who got the worst part of that deal, perhaps they both simply got what they deserved!

Great detail!

Posted by Diggymart on 6/20/19 @ 2:41:04 PM