You must be logged in to rate content!

8 minute(s) of a 548 minute read

12-3-2012

Hi All

As suggested Tony has now finished his part of the work with the exception of the door check straps but he cannot finish those until I collect the breeching cleats from the plater so I will end up fitting them and the interior door pull handles hopefully before Christmas. I delivered the remains of the exhaust down pipe and tail pipe to a local exhaust shop to have new ones bent to match. Unfortunately the tube benders that I have used for years have simply disappeared. It seems that their site was too valuable and all their repetition work was going "off-shore". I just hope that this new "specialist" is as good as he says. I will know later this week. Jimmy my friendly tilt tray operator is booked to collect the Packard tomorrow morning so stand by for lots of photographs. I think that it is looking great but I may be biased. Still lots of little jobs to finish. Enough to keep me entertained for a week or two at least.

12-5-2012

Another day and another Dollar (Spent) The good news is that the Packard is home again so I can make a start on finishing all those little jobs. I am sorry about the quality of the photographs but they will give you some idea. Bright sunlight outside and shadow inside do not go to make good photography. No work tomorrow a pre-Christmas social day.

12-7-2012

Thank you all for the nice compliments.

Appearances can be deceptive. I have just returned from collecting a bunch of exhaust pipes bent to match the originals along with some new flanges and gaskets. Todays temperature is predicted to top 40 degrees C. so while lying on a cool concrete floor may sound tempting, cutting, filing and gas welding are all "no no"s on days of "total fire ban" so I have a good excuse. I have also just received the two new repro tail lamps to be mounted on the rear numberplate board so i will have something to do.

"Keep on keeping on"

12-8-2012

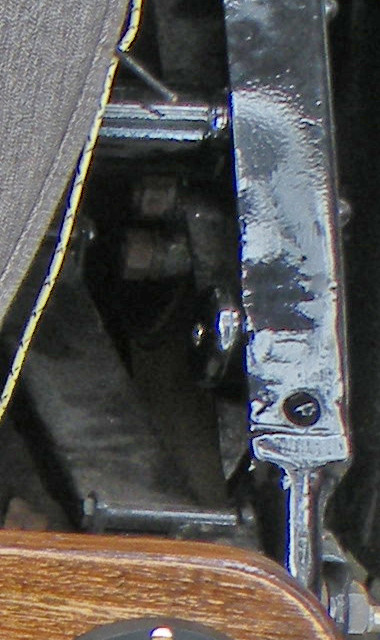

Well I am not sure if we got to the predicted temperature but regardless the tail lamps are now mounted on the number plate board and the wires coyly peeking out around the spare wheel. In the second (smaller) photograph you may just be able to make out the electrical junction box mounted in the channel section of the rear chassis member read to receive the wires for the stop and tail lamps. the sharp eyed people will also catch a glimpse of the original tail pipe and its new counter part awaiting my attention. The "engine" pipe is set up but will require some more minor adjustments and then a coat of hi-temp exhaust paint before it can finally be fitted.

"Keep on keeping on"

12-10-2012

Hi All

Don't panic! I have not gone away, it is just that it is "that time of year" and I seem to have lots of non car commitments. I will be back at work on the exhaust system and other things tomorrow.

12-11-2012

OK! Just one photograph but I am back working on the Packard. Our son Steve came down from the Yarra Valley to assist me with drilling and tapping the windscreen pillars for the external rear view mirrors. Since i have damaged my right shoulder I am terrified of breaking a tap off in the hole due to a muscle spasm. This afternoon I have made some real progress with the exhaust system and now have the engine pipe back to the muffler sorted out and hanging up waiting for the high temperature paint to fully dry before installing it.

12-12-2012

Anyone wanting confirmation that I am totally mad this has to be it.

I now know why the present day exhaust industry is so keen to use slip joints and flexible mounts.

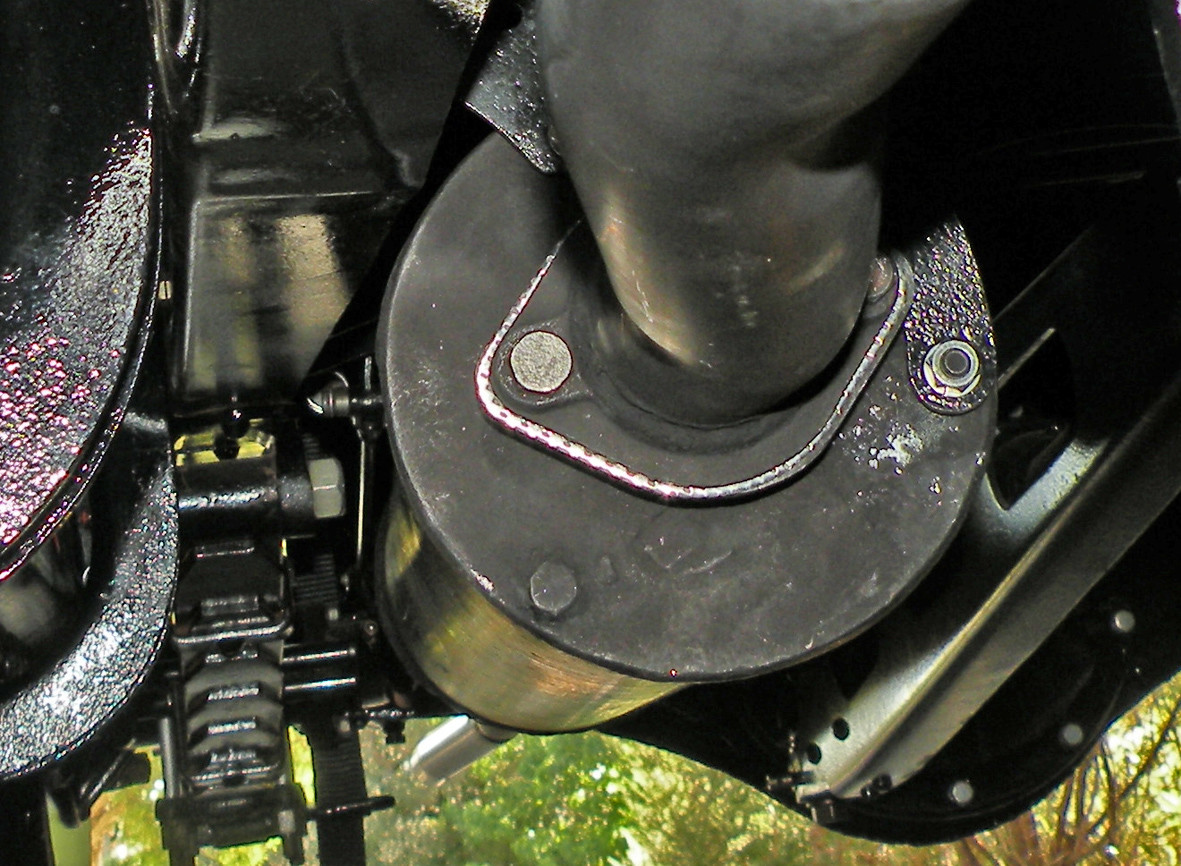

I have spent the last two days under the Packard wrestling with the original muffler and exhaust hangers. The muffler required a new outer skin thanks to "careful" fork lift truck drivers but the internals are so solid I am sure that they have at least another 90+ years of life left. all joints are two bolt flanges and in the never ending quest for originality these have been retained along with the original rigid hangers. I probably have another days work fitting the tail pipe, also flange connected to the outlet of the muffler and the original cast iron exhaust outlet. With flange joints and rigid mountings absolutely everything has to be perfectly aligned.

Hi y'all

With the Packard edging closer to completion the question of my next project seems to constantly creep into conversations I have with my friends.

This now seems to be resolved with my good friend Jim Williams offering me his unloved little Autobianchi. All I need to do is have it moved out of the woods behind his home in the north east of South Carolina. All offers of help would be much appreciated. Jim is now over eighty and while he can co-ordinate the move he will require some muscle power.

12-13-2012

Hi John

Of course I should have added Bianchina but I did not want to confuse people. I may have to learn Italian but then I have owned several Fiats in the past. These are just two. The single seat hillclinb car used a Fiat 1100cc engine driving a back- to-front Fiat 600 trans-axle. Its 14:1 comp ratio engine ran to 8,000 rpm on a mix of 100 octane Avgas and methanol. Its one big problem was that it kept trying to pass itself. The start line officials complained that it hurt their ears, even with industrial ear muffs! The Green car is a 1959 Fiat-OSCA which used a fabulous 1500cc 4cylinder 2 OHC engine designed by the Maserati Brothers and lots of other goodies to suit its performance. It was found out in the open at the back of a builders yard with the engine totally dismantled and all the nuts and bolts lost.

12-14-2012

While it may not look like it, the attached photograph represents another mile-stone. After almost a week of lying underneath the car, measuring, cutting, welding then crawling under again. This is the original exhaust tip fitted in the factory in 1923. while the two pipes (engine to muffler and tail pipe) and the black paint are new, everything else in the complete exhaust system is as fitted when the car was new, the muffler, flange joints, and all hangers are those fitted in 1923.

Hello Roger

You asked about compensation for the exhaust dilatation, that I understand is expanding with heat. I am sorry but that, I cannot answer. It passed through my mind too but I have made the exhaust on the Packard as close to the original as possible. The only answer I could think of was that with it's low compression ratio and relatively low octane fuel requirement the exhaust gasses do not reach the same temperatures as in a modern engine and accordingly the rate of expansion is lower. Certainly the factory seems to have made no allowance for the exhaust "growing". I did think about adding a flexible section into the front (engine) pipe but in the interests of originality, decided against it. Perhaps someone with a similar car may care to comment.

bravo!

Posted by CCmyVW on 1/26/20 @ 5:30:36 PM