You must be logged in to rate content!

9 minute(s) of a 548 minute read

2-18-2012

Wasted an hour this morning. I had ordered som 3/16 clevis pins to fit to the hand control linkages earlier this week so drove out to the supplier only to discover they had managed to get in 3/8 pins Baah! However I could get a new 9/16 NF castle nut for the drop arm on the steering box so the trip was not entirely wasted. This afternoon has been devoted to finishing cutting out the interior trim panels and the little timber cap for the front door pillar.

I managed to get one done so at least I know what is needed for the other side. These cappings are Black Walnut a really nice timber to work with. Once they are all finished and given a coat of clear they should look great.

2-19-2012

Yesterday I took a day off and went to The Vintage Drivers Club Swap Meet buying a plug for the horn wire where it connects to the bottom of the Steering column. An expenditure of $3. I managed to sell a bit of "garage Junk' so came out slightly ahead.

While there I had a quick look at a newly restored 1929 Six Saloon. Very nicely done. The attached photo may help Donald decide about a sun visor for his car.

2-20-2012

Hi Ian

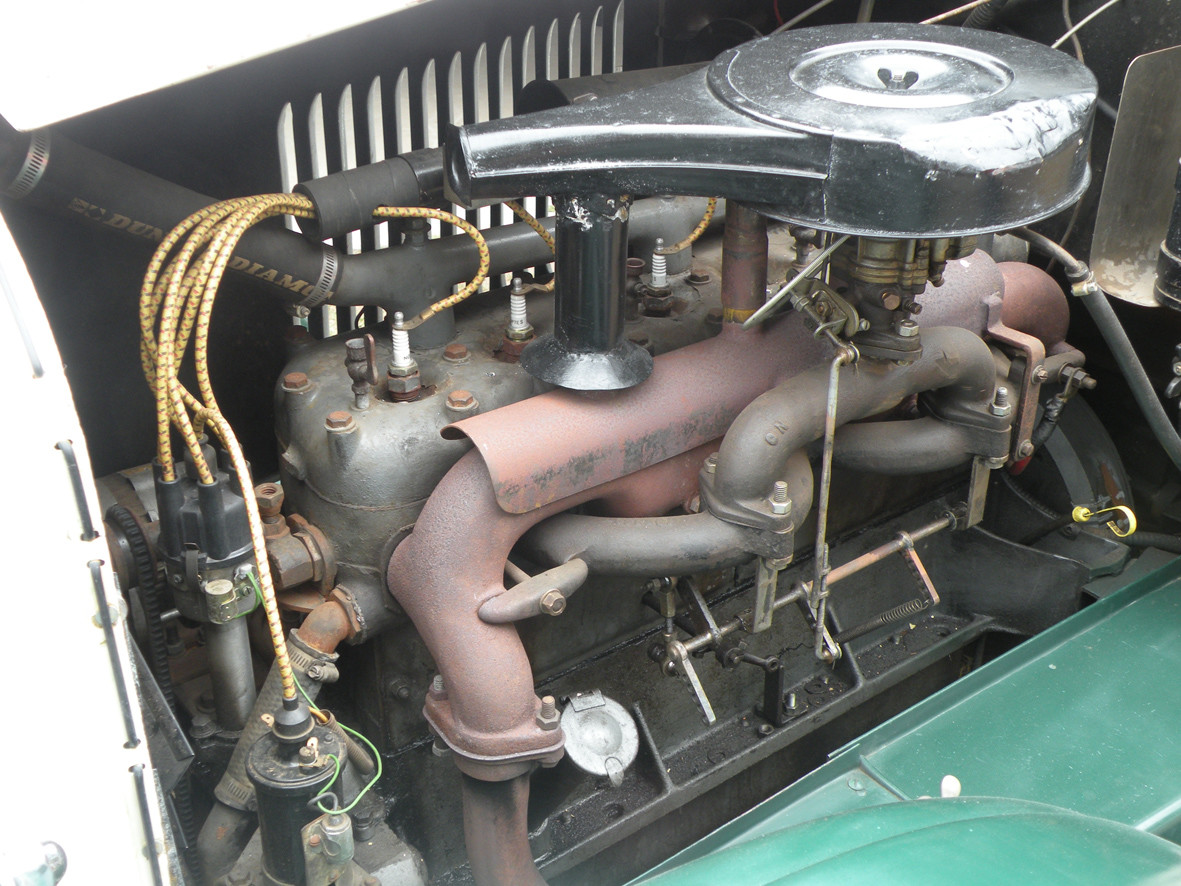

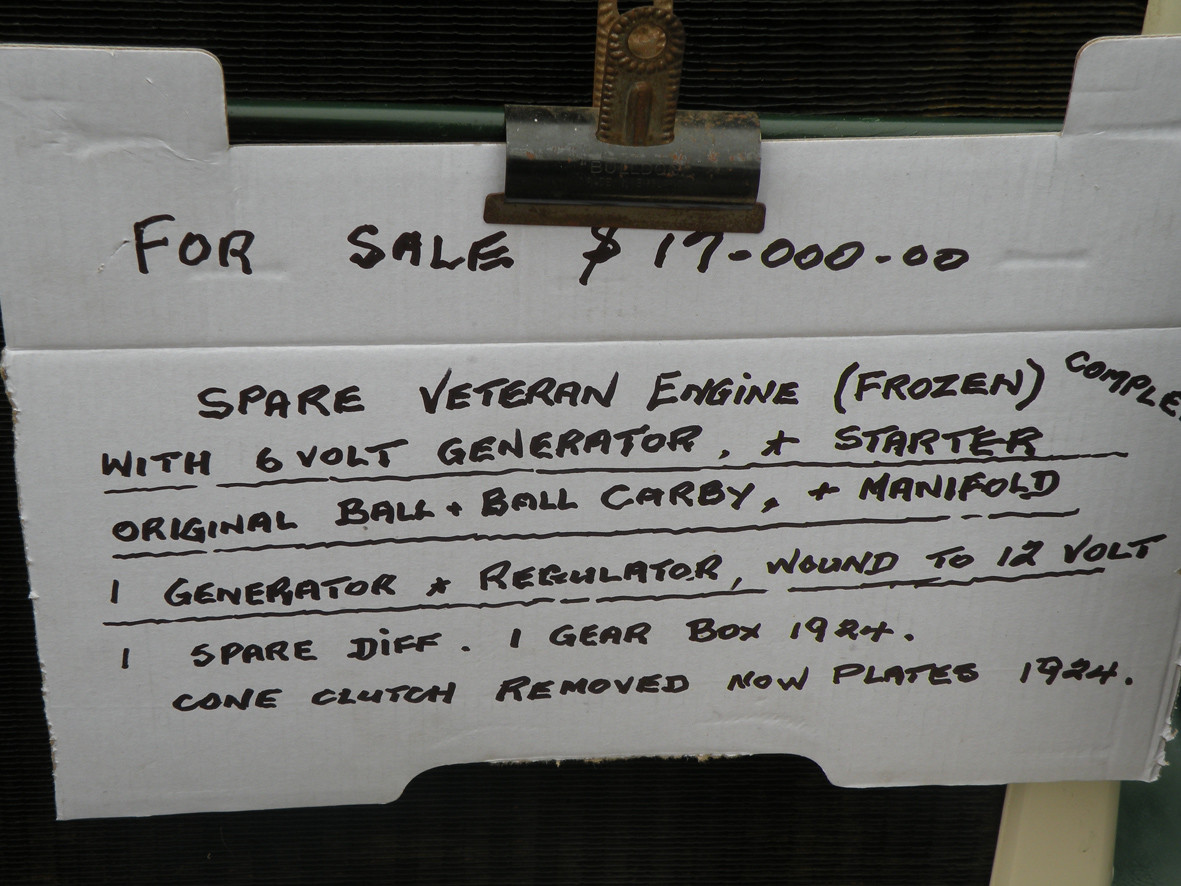

I have had the same site at Yarra Glen for years. Almost opposite where the 1918 Studebaker 7 passenger tourer was parked. Site 213, I have already booked it for next year. Don't sell much but catch up with a lot of friends. I took lots of photographs as I know that quite a few people are interested in early Studebakers. This one has been owned by the same man, now in his 80s, since the 1960s. I cannot believe that it has not sold at the price he is asking. $17,000. It has a modern down-draft carb fitted so he can fit an air filter but he still has the original carb and all that needs to be done to fit it is to turn the inlet manifold over.

2-21-2012

Here we are and it is Wednesday morning already! Today I must make a start on making the patterns for the windscreen pillars. I have been giving these some serious thought, at first I had thought about fabricating them by silver soldering stock brass extrusions to obtain the desired profile. after the first experimental effort some weeks ago this was abandoned.

Next thought was to machine them out of brass bar stock but the thought off all those hours of machining and all that brass going into the waste bin put paid to that.

This morning I will try to develop my minimal wood working skills to make the required and aforementioned patterns. By making wood patterns I can adjust sizes and dimensions to achieve the most satisfactory (and pleasing) size and shape before committing them to metal. Wish me luck....

Further to the above the first step is to calculate the angle of the at the base of the pillar to the side of the cowl.

2-22-2012

Hi All

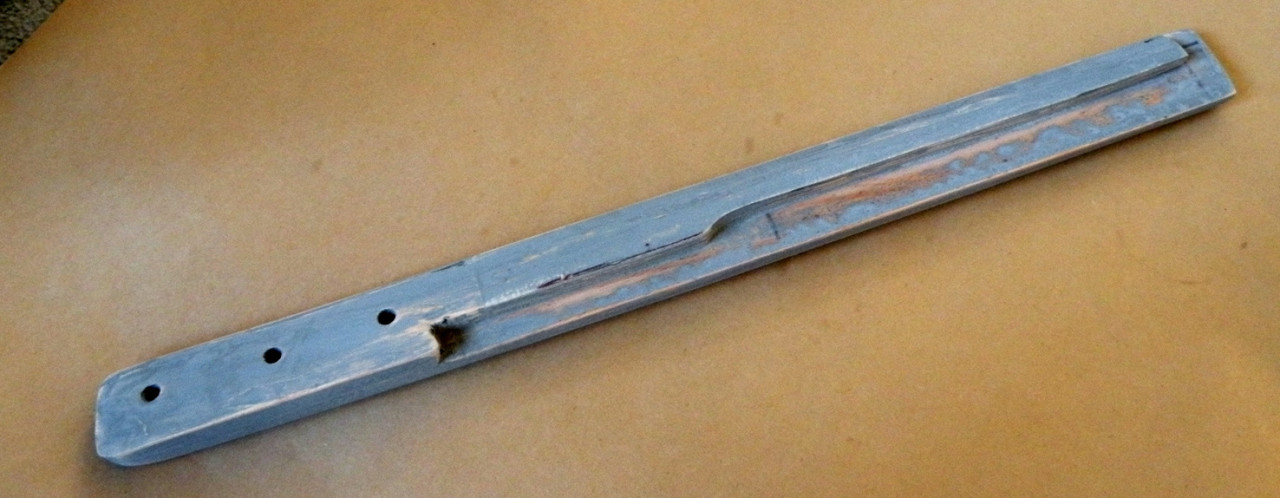

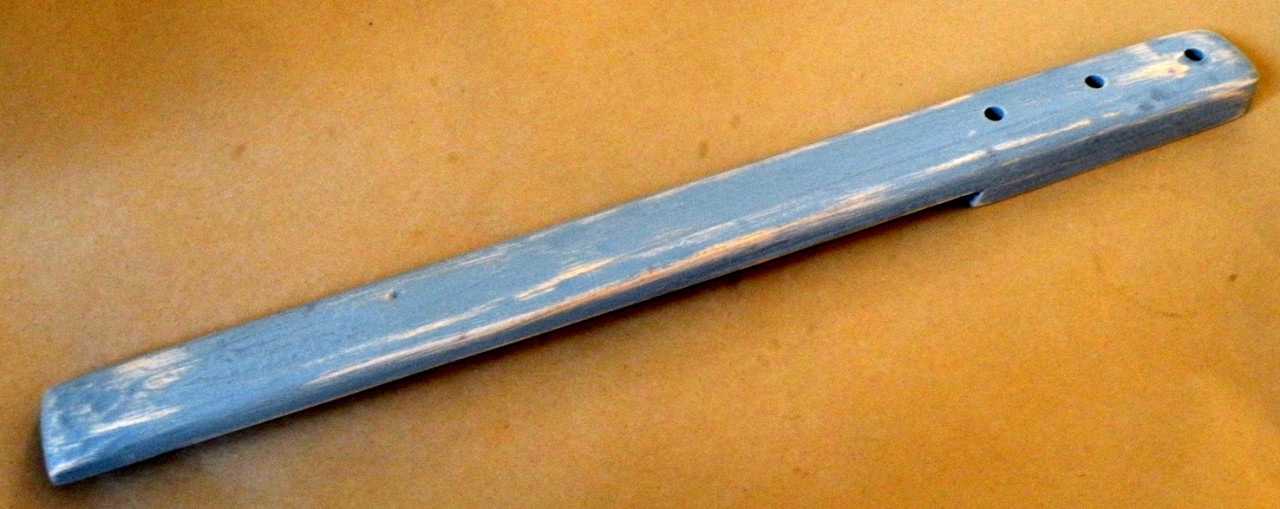

You will be pleased to learn that I have not completely waisted my day. Having spend an hour or so cogitating and doing doodles on the back of an envelope I started working in my usual "free hand" style. I seem to think better in three dimensions. By 5.30 this afternoon I have completed the first of the two windscreen pillar patterns. The next should be much easier as I have done all the problem solving with this one. When cast in bronze any minor adjustments can be made during the "fettling" process prior to nickel plating. Of course this one will still require some minor filling and "dressing up" before it goes to the foundry

2-23-2012

Hi Roger

With my windscreen pillars this is not quite so critical. The important dimension is the distance between the two inside faces of the pillars. This is governed by the width of the cowl which is not going to change. I have filled the mounting holes so these will be drilled after the castings are fettled (cleaned up ready for plating) The height is also not critical as the brass channel for the actual windshield frame will not be finally silver soldered together until the pillars are finished and trial fixed to the cowl. This will not be plated until it is soldered together. The very last operation will be to cut and fit the actual glass.

I know I keep saying this but the simple fact is that I have done this sort of one off fabrication countless times before. I think that by now I have some idea of what I am doing. Building one off sports "specials" is very different to restoring a production car, where everything has been done on a production line several thousand times, each time exactly the same using exactly the same stock production part. Even then, it seems to me that a lot of so called restorers get it wrong!

With the Packard while basically a stock factory body it would have been hand built 83 years ago. Like so many hand built cars there are no two that are precisely the same. Any one who has tried to fit a door from one seemingly identical pre 1925 car on to another will know what I am talking about.

Then there is the added complication forced onto me by whoever cut the roof off. In effect the car has become a one off. This is especially true when it comes to the windscreen, top and interior trim. Having said that I am going to enormous lengths to keep the car in the spirit of the year it was first built. No Doubt there are the doubters who are saying "But it is not original, it is not being restored as it left the factory"

My reply to them is two fold. First, yes you are right, but then it has not gone to China as pelletised scrap metal! Secondly wait until you see the finished product. Then and only then you can look at it but you will not be able to say "Look at what I have just done". Finally when it comes down to the bottom line there is only one person who has to like it. One person who can either be disappointed with the result or proud of what they have achieved. Before I bought the car it was widely offered for sale and there was only one person even vaguely interested in buying it and then again only one person silly enough to take on what has been and continues to be on occassion a mind-numblngly difficult task.

Thank you for your interest and patience.

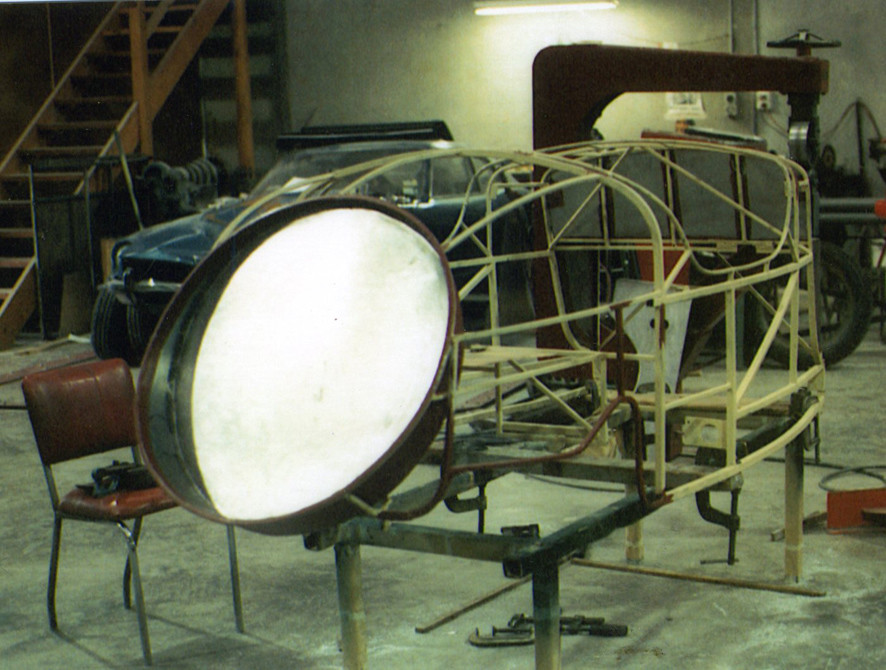

Just for the record another pile of junk that no one wanted.

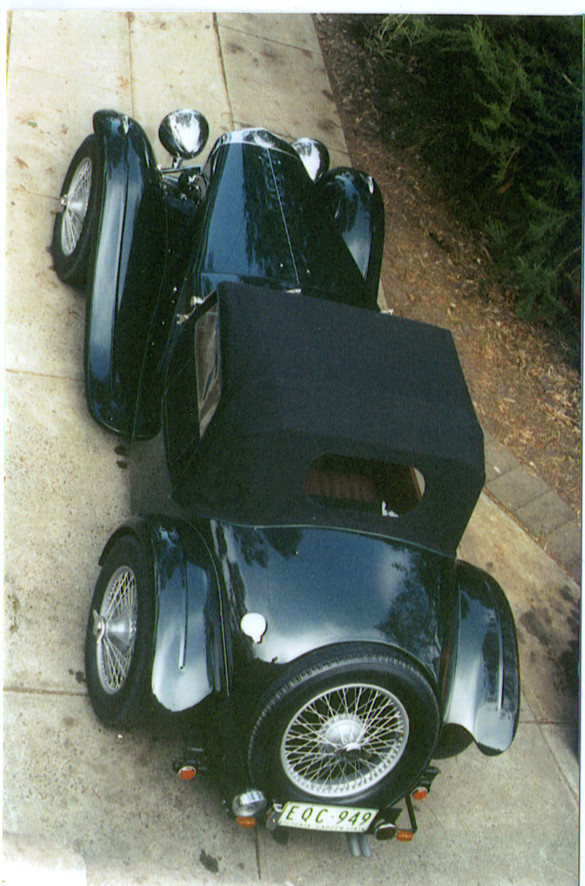

and what it became. the 1938 SS-Jaguar 1.5-3.5 Special.

Funny thing the last time I saw it it was in Switzerland.

Another rough home built special obviously made by someone who did not have a clue!

Bernie J.

Want to see some more? I have dozens of photographs of one off sports specials that I have constructed over the years.

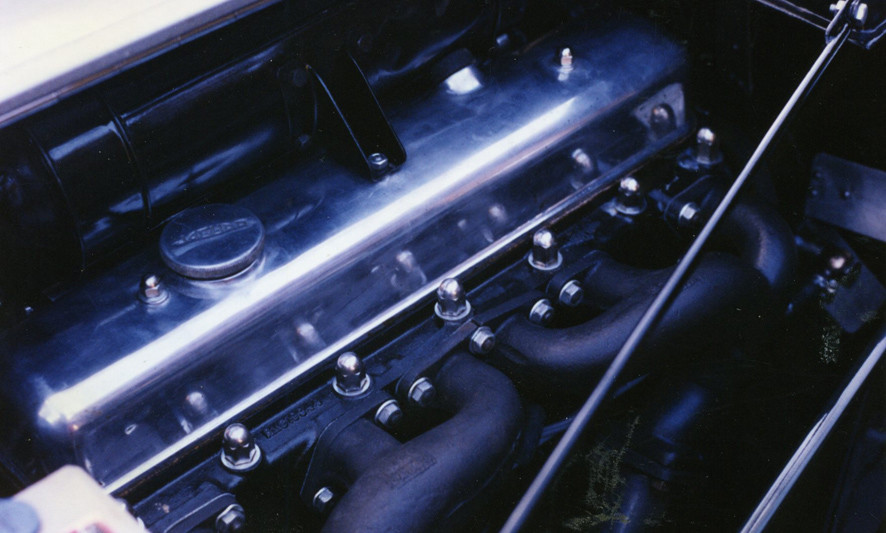

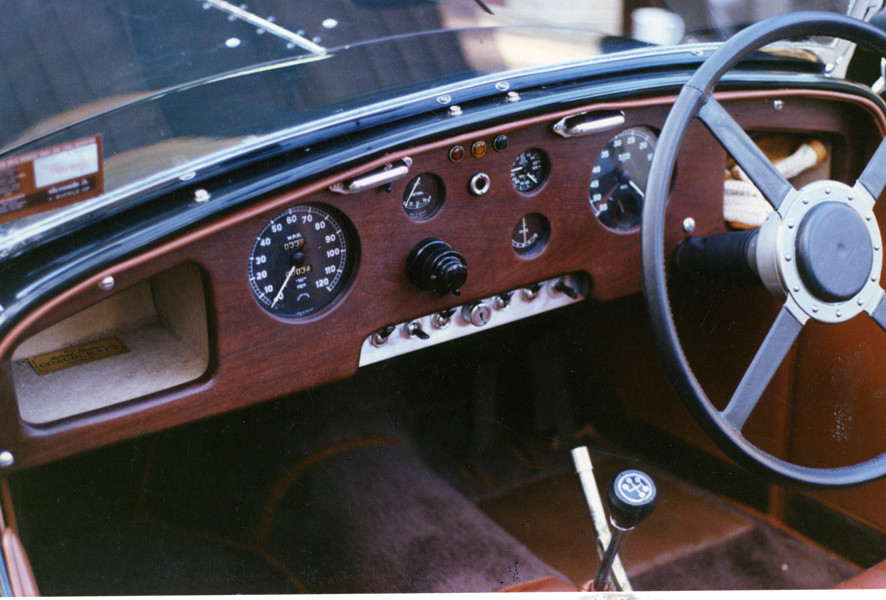

I though that this may happen. here are the photos I sent to West.

Having gone this far I may as well share the whole story. It was not just a pretty face. It earned the nic-name of "Cross-cat". It is six inches shorter, 4 inches narrower track and approximately one hundredweight lighter than a SS100. It has a close ratio 4speed gearbox and a high ratio rear axle. Maximum speed between 105 to110 mph and a 90mph third gear. Great for highway overtaking. There is no spare room under the hood.

Last heard of it was "somewhere" in Europe.

Bernie J.

Now back to the Packard.

bravo!

Posted by CCmyVW on 1/26/20 @ 5:30:36 PM