You must be logged in to rate content!

9 minute(s) of a 548 minute read

8-31-2011

When I said yesterday that I was "bask to basics" I was really jumping the gun. However today I can say "really back to basics" after a morning of persuading 88 year old nuts and bolts that have not been touched since they left Detroit to come undone. Remarkably the shackle pins and bushes show virtually no wear. The brake cross shaft was frozen solid indicating just how long it must be since the car was last driven. I am finding it difficult to relate the almost total absence of wear on any of the chassis moving parts with the condition of the motor. Despite this I am convinced that the motor is the original and has never been out of the chassis before. Those with fully equipped workshops with travelling cranes and fork lift trucks can have a smile at my expense.

How does a 74 10/12s year old move a Packard Chassis single handed? Well you may ask. The answer is demonstrated below. With a almost worn-out home handyman trolley jack and a pensioned off push lawn mower.

Now I can go back to dismantling the front axle. Has anyone got a spare 2 inch a/f spanner. I need one to undo the front wheel bearing retaining nuts.

One more question is there someone who knows where to buy reproduction rubber bump stops?

9-1-2011

Hello B

I have answered your question about AF Spanners

regarding what I call "Bump Stops". These are the rubber buffer attached on the front axle under the U bolts and at the rear bolted to the chassis immediately above the axle tube. so I guess that they could be referred to as rebound pads.

I have shown both the front and rear types below. The front are recoverable but unfortunately the rear have taken an absolute belting.

Also shown is the LH front spring. The first thing that is obvious is that the smallest Leaf is incorrect but what you cannot see is that the centre bolt that locates the spring on the axle and keeps the leaves in their correct place is broken, into four pieces. This tends to confirm my theory that the cars early life was mainly on rough potholed country roads.

Hi "B"

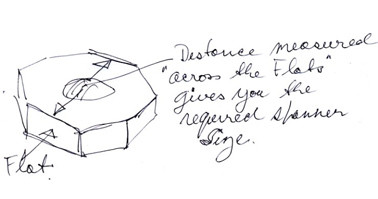

AF is simply a system of identifying Nut and Bolt head size rather than the diameter of the shank. It takes the distance in inches across the head of a bolt from side (flat) to side (flat) so AF refers to the size of the spanner you need to fit a particular nut or bolt. Usually metric spanners also give you the size of the bolt head not the diameter of the shank( The diameter of the hole that it goes through). Imperial (English) BSF (fine thread) or Whitworth (coarse thread) spanner sizes refer to the size of the shank of the bolt not the size of the head which if fine unless you come across some special purpose bolt with a non standard size head.

In short the AF size stamped on a spanner refers to the size of the head not the size hole that the bolt goes through.

When you are buying nuts and bolts you alway refer to the size of the shank so a 1/4 inch bolt goes through a 1/4 inch hole but you need a 7/16 (Across the flats) spanner to tighten it up.

Remember that front spring shown in yesterdays post.....

One thing that has shown up for which I will have to seek some outside help.

The front axle beam has about 1 1/2 inches bend. Fortunately I know someone with a LARGE press.

9-2-2011

Hi y'all

My good friends at Blast Off picked up the chassis frame this afternoon and while not wanting to start into anything major at 3.30 on a Friday afternoon I though I would make a start in straightening out the tinware for the rear "bump-stops". The front ones were OK as they mount onto the top of the spring and are anchored by the 'u' bolts. I think that I mentioned that the rear ones had suffered from a little gentle battering.

I have ordered new rubber pads from Steele Rubber thanks to 'B' giving me their web-site link. (See his post above) So far I have been unsuccessful in finding a source of the tin-ware that locates the rear one onto the underside of the chassis directly above the rear axle.

So with an hour or two to fill in I thought that I would have a go at repairing the originals. Below is a progress photograph of the first attempt along with its partner in as found condition.

The second photograph shows the work in progress with an original rubber pad trial fitted in place.

Before I go much further can anyone suggest a possible source of this tin-ware

Hello Bill

Good to hear from you again.

I have decided to paint mine too. After welding and panel-beating them back into a reasonable shape they still are not good enough to simply tin plate. After wire-brushing them clean they appeared to have enough paint remaining to convince me that they had been painted in the first place. I have ordered the rubber pads for the rear from Steele Rubber but will have to cast the front myself. Fortunately I have one that with a small amount of filling will make a good pattern.

9-3-2011

Thanks David

Packard seemed to have a dislike of LH threads although the wheel bearing retaining nuts are "handed"

As I continue to dismantle the front end the more I become convinced of the short but rough life theory. None of the steering rod "ends" are showing any signs of wear. I believe that with a thorough clean and re-pack the wheel bearings can go back in, likewise with the king-pins, etc. Every thing is packed with a soild mixture of mud and grease. The track rod ends still have their original leather "boots" although as these have hardened I will be making new ones.

I really do wish that I could find out something, anything, about the cars early history. The more that I think about it the more I am convinced that its active life would have been finished well before WW2. Surely some of the older Packard people can remember something. It is not every day that someone cuts the roof off a coupe. Or for that matter do they ship a derelict car off to the other side of the world, albeit 40 years ago! Someone had to do it, the car did not just hop onto a boat all by itself.

Come of people put your thinking caps on... Please.

9-5-2011

Oh well! It seems that either no one actually looks at this "thread" or that most of you are either little more than school age or are so elderly that you simply have no memory left.

This is a pity as all the Packards early history is in the USA. I may be strange some would even say perverse but I really do like to learn as much as possible about my car's history.

Can any of the historians among you, tell me if there are any early Packard records still in existence?

Things like which chassis/id number car went to which dealer?

Enough of all that.. the photograph below shows the bare front axle beam before I take it to be straightened. My meagre workshop just does not run to a 50 ton press...

My other task for this afternoon was taking the stop light switch completely apart, carefully wire brushing and sand papering the folded tin body and mounting platform then giving them a coat of primer. They should be ready to give a light sand and a coat of black enamel tomorrow. While not a big deal even the stop light switch has to be restored back to working order. While it would be easy just to send off the money and have a reproduction one posted to me. The result would just not be the original, and not nearly as satisfying as bringing a 80+ year old switch back to useable life. Once you have taken one apart they are not rocket science.

Hi Folks

Many many thanks for all your support and comments.

I have just started an inquiry with the Australian Government Archives to see if I can at least learn when the Coupe (remains) arrived here in Australia and to whom it was first consigned and by whom. Having tried to instigate similar (Government) searches in the past I will be amazed if I get a result but as the old adage says "Nothing ventured, nothing gained" Or if you prefer in layman terms "If you don't have a go you will never know".

My favourite breed of dog is an Airedale Terrier. Never try to take a bone from an Airedale!

bravo!

Posted by CCmyVW on 1/26/20 @ 5:30:36 PM