You must be logged in to rate content!

10 minute(s) of a 548 minute read

8-13-2011

Re: Some things I do twice.

This simply means that as I grow older I have become more discerning, when I am dis-satisfifed with the finish achieved the first time, I re-work the particular item to achieve a better end product. These days "near enough is good enough" no longer applies.

As an example I am currently busy filling the Phillips heads of countersunk screws with bronze and cutting screwdriver slots in them before nickel plating. I minor thing and time consuming but important if the result is to bring them into "period".

THANK YOU Steve.

Just one word of warning; don't bite off more than you can chew. My creed has been for a long long time. One car at a time. If you try to spread your time too thinly nothing ever seems to get finished and you can become frustrated. I know that you are younger but the market is overflowing with unfinished projects. Having said that, for your next project try a 1920s car. Then the FUN will really start.

8-14-2011

Quite some time ago somebody asked me about Packard sedan/coupe windscreen fittings (Photograph attached) at the time I was uncertain if I was going to need them myself. Having moved some way towards fabricating a windscreen frame I find that I will not be using them and they are now available.

I need to recover the cost of the nickel plating. Otherwise I will offer them for sale on the Packard section buy/sell.

Further to the above. 1.You cannot imagine how difficult it is to photograph a single slot head screw. 2. Yes we do eat a lot of yogurt. 3. Several gallons of nuts, washers, bolts & screws. And as they say in those dreadful TV commercials "But wait there is more......."

8-16-2011

Without meaning to be offensive, some people may be out picking the daisies, while others smell the roses and maybe even one or two are mowing the lawn, others are hard at it working on their Antique Automobile of choice.

The two photographs below may seem to be a contradiction but in fact they show progress. The first was taken this morning at 10.00 am shortly after I arrived at Sleeping Classics workshop. The second was taken at 12.30pm just before I left to drive home for lunch. While this may not appear to some like progress that is exactly what it is. Dave, my painter, can start prepping the fenders and valances while the rest returns to Glendora Lane for me to lift the body off the chassis. Two things then need to happen. First I have to secure the panels and finish off some details on the underside of the body. Then my next task is to strip down the chassis frame so that it can go to be sand blasted before painting and re-assembly.

What did you do this morning?

8-18-2011

On the subject of SCREWS

Sometimes it is worth looking in those bins at your local hardware retailer's

These are self tappers but any pack of 100 slotted raised heads for $3.91 is worth picking up especially when the bin is labeled "Everything $2."

A handful of the above will be OK to use in conjunction with cup washers to secure parts of the interior trim where they cannot be seen. The rest will go into another of those yogurt containers and onto the shelf perhaps never to be used. At 2 cents each it is not going to break the bank. At least they will be better than the dreaded Phillip's heads.

8-19-2011

Hello again

Following my policy of doing things as the opportunity arises I am in the process of restoring a Stewart Vacuum tank for the Packard. The original had long since departed before I bought the car. Now I am faced with the task of finding one or two of the correct brass fittings. In particular the 5/8 inch fitting for the gasoline inlet on the top of the tank. I have two tops slightly different in detail but neither have this particular item in place. Does anyone have a spare that I could purchase or can anyone suggest a suitable supplier.

Thank you.

8-24-2011

The last two or three days have been spent doing the mind numbing job of screwing the panels back onto the timber frame. I have just about finished the first box of 100 slotted countersunk head 3/4 inch screws fortunately I was able to buy a second box of 100 so will have sufficient to finish the job.

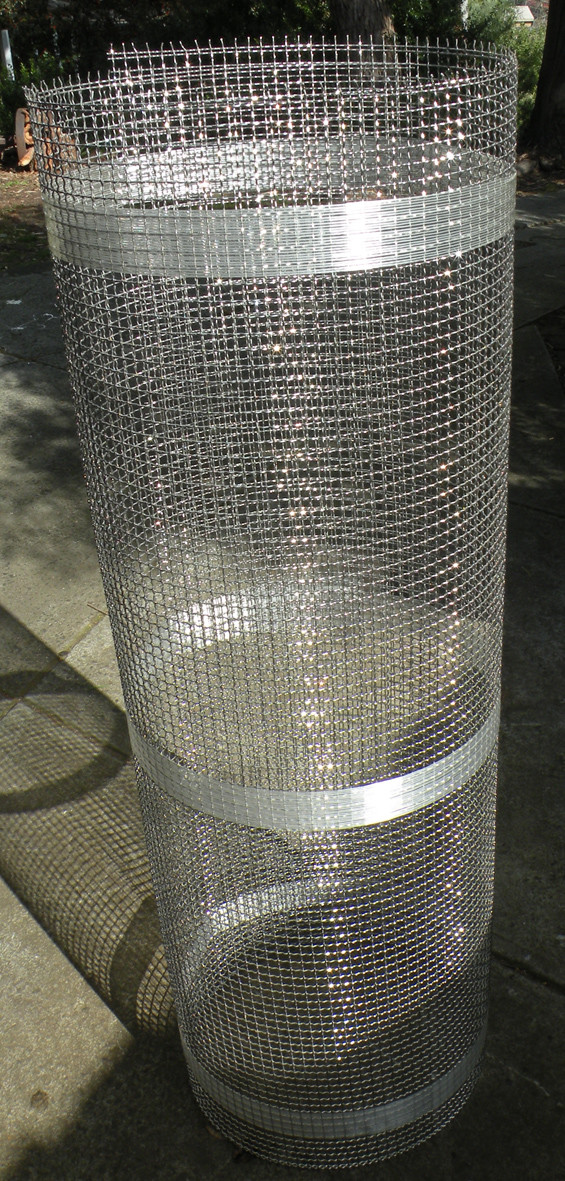

To break the monotony I spent yesterday going to buy the stainless mesh for the radiator stone guard and the brass channel section for the windscreen frame. The other job that is almost finished is sorting out a Vacuum tank. While this one is not perfect it will suffice until a correct one comes along.

8-26-2011

It seems such a shame today I am locked in at my computer finishing a report on last Sunday's VSCC "Rob Roy" Hill-climb for the Automobile magazine in the UK while outside it is a beautiful Spring day.

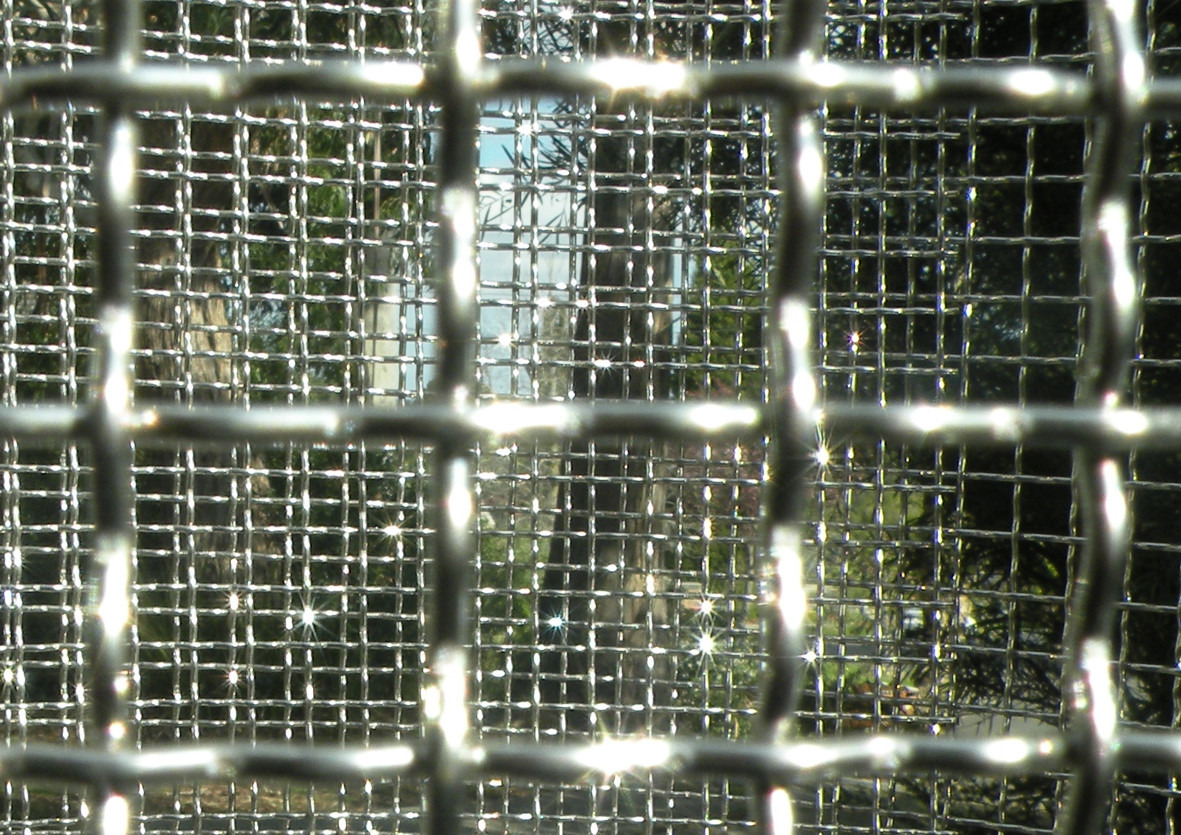

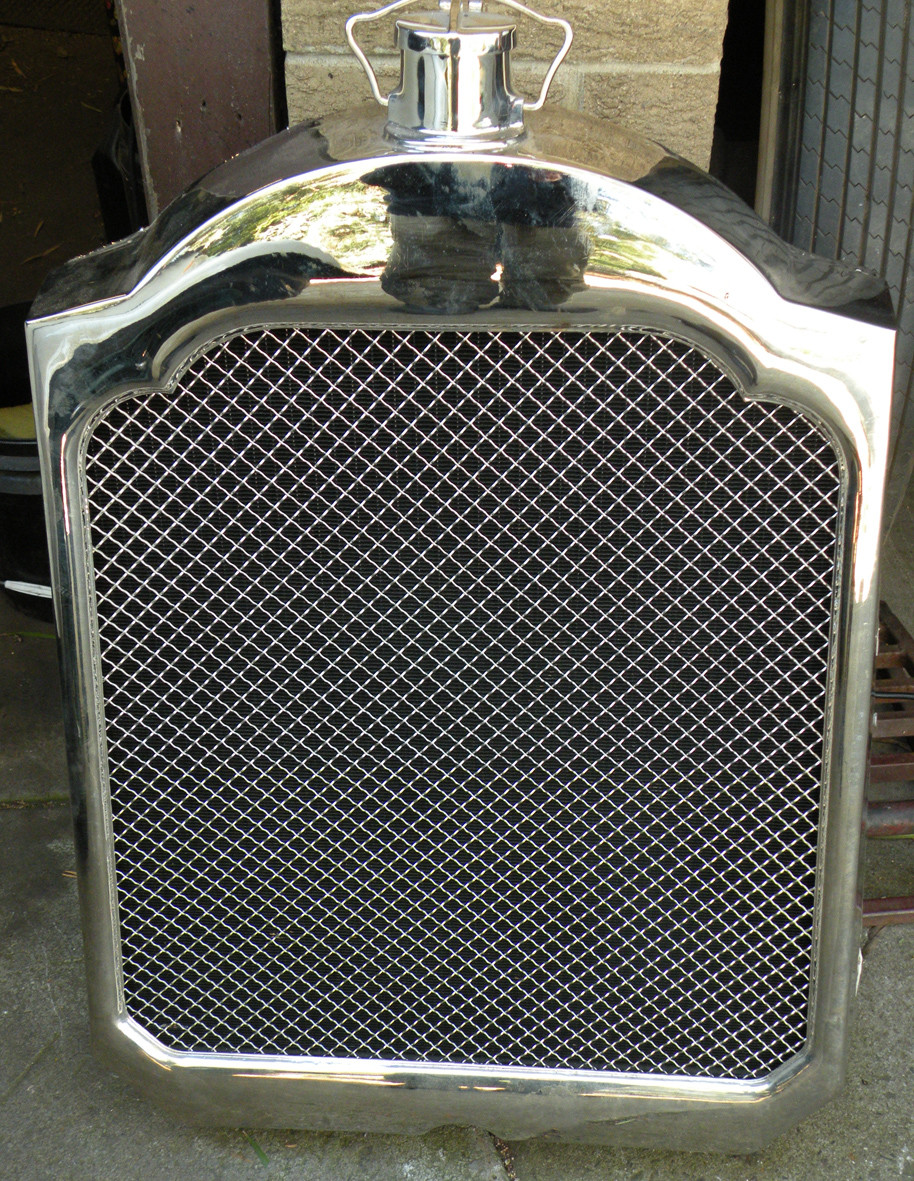

Previously I mentioned buying the mesh for the radiator stone guard. This comes in a roll 54 inches wide and a minimun purchase of $100 which worked out nicely. I now have a 4ft 6 inch square which should give me sufficient to cut out the shape of the radiator on the diagonal.

This brings me to the big question. Which is correct for Packard radiator stone guards. I have seen both. Either with the mesh on the square and diagonal. Personally I prefer on the diagonal but before I cut it I would like to know what is correct.

The mesh I have is, double crimp, stainless steel woven in 1.6mm (1/16 inch) wire with the spaces 11.2 mm (7/16 inch) across, which seemed to be about the most suitable readily available.

What do the experts think???

Thank you Chris

I know that the later 20s cars used this rather special weave mesh. I would be inclined to worry about the amount of air that it excluded from the radiator. It appears to block something in excess of 50% of the available area. In these times of Global warming we need to take these things into account. It is probably fine for show cars that take all their journeys inside totally enclosed trailers but I own neither a trailer or a vehicle big enough to pull one. Even if I did, with the cost of our fuel at around $1.50 per litre, I could not afford to take it anywhere. Helen's 2 Litre turbo diesel VW does around 1,000 kms to the 60 litre tankful. 621 Miles to 13.5 Imperial gallons.(46 mpg or 9 Aust Cents per km or 14.5 Aust Cents per mile) Sorry I don't have a conversion to US Gallons. My 1996 2 litre petrol fuel injected Peugeot 405 SRi is not quite so frugal.

Sorry about that diversion. I will post some more mesh photographs as work proceeds.

8-27-2011

Hi All

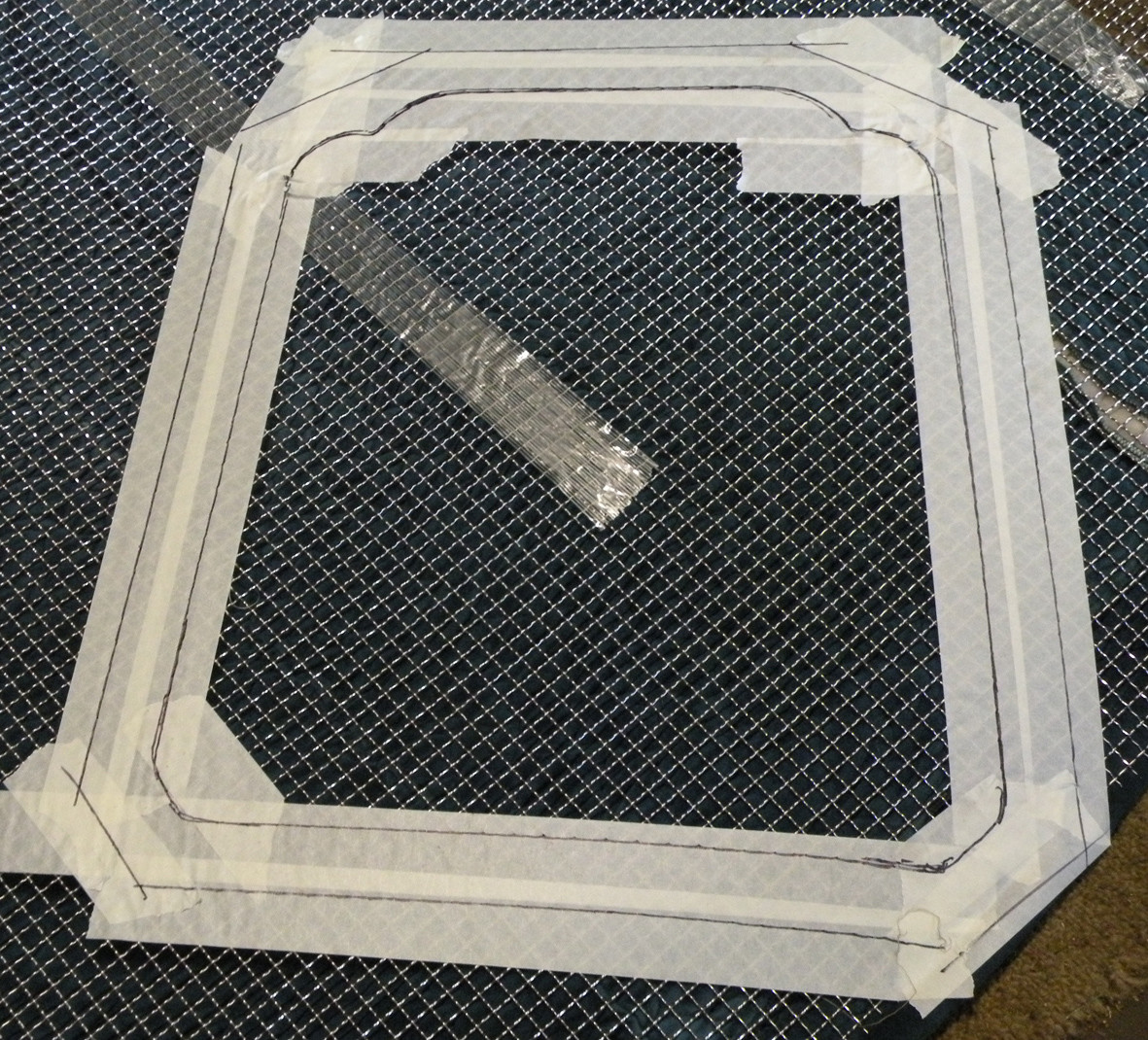

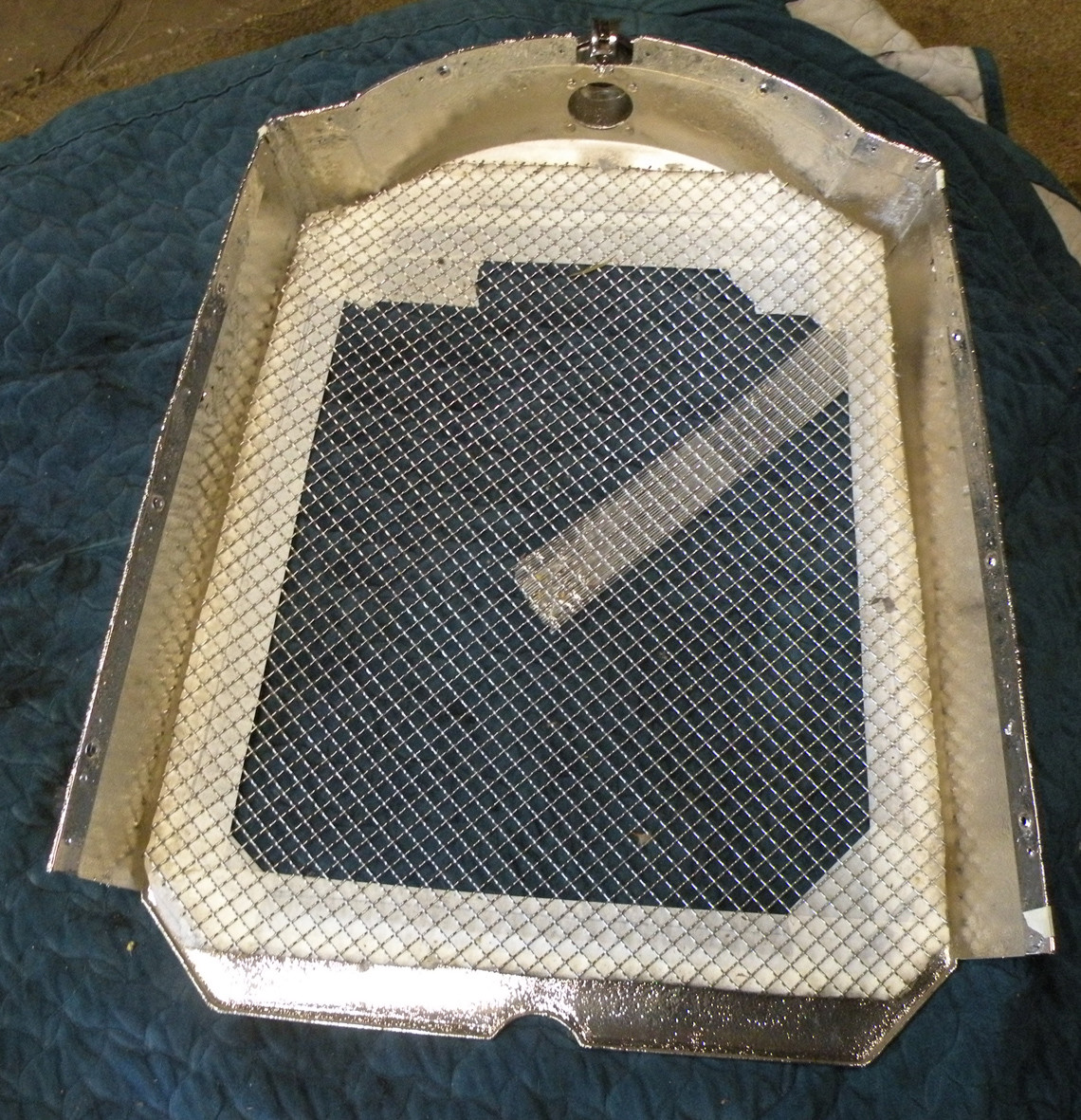

As this morning is a lovely sunny Spring day in Melbourne I decided that the time to end procrastination had come. You can see the results of this mornings efforts below. Please comment if you feel so inclined.

The various stages of the work should be self explanatory.

I am happy with the result and I guess that is what counts in the long run.

8-29-2011

Your are correct to be critical. Probably "Stone Guard" was the wrong term to use although it got the message across (sort of). The mesh is purely cosmetic, to disguise the fact that being extremely impecunious and also concerned about the reported reputation regarding the lack of cooling capacity of some reproduction honey-combe cores that I had used a modern core for the Packards radiator. I am sure that I had already explained this but that may have been on the thread that I started on the Packard section of the forum. (now closed) The mesh is attached to the frame of the actual radiator rather than to the surround. The difference in cost between a reproduction honey-combe and a modern core was around Aust $2,500/3000. In the same way the difference in cost between buying, admittedly the incorrect mesh, and doing the job myself and one of Henry Yeska's external mounted totally CORRECT Stone Guards was approximately $1,000. all in all almost the price of a set of four tires. I am sure that there a lot of people reading this saying "If he is that poor he should not (how dare he) have bought a Packard"! Unfortunately I am a slow learner. If I had not bought the "coupe" it would have most likely ended up in the melting pot to be recycled into saucepan lids or something similar. Anyone who feels that they are better qualified to complete the restoration (and of course do it correctly) are welcome to make me an offer.

I do try to be as honest as absolutely possible in all things that I do, say and write. Nothing is hidden what you see is what you get.

I am told that "Old habits are the hardest to overcome". My 1934 Lagonda Rapier (the poor mans Lagonda) has had a mesh in front of its radiator since the 1950s. The original vertical slats were removed to improve cooling. We have had global warming here in Australia for a long time.

Back to basics! This mornings task was to remove the body intact and single handed. Now while to some this may appear to be a retrograde step it is actually a giant step forward! With the axles and springs removed there will be only one way that this restoration can move...forward.

bravo!

Posted by CCmyVW on 1/26/20 @ 5:30:36 PM